Professional Documents

Culture Documents

Three Arm Caliper (9074, 8074 & 7074) : User Guide

Three Arm Caliper (9074, 8074 & 7074) : User Guide

Uploaded by

mhasansharifiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Three Arm Caliper (9074, 8074 & 7074) : User Guide

Three Arm Caliper (9074, 8074 & 7074) : User Guide

Uploaded by

mhasansharifiCopyright:

Available Formats

Century Geophysical Corp.

, Three Arm Caliper User Guide Page 1 of 4

Three Arm Caliper (9074, 8074 & 7074) User Guide

Use Proper Users Guide

The three arm caliper tool has optional sensors selections which are determined at the time the tool is

manufactured.

1. Model 7074 Sensors: Casing Collar Locator and Three Arm Caliper

2. Model 8074 Sensors: Three Arm Caliper only

3. Model 9074 Sensors: Natural Gamma and Three Arm Caliper

Compu-Log System Check

Before attempting to use the 9074, 8074 or 7074 check to insure that the required program files are in

place on the Compu-Log system (Ultra-Lite or Desk Top).

1. Using Windows Explorier, open the C:Century/log/tm folder and check for a file 9074.tm,

8074.tm or 7074.tm (only the file whose name corresponds to the three arm caliper model number

is required) with a date of June 27, 2000 or more recent. This file is the tool module file which

contains all the engineering data on the tool, such as the distance to each sensor, the equation for

the conversion from CPS to engineering units, the sensors that are calibratable and the telemetry

format for the data being sent from the tool. If this tool module file is not in the tm folder it must

be copied into the folder before the tool can be used. The most recent version of the tool's tool

module file is attached to the tool (on a floppy disk) when it arrives from Century. If the floppy

disk tool module file is no longer available, the tool module file can be downloaded from

www.century-geo.com.

2. Using Windows Explorier, open the C:Century/log/cal folder and check for a file XXXX.cal

(substitute the individual tool serial number (S/N) for XXXX). This file is the calibration file that

contains the identification of the tool model, the sensor cabibration data and the calibration date. If

this cal file is not in the cal folder it must be copied into the folder before the tool can be used.

NOTE 1: If the S/N number for the tool is not known it can be determined by 1) connect the tool

to the drawworks, 2) turn on the computer, 3) start the Log program, 4) click on the LOG button,

5) the S/N will appear in one of two places, either beside the S/N or at the end of the message

"NO CAL FILE FOR TOOL XXXX".

NOTE 2: A calibration file can be created by following the following steps: 1) start the Log

program, 2) click on the CAL button, 3) click on the TOOL button, 4) enter the tool S/N followed

by .cal (XXXX.cal), 5) enter the generic tool name (same as tool model) 8074, 6) click OK, 7)

message should appear "CAL FILE CREATED".

Three Arm Caliper Sensor Names

The three arm caliper tool can be run with three different caliper arm lengths. The length are used is

described to the logging system by answering the configurability questions. The Compu-Log logging

system records the log data using the sensor the sensor name which corresponds to the arm length. The

calibration data corresponding to the sensor name is also used.

IT IS VERY IMPORTANT THAT THE CONFIGURATION QUESTIONS BE ANSWERED

CORRECTLY OR THE LOG DATA WILL BE BAD!

file://C:\Documents and Settings\Ingram\Desktop\files\ug\9074-ug.html 4/29/2009

Century Geophysical Corp., Three Arm Caliper User Guide Page 2 of 4

1. Short Arms (40.5 cm long): Sensor Name = CALIPER

Answers to configurability questions:

IS CALIPER LONG ARM (63.4 CM): ANSWER NO

IS CALIPER EXTRE LONG ARM (86.2 CM): ANSWER NO

2. Long Arms (63.4 cm long): Sensor Name = CALIPERL

Answers to configurability questions:

IS CALIPER LONG ARM (63.4 CM): ANSWER YES

IS CALIPER EXTRE LONG ARM (86.2 CM): ANSWER NO

3. Long Arms (86.2 cm long): Sensor Name = CALIPERX

Answers to configurability questions:

IS CALIPER LONG ARM (63.4 CM): ANSWER NO

IS CALIPER EXTRE LONG ARM (86.2 CM): ANSWER YES

NOTE: Measure caliper arm from end of carbide tip to the caliper pivot point.

Three Arm Caliper Range

Three configurations of the tool are possible.

1. Short-armed configuration: hole sizes from 5.1 to 61.0 cm (2.0 to 24.0 in.) can be measured.

2. Long-armed configuration: hole sizes from 5.1 to 91.4 cm (2.0 to 36 in.) can be measured.

3. Extra-long-armed configuration: hole sizes from 5.1 to 116.8 cm (2.0 to 46.0 in.) can be

measured.

NOTE: THE EXTRA LONG CONFIGURATION EXCEEDS THE DESIGN LIMITS FOR THE 9074;

THEREFORE, THE TOOL WARRANTY DOSE NOT COVER BREAKAGE THAT OCCURS

WHEN EXTRA LONG ARMS ARE USED. BE VERY CAREFUL WHEN USING THE EXTRE

LONG ARMS!

Default Calibrations

The 9074 tool natural gamma sensor is a sentalation detector and is bench calibrated by the technician

by setting the threshold and pulse height of the detector. The conversion factor from CPS to GAM

(NAT) units is 1 CPS = 1.175 API units.

The 7074 tool casing collar locator sensor is not calibrated. The units are in CPS and the change in CPS

relates to the voltage change across the sensor coil.

The 9074, 8074 and 7074 tools short arm caliper sensor is bench calibrated by the technician. This

file://C:\Documents and Settings\Ingram\Desktop\files\ug\9074-ug.html 4/29/2009

Century Geophysical Corp., Three Arm Caliper User Guide Page 3 of 4

bench ("default") calibration numbers may be used when logging the tool or for improved accuracy the

tool can be field calibrated usinging the "Calibration Procedures" section of this users guide. If the

default calibration is to be used, it is recommended that a pre log calibration check be made to verify the

tool accuracy prior to logging. The default calibration is used by the logging system any time the values

of 0 cps equals 0 engineering units are listed in the calibration.

The 9074, 8074 and 7074 tools long and extra long arm sensors are not bench calibrated. Do not use the

default calibrations for these sensors! Folow the calibration procedures to calibrate these sensors. The

default (bench) calibration points limits are the following:

Name/Sensor Standard Response

CALIPER 7.62 cm (3 in.) 112,320 cps

(short arms) 20.3 cm (8 in.) 98,580 cps

Notes On Logging The Three Arm Caliper Tool

Prior to logging, calibration of the tool is recommended. If logging a known hole size, such as surface

casing, one calibration point would then be the pipe ID. A second point near the hole size is also

recommended. Upon reaching hole TD, the arms are opened by using the tool current reverse switch.

When the reverse switch is activated, the tool will "turn off" until the arms are opened. Once fully

opened, the tool parameters will come back on, and the tool can be logged in the upwards direction only.

CALIPER, CALIPERL, CALIPERX Calibration Procedures

1. Connect probe to drawworks.

2. Start the computer.

3. Start the Log program.

4. Click on the LOG button to open the Control Menu.

5. Configure tool. Do not create a log header or set tool position.

6. To calibrate caliper click on open caliper and wait for the caliper to open completely.

7. Click on the CAL button then click on the TOOL button.

8. The calibration window will automatically open for the tool, which is connected and ID to the

system.

9. Select CALIPER,CALIPERL OR CALIPERX depending on the configuration of your caliper arm

on the tool being calibrated from the list of curves to calibrate.

10. Double click on the curve name or click once on the curve name and click on the word calibrate.

11. This is a two- (2) point calibration. The value in inches or cm will be determined by the value of

the calibration device used. It is recommended that you use two measurements, which bracket the

borehole diameter, which is to be logged. Example: use 6 inch and 10 inch calibration fixtures to

calibrate a probe, which will be used to measure a borehole of 8 inches in diameter. Cut pieces of

PVC pipe or old casing can be used as a calibration fixture for this purpose. It is only important

that you know the diameter of the fixture used to perform the calibration.

12. Enter the diameter of the first calibration fixture in the inches/cm window for point 1. Place your

calibration fixture on the probe so that the caliper arm is fully opened against the inside diameter

of your calibration fixture.

13. Enter the tool response from the data display in the next slot, Caliper (CPS).

14. Repeat steps 10 and 11 for point 2.

15. Click on OK and save your calibration changes.

16. Exit calibration.

file://C:\Documents and Settings\Ingram\Desktop\files\ug\9074-ug.html 4/29/2009

Century Geophysical Corp., Three Arm Caliper User Guide Page 4 of 4

17. Close caliper.

18. Turn tool power off.

19. Exit Log.

Century

Phone: 918-838-9811 Geophysical Corp. sales@century-geo.com

Fax: 918-838-1532 1223 S. 71st E. Ave www.century-geo.com

Tulsa Oklahoma, 74112

file://C:\Documents and Settings\Ingram\Desktop\files\ug\9074-ug.html 4/29/2009

You might also like

- Sop DBA AjayDocument76 pagesSop DBA Ajayganesh100% (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- BasicsPractice ExercisesDocument17 pagesBasicsPractice ExercisesCecille IdjaoNo ratings yet

- Computer Sonics Radial Bond ServicesDocument31 pagesComputer Sonics Radial Bond Servicesandy xuuNo ratings yet

- Warrior COOKBOOK CSSMDocument47 pagesWarrior COOKBOOK CSSMArpiNo ratings yet

- 5 DefHi Application GuideDocument60 pages5 DefHi Application GuideSuleman JahangirNo ratings yet

- Dickson: Remote Sensing Temperature Chart RecorderDocument10 pagesDickson: Remote Sensing Temperature Chart RecorderkmpoulosNo ratings yet

- 9 NFA Application GuideDocument60 pages9 NFA Application GuideSuleman JahangirNo ratings yet

- Ultimate Measurement Instruments: General CatalogDocument56 pagesUltimate Measurement Instruments: General Catalogzivkovic brankoNo ratings yet

- m500 Manual Rev3Document54 pagesm500 Manual Rev3Juan Daniel'sNo ratings yet

- The Instrument Name and DescriptionDocument9 pagesThe Instrument Name and DescriptionMakmal FarmaseutikalNo ratings yet

- Reference Temperature CalibratorDocument12 pagesReference Temperature Calibratormfj79607555No ratings yet

- ADM31Document8 pagesADM31JasonYedufroNo ratings yet

- South Africa 0 800 203 199 Ni - Southafrica@natinst - Co.za: Technical SalesDocument6 pagesSouth Africa 0 800 203 199 Ni - Southafrica@natinst - Co.za: Technical Salesmarina890416No ratings yet

- 8100 Performance Verification Manual 2023.3.2Document22 pages8100 Performance Verification Manual 2023.3.2wang MrNo ratings yet

- Basic Steps For Setup 2 - 0 SWDocument29 pagesBasic Steps For Setup 2 - 0 SWnathaniel ekaikoNo ratings yet

- 939 FirmwareDocument5 pages939 FirmwareDeepesh SachdevNo ratings yet

- 8 NFT Application GuideDocument57 pages8 NFT Application GuideSuleman JahangirNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNo ratings yet

- App-4Sdd Data Acquisition Software Operation Manual: Technoap Co., LTDDocument37 pagesApp-4Sdd Data Acquisition Software Operation Manual: Technoap Co., LTDOmar SuarezNo ratings yet

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocument3 pagesItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNo ratings yet

- Aquilion64 Technical CourseDocument10 pagesAquilion64 Technical CoursePabloNo ratings yet

- Gocator 2000 2300 Appnote Multi Sensor Alignment CalibrationDocument6 pagesGocator 2000 2300 Appnote Multi Sensor Alignment CalibrationTommy AsselinNo ratings yet

- Past Paper SolutionDocument11 pagesPast Paper SolutionMuhammad Ahmad KamalNo ratings yet

- 10 MFL Application GuideDocument56 pages10 MFL Application GuideSuleman JahangirNo ratings yet

- Oral Questioning 2021Document4 pagesOral Questioning 2021Lloyd Cioco HeÑosaNo ratings yet

- Omniscan Setup - Basic SetupDocument29 pagesOmniscan Setup - Basic SetupcarlosNo ratings yet

- Kti Agilent 3000 Manual v1.8Document10 pagesKti Agilent 3000 Manual v1.8Zakir BashaNo ratings yet

- Show FTG Contents PaneDocument10 pagesShow FTG Contents Panelucky dwivediNo ratings yet

- CelTools TrainingDocument37 pagesCelTools TrainingBless MkhizeNo ratings yet

- Ultrasonic Air Leak Systems UA Ultraprobe 15000 BrochureDocument4 pagesUltrasonic Air Leak Systems UA Ultraprobe 15000 BrochureFirmanJohannesMaruliTuaSimanullangNo ratings yet

- enCORE v18 Software - TBS Calibration Tool User Guide - Febru - UM - LU45786 - enCORE - v18SP5 - 2Document15 pagesenCORE v18 Software - TBS Calibration Tool User Guide - Febru - UM - LU45786 - enCORE - v18SP5 - 2Sandro RebecNo ratings yet

- Aitek Magnetic Pickups MPU Cat08 - SensorsDocument40 pagesAitek Magnetic Pickups MPU Cat08 - SensorsJose Luis Castro Aguilar0% (1)

- Smith Meter Flow ComputerDocument10 pagesSmith Meter Flow Computeriky7750% (2)

- Basic Tools, Instrumentation, and EquipmentDocument10 pagesBasic Tools, Instrumentation, and EquipmentFairos ZakariahNo ratings yet

- 7 RFA Application GuideDocument87 pages7 RFA Application GuideSuleman JahangirNo ratings yet

- 4 ECT Application GuideDocument67 pages4 ECT Application GuideSuleman JahangirNo ratings yet

- Using The Stellaris® Microcontroller Analog-to-Digital Converter (ADC)Document16 pagesUsing The Stellaris® Microcontroller Analog-to-Digital Converter (ADC)asdsadNo ratings yet

- Calibration of Dial GaugeDocument21 pagesCalibration of Dial GaugeAnthony Burns82% (11)

- Manual Weld Inspection With Ultrasound - Conventionally or With Phased Arrays?Document10 pagesManual Weld Inspection With Ultrasound - Conventionally or With Phased Arrays?Raul2307No ratings yet

- SodocDocument10 pagesSodocMuthu KumarNo ratings yet

- M 316ra/rb/rad/rbd T o A I MDocument24 pagesM 316ra/rb/rad/rbd T o A I MFélix EnríquezNo ratings yet

- Ccelerometer Alibration Orkstation: Modal ShopDocument4 pagesCcelerometer Alibration Orkstation: Modal ShopPhi MacNo ratings yet

- RIB Set UpDocument59 pagesRIB Set UpSedat TopcuNo ratings yet

- REAM HMI With Military ConnectorsDocument23 pagesREAM HMI With Military ConnectorsVirnando NainggolanNo ratings yet

- TAXT PlusDocument7 pagesTAXT Plusdéborah_rosalesNo ratings yet

- AS300 (En Manual)Document24 pagesAS300 (En Manual)natchapon.testNo ratings yet

- Techniques of Visual InspectionDocument80 pagesTechniques of Visual InspectiontranngNo ratings yet

- Dma Sop UwashDocument5 pagesDma Sop UwashTomas JeffersonNo ratings yet

- Transverse Vibration8thDocument4 pagesTransverse Vibration8thAbhishek KudalNo ratings yet

- Corrosion ErosionDocument4 pagesCorrosion ErosionChokri HmeidiNo ratings yet

- Curvex 3 Nano cx3040 m44Document16 pagesCurvex 3 Nano cx3040 m44RAHUL KIRAN DUSANENo ratings yet

- InM Lab 9Document10 pagesInM Lab 9sufyanNo ratings yet

- AccuPAR LP 80 ManualDocument105 pagesAccuPAR LP 80 ManualhmrssNo ratings yet

- Detector Refurbishing - Tech - Fax - No - 100003Document2 pagesDetector Refurbishing - Tech - Fax - No - 100003Omar Alfredo Del Castillo QuispeNo ratings yet

- Successful VSA Analysis Using An OscilloscopeDocument18 pagesSuccessful VSA Analysis Using An OscilloscopearinramNo ratings yet

- Hygk307 ManualDocument16 pagesHygk307 Manualkenlavie1No ratings yet

- Sigma New Features Quick ManualDocument24 pagesSigma New Features Quick ManualAlexandre HesslerNo ratings yet

- 6 RFT Application GuideDocument75 pages6 RFT Application GuideSuleman JahangirNo ratings yet

- Multigas Detector: Frequently Asked QuestionsDocument2 pagesMultigas Detector: Frequently Asked Questionsmedodedo2010No ratings yet

- Ligo Ble Configurator App User GuideDocument16 pagesLigo Ble Configurator App User Guidentnhung2607No ratings yet

- Vibration-based Condition Monitoring: Industrial, Aerospace and Automotive ApplicationsFrom EverandVibration-based Condition Monitoring: Industrial, Aerospace and Automotive ApplicationsNo ratings yet

- Projecting Hints: GeneralDocument1 pageProjecting Hints: GeneralmhasansharifiNo ratings yet

- Projecting Hints: Function Modules FS20D-SR-WSDocument1 pageProjecting Hints: Function Modules FS20D-SR-WSmhasansharifiNo ratings yet

- Inlet Modules Model Code: ExampleDocument1 pageInlet Modules Model Code: ExamplemhasansharifiNo ratings yet

- Cylinder Function Modules Model Code: ExampleDocument1 pageCylinder Function Modules Model Code: ExamplemhasansharifiNo ratings yet

- Adm485 13Document1 pageAdm485 13mhasansharifiNo ratings yet

- Main Load Modules Model Code: ExampleDocument1 pageMain Load Modules Model Code: ExamplemhasansharifiNo ratings yet

- ADM485 Test Circuits: Figure 20. Driver Voltage Measurement Figure 23. Driver Enable/DisableDocument1 pageADM485 Test Circuits: Figure 20. Driver Voltage Measurement Figure 23. Driver Enable/DisablemhasansharifiNo ratings yet

- Adxl202 5 PDFDocument1 pageAdxl202 5 PDFmhasansharifiNo ratings yet

- ADM485 Switching CharacteristicsDocument1 pageADM485 Switching CharacteristicsmhasansharifiNo ratings yet

- ADM485 Absolute Maximum Ratings: Table 4. TransmittingDocument1 pageADM485 Absolute Maximum Ratings: Table 4. TransmittingmhasansharifiNo ratings yet

- Timing Specifications: Table 2Document1 pageTiming Specifications: Table 2mhasansharifiNo ratings yet

- Adm485 16 PDFDocument1 pageAdm485 16 PDFmhasansharifiNo ratings yet

- Figure 15. Unloaded Driver Differential Outputs Figure 18. Driver/Receiver Propagation Delays, High To LowDocument1 pageFigure 15. Unloaded Driver Differential Outputs Figure 18. Driver/Receiver Propagation Delays, High To LowmhasansharifiNo ratings yet

- Adm485 Specifications: V 5 V 5%, All Specifications T Tot, Unless Otherwise NotedDocument1 pageAdm485 Specifications: V 5 V 5%, All Specifications T Tot, Unless Otherwise NotedmhasansharifiNo ratings yet

- ADM485 Typical Performance Characteristics: Rev. F - Page 7 of 16Document1 pageADM485 Typical Performance Characteristics: Rev. F - Page 7 of 16mhasansharifiNo ratings yet

- ADM485 Pin Configuration and Function DescriptionsDocument1 pageADM485 Pin Configuration and Function DescriptionsmhasansharifiNo ratings yet

- Adm485 8Document1 pageAdm485 8mhasansharifiNo ratings yet

- 5 V Low Power EIA RS-485 Transceiver ADM485: Features Functional Block DiagramDocument1 page5 V Low Power EIA RS-485 Transceiver ADM485: Features Functional Block DiagrammhasansharifiNo ratings yet

- Revision History: 04/08-Rev. E To Rev. F 1/03-Rev. B To Rev. CDocument1 pageRevision History: 04/08-Rev. E To Rev. F 1/03-Rev. B To Rev. CmhasansharifiNo ratings yet

- Adxl202 5 PDFDocument1 pageAdxl202 5 PDFmhasansharifiNo ratings yet

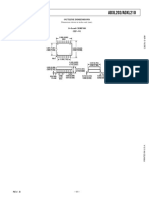

- ADXL202/ADXL210: Absolute Maximum Ratings Pin ConfigurationDocument1 pageADXL202/ADXL210: Absolute Maximum Ratings Pin ConfigurationmhasansharifiNo ratings yet

- Adxl202 4 PDFDocument1 pageAdxl202 4 PDFmhasansharifiNo ratings yet

- Adxl202/Adxl210-Specifications: ADXL202/JQC/AQC ADXL210/JQC/AQC Parameter Conditions Min Typ Max Min Typ Max UnitsDocument1 pageAdxl202/Adxl210-Specifications: ADXL202/JQC/AQC ADXL210/JQC/AQC Parameter Conditions Min Typ Max Min Typ Max UnitsmhasansharifiNo ratings yet

- Low Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedDocument1 pageLow Cost Accelerometers With Digital Output ADXL202/ADXL210: G/ HZ Allowing Signals Below 5 MG To Be ResolvedmhasansharifiNo ratings yet

- ADXL202/ADXL210: Outline DimensionsDocument1 pageADXL202/ADXL210: Outline DimensionsmhasansharifiNo ratings yet

- Adxl202 9Document1 pageAdxl202 9mhasansharifiNo ratings yet

- ADXL202/ADXL210: Peak-to-Peak Noise Estimate 95% Bandwidth C, C Rms Noise Probability (RmsDocument1 pageADXL202/ADXL210: Peak-to-Peak Noise Estimate 95% Bandwidth C, C Rms Noise Probability (RmsmhasansharifiNo ratings yet

- ADXL202/ADXL210: F C (X, Y) F CDocument1 pageADXL202/ADXL210: F C (X, Y) F CmhasansharifiNo ratings yet

- ADXL202/ADXL210: Using The Analog Output Power Cycling When Using The Digital OutputDocument1 pageADXL202/ADXL210: Using The Analog Output Power Cycling When Using The Digital OutputmhasansharifiNo ratings yet

- AD8009 Part9 PDFDocument1 pageAD8009 Part9 PDFmhasansharifiNo ratings yet

- 75X120MM 双面彩印 折页 128G铜版纸: Foldable Bluetooth Keyboard User ManualDocument1 page75X120MM 双面彩印 折页 128G铜版纸: Foldable Bluetooth Keyboard User ManualPa MideNo ratings yet

- Java Language Fundamental by Druga SirDocument48 pagesJava Language Fundamental by Druga SirSheikhShoaibNo ratings yet

- CN Unit-IIIDocument14 pagesCN Unit-IIIAb VNo ratings yet

- CKA QuestionsDocument11 pagesCKA QuestionsEnes PekdasNo ratings yet

- HTGETDocument2 pagesHTGETdmitry esaulkovNo ratings yet

- Frames and Semantic Nets Predicate LogicDocument11 pagesFrames and Semantic Nets Predicate LogicVrajesh ShahNo ratings yet

- Cable ID Test Limit Length Headroom Date / Time: Untitled1Document8 pagesCable ID Test Limit Length Headroom Date / Time: Untitled1Yogavasth ManiNo ratings yet

- Micromake 3D Printer Manual LevellingDocument9 pagesMicromake 3D Printer Manual LevellingAngel GonzalesNo ratings yet

- Kernel Memory ManagemenDocument30 pagesKernel Memory ManagemenValente S RodriguezNo ratings yet

- Inflection PointDocument32 pagesInflection PointRoberto SantiagoNo ratings yet

- Machine Learning Algorithms For Electrical Appliances Monitoring System Using Open-Source SystemsDocument10 pagesMachine Learning Algorithms For Electrical Appliances Monitoring System Using Open-Source SystemsIAES IJAINo ratings yet

- Dell EMC Networking 6.6.3.3 / 6.6.3.33 Firmware Release NotesDocument85 pagesDell EMC Networking 6.6.3.3 / 6.6.3.33 Firmware Release NotesGermanogtsNo ratings yet

- Installation Qualification: LC-2010A /CDocument39 pagesInstallation Qualification: LC-2010A /CAbdul KalimNo ratings yet

- Abstrak Id enDocument1 pageAbstrak Id enMuazziss NajmiNo ratings yet

- Manual - Netinstall - MikroTik WikiDocument12 pagesManual - Netinstall - MikroTik Wikivulkan.abriyanto5599No ratings yet

- 3BDS013987-510 A en 800xa For AC 100 Installation 52Document66 pages3BDS013987-510 A en 800xa For AC 100 Installation 52ilke HANNo ratings yet

- Ch4.1. Black Box Testing Deadline 21 - 00 Mon 07 NovDocument4 pagesCh4.1. Black Box Testing Deadline 21 - 00 Mon 07 Novloitlttl1342002No ratings yet

- Acme An Architecture Description Interchange LanguageDocument15 pagesAcme An Architecture Description Interchange LanguageCarlos Arrieta TapiaNo ratings yet

- CompTIA Premium PT0-001 by - VCEplus 65q-DEMODocument36 pagesCompTIA Premium PT0-001 by - VCEplus 65q-DEMOjohn miloNo ratings yet

- Application Software 2Document20 pagesApplication Software 2Mohd AsrulNo ratings yet

- Creating and Using Virtual DPUsDocument20 pagesCreating and Using Virtual DPUsDeepak Gupta100% (1)

- Zxur 9000 Umts: Configuration Tool Operation GuideDocument33 pagesZxur 9000 Umts: Configuration Tool Operation GuidenazilaNo ratings yet

- Unit-3-The Data Link Layer (Edited)Document24 pagesUnit-3-The Data Link Layer (Edited)Neeraj KumarNo ratings yet

- Fastpath Configuration Guide v1.1 PDFDocument110 pagesFastpath Configuration Guide v1.1 PDFMonowarul Alam MonirNo ratings yet

- How To Create A Lock FolderDocument2 pagesHow To Create A Lock FolderChakshu GuptaNo ratings yet

- Cyber TerrorismDocument14 pagesCyber TerrorismPranav KajareNo ratings yet

- DAY 1 Temenos Transact Overview - Technical 4Document62 pagesDAY 1 Temenos Transact Overview - Technical 4Manasa C M100% (1)

- Yahsat Antenna Poining Guide R1aDocument16 pagesYahsat Antenna Poining Guide R1aRiyas PerumbadanNo ratings yet