Professional Documents

Culture Documents

Jai Paras Construction & Engg. Co. Bill of Quantity For Water Line

Jai Paras Construction & Engg. Co. Bill of Quantity For Water Line

Uploaded by

Nirajan Marwait0 ratings0% found this document useful (0 votes)

40 views3 pages1. The document is a bill of quantity for a water line project containing item descriptions, quantities, dimensions, and costs. It includes items for excavation, concrete work, pipe installation, and demolition of existing pipes.

2. Key items include excavating trenches up to 1.5m deep (145 linear meters), laying concrete (145 cubic meters), installing new 100mm diameter ductile iron pipes (145 linear meters), and dismantling old 100mm cast iron pipes (145 linear meters).

3. The total estimated cost is based on the quantities of materials and work required for each line item in the bill of quantities.

Original Description:

Original Title

WATER LINE BOQ(1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1. The document is a bill of quantity for a water line project containing item descriptions, quantities, dimensions, and costs. It includes items for excavation, concrete work, pipe installation, and demolition of existing pipes.

2. Key items include excavating trenches up to 1.5m deep (145 linear meters), laying concrete (145 cubic meters), installing new 100mm diameter ductile iron pipes (145 linear meters), and dismantling old 100mm cast iron pipes (145 linear meters).

3. The total estimated cost is based on the quantities of materials and work required for each line item in the bill of quantities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

40 views3 pagesJai Paras Construction & Engg. Co. Bill of Quantity For Water Line

Jai Paras Construction & Engg. Co. Bill of Quantity For Water Line

Uploaded by

Nirajan Marwait1. The document is a bill of quantity for a water line project containing item descriptions, quantities, dimensions, and costs. It includes items for excavation, concrete work, pipe installation, and demolition of existing pipes.

2. Key items include excavating trenches up to 1.5m deep (145 linear meters), laying concrete (145 cubic meters), installing new 100mm diameter ductile iron pipes (145 linear meters), and dismantling old 100mm cast iron pipes (145 linear meters).

3. The total estimated cost is based on the quantities of materials and work required for each line item in the bill of quantities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

JAI PARAS CONSTRUCTION & ENGG. CO.

BILL OF QUANTITY FOR WATER LINE

DATE:

S.NO DSR NO. PARTICULARS NO. LENGTH BREADTH HEIGHT CONTENTS

1 2 3 4 5 6

Hire Charges of Suction Jeting machine 2200 PSI machine i/c

1 0087 2 2

POL and operator

2 0116 Fitter (grade 1) 4 4

3 1.1 Disposal Of Malba 90 0.6 0.5 27

55 0.6 0.2 6.6

Total 33.6

Excavating trenches of required width for pipes, cables, etc

including excavation for sockets, and dressing of sides,

ramming of bottoms, depth upto 1.5 m, including getting

4 2.10 out the excavated soil, and then returning the soil as

required, in layers not exceeding 20 cm in depth, including

consolidating each deposited layer by ramming, watering,

etc. and disposing of surplus excavated soil as directed,

within a lead of 50 m :

2.10.1 All kinds of soil

Pipes, cables etc. exceeding 80 mm dia. but not exceeding

2.10.1.2 145 145

300 mm dia

Filling available excavated earth (excluding rock) in

trenches, plinth, sides of foundations etc. in layers not

5 2.25 exceeding 20cm in depth, consolidating each deposited 90 0.6 0.5 27

layer by ramming and watering, lead up to 50 m and lift

upto 1.5 m.

55 0.6 0.2 6.6

Total 33.6

Providing and laying in position specified grade of

reinforced cement concrete, excluding the cost of

6 5.1

centering, shuttering, finishing and reinforcement - All work

up to plinth level :

1:2:4 (1 cement : 2 coarse sand (zone-III) : 4 graded stone

5.1.3 145 0.3 0.1 4.35

aggregate 20 mm nominal size)

Demolishing cement concrete manually/ by mechanical

7 15.2

means including disposal of material within 50 metres lead

as per direction of Engineer - in - charge.

Nominal concrete 1:3:6 or richer mix (i/c equivalent design

15.2.1 55 0.6 0.2 6.6

mix)

Dismantling manually/ by mechanical means including

stacking of serviceable material and disposal of

8 15.43

unserviceable material within 50 metres lead as per

direction of Engineer-in-charge :

15.43.2 bituminous road 90 0.6 54

Providing and fixing Chlorinated Polyvinyl Chloride (CPVC)

pipes, having thermal stability for hot & cold water supply,

including all CPVC plain & brass threaded fittings, including

9 18.7

fixing the pipe with clamps at 1.00 m spacing. This includes

jointing of pipes & fittings with one step CPVC solvent

cement and testing of joints complete as per direction of

Engineer in Charge.

18.7.1 15 mm nominal outer dia Pipes 6 6

Making connection of G.I. distribution branch with G.I. main

10 18.13

of following sizes by providing and fixing tee, including

cutting and threading the pipe etc. complete :

18.13.2 50 to 80 mm nominal bore 6 6

Providing push-on-joints to Centrifugally (Spun) Cast Iron

11 18.70 Pipes or Ductile Iron Pipes including testing of joints and the

cost of rubber gasket :

18.70.1 100 mm dia pipes 32 32

Providing and laying S&S Centrifugally Cast (Spun) / Ductile

12 18.72

Iron Pipes conforming to IS : 8329 :

18.72.1 100 mm dia Ductile Iron Class K-7 pipes 145 145

Dismantling old C.I. pipes including excavation and refilling

13 18.82 trenches after taking out the pipes, breaking lead caulked

joints, melting of lead and making into blocks, including

stacking of pipes at site lead up to 50 metre:

18.82.2 100 mm diameter C.I. pipe 145 145

14 18.83 Labour for cutting C.I. pipe with steel saw

18.83.2 100 mm diameter C.I. pipe 6 6

You might also like

- Name of Work: Àäzà Á Uáæ Àäzà°è Àiágàävéã Àégà À Àääzáaiàä Sà À À ÀiáðtDocument26 pagesName of Work: Àäzà Á Uáæ Àäzà°è Àiágàävéã Àégà À Àääzáaiàä Sà À À ÀiáðtBiradar SharanNo ratings yet

- Hume Pipe Culvert Cost EstimateDocument6 pagesHume Pipe Culvert Cost EstimateTabish100% (6)

- Vol-6 BOQDocument6 pagesVol-6 BOQAshish BhartiNo ratings yet

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- Is Valid Only With Original Photo ID: Railway Recruitment BoardDocument3 pagesIs Valid Only With Original Photo ID: Railway Recruitment BoardNirajan MarwaitNo ratings yet

- Vogue USADocument208 pagesVogue USAMaite Alcaina83% (6)

- Invoice: P.T.Evergreen Shipping Agency IndonesiaDocument1 pageInvoice: P.T.Evergreen Shipping Agency IndonesiaDody DermawanNo ratings yet

- Detailed Estimate, Fire TankDocument2 pagesDetailed Estimate, Fire Tankanish kvNo ratings yet

- S.No. Description Unit No L B H QtyDocument69 pagesS.No. Description Unit No L B H QtyRamLalJatNo ratings yet

- Bill of Quantity For The Work Water Supply Pipeline System From Saunda D Filter Plant To AKC Hospital Under Bhurkunda Project, Barkasayal AreaDocument3 pagesBill of Quantity For The Work Water Supply Pipeline System From Saunda D Filter Plant To AKC Hospital Under Bhurkunda Project, Barkasayal AreadineshkashniaNo ratings yet

- Bill of Quantity For The Work Dismantling and Shifting of Existing View Tower at New Birsa Outsourcing Mines Through Birsa Project. Remarks Sor-2014Document3 pagesBill of Quantity For The Work Dismantling and Shifting of Existing View Tower at New Birsa Outsourcing Mines Through Birsa Project. Remarks Sor-2014Tricolor C ANo ratings yet

- Bill of Quantities-TenderDocument12 pagesBill of Quantities-TenderbhartiNo ratings yet

- Global RoadDocument2 pagesGlobal RoadLucky KumarNo ratings yet

- Sor Ref No Description Unit Rate Qty. Amount Based On S.O.R. B.C.D.Govt. of Bihar Effective From 11/ /08/2013/Dsr-2012/MrDocument24 pagesSor Ref No Description Unit Rate Qty. Amount Based On S.O.R. B.C.D.Govt. of Bihar Effective From 11/ /08/2013/Dsr-2012/MrVincent De GuzmanNo ratings yet

- Model Estimate For Hume Pipe Culvert Dia - 600 MMDocument6 pagesModel Estimate For Hume Pipe Culvert Dia - 600 MMNirmal Singh AdhikariNo ratings yet

- Model Estimate For Hume Pipe Culvert Dia - 600 MMDocument6 pagesModel Estimate For Hume Pipe Culvert Dia - 600 MMRajkumar PalNo ratings yet

- Model Estimate For Hume Pipe Culvert Dia - 600 MMDocument6 pagesModel Estimate For Hume Pipe Culvert Dia - 600 MMdhiraj KumarNo ratings yet

- Concrete Pipe DrawDocument10 pagesConcrete Pipe Drawdhiraj KumarNo ratings yet

- Model Estimate For Hume Pipe Culvert Dia - 600 MMDocument6 pagesModel Estimate For Hume Pipe Culvert Dia - 600 MMRajkumar PalNo ratings yet

- Hume Pipe Culverts EstimateDocument6 pagesHume Pipe Culverts EstimateChandu NaniNo ratings yet

- Jai Paras Construction & Engg. Co. Bill of Quantity For Storm Water LineDocument3 pagesJai Paras Construction & Engg. Co. Bill of Quantity For Storm Water LineNirajan MarwaitNo ratings yet

- NWC EstimateDocument4 pagesNWC Estimatekrishansoni1965No ratings yet

- Changing RoomDocument15 pagesChanging RoomJignesh P KoratNo ratings yet

- Fountain EstimateDocument3 pagesFountain EstimateDeepak Chhugani100% (1)

- Estimate 0.40 Lacs Gallons OHT FinalDocument38 pagesEstimate 0.40 Lacs Gallons OHT FinalAmjid ManhasNo ratings yet

- Harisiddi Ground Floor Civil Work Only-8decDocument3 pagesHarisiddi Ground Floor Civil Work Only-8deckiran NeedleweaveNo ratings yet

- Estimated Amount: Rs 14,99,780.00Document13 pagesEstimated Amount: Rs 14,99,780.00GamersClan OSNo ratings yet

- Aaaa 4Document1 pageAaaa 4ravi rajNo ratings yet

- 8primary School Building PWDDocument32 pages8primary School Building PWDAATVIK SHRIVASTAVANo ratings yet

- 6middle School PWDDocument29 pages6middle School PWDAATVIK SHRIVASTAVANo ratings yet

- 13012022031816815Document2 pages13012022031816815Faisal KhanNo ratings yet

- ANNEX C Quantity of BridgeDocument2 pagesANNEX C Quantity of Bridgesurendra bhattaNo ratings yet

- Serial Number Item Number Length Bredth Height Quantity UnitDocument5 pagesSerial Number Item Number Length Bredth Height Quantity Unitapi-19745405No ratings yet

- Name of Work:-Replacement of Old Sewer Line at Sector 10 Bharat, Shiv Sagar, Shrdha, Shanti Kunj Apartment in Condominium at VashiDocument6 pagesName of Work:-Replacement of Old Sewer Line at Sector 10 Bharat, Shiv Sagar, Shrdha, Shanti Kunj Apartment in Condominium at VashiSheezan KhanNo ratings yet

- 13012022031306157Document4 pages13012022031306157Shah FaisalNo ratings yet

- Av MorwaniDocument2 pagesAv MorwaniAnurag AtreNo ratings yet

- DPR - Food KitchenDocument7 pagesDPR - Food Kitchenmkkmsa1321No ratings yet

- Papa Document 8Document10 pagesPapa Document 8krishansoni1965No ratings yet

- Indoors Tedium Bill of QuantityDocument27 pagesIndoors Tedium Bill of Quantityvaibhavsk110No ratings yet

- NAME OF WORK: (1) VERAVAL: Repairs To Damaged Roof of Health Unit atDocument9 pagesNAME OF WORK: (1) VERAVAL: Repairs To Damaged Roof of Health Unit atamitdostNo ratings yet

- Report - BelaguruDocument25 pagesReport - BelaguruANIL KUMAR H CNo ratings yet

- Scheduleofquantities - 071218Document2 pagesScheduleofquantities - 071218Anand Kumar KanojiyaNo ratings yet

- BoqitibakhriDocument65 pagesBoqitibakhriVinay KumarNo ratings yet

- NITSCHEDULEDocument7 pagesNITSCHEDULEmarcNo ratings yet

- Water Tank & Outdoor Plumbing Works at Jigmecholing MSSDocument5 pagesWater Tank & Outdoor Plumbing Works at Jigmecholing MSSPema GyelpoNo ratings yet

- CIVILDocument45 pagesCIVILSunita ThakurNo ratings yet

- Arsar Kulam Estimate Final 01.12.2023Document92 pagesArsar Kulam Estimate Final 01.12.2023mohamed.zunaithNo ratings yet

- Revised BOQ Civil Works 11.02.2022Document35 pagesRevised BOQ Civil Works 11.02.2022Head Development ProjectNo ratings yet

- TECHMERGED 5 Buycon23.iocl - CNDocument2 pagesTECHMERGED 5 Buycon23.iocl - CNcontracts1.delhiNo ratings yet

- Construction of Poultry Shed: Janpad Panchayat Balrampur Distt.-BalrampurDocument6 pagesConstruction of Poultry Shed: Janpad Panchayat Balrampur Distt.-BalrampurUpendra kumarNo ratings yet

- Sanitary and Water Supply EstimateDocument98 pagesSanitary and Water Supply EstimateRoshan KejariwalNo ratings yet

- Pradhan Mantri Gram Sadak Yojana - IiiDocument2 pagesPradhan Mantri Gram Sadak Yojana - Iiiabhijeet sahuNo ratings yet

- Water Booth EstimateDocument5 pagesWater Booth Estimateapi-3823524No ratings yet

- 2bhk Septic TankDocument72 pages2bhk Septic Tankkrishna pandagaNo ratings yet

- Plate Girder BridgeDocument12 pagesPlate Girder BridgeRAYEES NABI NAQASHBANINo ratings yet

- 250mm B - WALL Estimate NewDocument112 pages250mm B - WALL Estimate NewRAHUL KUMARNo ratings yet

- Reinforced Cement Concrete in Steps, Including Setting in CementDocument3 pagesReinforced Cement Concrete in Steps, Including Setting in CementVenkata PrasadNo ratings yet

- C C C CDocument11 pagesC C C Ckalpana_8912No ratings yet

- Tender Schedule Renovation of Vadakkechira Bus StandDocument61 pagesTender Schedule Renovation of Vadakkechira Bus Standsuji91No ratings yet

- EstimationDocument4 pagesEstimationArif AbbihalNo ratings yet

- DrainDocument3 pagesDrainPachuau MesiahNo ratings yet

- PH and Rising MainDocument17 pagesPH and Rising MainTechnowisdom ConsultantsNo ratings yet

- Pricebid - NIT 04T-19-20Document9 pagesPricebid - NIT 04T-19-20vivekanand sawkarNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Quotaion For 53Document1 pageQuotaion For 53Nirajan MarwaitNo ratings yet

- Ashok Shuttering Measurment: S.NO. Description Nos. Length Breadth Total Oty. RemarksDocument3 pagesAshok Shuttering Measurment: S.NO. Description Nos. Length Breadth Total Oty. RemarksNirajan MarwaitNo ratings yet

- Tutorial Material For Mandatory Basic Safety Training Course (Construction Work)Document22 pagesTutorial Material For Mandatory Basic Safety Training Course (Construction Work)Nirajan MarwaitNo ratings yet

- Pole in Between CP-55 & P-56: MVR F875Document5 pagesPole in Between CP-55 & P-56: MVR F875Nirajan MarwaitNo ratings yet

- HIV PolicyDocument1 pageHIV PolicyNirajan MarwaitNo ratings yet

- SF 23 & 24 Work Permit Lifting - Tandem LiftingDocument8 pagesSF 23 & 24 Work Permit Lifting - Tandem LiftingNirajan Marwait100% (2)

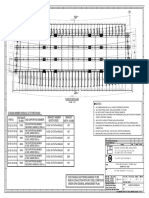

- Notes: - : Plan of Deck SlabDocument1 pageNotes: - : Plan of Deck SlabNirajan MarwaitNo ratings yet

- Drain CoverDocument2 pagesDrain CoverNirajan MarwaitNo ratings yet

- Jai Paras Construction & Engg. Co. Bill of Quantity For Storm Water LineDocument3 pagesJai Paras Construction & Engg. Co. Bill of Quantity For Storm Water LineNirajan MarwaitNo ratings yet

- Ehs Risk Register / Assessment: Name of The Project Reference No Activities CoveredDocument7 pagesEhs Risk Register / Assessment: Name of The Project Reference No Activities CoveredNirajan MarwaitNo ratings yet

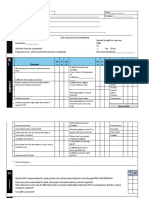

- FORMATDocument3 pagesFORMATNirajan MarwaitNo ratings yet

- Monthly Progress ReportDocument8 pagesMonthly Progress ReportNirajan MarwaitNo ratings yet

- PIONEER Fabricators (P) LTD.: AN ISO 9001:2008 COMPANYDocument1 pagePIONEER Fabricators (P) LTD.: AN ISO 9001:2008 COMPANYNirajan MarwaitNo ratings yet

- Particulars QTY Unit Rate Amount 1 2 3 4 5: S.No Ref. NoDocument1 pageParticulars QTY Unit Rate Amount 1 2 3 4 5: S.No Ref. NoNirajan MarwaitNo ratings yet

- Qap PDFDocument11 pagesQap PDFNirajan MarwaitNo ratings yet

- Aec 001-Bacc 001 (Econ) - Week 4 ModuleDocument3 pagesAec 001-Bacc 001 (Econ) - Week 4 ModuleNicole ValentinoNo ratings yet

- Sample Marketing PlanDocument4 pagesSample Marketing PlanSuhailNo ratings yet

- Midterm Exam DM 213 Fiscal ManagementDocument8 pagesMidterm Exam DM 213 Fiscal Managementbplo aguilarNo ratings yet

- 2020.11.05 Taylor v. Doe ComplaintDocument62 pages2020.11.05 Taylor v. Doe ComplaintseahorsieNo ratings yet

- MBA ABM SyllabusDocument33 pagesMBA ABM Syllabuszinga007No ratings yet

- Modeling and SimulationDocument11 pagesModeling and SimulationZain MughalNo ratings yet

- Shorting SupernovasDocument10 pagesShorting SupernovasAlexNo ratings yet

- Isihskipper January 2010Document25 pagesIsihskipper January 2010enelcharcoNo ratings yet

- Modification Instruction: Truck, Medium, Mc2 - Unimog - All TypesDocument7 pagesModification Instruction: Truck, Medium, Mc2 - Unimog - All TypesmichaelNo ratings yet

- J2Lite SRS TemplateDocument7 pagesJ2Lite SRS Templatesami_20031No ratings yet

- 21cs644 Module 3Document95 pages21cs644 Module 3gmaheshreddy229No ratings yet

- Mathematics Grade 12 21 Century Skills Based TestDocument7 pagesMathematics Grade 12 21 Century Skills Based TestChester Austin Reese Maslog Jr.No ratings yet

- Rutgers University, Department of Electrical and Computer Engineering Abet Course Syllabus COURSE: 14:332:366Document3 pagesRutgers University, Department of Electrical and Computer Engineering Abet Course Syllabus COURSE: 14:332:366HUANG YINo ratings yet

- Deutz 2008 SpecsDocument4 pagesDeutz 2008 SpecsaaasNo ratings yet

- MappletsDocument8 pagesMappletsjunkgr8mail6092No ratings yet

- Food and Cash Crops Social ScienceDocument19 pagesFood and Cash Crops Social ScienceSUKIRTHI K 19RBAR064No ratings yet

- Finance Exam Questions #2Document21 pagesFinance Exam Questions #2Cody Chivas100% (1)

- Activity Work ScheduleDocument7 pagesActivity Work ScheduleAndre JingNo ratings yet

- Catalogue Water Cooled Screw Chiller Cuwd-CDocument15 pagesCatalogue Water Cooled Screw Chiller Cuwd-CBayu SetiaNo ratings yet

- Mastering Ibm Cognos SecurityDocument24 pagesMastering Ibm Cognos Securityleonardo russoNo ratings yet

- HeinonlineDocument8 pagesHeinonlineSyed AsadNo ratings yet

- 2018 Annual Public Debt ReportDocument79 pages2018 Annual Public Debt ReportDr. Ọbádélé KambonNo ratings yet

- 01 Nederlandse Programma StichtingDocument4 pages01 Nederlandse Programma StichtingMilena ŠmigićNo ratings yet

- BRKDCN 2035 PDFDocument117 pagesBRKDCN 2035 PDFJorge Alberto Largaespada GonzalezNo ratings yet

- Percentage Increase and DecreaseDocument3 pagesPercentage Increase and DecreaseLai Kee KongNo ratings yet

- Account Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceDocument2 pagesAccount Statement From 27 Mar 2022 To 5 Apr 2022: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancePiyush AgarwalNo ratings yet

- Management of Information Systems in The Digital AgeDocument8 pagesManagement of Information Systems in The Digital Ageinescoste4No ratings yet

- Indian Ports Community SystemDocument6 pagesIndian Ports Community Systempatil sNo ratings yet