Professional Documents

Culture Documents

Vivaboard Catalog

Vivaboard Catalog

Uploaded by

Nida Naseer0 ratings0% found this document useful (0 votes)

10 views15 pagesOriginal Title

Vivaboard_Catalog

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views15 pagesVivaboard Catalog

Vivaboard Catalog

Uploaded by

Nida NaseerCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 15

VIVA Board is a cement bonded particle board. It conforms to

the Thai Standard TIS. 878-2537 for cement bonded particle

board quality requirements and the European Standard

EN 13986:2004 for wood-based panels use in construction.

VIVA Board also complies with Green Material Schemes such

<5 Thai Green Label, Singapore Green Label and Taiwan Green

Building. It proves to be both health and environmentally friendly

Beereinetene

VIVA Board is manufactured by Viva Industries Co., Ltd.

The company is certified by the quality management system

ISO 9001 and the environmental management system

ISO 14001

World Class Projects

With 30 years of experience, plus constant research and development,

VIVA Board has been proven to be a superior cement-bonded particle board,

and has been used in many world-class construction projects.

Ml

VIVA BOARD

THE BEST COMBINATION OF WOOD AND CEMENT

VIVA Board is a cement bonded particle board, It has unique smooth grey cement surface. It is made from planted Eucalyptus

chips, Portland cement, and mineralizing agents. Wood is processed into coarse and fine flake and thoroughly mixed with

cement, mineralizing agent, and water in computer-controlled mixer. The required amount of mixed material is laid continuously on

carrier plates using unique process which distributes coarse material in the middle and fine material on the two surfaces. The

carrier plates with the formed mat are stacked and compressed using very high pressure to convert the formed mat into boards

of required thickness with high strength and grey, smooth, cement-like surfaces, Once the boards are cured and conditioned,

they are trimmed to the finished size, thoroughly inspected for quality, and packed for dispatch,

k

Stonderd Suu) 22 |

4 =

———_

VIVA Clad

mS Root ya covered Wal

= Sai

RIVA

VIVA Exterior Wail

10 12 16 2 2%

VIVA Clad

VIVA Build: Residential Building Wall

VIVA Build: Public Building Wall

VA Easy Wal

VIVA Covered Well

VIVA Deco Wall Interior Well in Natural Finish

VIVA Deco Wall: Exterior Wallin Natural Finish

WA Ceiling

VIVA Sub Roof

VIVA Wet Area

VIVA Stb Floor

VIVA Floor

VIVA SOLUTION

coo ,

va =

Sie)

Mee)

coo

aL CRD)

8, 10, 12, 16, 20, 24

Size (mm)

SCE c cy

SP eezr)

PCa ee ce

rey

Sey

Seen)

SAN

A ANN

Z

Z

Z

Ay.

he

VIVA BOARD Applications

Exterior Cladding on Metal Structure or Existing Wall

pr

cd

Cree eee

Creda)

Pec)

Sy

Foc Top hat section on existing wall or metal structure with spacing 0.60 m.

a ee ee

Coy Height

Interior Exterior ‘sie e

Bolow 6 m 10- 12mm (675, 0.50 mm thick soem

emm

6-10m 2mm 1678, 078-1.00 mm thick coon

Below 10 m 12mm oom

Pree 10mm (€75, 075-100 mm thick

10-20m 12-16 mm 400m

On principal studs

in Acrylic paint

WIND LOAD TABLE

Corea)

re

Be ou eo

saad

al :

cy

0

«

©

Remark: For buldings over 20 meters height, please consult manufacturer

VIVA BOARD Applications Installation

VIVA Easy Wall

ViVABoaRe peer ]

Tustalinion Type |e |

Frames Galvanized steel Cand U section, 0.50 mm thick

| @sox240em

Frings Cee pe

Finjshings ores \

VIVA Covered Wall

ery

ca

Pe nena Roe

rd

Ceca

(On principal and common studs

rena!

Deu

Boe Sn ag

+ Attach covering material on board according tits installation

guide

See en eee

Pee neti

‘Tiling over board's joint and control joint are not

eee

@mm

cay

Galvanized stee! C64 and Uss section 0.50 mm thick for

See Loran Eco ee ee)

U76 section 0.50 mm thick for 90 minutes fire-rated partition

‘9mm Gypsum board for non-fire-rated partition

PO ee lo ne ue ec En

Corey

Ce ey

Rene enn ey

og

Be eC ets

SIE rca

+ Joint of VIVA board and Gypsum board must not overlap.

VIVA BOARD Applications

Interior Wall in Natural Finish

ee parr

tnstatixtion Type: | Flex

oe See

en Cro

Co Cn

a eer eed

Exterior Wall in Natural Finish on Metal Structure or

Existing Wall

— Seen ees =

eas Cera “wr

Lone Cay >

fy RSL |

instruction: a uC Dk) >

Peete

Interior Floor in Natural Finish

VIVA Bound Pern

Cm)

ces Light gauge C section, 2.3-3.2 mm thick

eter

coe ay

ed RCO

VIVA BOARD Applications eee

VIVA Wet Area

pr

cao

Galvanized steel C section 0.75 mm and U section 0.50 mm thick

Petry

Cee eae

‘Atevery 4.8-6 m. and comers of the room

mera

+ Bond boards edges together using epoxy glue

+ Caulk control joints with polyurethane sealant

Beene ene mee ead

eerie

See ee ee eee sc

Cee ar eres

ing over board's joint and control joint are not recommended

perry

cd

CE eee eed

@ 40x 40 cm to 60 x60 cm depending on required loading

re

Peony

reer tr

pee rere cay

+ Bond boards edges together using epoxy glue

et ae ees

+ Lay water proofing membrane on VIVA board deck before

a uy

Bren pest ero eee eee ears

Pere es

Soe ea he ees id

board's joint fill with polyurethane sealant

Tee ae ee)

Pe

Flood Protection Wall ae

VIVA BOARD Applications Installation

perry

oa

Cee ued

@ 40x 40 cm to 60 x 60 cm depending on required loading capability

(On principal and common joists

eure t er cere oy

Cone ata od

ee cerca!

Nee or

+ Caulk control joints with polyurethane sealant

+ Flx covering material on board according to its installation guide

nee cd

Rees

+ Spread polyurethane adhesive on back side of boards

perry

ee ene Ty

De eer i LuLu

+ Fix wood flooring or parquet on boards in crosswise direction

Board Thickness

Go)

a

20

a

ee eda

Sera ea au

eee ea ee eee

VIVA BOARD Applications Installation

VIVA Roof & Ceiling

een

Firm

eee Tea

rere)

Ce ec

PVC water proofing membrane

erry

Firm

Meer Tay

era

Ce ee Cod

ren

Pe ered

before covering with metal sheet

erry

cad

recor Tay

Cor

an

eee

Pe LUC cod

before attaching covering material

oo

coe

Creer rpc

Cra

ey

eed

‘emm

oo

cere

Cc a

een

Aeron Ee Con ee rod

+ Apply primer on both sides of boards to prevent warping

ese

VIVA Installation Instruction

\VIVA Board is a combination of wood and cement. It inherits many properties of the two main components, I is weather resistant lke cement,

However. ke ary boards with wood or wood derived component, it has a degree of moisture mavement. meaning that it contracts and expands

in relation to changes in ambient moisture and temperature, The direction and degree of movement can be predicted and must be taken into

account when installing the boards. Board should be fixed by a method that allows linear movement in most situations. This eliminates formal

movement such as warping and bowling and prevents damages. Paint and coating reduces degree of movement. When covering material is apple,

boards should be fixed fimly to minimize movement Following are the two installation methods: Flex and Firm Installation

rame ie assembled to allow movement when board is exposed to

high degree of changes in temperature and moisture.

‘© Two pieces of steal frame should be used at joint between boards.

I timber frame is used, two pieces of frame at joint between boards

isnot necessary.

For VIVA Easy Wall, VIVA Deco Wall, VIVA Build and VIVA Clad

Jee only vertical fame. Attach frama to supporting structure by fixing

it to L'shape bracket of 'U' Track

«© Apply two pieces of frame at jint between boards. Fix frame together

by using screws to allow some movernent

Recommend strengthen the frame by fixing ‘U' galvanized steel ame

at every 120 cm,

«© Top Hat section can substitute two pieces of 'C' section frame by

placing Top Hat inversely wing-up. VIVA Boards shall be fixed on

sifferent wings.

© Set principal joist cross-wise from board direction at 30 cm, 40 om

‘or 60 cm. Set common joist to support the long edges.

# Apply two pieces of frame at joint between boards. Fx joist together

by using screws to allow some movernent,

oe tay

Ae

ee

Pe

ixing Distance

Flox Installation: 90 mm 8-16 mm

75m

Fem Installation: 20 mm

20-24 mm

FIRM Installation

Frame is rigidly assembled to prevent untoward results due to

‘board movement when a covering material such as ceramic tle

‘oF wood flooring is applied

Set frame at 30 em x 30 em, 40 em x 40 em, or 60 em x 60 em

depending on required rigiclty and load capabilty.

@ Fimiy assemble the frame together by welding or screwing

Iva singe frame's with fe ineufcient. two frames at the joint

between boards ave recommended. Frame must be welded

together to ensure no frame's movement,

Provide control joint (movement joint) at every 48 - 6 meters

‘and around the room's perimeter by using flex installation method

to allow movement.

200 - 300 mm 00 - 400 mm

we ie wl PR Pe

| Tht | ; *

Staggered Patio

Cc Con et Con it “VA

coo Sit | 880m 480m Foren Sect

lel T 20.90 wn 2029 an

I i

Control Jit — cael it | t

I T Wa Siew

“600 \ SF tos

cor it

Control

FRAME SELECTION

/

txt

Se 75 ur con

a 65x90mm 07-40. mm

f 100-150 x 50x 20mm 23-32 mm

G4 400-190 %50mm 28-82 mm

High VIVA Deco Wall, VIVA Easy Wall

High WAEasy Wal. VA Bul fiat bung. VIVA Comb Wal

High VIVA Clad, VIVA Deco Wall exterior)

Low VIVA Bull pute bug), VIVA Covered Wal, VIVA Wet Area

Very Low VIVA Deco Floor

No Flexblty VIVA Floor with covering material

Working with VIVA BOARD

cutting: VIVA Board can be cut with portable circular saw with tungsten carbide tipped blade or jigsaw. Crosscut

hhand saw can be used for thickness up to 12 mm

iting: YIVA Board can be milled for hal-lap, tongue and groove, tapered and etc. The milling tip should be made of

‘tungsten carbide. Please note that minimal thickness of board should be considered when miling,

Grinding: “Manual grinding or electic hand-held grinding tools with abrasive paper of 40 - 60 granularity can be used at

joint areas of boards when boards! evenness is needed or the board surface should be coarsened,

‘Screwing: LWA Screw is recommended because it alows dling and countersinkig in one step. When using se-apping screw,

pre-diling with slightly oversize hole is required

‘Scrow Head Covering: Touch-up the screw heads with acrylic fillar, epoxy putty or VIVA epoxy. To match screw hoad color with

IVA board, use a mixture of Portland cement, adhesive, saw dust and pigment

Nailing: IVA Board up to 10 mm thickness can be manually nailed onto timber frame without pre-cling

Wide Opening: In cutting a wide opening such as door or window. studs should be placed around the perimeter ofthe opening

to suffciently reinforce the opening.

Flashing:

‘opening, and top comer to prevent water leakage.

Interior co

Gasmet erent

ao

er

Exterior Glose/Matte polyurethane

Remark:

‘Akaline resisting primer should always be applied as base before painting due to

akalinty of VIVA Board's surace

‘The boars surface should be clean and dry before paint 0 coating

(i-based paint i not recommended to use with VIVA Bostd

‘Appling paint or primer on the backside ofthe board ensure thatthe board is

batter condoned for use where there are changes in moisture content and

temperature ofthe board or where conditions on two sides of the boards ctfer

substantially 2g. T-Bar caling.

For applications used io high humity area, molsture resistant costing should be

applied to both surtaces belore appving covering materials

Each paint and coating type has its special properties; please consult the paint

rmanulacture fr more details

Exterior flor in natural frish or painting isnot recommended,

For exterior applications, fashing should be installed forthe areas such as window and door frame adjoining val,

Tr 4 in &

VIVA Board must be stored under a rooted area, in a dry

environment and wall protected rom weather. Floor area should

be leveled and soi

VIVA Board should be stored in is original packing supplied

Hf taken out from the pales, board can be stacked with the

‘maximurn height of 75 em. The stack shal be lad on § bearing

ates with maximum of 60 em space ameng plates. The stack

hal b covered with waterprf protoctve plastic shoot

Masaru of 4 pals or stacks shal be lad ontop of eachother.

VIVA Board must never be stored on edge or upright. Outdoor

Storage is not recommended.

VIVA Board shoud bela lat and be adequately rotcted dng

transportation by waterproof covering

Liting the board from is tack should be dane one piace at

1 time by sling to the side. Never It VIVA Board fram ts both

fends because it may cause the boards to bend resulting in

bow breakage VA Boat must be cared na verical positon,

VIVA Board should be allowed 24 - 48 hours to adapt to the

ambient humity lve prior fixing for ts mest capabity working

Concions Ifthe board gets wet, t should be alowed to dry

indvicually prior

raainen” EE gi Mix

Accessories

4

Net content : 3.785 litres

Available color: Light grey see

Weight: 2 kg/set (part A+B) a

VIVA Screw is made from steel and coated with rust protective of 25 micron thick in compliance with AS 3566

(Class 3, VIVA Sorew can dr and countersink onto VIVA Board and frame without pre-drling, It can be used

with an electric ceil with speed of over 2700 rounds per minute,

‘Stal costing ss 3s sate for using in moderate tempi For har wean condo, sta cating eas 4 is gly recomended

VIVA Backing Rod is functioned to minimize the amount of polyurethane sealant

Used and to act as a bond breaker between surfaces. VA Backing Rd is avalable

in two sizes: 3 mm and 6 mm.

‘3 mm for VIVA Board 8 - 10 mm |

6 mm for VIVA Board 12 mm. and above, 7

Length of VIVA Backing Rod is 60 meters per uni.

St0p 4: at VA Backing Rod to ooo

VIVA Flex Polyurethane Sealant conforms to SNJF, ASTM C920, ISO 8339 and

ASTM D412 standard, Sausage package contains 600 ml and cartidge package

Contains 310 mI is avaiable in two colors: white and light grey.

‘Step 2: Fl ne gap with VIA Fi

VIVA BOARD Technical Data

ay

Specific Properties Soe MN oD

Gaeta occ a)

Cod

Crete

er

Cen)

ey

Se Re aCe)

See ee eee cca

aes

Peery pH

Length Change (after 24 hours immersed in water)

‘Water Absorption (after 24 hours immersed in water)

Fire Resistance Proper

WE VIVA Board contains high percentage of cement content permitting it to be highly fire-resistant

VIVA Board passed BS 476 Part 6 and 7 and Is classified as vitually non-combustible or class 'O'

‘material and itis also classified as class 'B' according to BS EN 13501-1

¥VWA Board parton system also passed the 1-hour,2-hour and 4-hour fe rating test according

to BS 476 Part 22, proving its fre prevention capability.

¥i Due to its high density, VIVA Board contributes significant sound insulating

performance than any other types of building boards.

Remark: Please consult the manufacturer for more details of fire resistance and sound insulating solutions.

Features and Benefit:

oa eorpon

eat Ineuaton Sound nating any Wovkabaly Economical Aibodos ee Foon

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Water Tank DesignDocument37 pagesWater Tank DesignWrishad Zia95% (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Update Sky Walk -Sky Hall-สะพานลแย Layout Planบางกะปิ - 05-11-2020Document6 pagesUpdate Sky Walk -Sky Hall-สะพานลแย Layout Planบางกะปิ - 05-11-2020MomayKradookkradicNo ratings yet

- CC Tall Buildings GuideDocument164 pagesCC Tall Buildings Guidemexces100% (19)

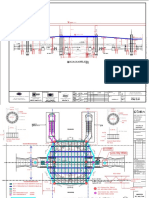

- 2020-10-28 - แบบขยายเสาเข็ม (บางกะปิ) Comment 1Document1 page2020-10-28 - แบบขยายเสาเข็ม (บางกะปิ) Comment 1MomayKradookkradicNo ratings yet

- Sky Hall คลองแสนแสบ - Detail Design - Profile 09-11-2020 PDFDocument6 pagesSky Hall คลองแสนแสบ - Detail Design - Profile 09-11-2020 PDFMomayKradookkradicNo ratings yet

- MRT 1571-62 PDFDocument139 pagesMRT 1571-62 PDFMomayKradookkradicNo ratings yet

- Sky Hall คลองแสนแสบ - Detail Design - Profile 07-11-2020Document5 pagesSky Hall คลองแสนแสบ - Detail Design - Profile 07-11-2020MomayKradookkradicNo ratings yet

- Special Specification 4659 Transparent Noise Barrier PanelsDocument8 pagesSpecial Specification 4659 Transparent Noise Barrier PanelsMomayKradookkradicNo ratings yet

- Course Book of Foundation For Civil Engineering 2012-2013 PDFDocument23 pagesCourse Book of Foundation For Civil Engineering 2012-2013 PDFMomayKradookkradic100% (2)

- Kemrex Presentation - 18032019Document53 pagesKemrex Presentation - 18032019MomayKradookkradicNo ratings yet

- มยผ มาตรฐานการป้องกันอัคคีภัยของอาคารเหล็ก โครงสร้างรูปพรรณDocument44 pagesมยผ มาตรฐานการป้องกันอัคคีภัยของอาคารเหล็ก โครงสร้างรูปพรรณMomayKradookkradicNo ratings yet

- TrnsLine PDFDocument495 pagesTrnsLine PDFMomayKradookkradicNo ratings yet

- Viva Board (Japn)Document16 pagesViva Board (Japn)MomayKradookkradicNo ratings yet

- Design of Anchorage To Concrete Using ACI 318 08 & CSA A23.3 04 Code PDFDocument155 pagesDesign of Anchorage To Concrete Using ACI 318 08 & CSA A23.3 04 Code PDFMomayKradookkradicNo ratings yet

- Tis107 2533Document21 pagesTis107 2533Th NattapongNo ratings yet

- HOLLOW-STEEL-SECTIONS-Rectangular Tubes PDFDocument2 pagesHOLLOW-STEEL-SECTIONS-Rectangular Tubes PDFMomayKradookkradicNo ratings yet

- Jis G 3466square and Rectangular Hollow PDFDocument3 pagesJis G 3466square and Rectangular Hollow PDFMomayKradookkradicNo ratings yet

- Light GaugeDocument2 pagesLight GaugeMomayKradookkradicNo ratings yet