Professional Documents

Culture Documents

Cuplocks Scaffolding JSA Utility

Cuplocks Scaffolding JSA Utility

Uploaded by

soubhagyaCopyright:

Available Formats

You might also like

- Flocare Infinity Pump Troubleshooting GuideDocument6 pagesFlocare Infinity Pump Troubleshooting GuideLorena GuzmanNo ratings yet

- Method Statement - Cable Tray ErectionDocument2 pagesMethod Statement - Cable Tray Erectionsoubhagya50% (4)

- JSA Painting WorkDocument2 pagesJSA Painting WorkKhalid NaseemNo ratings yet

- Drilling Work by MCDocument1 pageDrilling Work by MCChandru100% (1)

- Jsa For Work at HeightDocument8 pagesJsa For Work at HeightMuhammad Umar Gondal50% (2)

- Jsa For Mechanical Activity: H/M/L H/M/LDocument1 pageJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarNo ratings yet

- Method Statement: Errection of Canopy Shed. PurposeDocument1 pageMethod Statement: Errection of Canopy Shed. Purposesoubhagya100% (2)

- Risk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001Document7 pagesRisk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001123shripad100% (1)

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRaju100% (1)

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Hira - RCC Road ActivityDocument3 pagesHira - RCC Road Activitytariq1987100% (2)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- Hoist Erection Operation & Maintenance Work - R0 - 30.09.2017Document6 pagesHoist Erection Operation & Maintenance Work - R0 - 30.09.2017Nikhil Manjrekar100% (2)

- HIRA For Work at HeightDocument5 pagesHIRA For Work at HeightMD. Nayyar Mirza100% (1)

- Excavation, Trenching & Pot HolingDocument1 pageExcavation, Trenching & Pot HolingHafiz SabriNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA For SRP Instolation and DismentlingDocument17 pagesJSA For SRP Instolation and DismentlingShekh BabulNo ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Job Safety Analysis - Overhead Power LinesDocument2 pagesJob Safety Analysis - Overhead Power Linesrenee100% (2)

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- 2.7 Working Near Live SwitchyardDocument3 pages2.7 Working Near Live SwitchyardYusuf Afraz100% (1)

- JHA Jack Hydraulic PalletDocument1 pageJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- Standard Activity Risk Assessment Facade Concrete Walls WF ADocument6 pagesStandard Activity Risk Assessment Facade Concrete Walls WF AChoubi ChoubacaNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- All HiraDocument34 pagesAll HiraSuryavenkat RaghavanNo ratings yet

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- AHU AssemblyDocument3 pagesAHU AssemblyKrishna Patil100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Working at Height Op (Eration Scaffolding Work Risk AssessmentDocument22 pagesWorking at Height Op (Eration Scaffolding Work Risk AssessmentAhmed Farman Alqaysi100% (1)

- Insulation of Ducting and PipingDocument1 pageInsulation of Ducting and PipingKrishna Patil100% (1)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- 4.HIRA Excavation OnlyDocument6 pages4.HIRA Excavation OnlyMD Abdullah100% (1)

- HIRA For Waterproofing Work at B-Hub ProjectDocument8 pagesHIRA For Waterproofing Work at B-Hub ProjectRajat Kumar MishraNo ratings yet

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pages2020 06 17 JSA For AC Servicing-Server RoomDarren OscarNo ratings yet

- Summer Preparedness PlanDocument20 pagesSummer Preparedness PlanGovind Kumar100% (1)

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- Safety Observtion Register FarhadDocument2 pagesSafety Observtion Register Farhadalla malikNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- Unloading of Reinforcement SteelDocument1 pageUnloading of Reinforcement SteelGyanendra Narayan NayakNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- 5.confined Space EntryDocument6 pages5.confined Space EntryMohammad Fazal KhanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- HIRA - Pile CapDocument4 pagesHIRA - Pile CapMMRDACA07 SAFETYNo ratings yet

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Document3 pagesRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanNo ratings yet

- Job Safety Analysis: Cooling Tower OperationDocument2 pagesJob Safety Analysis: Cooling Tower OperationVi VekNo ratings yet

- Db Shr 010 전사 안전보건방침Document2 pagesDb Shr 010 전사 안전보건방침Tigor GurningNo ratings yet

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- JSA Bore We Jabil SiteDocument3 pagesJSA Bore We Jabil SitesoubhagyaNo ratings yet

- ELCB Checklist PDFDocument1 pageELCB Checklist PDFsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument5 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Electrical Safety Do - S - Dont - SDocument2 pagesElectrical Safety Do - S - Dont - SsoubhagyaNo ratings yet

- Jha RWFW Raft Cocrete JobDocument3 pagesJha RWFW Raft Cocrete JobsoubhagyaNo ratings yet

- JSA Gypsom WorkDocument5 pagesJSA Gypsom WorksoubhagyaNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- METHOD STATMENT FORFIRE DETECTOR INSTALATIONDocument2 pagesMETHOD STATMENT FORFIRE DETECTOR INSTALATIONsoubhagyaNo ratings yet

- Method Statement For Horizontal Tray Erection.Document5 pagesMethod Statement For Horizontal Tray Erection.soubhagyaNo ratings yet

- Method Statement - Tower ErectionDocument2 pagesMethod Statement - Tower ErectionsoubhagyaNo ratings yet

- Method Statement - Bus DuctDocument2 pagesMethod Statement - Bus Ductsoubhagya100% (1)

- Method Statement Bolero Shed: Purpose: Scope of WorkDocument2 pagesMethod Statement Bolero Shed: Purpose: Scope of WorksoubhagyaNo ratings yet

- CONCRETING OF BOLERO SHEDDocument1 pageCONCRETING OF BOLERO SHEDsoubhagyaNo ratings yet

- Method Statement Staircase (Process Plant) LocationDocument4 pagesMethod Statement Staircase (Process Plant) LocationsoubhagyaNo ratings yet

- Method Statement Mrs Building: Purpose: Scope of WorkDocument1 pageMethod Statement Mrs Building: Purpose: Scope of WorksoubhagyaNo ratings yet

- Safe Work Method Statement For Erection of All Works:: Client ConsultantDocument4 pagesSafe Work Method Statement For Erection of All Works:: Client ConsultantsoubhagyaNo ratings yet

- Method Statement: Erection, Shuttering & Casting of ColumnDocument2 pagesMethod Statement: Erection, Shuttering & Casting of Columnsoubhagya50% (2)

- Method Statement: Purpose: Scope of WorkDocument1 pageMethod Statement: Purpose: Scope of WorksoubhagyaNo ratings yet

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable LayingsoubhagyaNo ratings yet

- METHOD STATEMENt FabricationDocument2 pagesMETHOD STATEMENt FabricationsoubhagyaNo ratings yet

- Method Statement - Panel ErectionDocument2 pagesMethod Statement - Panel ErectionsoubhagyaNo ratings yet

- METHOD STATEMENT FORVacuum PipingDocument2 pagesMETHOD STATEMENT FORVacuum PipingsoubhagyaNo ratings yet

- Method Statement - Bus BarDocument2 pagesMethod Statement - Bus Barsoubhagya100% (1)

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- JSA FOR Using The Hand and Power Tools - 2Document2 pagesJSA FOR Using The Hand and Power Tools - 2soubhagya100% (2)

- Life Calling Map Fillable FormDocument2 pagesLife Calling Map Fillable Formapi-300853489No ratings yet

- Monthly Report Bundle 2021Document55 pagesMonthly Report Bundle 2021Don alewoh7No ratings yet

- One Health Concepts and Knowledge Presentation SlidesDocument48 pagesOne Health Concepts and Knowledge Presentation Slideskarunia nihaya100% (1)

- IELTS Cause-Problem and Effect-Solution Model EssayDocument17 pagesIELTS Cause-Problem and Effect-Solution Model EssaySayaf RashadNo ratings yet

- CSQ Nap4 FullDocument219 pagesCSQ Nap4 FullJeisson FarroNo ratings yet

- NMC Eligibililty ApplicationDocument2 pagesNMC Eligibililty ApplicationYergnoirNo ratings yet

- 16012019FV4Q6RWBAnnexure documentofEIAEMP PDFDocument400 pages16012019FV4Q6RWBAnnexure documentofEIAEMP PDFJainam Shah100% (1)

- 5 1 Why Your Body Needs NutrientsDocument3 pages5 1 Why Your Body Needs Nutrientsapi-261782961No ratings yet

- Benefits of Hypnosis Author Mental Health America of Northern KentuckyDocument4 pagesBenefits of Hypnosis Author Mental Health America of Northern KentuckyJakarta SelamatNo ratings yet

- 12.2 - Regulation of Body TemperatureDocument38 pages12.2 - Regulation of Body Temperature022797SemelllNo ratings yet

- Sydenham's ChoreaDocument11 pagesSydenham's ChoreaKosi UdohNo ratings yet

- PREGNANCYDocument4 pagesPREGNANCYShaileeNo ratings yet

- Deep Fat FryingDocument2 pagesDeep Fat FryingalinawidagdoNo ratings yet

- Werner Erhard S Est Training in The PrisonsDocument8 pagesWerner Erhard S Est Training in The PrisonsMauroVentolaNo ratings yet

- ELIGIBILITY BKPDocument1 pageELIGIBILITY BKPLydia FrederickNo ratings yet

- Lecture 2 Hope 1Document4 pagesLecture 2 Hope 1cally20smithNo ratings yet

- How To Prevent BullyingDocument4 pagesHow To Prevent BullyingLiezel-jheng Apostol LozadaNo ratings yet

- JSP 403 Vol 2 Chapter 2Document61 pagesJSP 403 Vol 2 Chapter 2SOOD ASSOCIATES GOANo ratings yet

- Rabbit KeepingDocument12 pagesRabbit KeepingMoses NdwaruNo ratings yet

- Manual Oral-B GENIUS-XDocument19 pagesManual Oral-B GENIUS-XsaulobbNo ratings yet

- HypothermiaDocument5 pagesHypothermiaMRS CHAKRAPANINo ratings yet

- Behcet's Disease (Adamantiades Syndrome) : DefinitionDocument9 pagesBehcet's Disease (Adamantiades Syndrome) : DefinitionNuzairah AynoorNo ratings yet

- Molly McDowell - Course Project Part 1Document5 pagesMolly McDowell - Course Project Part 1Adelaide DariaNo ratings yet

- IS 501 2021-2022 Spring Assignment #4: Part-1: Can The National Health Service Go Paperless?Document3 pagesIS 501 2021-2022 Spring Assignment #4: Part-1: Can The National Health Service Go Paperless?adsfNo ratings yet

- Section A Multiple Choice Questions Gynaecology: Prepared by Da Roux Barrett Class of 2014Document13 pagesSection A Multiple Choice Questions Gynaecology: Prepared by Da Roux Barrett Class of 2014Sheldon FerronNo ratings yet

- Clinical AssignmentDocument9 pagesClinical AssignmentkomalNo ratings yet

- Daftar Obat %pareto Dan Ven 15Document200 pagesDaftar Obat %pareto Dan Ven 15sofia nofiantiNo ratings yet

- Brain Workshop - a Dual N-Back game - نسخةDocument4 pagesBrain Workshop - a Dual N-Back game - نسخةBTQNo ratings yet

- HOLANDA ALEX CFE103 Module4 ContextEngageActivitiesDocument4 pagesHOLANDA ALEX CFE103 Module4 ContextEngageActivitiesAsus LaptopNo ratings yet

Cuplocks Scaffolding JSA Utility

Cuplocks Scaffolding JSA Utility

Uploaded by

soubhagyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cuplocks Scaffolding JSA Utility

Cuplocks Scaffolding JSA Utility

Uploaded by

soubhagyaCopyright:

Available Formats

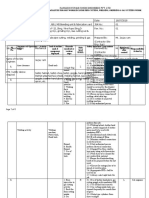

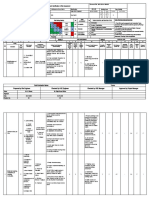

ISO 9001

DSM—Engineering –MIDC Ranjangaon Job Hazard Analysis

TASK : Cap locks Scaffolds Erection CONTRACTOR: Rohan Builders JOB No.:

SUPERVISOR : Vinod Singh / K.Govind Raj LOCATION : Utility Area- Workshop/ West Stack Yard/ Sub station etc. DATE: 20/08/07

JOB STEP HAZARDS Control Measure ACTION

Break the job into steps. List the hazard or type of List the necessary control measures to be followed to eliminate the identified Person who will ensure

Listing work which may be hazardous. harm identified with each hazards this happens

step

Scaffolding Material Shifting By Tripping Hazard Only Use Of standard material for erected scaffolding.

Manually ( Stock Yard To Scaffold

Erection Area) Cut Injury proper pathway.

Use of PPE’s ( Safety helmet with chin strip, safety

shoes, goggles, Reflective vest.handgloves,)

Safe Method Of Shifting Material.

Scaffold Erection By Manually Cut injury Use of Hand Gloves.

Erection Area Should be proper compaction.

--Height -6mtr. Fall Hazard

Area to be barricaded and entry restricted

Will give them tool box Regarding the scaffold Erection.

Scaffolding Erection worker to be trained gang under

strict supervision.

Fall protection equipment is available prior to beginning

erection.

DSM This document is current at20/08/07

Ver 1

ISO 9001

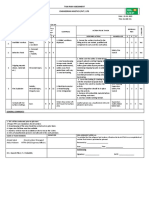

Full body harness with double lanyard to be provided

for all those who are working at height above 2mttrs.

Material to tied properly before lifting or getting down

and the time of lifting pr getting the area barricaded

Use of inspected Tools.

Do not over load platform with materials & platform

should be cleared from all unwanted materials.

Provided suitable access.

Trained and selected scaffolding team with a foreman

will erect the scaffolding and the same will be inspected

by area supervisor and SHE Personal.

Height work training to be given to all scaffold worker.

DSM This document is current at20/08/07

Ver 1

ISO 9001

Job Hazard Analysis Attendees:

Name Signature Date

Written by:

Reviewed by:

DSM This document is current at20/08/07

Ver 1

ISO 9001

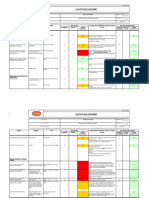

Score TABLE OF CONSEQUENCE Score LIKELIHOOD

People Plant Environment

5 – Very High/ Multiple Fatalities Greater than Catastrophe, destruction of sensitive environment, worldwide 5 – Almost The event is expected to occur in most

Catastrophic $10Million Loss attention. Likely EPA prosecution. More than 30 days delay. certain circumstances. Likely to occur frequently-

More than 1 per year

4 – High/ Major Fatality or Permanent Disabilities $1Million to Disaster, high levels of media attention, high cost of clean 4 – likely/ The event will probably occur in most

$10Million Loss up. Offsite environmental harm, more than 10 days delay. probable circumstances. Likely to occur several tines. 1

per year

3 – Moderate Major Injuries - Incapacitations or $100Thousand to Major spills, onsite release, substantial environmental 3– The event should occur at some time. Likely to

requiring time of work $1Million Loss nuisance, more than 1day delay. (Leads to an additional moderate/ occur some time. 1 per 5 years

resources call out i.e. SES) occasional

2 – Low/ Minor Significant Injuries – Medical $10Thousand to Significant spills (leads to a call out of Site Emergency 2 – remote/ The event could occur at some time. Unlikely

Treatments, non-permanent injury $100Thousand Loss Response Group) unlikely but possible. 1 per 10 years

1 – Very Low/ Minor Injuries – First Aid Treatments Less than Low environmental impact. Minor Spills less than 80 Litres. 1 – rare/ The event may occur only in exceptional

Insignificant (cuts/bruises) $10Thousand Loss very circumstances. Assumed it may not be

unlikely experienced. 1 per 100 years

Action Required

Intolerable Task not to start till the risk is eliminated or reduced. Bring to the immediate attention of

5 6 7 8 9 10 8 - 10

management. Formal assessment required. MUST reduce the risk as a matter of priority.

High Bring to the immediate attention of management. Task not to start till the risk is eliminated or

4 5 6 7 8 9 7

reduced. Further Assessment required. MUST reduce the risk as a matter of priority.

Significant Risk Bring to the attention of supervision. Review risks and ensure that they are reduced to as low as

3 4 5 6 7 8 6 reasonably practicable. To be dealt with as soon as possible, preferably before the task

commences. Introduce some form of hardware to control risk.

Moderate Risk Needs to be controlled but not necessarily immediately, an action plan to control the risk should be

2 3 4 5 6 7 5 drawn up. Review effectiveness of controls. Ensure responsibilities for control are specified.

Low Risk If practical reduce the risk. Ensure personnel are competent to do the task. Manage by routing

1 2 3 4 5 6 2-4

procedure. Monitor for change

1 2 3 4 5 A JHA considers a variety of activities/tasks involved in a job scope and analyses the key hazards (sources of harm) and their

consequences (types of harm) eg. Sources of harm – lifting a heavy pipe, which is manual handling. Types of harm – Back strain.

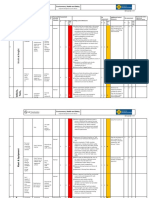

Main Points – On how to write a JHA. Hierarchy of Hazard Management – Control Measures

1. Define the task – what is to be done. These steps outline what should be planned for when deciding what control measures are to be put in

2. Review previous JHA if any – have we done it before? place. Whenever possible the highest step should be used first and then progress down the list.

3. Identify the steps – what is to be done. 1. Eliminate the hazard.

4. Identify the hazards of each step. 2. Substitution.

5. Identify who or what could be harmed. 3. Reducing the frequency of a hazardous task.

6. Give the task a risk rating – Consequence + Frequency 4. Enclosing the hazard.

7. Develop solutions to eliminate or control hazards in each step. 5. Additional procedures.

8. Review the risk rating after the control system has been implemented. 6. Additional supervision.

9. If risk rating unacceptable review the solutions till risk rating acceptable. 7. Additional training.

10. Agree who will implement the control system. 8. Instructions / information.

11. Document the JHA and discuss with the relevant personnel. 9. Some personal protective equipment.

DSM This document is current at20/08/07

Ver 1

You might also like

- Flocare Infinity Pump Troubleshooting GuideDocument6 pagesFlocare Infinity Pump Troubleshooting GuideLorena GuzmanNo ratings yet

- Method Statement - Cable Tray ErectionDocument2 pagesMethod Statement - Cable Tray Erectionsoubhagya50% (4)

- JSA Painting WorkDocument2 pagesJSA Painting WorkKhalid NaseemNo ratings yet

- Drilling Work by MCDocument1 pageDrilling Work by MCChandru100% (1)

- Jsa For Work at HeightDocument8 pagesJsa For Work at HeightMuhammad Umar Gondal50% (2)

- Jsa For Mechanical Activity: H/M/L H/M/LDocument1 pageJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarNo ratings yet

- Method Statement: Errection of Canopy Shed. PurposeDocument1 pageMethod Statement: Errection of Canopy Shed. Purposesoubhagya100% (2)

- Risk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001Document7 pagesRisk Assessment Scaffolding, Painting, Stone Cutting & Fixing and Working at Height Work ISO 45001123shripad100% (1)

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRaju100% (1)

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Hira - RCC Road ActivityDocument3 pagesHira - RCC Road Activitytariq1987100% (2)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- Hoist Erection Operation & Maintenance Work - R0 - 30.09.2017Document6 pagesHoist Erection Operation & Maintenance Work - R0 - 30.09.2017Nikhil Manjrekar100% (2)

- HIRA For Work at HeightDocument5 pagesHIRA For Work at HeightMD. Nayyar Mirza100% (1)

- Excavation, Trenching & Pot HolingDocument1 pageExcavation, Trenching & Pot HolingHafiz SabriNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA For SRP Instolation and DismentlingDocument17 pagesJSA For SRP Instolation and DismentlingShekh BabulNo ratings yet

- PCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Document17 pagesPCR-LP-362-Tower Crane Dismantling (LTM1450-8.1)Geethika SandaruwanNo ratings yet

- Job Safety Analysis - Overhead Power LinesDocument2 pagesJob Safety Analysis - Overhead Power Linesrenee100% (2)

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- 2.7 Working Near Live SwitchyardDocument3 pages2.7 Working Near Live SwitchyardYusuf Afraz100% (1)

- JHA Jack Hydraulic PalletDocument1 pageJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- Standard Activity Risk Assessment Facade Concrete Walls WF ADocument6 pagesStandard Activity Risk Assessment Facade Concrete Walls WF AChoubi ChoubacaNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- All HiraDocument34 pagesAll HiraSuryavenkat RaghavanNo ratings yet

- Diesel Generator Hazard Assessment PDF Master HireDocument6 pagesDiesel Generator Hazard Assessment PDF Master HireMuhammad MalikNo ratings yet

- AHU AssemblyDocument3 pagesAHU AssemblyKrishna Patil100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Working at Height Op (Eration Scaffolding Work Risk AssessmentDocument22 pagesWorking at Height Op (Eration Scaffolding Work Risk AssessmentAhmed Farman Alqaysi100% (1)

- Insulation of Ducting and PipingDocument1 pageInsulation of Ducting and PipingKrishna Patil100% (1)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiNo ratings yet

- 4.HIRA Excavation OnlyDocument6 pages4.HIRA Excavation OnlyMD Abdullah100% (1)

- HIRA For Waterproofing Work at B-Hub ProjectDocument8 pagesHIRA For Waterproofing Work at B-Hub ProjectRajat Kumar MishraNo ratings yet

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pages2020 06 17 JSA For AC Servicing-Server RoomDarren OscarNo ratings yet

- Summer Preparedness PlanDocument20 pagesSummer Preparedness PlanGovind Kumar100% (1)

- JSA For Scaffolding Erection Removal Around AT-911Document1 pageJSA For Scaffolding Erection Removal Around AT-911Equipment Materials100% (1)

- Safety Observtion Register FarhadDocument2 pagesSafety Observtion Register Farhadalla malikNo ratings yet

- JSA For DuctDocument13 pagesJSA For DuctRakeshkasarlaNo ratings yet

- Unloading of Reinforcement SteelDocument1 pageUnloading of Reinforcement SteelGyanendra Narayan NayakNo ratings yet

- HIRA 008 Height Work.Document4 pagesHIRA 008 Height Work.srinibas mohapatraNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- 5.confined Space EntryDocument6 pages5.confined Space EntryMohammad Fazal KhanNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- HIRA - Pile CapDocument4 pagesHIRA - Pile CapMMRDACA07 SAFETYNo ratings yet

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Document3 pagesRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanNo ratings yet

- Job Safety Analysis: Cooling Tower OperationDocument2 pagesJob Safety Analysis: Cooling Tower OperationVi VekNo ratings yet

- Db Shr 010 전사 안전보건방침Document2 pagesDb Shr 010 전사 안전보건방침Tigor GurningNo ratings yet

- Jsa Trial Run of DGDocument3 pagesJsa Trial Run of DGDwitikrushna RoutNo ratings yet

- JSA Bore We Jabil SiteDocument3 pagesJSA Bore We Jabil SitesoubhagyaNo ratings yet

- ELCB Checklist PDFDocument1 pageELCB Checklist PDFsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument5 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Electrical Safety Do - S - Dont - SDocument2 pagesElectrical Safety Do - S - Dont - SsoubhagyaNo ratings yet

- Jha RWFW Raft Cocrete JobDocument3 pagesJha RWFW Raft Cocrete JobsoubhagyaNo ratings yet

- JSA Gypsom WorkDocument5 pagesJSA Gypsom WorksoubhagyaNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- METHOD STATMENT FORFIRE DETECTOR INSTALATIONDocument2 pagesMETHOD STATMENT FORFIRE DETECTOR INSTALATIONsoubhagyaNo ratings yet

- Method Statement For Horizontal Tray Erection.Document5 pagesMethod Statement For Horizontal Tray Erection.soubhagyaNo ratings yet

- Method Statement - Tower ErectionDocument2 pagesMethod Statement - Tower ErectionsoubhagyaNo ratings yet

- Method Statement - Bus DuctDocument2 pagesMethod Statement - Bus Ductsoubhagya100% (1)

- Method Statement Bolero Shed: Purpose: Scope of WorkDocument2 pagesMethod Statement Bolero Shed: Purpose: Scope of WorksoubhagyaNo ratings yet

- CONCRETING OF BOLERO SHEDDocument1 pageCONCRETING OF BOLERO SHEDsoubhagyaNo ratings yet

- Method Statement Staircase (Process Plant) LocationDocument4 pagesMethod Statement Staircase (Process Plant) LocationsoubhagyaNo ratings yet

- Method Statement Mrs Building: Purpose: Scope of WorkDocument1 pageMethod Statement Mrs Building: Purpose: Scope of WorksoubhagyaNo ratings yet

- Safe Work Method Statement For Erection of All Works:: Client ConsultantDocument4 pagesSafe Work Method Statement For Erection of All Works:: Client ConsultantsoubhagyaNo ratings yet

- Method Statement: Erection, Shuttering & Casting of ColumnDocument2 pagesMethod Statement: Erection, Shuttering & Casting of Columnsoubhagya50% (2)

- Method Statement: Purpose: Scope of WorkDocument1 pageMethod Statement: Purpose: Scope of WorksoubhagyaNo ratings yet

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable LayingsoubhagyaNo ratings yet

- METHOD STATEMENt FabricationDocument2 pagesMETHOD STATEMENt FabricationsoubhagyaNo ratings yet

- Method Statement - Panel ErectionDocument2 pagesMethod Statement - Panel ErectionsoubhagyaNo ratings yet

- METHOD STATEMENT FORVacuum PipingDocument2 pagesMETHOD STATEMENT FORVacuum PipingsoubhagyaNo ratings yet

- Method Statement - Bus BarDocument2 pagesMethod Statement - Bus Barsoubhagya100% (1)

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- JSA FOR Using The Hand and Power Tools - 2Document2 pagesJSA FOR Using The Hand and Power Tools - 2soubhagya100% (2)

- Life Calling Map Fillable FormDocument2 pagesLife Calling Map Fillable Formapi-300853489No ratings yet

- Monthly Report Bundle 2021Document55 pagesMonthly Report Bundle 2021Don alewoh7No ratings yet

- One Health Concepts and Knowledge Presentation SlidesDocument48 pagesOne Health Concepts and Knowledge Presentation Slideskarunia nihaya100% (1)

- IELTS Cause-Problem and Effect-Solution Model EssayDocument17 pagesIELTS Cause-Problem and Effect-Solution Model EssaySayaf RashadNo ratings yet

- CSQ Nap4 FullDocument219 pagesCSQ Nap4 FullJeisson FarroNo ratings yet

- NMC Eligibililty ApplicationDocument2 pagesNMC Eligibililty ApplicationYergnoirNo ratings yet

- 16012019FV4Q6RWBAnnexure documentofEIAEMP PDFDocument400 pages16012019FV4Q6RWBAnnexure documentofEIAEMP PDFJainam Shah100% (1)

- 5 1 Why Your Body Needs NutrientsDocument3 pages5 1 Why Your Body Needs Nutrientsapi-261782961No ratings yet

- Benefits of Hypnosis Author Mental Health America of Northern KentuckyDocument4 pagesBenefits of Hypnosis Author Mental Health America of Northern KentuckyJakarta SelamatNo ratings yet

- 12.2 - Regulation of Body TemperatureDocument38 pages12.2 - Regulation of Body Temperature022797SemelllNo ratings yet

- Sydenham's ChoreaDocument11 pagesSydenham's ChoreaKosi UdohNo ratings yet

- PREGNANCYDocument4 pagesPREGNANCYShaileeNo ratings yet

- Deep Fat FryingDocument2 pagesDeep Fat FryingalinawidagdoNo ratings yet

- Werner Erhard S Est Training in The PrisonsDocument8 pagesWerner Erhard S Est Training in The PrisonsMauroVentolaNo ratings yet

- ELIGIBILITY BKPDocument1 pageELIGIBILITY BKPLydia FrederickNo ratings yet

- Lecture 2 Hope 1Document4 pagesLecture 2 Hope 1cally20smithNo ratings yet

- How To Prevent BullyingDocument4 pagesHow To Prevent BullyingLiezel-jheng Apostol LozadaNo ratings yet

- JSP 403 Vol 2 Chapter 2Document61 pagesJSP 403 Vol 2 Chapter 2SOOD ASSOCIATES GOANo ratings yet

- Rabbit KeepingDocument12 pagesRabbit KeepingMoses NdwaruNo ratings yet

- Manual Oral-B GENIUS-XDocument19 pagesManual Oral-B GENIUS-XsaulobbNo ratings yet

- HypothermiaDocument5 pagesHypothermiaMRS CHAKRAPANINo ratings yet

- Behcet's Disease (Adamantiades Syndrome) : DefinitionDocument9 pagesBehcet's Disease (Adamantiades Syndrome) : DefinitionNuzairah AynoorNo ratings yet

- Molly McDowell - Course Project Part 1Document5 pagesMolly McDowell - Course Project Part 1Adelaide DariaNo ratings yet

- IS 501 2021-2022 Spring Assignment #4: Part-1: Can The National Health Service Go Paperless?Document3 pagesIS 501 2021-2022 Spring Assignment #4: Part-1: Can The National Health Service Go Paperless?adsfNo ratings yet

- Section A Multiple Choice Questions Gynaecology: Prepared by Da Roux Barrett Class of 2014Document13 pagesSection A Multiple Choice Questions Gynaecology: Prepared by Da Roux Barrett Class of 2014Sheldon FerronNo ratings yet

- Clinical AssignmentDocument9 pagesClinical AssignmentkomalNo ratings yet

- Daftar Obat %pareto Dan Ven 15Document200 pagesDaftar Obat %pareto Dan Ven 15sofia nofiantiNo ratings yet

- Brain Workshop - a Dual N-Back game - نسخةDocument4 pagesBrain Workshop - a Dual N-Back game - نسخةBTQNo ratings yet

- HOLANDA ALEX CFE103 Module4 ContextEngageActivitiesDocument4 pagesHOLANDA ALEX CFE103 Module4 ContextEngageActivitiesAsus LaptopNo ratings yet