Professional Documents

Culture Documents

Gohar Spiral Steel Pipe Company PDF

Gohar Spiral Steel Pipe Company PDF

Uploaded by

Irfan SaeedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gohar Spiral Steel Pipe Company PDF

Gohar Spiral Steel Pipe Company PDF

Uploaded by

Irfan SaeedCopyright:

Available Formats

LOGO

Gohar Spiral Pipe Company

By:

Mona Ghiasi

Zahra Mahdi

Description

Gohar spiral steel pipe company,

Is a manufacturer of thick spiral pipes with 2m diameter,

20mm thickness and length of 8-18 m

the products are applicable for petroleum ,natural gas

and water transportation, and also industrial applications.

2 Gohar Spiral Pipe Company

Market Analysis

Iran is one of the largest producer and exporter of oil and

gas in the world.

By considering the necessity of providing spiral pipes, as

the main tools for transferring gas and oil, pipe

production has a great importance.

Domestic demand of spiral steel pipe is 1,08 million tone

Per year.

in long term, when the domestic consumption is fulfilled,

pipe export to neighbor countries can be considered as

one of the main priority of the company.

3 Gohar Spiral Pipe Company

Market Analysis

Main competitors:

Iran Spiral Co. 180.000 tone/year

Ahvaz Pipe Mills Co. 100.000 tone/year

Sadid Pipe & Equipment Co. 250.000 tone/year

Safa Toos Rolling and Pipe Mills Co. 160.000 tone/year

Final price is severely dependent on:

The market for spiral steel pipes (supply and demand)

Cost of raw material

Price for consumers:

for inner consumers 960 $/ton

For export 1200$/ton

4 Gohar Spiral Pipe Company

Description of Production

Coil Feed in & Pre-Forming Section

Coils are loaded on the decoiler of the Spiral Pipe machine. The strip is

straightened , then the irregular opening of the strip is cut, and

edges are milled to desired joint geometry.

Pipe Forming Section

The strip is guided into a forming station, where it is formed to

produce a cylindrical hollow body at a predetermined forming angle,

ensuring proper welding gap between the abutting edges. Inside, and later,

outside welding is performed by an automatic submerged arc

process.

Pipe Pay-off Section

Pipes are cut to a predetermined length by an automatic plasma arc

cutting device. After that, Flux and slag from inside the pipes is

cleaned. Pipes are inspected for any visual defects. Fluoroscopic

inspection of pipes presents the entire spiral seam on visual display for

analysis of all the ultrasonic indications for defects, if any, in the weld

seam.

5 Gohar Spiral Pipe Company

Description of Production

Pipe Finishing Process

At the end facing machine both ends of pipes are machined to suit the joint to be

used on the pipe line. Each end is worked separately. Each pipe is hydrostatically

tested to a given pressure as per API 5L specification or other desired standard.

At the end X-ray station radiographs are taken at weld seam for each pipe end to

a distance of 4". Every length of pipe is subjected to a rigorous check at the final

stand - before it is accepted by the quality control department.

6 Gohar Spiral Pipe Company

Licenses and State

Licenses

We should achieve ISO14001 OHSAS18001 HSE IMS certificates and also, in

order to enter the market of oil and gas pipe the company have to obtain the

essential international API 5L and ISO3183 certificate.

This company will be found in Iran,

Kashan-Ghom Road.

The advantages of selecting this location for the company:

Close to MOBARAKEH STEEL COMPLEX, which is the only supplier of hot

rolled steel coils in Iran, therefore we will be able to minimize

transportation charges of raw materials.

Its location in the center of IRAN ensures most economic logistics charges

for deliveries to customers throughout the country.

7 Gohar Spiral Pipe Company

Definition of Capacities

Our company has 130 employees.

Annual production capacity is equal to 30,000 tons/year

or 110 tons/day.

Work time/production time: 280 days / year, one shift of

8 hours.

8 Gohar Spiral Pipe Company

Financing the Company

Providing financial resources are one of the most

important parts of foundation a company.

In this regard it was felt that obtaining finance and Rial

credits are essential for purchasing industrial machines

and equipments, providing raw materials and signing

appropriate contracts.

25 million dollars in form of finance from Iran Saderat

Bank will be obtained, a finance over a period of 5 years

with constant annual loan redemption and a 24% interest

rate.

9 Gohar Spiral Pipe Company

Calculation of the Investments

Investment costs Amounts of investment

in $

Investment for the Ground 1,300,000

Buildings 1,000,000

Investment for machinery 15,000,000

Raw material 13,500,000

Additional expenses * 330,000

Energy cost 1,260,000

Transportation cost of raw material 600,000

Salary & benefits 630,880

5 Passenger cars 125,000

3 Trucks 300,000

Informatics 22,000

Furniture 40,000

Overhead 100,000

Overall 34,207,880

10 Gohar Spiral Pipe Company

Buildings

Three different buildings are needed:

Area m2

Covered area 11,000

(production hall)

Building as warehouse 5,000

(raw materials and products)

Administration building 450

Total area 19,000

11 Gohar Spiral Pipe Company

Raw material Costs

Hot rolled steel coil consumption 30,000 tons/year

Hot rolled steel coil price 450$/tone

Additional expenses

Submerged arc welding flux

Submerged arc welding wire

Industrial lubricants

EPOXY EX4413L300

12 Gohar Spiral Pipe Company

Labor Costs

About 130 personnel will be working in the factory:

23 persons in official department,

34 persons in production department and,

76 persons in production services.

That:

6 persons have PHD and Master degree,

48 persons have Bachelor degree and,

76 persons are under graduated.

13 Gohar Spiral Pipe Company

Labor Costs in First Year

Persons Insurance Total

Wages/ Paid salaries

in cost Number & other salaries /

month benefits /month

centre benefits year

Under

76 230 $ 20 $ 120 $ 370 $ 337,440 $

graduated

Bachelor

48 280 $ 20 $ 120 $ 420 $ 241,920 $

Degree

Master

4 320 $ 20 $ 120 $ 460 $ 22,080 $

Degree

Ph.D Degree 2 480 $ 20 $ 120 $ 620 $ 14,880 $

Sum of

616,320 $

Salaries

Food

1213 $ 14,560 $

Expenses

Sum of personnel

expenditure 630,880 $

(1 Shift)

14 Gohar Spiral Pipe Company

Labor Costs

Total Salaries Paid p.a.

Year

In $

1st 630.880

In regard to high

inflation rate in Iran, 2nd 725.512

salaries should 3rd 834.338

increase 15% each 4th 959.489

year.

5th 1.103.413

6st 1.268.925

7nd 1.459.264

8rd 1.678.153

9th 1.929.876

10th 2.219.358

15 Gohar Spiral Pipe Company

Depreciation Rates & Costs

Depreciation in $

Description Investment in $ Depreciation rate

/year

Machines 15,000,000 20% 3,000,000

Buildings 1,000,000 10% 100,000

license 80,000 10% 8,000

Informatics 22,000 25% 5,500

Passenger cars 125,000 20% 25,000

Trucks 300,000 20% 60,000

Furniture 40,000 10% 40,00

Total depreciation

Total investment 16,567,000 3,202,500

cost

16 Gohar Spiral Pipe Company

Financing Costs

Paying back Total

Balance of Interest Interest cost

Year finance p.a. payment

debt $ rate paid p.a. in $

in $ p.a. in $

1st 25.000.000 24% 6.000.000 5.000.000 11.000.000

2nd 20.000.000 24% 4.800.000 5.000.000 9.800.000

3rd 15.000.000 24% 3.600.000 5.000.000 8.600.000

4th 10.000.000 24% 2.400.000 5.000.000 7.400.000

5th 5.000.000 24% 1.200.000 5.000.000 6.200.000

Total

Interest 18.000.000$

Paid

Total

Payment in $ 25.000.000$

17 Gohar Spiral Pipe Company

Selling Prices & Costs

Selling

Sales per

Year Costs in $ price/ton

year in $

in $

1st 15.790.000 960 28.800.000

The prices of raw

materials, energy 2nd 16.263.700 989 29.664.000

and transportation 1.018

3rd 16.751.611 30.553.920

costs and also

selling prices will 4th 17.254.159 1.049 31.470.538

be increased by 5th 1.080

17.771.784 32.414.654

the rate of 3% per

year, due to 6st 18.304.937 1.113 33.387.093

inflation rate in 7nd 18.854.085 1.146 34.388.706

Iran.

8rd 19.419.708 1.181 35.420.367

9th 20.002.299 1.216 36.482.978

10th 20.602.368 1.253 37.577.468

18 Gohar Spiral Pipe Company

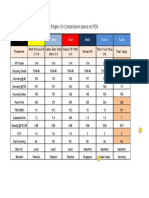

Profit Calculation

Deprecia Profit

Costs + Profit Corporate

tion Sales p.a. after tax

Year Salaries before tax

costs p.a. in $ in $

p.a. in $ tax in $ (10%)

in $

1st 17.640.880 3.202.500 28.800.000 7.956.620 795.662 7.160.958

2nd 16.989.212 3.202.500 29.664.000 9.472.288 947.229 8.525.059

3rd 17.585.950 3.202.500 30.553.920 9.765.470 976.547 8.788.923

4th 18.213.649 3.202.500 31.470.538 10.054.389 1.005.439 9.048.950

5th 18.875.197 3.197.000 32.414.654 10.342.457 1.034.246 9.308.211

6st 19.573.863 112.000 33.387.093 13.701.231 1.370.123 12.331.108

7nd 20.313.350 112.000 34.388.706 13.963.357 1.396.336 12.567.021

8rd 21.097.862 112.000 35.420.367 14.210.506 1.421.051 12.789.455

9th 21.932.176 112.000 36.482.978 14.438.802 1.443.880 12.994.922

10th 22.821.726 112.000 37.577.468 14.643.741 1.464.374 13.179.367

19 Gohar Spiral Pipe Company

Cash Flow & Dividend

Cash flow

Depreciatio

Profit after (net profit+ Repayme Dividend

Year n costs p.a.

tax in $ depreciation) nt in $ in $

in $

in $

1st 7.160.958 3.202.500 10.363.458 11.000.000 -636.542

2nd 8.525.059 3.202.500 11.727.559 9.800.000 1.927.559

3rd 8.788.923 3.202.500 11.991.423 8.600.000 3.391.423

4th 9.048.950 3.202.500 12.251.450 7.400.000 4.851.450

5th 9.308.211 3.197.000 12.505.211 6.200.000 6.305.211

6st 12.331.108 112.000 12.443.108 0 12.443.108

7nd 12.567.021 112.000 12.679.021 0 12.679.021

8rd 12.789.455 112.000 12.901.455 0 12.901.455

9th 12.994.922 112.000 13.106.922 0 13.106.922

10th 13.179.367 112.000 13.291.367 0 13.291.367

20 Gohar Spiral Pipe Company

LONG TERM GOAL

Increasing the variety of steel products and entering new

internal and global markets and increasing the market

share of the depending companies through creating new

capacities and improving the current capacities.

21 Gohar Spiral Pipe Company

22 Gohar Spiral Pipe Company

You might also like

- Aluminium Foil & Sheet Project ReportDocument90 pagesAluminium Foil & Sheet Project Reportsugaimpax60% (10)

- MS Tube ManufacturingDocument2 pagesMS Tube ManufacturingDhanraj PatilNo ratings yet

- Overview of Bhushan Power and SteelDocument18 pagesOverview of Bhushan Power and SteelAbhishek Dhawan0% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Bin Card Format ExcelDocument6 pagesBin Card Format Excellsatchithananthan100% (3)

- 10.performance Improvement of Grid Integrated Solar PV System Using DNLMS Control AlgorithmDocument3 pages10.performance Improvement of Grid Integrated Solar PV System Using DNLMS Control Algorithmralu_mnbNo ratings yet

- A Project Report OnDocument45 pagesA Project Report Onamruta_warwatkarNo ratings yet

- Fast NerDocument10 pagesFast NerVenkatashanthi PNo ratings yet

- Seamless Pipes & TubesDocument6 pagesSeamless Pipes & TubesParinita DevadigaNo ratings yet

- Revival ProjectDocument22 pagesRevival ProjectNIYAS NICHUNo ratings yet

- 6.revised Galvanized Iron Sheet Product Producing PlantDocument23 pages6.revised Galvanized Iron Sheet Product Producing PlantaschalewNo ratings yet

- PROJECT - UpdatedDocument7 pagesPROJECT - UpdatedSuraj GantayatNo ratings yet

- Wire Drawing: Profile No.: 115 NIC Code: 24108Document10 pagesWire Drawing: Profile No.: 115 NIC Code: 24108Sabhaya ChiragNo ratings yet

- C. Cosmic DuctDocument14 pagesC. Cosmic DuctShubhrajeet TiwariNo ratings yet

- Company ProfileDocument189 pagesCompany ProfileplanningNo ratings yet

- Bhel ReportDocument13 pagesBhel ReportAtul TripathiNo ratings yet

- 6.revised Galvanized Iron Sheet Product Producing PlantDocument23 pages6.revised Galvanized Iron Sheet Product Producing PlantFekadie TesfaNo ratings yet

- BhushanDocument13 pagesBhushanmamtadevaNo ratings yet

- KapilanshDocument7 pagesKapilanshAnushka DeshmukhNo ratings yet

- Project Report - Paras AssociateDocument13 pagesProject Report - Paras AssociaterajuNo ratings yet

- General:: Name of The Entrepreneur: Mr. Prabhupad BharadwajDocument14 pagesGeneral:: Name of The Entrepreneur: Mr. Prabhupad Bharadwajpbharadwaj3No ratings yet

- Apl Company ProfileDocument16 pagesApl Company ProfilerdxkreenNo ratings yet

- Apohan Forging Sell Side Advisory Advertisement v13 22-06-2020 SWDocument6 pagesApohan Forging Sell Side Advisory Advertisement v13 22-06-2020 SWarunjoshi12345No ratings yet

- BAJRANGDocument23 pagesBAJRANGvikash BhadoriaNo ratings yet

- Jai Bajrang Sales, Khamgaon QTN 30 TR Cooling Tower ECT 7712 (05 OCTOBER 2020)Document14 pagesJai Bajrang Sales, Khamgaon QTN 30 TR Cooling Tower ECT 7712 (05 OCTOBER 2020)9D 24 Prem b jadhaoNo ratings yet

- GI Sheet ProductsDocument23 pagesGI Sheet Productsbirukbrook2No ratings yet

- Aluminium Pressure Die CastingDocument11 pagesAluminium Pressure Die CastingMarcos100% (1)

- PVC Piper With Coatting PlanDocument13 pagesPVC Piper With Coatting PlanVIJAY PAREEKNo ratings yet

- Internship Report: Training Centre - Mysore ComplexDocument28 pagesInternship Report: Training Centre - Mysore Complexshubhashini K NNo ratings yet

- 5.SH LTDDocument4 pages5.SH LTDDhrubajyoti PatraNo ratings yet

- ch22 PDFDocument5 pagesch22 PDFSumeet Singh KohliNo ratings yet

- CH 22Document5 pagesCH 22alkaNo ratings yet

- V.T Report SailDocument32 pagesV.T Report SailAshish Jha100% (1)

- Duke Plasto Technique PVTDocument25 pagesDuke Plasto Technique PVTVishnu Suthar100% (2)

- Indian Pump IndustryDocument4 pagesIndian Pump IndustryChristopher MartinNo ratings yet

- Domestic LPG Stove PDFDocument11 pagesDomestic LPG Stove PDFRizal DeriNo ratings yet

- Aluminum Household Utensil Making PlantDocument43 pagesAluminum Household Utensil Making PlantmelkamuNo ratings yet

- Iron and Steel ReviewDocument2 pagesIron and Steel ReviewSajal SinghNo ratings yet

- Friend Ice FactoryDocument25 pagesFriend Ice FactoryHafizAhmadNo ratings yet

- Final DPRDocument10 pagesFinal DPRGateway ComputersNo ratings yet

- Insulation System in Turbo GeneratorsDocument34 pagesInsulation System in Turbo GeneratorsVamshi Raj100% (2)

- Industrial Training in Sifl Industrial AthaniDocument34 pagesIndustrial Training in Sifl Industrial AthaniGO KUNo ratings yet

- Feasibility Study of Best Coffee Roasting, Grinding and PackingDocument19 pagesFeasibility Study of Best Coffee Roasting, Grinding and PackingFekaduNo ratings yet

- Auto Pistons: NtroductionDocument5 pagesAuto Pistons: NtroductionProfNDAcharyaNo ratings yet

- THQ Shahpur - Civil, Electrical and Plumbing Work: SR - No. DescriptionDocument8 pagesTHQ Shahpur - Civil, Electrical and Plumbing Work: SR - No. DescriptionAbid HussainNo ratings yet

- Wire and Wire ProductsDocument29 pagesWire and Wire ProductsThomas MNo ratings yet

- الخليجDocument10 pagesالخليجmohamedNo ratings yet

- Welding Electrodes: Profile No.: 235 NIC Code:27102Document12 pagesWelding Electrodes: Profile No.: 235 NIC Code:27102ram prasad100% (1)

- Presentation 2Document20 pagesPresentation 2Bisrat MekonnenNo ratings yet

- Fastener ProjectDocument10 pagesFastener ProjectParam Saxena0% (1)

- Metals and Engineering Corporation: Feasibility Study ONDocument15 pagesMetals and Engineering Corporation: Feasibility Study ONkinfegetaNo ratings yet

- Aidan Singh ReportDocument25 pagesAidan Singh ReportGolyanShubhamNo ratings yet

- Bhel Mini Pro Report On Turbo Generators 1Document53 pagesBhel Mini Pro Report On Turbo Generators 1Akirakumar100% (2)

- Hdpe Pipes: Profile No.: 63 NIC Code: 24311Document8 pagesHdpe Pipes: Profile No.: 63 NIC Code: 24311parameswaranr79No ratings yet

- Project Profile FoundryDocument12 pagesProject Profile FoundryAkshay VarmaNo ratings yet

- High Tensile Nuts BoltsDocument10 pagesHigh Tensile Nuts BoltssagarhalappaNo ratings yet

- Galvanized Iron Bathtubs Making PlantDocument22 pagesGalvanized Iron Bathtubs Making PlantFirezegiNo ratings yet

- PVC Conduit Pipes and FittingsDocument8 pagesPVC Conduit Pipes and FittingsmmtaassociatesNo ratings yet

- Internship Report On BemlDocument28 pagesInternship Report On BemlRam Prathap100% (5)

- Delhi Market Analysis CompilationDocument45 pagesDelhi Market Analysis CompilationPromitNo ratings yet

- Project Proposal BriefDocument7 pagesProject Proposal BriefRama KrishnaNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryFrom EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryNo ratings yet

- Parts Manual XAS 67 Type SeriesDocument197 pagesParts Manual XAS 67 Type SeriesIrfan SaeedNo ratings yet

- Caterpillar Industrial C9 SpecificationsDocument5 pagesCaterpillar Industrial C9 SpecificationsIrfan SaeedNo ratings yet

- Komatsu PC 210LC 7KDocument24 pagesKomatsu PC 210LC 7KIrfan SaeedNo ratings yet

- Ingersoll Rand 9200 Series Parts ManualDocument105 pagesIngersoll Rand 9200 Series Parts ManualIrfan Saeed100% (1)

- Komatsu Crawler 220 Excavator SpecsDocument7 pagesKomatsu Crawler 220 Excavator SpecsIrfan SaeedNo ratings yet

- Ingersoll Rand 9200 Series Operation ManualDocument57 pagesIngersoll Rand 9200 Series Operation ManualIrfan Saeed50% (2)

- FIAT-HITACHI EX235 - Excavators - Valuepart Spare Parts PDFDocument1 pageFIAT-HITACHI EX235 - Excavators - Valuepart Spare Parts PDFIrfan Saeed0% (1)

- Modelling of Spiral-Welded Pipe Manufacturing and Its Effect On Pipeline Structural PerformanceDocument9 pagesModelling of Spiral-Welded Pipe Manufacturing and Its Effect On Pipeline Structural PerformanceIrfan SaeedNo ratings yet

- Hyundai H380 TrucksDocument12 pagesHyundai H380 TrucksIrfan SaeedNo ratings yet

- Pneumatic RollerDocument8 pagesPneumatic RollerIrfan SaeedNo ratings yet

- Flyer 3D Laser Gap Tracker 2014 11 14 E PDFDocument2 pagesFlyer 3D Laser Gap Tracker 2014 11 14 E PDFIrfan SaeedNo ratings yet

- Domestic Pipe ReportDocument122 pagesDomestic Pipe ReportIrfan SaeedNo ratings yet

- DE550E0 Secours 550kVA Fiche Technique en PDFDocument3 pagesDE550E0 Secours 550kVA Fiche Technique en PDFIrfan SaeedNo ratings yet

- Titan Cargo 15W-40: Product InformationDocument2 pagesTitan Cargo 15W-40: Product InformationIrfan SaeedNo ratings yet

- Dynapac CP275 Dynapac CP275: Pneumatic Rollers Pneumatic RollersDocument2 pagesDynapac CP275 Dynapac CP275: Pneumatic Rollers Pneumatic RollersIrfan SaeedNo ratings yet

- Dozer CAT D6K Controllers PDFDocument2 pagesDozer CAT D6K Controllers PDFIrfan SaeedNo ratings yet

- Compare Oil For Diesel EnginesDocument1 pageCompare Oil For Diesel EnginesIrfan SaeedNo ratings yet

- 2000kva Power ModuleDocument8 pages2000kva Power ModuleIrfan SaeedNo ratings yet

- Bapco Lubricants Product BrochureDocument2 pagesBapco Lubricants Product BrochureIrfan SaeedNo ratings yet

- Read 2Document15 pagesRead 2Tran Ngo Tra My (FGW DN)No ratings yet

- Fanuc 0i-T-B-64303EN-1 - 01 Connection Manual Function 0i-DDocument2,080 pagesFanuc 0i-T-B-64303EN-1 - 01 Connection Manual Function 0i-Deeevinoth198975% (4)

- W / 5 Ÿ NX GDocument71 pagesW / 5 Ÿ NX GIslamic Reserch Center (IRC)No ratings yet

- Robin CVDocument6 pagesRobin CVAulya MuctNo ratings yet

- LG 5 Year Promotion Terms and Conditions 2016Document4 pagesLG 5 Year Promotion Terms and Conditions 2016sadlkasdNo ratings yet

- AGA Dry Ice Brochure A4 UK - tcm639-101282Document20 pagesAGA Dry Ice Brochure A4 UK - tcm639-101282শুভঙ্করNo ratings yet

- UEFA Financial Fair Play, Club Toolkit 2013Document110 pagesUEFA Financial Fair Play, Club Toolkit 2013Tifoso BilanciatoNo ratings yet

- 009 (MEP COMPARE) 19-01-15 - ONYX Reply - 19-01-16 - PB - JVDocument31 pages009 (MEP COMPARE) 19-01-15 - ONYX Reply - 19-01-16 - PB - JVJimmy WalkerNo ratings yet

- Archies LTD Imc Assignment: Group No 04, IMC - BDocument6 pagesArchies LTD Imc Assignment: Group No 04, IMC - BNirmal KumarNo ratings yet

- 2B3.1. Robbery, FSG 2B3.1Document4 pages2B3.1. Robbery, FSG 2B3.1RichardNo ratings yet

- Application For ECFMG Certification - InstructionsDocument2 pagesApplication For ECFMG Certification - InstructionszidaneNo ratings yet

- Social MediaDocument1 pageSocial MediaReham Al-EkhtiarNo ratings yet

- 4976 15636 1 PBDocument26 pages4976 15636 1 PBNoor Ainun CameliyaNo ratings yet

- PL 2022-23 Weekly Reflective Journal PDP Assessment TemplateDocument11 pagesPL 2022-23 Weekly Reflective Journal PDP Assessment TemplateImran khanNo ratings yet

- Sony STR K1600 Service ManualDocument68 pagesSony STR K1600 Service ManualJayNo ratings yet

- Mindset MattersDocument19 pagesMindset Mattersracer100% (2)

- Laudon Traver Ec16 PPT Ch09 Accessible 26022023 080617pmDocument49 pagesLaudon Traver Ec16 PPT Ch09 Accessible 26022023 080617pmGreson JamesNo ratings yet

- Advanced Tax Laws and PracticeDocument8 pagesAdvanced Tax Laws and Practicesheena2saNo ratings yet

- Air System 773E Off-Highway Truck: Fluid Power SymbolsDocument4 pagesAir System 773E Off-Highway Truck: Fluid Power SymbolsfalahNo ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- MKT 460.6 Final AssignmentDocument93 pagesMKT 460.6 Final AssignmentSirajis SalekinNo ratings yet

- Alg Review Quiz 2.1-2.4Document3 pagesAlg Review Quiz 2.1-2.4jornelasNo ratings yet

- SAN Troubleshooting PDFDocument510 pagesSAN Troubleshooting PDFSanjay DeyNo ratings yet

- CV Review 35Document1 pageCV Review 35Pean CkNo ratings yet

- Chapter 2 Lost Spring With AnswersDocument15 pagesChapter 2 Lost Spring With AnswersSqop GamingNo ratings yet

- Service DM Kalibrierung Tab Dienstleistungen enDocument2 pagesService DM Kalibrierung Tab Dienstleistungen enrcnexyNo ratings yet

- Nigeria: Author: DR Roland IgbinobaDocument4 pagesNigeria: Author: DR Roland IgbinobaTihitna GezahegnNo ratings yet