Professional Documents

Culture Documents

Flushing Procedure PDF

Flushing Procedure PDF

Uploaded by

cmc261185100%(1)100% found this document useful (1 vote)

705 views16 pagesOriginal Title

flushing procedure (2).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

705 views16 pagesFlushing Procedure PDF

Flushing Procedure PDF

Uploaded by

cmc261185Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 16

SAIGON SHIPYARD LTD.

‘99 Quarter 3, Thanh My Loi Ward, Diet 2,

Ho Chi Mink Git, Vietnam

‘Tol: 84-8-3807 6208, Fax: 84-8-3907 6446,

Email seigonshipyard@sey.com.vn

FLUSHING PROCEDURE

Doc. No. PCD-PIP-07

Issued Date: 25 Mar 2010

REVISION: 00

CONTROLLED

Document COPY No

Description Composed by Checked by neonate

Position ttle Se aie 1SO 9001QMR General ana

Sign so Ju“. qi

39 )3/ 2040 ade td

I. lourben Poon

“Tudo se proper of ago Shipyard 0 Al inforantion contained erin shal be reat content andy either be

ai ‘reproduced, used, disclosed or transmitted without the written permission of the owner.

Fullname | Mr. Nguyen Thuong Nhan | Ms. Nguyen Thi Kim Thanh

0)

‘QUALITY ASSURANCE PROCEDURE

PCD-PIP-O7

00

FLUSHING PROCEDURE Isuance date: 25 March 10_|

Page No, :20f14

CHANGE RECORDS (For each issue)

No | Page/Form | Revision Content Effective | Approved

date by

0 |All 00 First issuance 25/03/10 _| GM

= QUALITY ASSURANCE PROCEDURE ; 2

LiL. FLUSHING PROCEDURE isuance dat

‘SAIGON SHIPYARD : Page No,

1. PURPOSE

muc picH

To ensure that all phases of pipe spool cleaning is managed and that workmanship meets

Company Shipbuilding Workmanship Standards & Practices and Client requirements.

Bao dam tét cd cdc giai doan etia xt? ly lam sach éng duge quan ly va trinh d6 chuyén mén

dp ting cdc tiéu chudn & qui trinh ky thuét cia céng ty dong tau va yéu cau cila khach

hang.

To guide & require Pipe Engineers, Foremen, and Supervisor to ensure all Piping cleaning

operations are performed in accordance with this procedure.

Huéng dan & yéu cau ky sur éng, déc céng, va gidm sat bao dam tat cd éng duoc vé sinh~

phi hop v6i qui trinh,

Il, SCOPE OF APPLICATION

This procedure is applicable to Saigon Shipyard Ltd. (SSY) in Vietnam.

Qui trinh nay duge 4p dung béi céng ty Saigon Shipyard tai Vist Nam

Reference to ASME B31.3-Process piping guide

Tham khéo theo huténg dan qui trinh dudng éng ASME 831.3

II. ABREVIATIONS & DEFINITIONS

AFC Approved for Construction

BOM: Bill of Material

D&E: Design & Engineering

FM: Foreman a

PIP. Piping

PRU: Project

Qa: Quality Assurance

RF: Requisition Form

SUP: Supervisor

IV, PROCEDURE CONTENT

The purpose of the flushing is to remove all debris and foreign material from the pipelines,

which could cause damage to engine and system.

Myc dich ciia viée sac nia 1a loai bé hodn toan c&n ban va cdc vat liéu khéc trén dung

ng, la nguyén nhan gay hw héng cho may va hé théng.

1. To specify flushing equipment

Qui dinh dung cu ste riva

‘QUALITY ASSURANCE PROCEDURE

FLUSHING PROCEDURE

To choose the flushing pump, tank, heater capacity and the filter size the following values

from the different system has to be checked:

Chon bom ding sic riva, bén, céng suat b6 gia nhiét va kich 06 lu6i loc cho timg hé théng

khéc nhau phai xée dinh:

© Flow rate in each system.

Téc dé chay timg hé théng

© Operating temperature of liquids.

Nhiét d6 hoat déng cua cdc lu chat

© Liquid volume in system plus tank and piping.

Thé tich luu chat trong hé théng, bén chtra va éng néi.

Flushing pump capacity is straight comparable to flushing time and also to the flushing

resuit. The heater capacity has to be calculated (flushing temperature shall at least be the

same as the temperature in normal operation).

Céng suét cia méy bom anh huéng tre tiép dén thoi gian va két qua suc riva. Cong sudt

cilia thiét bj gia nhiét phai dugc tinh todn (nhiét d6 sic riva t6i thiéu bang nhiét dé hoat déng

binh thuong cua hé théng)

‘The capacity of the flushing pump should be dimensioned so that Reynolds number (Re) is

>25000. For the inner pipe diameter the largest pipe’ size in the system shall be used. A

higher oil temperature decreases the viscosity and therefore increases the Reynolds

number. The cleaning efficiency increases with the Reynolds number and Re=25000 is

considered as the lower limit for efficient cleaning.

Luu long cua bom stic ria phai dat thong s6 Reynolds (Re)>25000. D4u vao cia may

bom nén bang duéng kinh éng lén nhét cita hé théng. Nhiét d6 cao 36 kam giam di d6 nhot

oda d4u va nh vay [am ting thong s6 Reynolds. Hiéu qué ciia vie vé sinh sé tf I6 thuén

v6i théng sé Reynolds va Re=25000 a giéi han thép nhdt dé viée vé sinh dat hiéu qua.

Re = 21200 xQ

axd

Where = Viscosity, cSt. Dé nhot

D = pipe inside diameter, mm. Budéng kinh trong cita éng

Q = flow l/min. Luu lueng

Re = Reynolds number. Théng sé Reynolds

Flushing oil shell Tellus TX 32. Stic rita voi ddu Teilus TX 32

Example _ = 10cSt, at 80°C

D=@ 150mm

‘QUALITY ASSURANCE PROCEDURE Doc. No.

| Revision 00

FLUSHING PROCEDURE isuance date : 26 March 10_|

PageNo._:50f14

Q=1770l/min

Re = 21200x1770 = 265016(>25000 ok)

10x150.

OR

‘Qmin = 10x150x25000 = 17691 l/min

21200

1

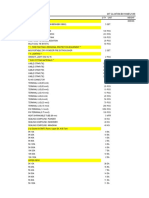

DN _| Flow (Wimin) for Shell Tellus at 80°C = Re25000

25 336

32 442

40 508

50 643

65 829

80 973

100 1263

125 1545

150 __1879

200 2445

Table: Min. flow capacity for different pipe diameters (2)

Re-number for SHELL TELLUSS TX 32

35000-

30000:

|p (25000,

1 | 20000

FF OK

&

| 20000

200" ——

| al

[20 30 “ 50 6 | 70 Ey 20 100 210

Diagram 1: Re number variation for different temperatures. The diagram is based on flow

rate in table (2).

‘QUALITY ASSURANCE PROCEDURE [i

FLUSHING PROCEDURE | Is

6t d6 sic riva

The temperature of flushing oil is very important to achieve best flushing result. The

flushing temperature must be at least the same as the temperature in normal operation.

Diagram 1 shows how the Re-number is depending on the oil temperature.

Nhiét d6 ctia déu stic riva rét quan trong dé dat duoc két qua tét nhat,t6i thiéu_ phai bang

nhiét d6 hoat déng binh thurdng cila hé théng. Biéu dé 1 biéu din théng sé Re phy thuéc

nhiét d6.

Re-number variation depending on viscosity

Ree Peer eee eee eee

Re-number

5009.

| #9

ed on flow rate in

6

i s|__10 as [20 | 2 | = | 38

Diagram 2: Re number variation for diffirent viscosity.

table (2)

» Flushing procedure

Qui trinh suc riva

During flushing the filters shall be inspected regularly and cleaned when necessary and

according to the flushing procedure.

Trong qué trinh sic riva, lu6i loc phai duoc kiém tra thudng xuyén va vé sinh khi can thiét

va tuy theo qui trinh tay ria.

Flushing filter that should be used

Lui loc thuéng ding cho ste ria:

© 30mesh= 0.5mm

© 60 mesh =0.25mm

© 100 mesh =0.15mm

Ludi 30 = 0.6mm

Lu6i 60 = 0.25mm

Lui 100 0.15mm

QUALITY ASSURANCE PROCEDURE Doc. No.

Revision 0

FLUSHING PROCEDURE isuance date :25 March 10_|

Page No. _:7of 14

Start the flushing with the 30 mesh and continue with 60 mesh and finally use the 100

mesh. If the pipes are very clean you can start with the 100 mesh at once. The systems

that shall be flushed with these meshes are:

© Lube oil piping

© LFO-piping

Bat dau sc riva v6i lu6i 30 va tiép tue véi Idi 60 va cudi cing str dung fu6i 100. Néu éng

sach $6 thi c6 thé b&t dau voi lu6i 100 va chi ding mét lan. Nhaing hé théng sie dung [uot

8 sic rita 1a:

© Buéng éng déu béi tron

o Pudng éng dau FO

4, After the flushing is finished

Céng viéc sau khi suc riva

1) Drain the entire system from flushing oil.

Xa hét ddu trong hé théng déi vot viée tay niva bang dau.

2) Dismount some pipe and check visually that the pipes are clean. Place a piece of paper

or cloth on the floor. Hold the pipes upwards by hand above the paper sheet and give a

couple of blows with a hammer on the pipe and check that no debris comes out. If debris

is found on the paper the whole pipe system shall be cleaned again. Check also hidden

spaces of the inner tubing by means of a swiveled mirror.

Théo vai 6ng va kiém tra bang m&t d6 sach cia éng. Ding giéy trang hodc vai sach dat

trén san. Dung éng théng dttng Ién gidy hoae vai, ding bia gé trén éng va théi gid trong

6ng, kiém tra khéng cén can bui nao roi ra. Néu thay can bui thi toan bé hé théng éng phai

duoc lam sach lai. Nhiing vj tri khudt bén trong éng efing diye kiém tra edn than bang

guong xoay.

3) If the piping system includes valve, such as thermostatic valve, disconnect and drain

them one by one to ensure that no flushing oil is left in them.

Néu hé théng éng bao gém ca van, van nhiét ké, thao ra va lam sach ching timg cai mét

d6 dam bao ching khéng con dau sic rita.

4) Plug all pipelines to ensure that no dirt can enter into the system. Take the plugs off in the

last moment before re-mounting of the pipe work.

Bit kin duéng dng, phai dam bao bui ban khéng thé vao hé théng. Chi thao cae nap bit kin

truée khi k6t néi dé éng lam vie.

QUALITY ASSURANCE PROCEDURE

FLUSHING PROCEDURE

5. Flushing of LO systems

Stic riba hé théng LO

4) Visually inspect the pipe, check that all flange connections are tight and that they have

gasket.

Kiém tra éng bang mét thuong, kiém tra cée ché néi mat bich duoc xiét chat va c6 joan

dém khéng.

2) Install the flushing mesh to the filter on top the flushing tank. Start with mesh 60

Lap dat lui stic rita trén dinh cuia bén stic riva. Bat du voi loai lu6i 60.

3) Fill the flushing tank with clean oil (fill through a fine filter). Check that there are no leaks.

6 dau ste rita vao bén (45 qua lu6i loc min). Kiém tra dam bao kh6ng 06 r6 ri.

4) Start the heating of the oil. Stop the heating when the temperature of the oil reaches 60°C

Khéi d6ng ham néng dau. Dung viée ham néng dau Khi nhiét dé cia déu dat 60 °C.

NOTE! Check the cable connection of the heater. Continuously check the off

temperature.

Cha y: kiém tra day dién néi voi may ham nong. Thuong xuyén kiém tra nhiét d6 cda

dau.

5) Start the filling of the system. Run the pump for a few seconds only and top-up the tank

level when required until the system is filled up.

Bat dau cp dau vao hé théng. Chay bom vai giéy va dé thém dau vao bén cho dén khi hé

théng duoc cdp day dau.

© Check the filter every 4 hours.

Kiém tra thuong xuyén lu6i loc 4 gio mét lan

© Change to mesh 100 when after 4 hours of flushing no more dirt is trapped in mesh 60.

(Noted: Minimun flushing time is 4 hours)

Thay loai lei 100 sau 4 git hoat dong ma khong cé bul ban bj dinh vao khi ste dung tuoi

60. (Cha J: thoi gian chay stic ria t6i thiéu la 4 gid)

co When no more particles are trapped in the mesh’ 100-after 4 hours running-stop the oil

heating and circulation.

Khi khéng c6 bui nhé bi dinh véo lu6i 100, sau khi chay thém 4 gid thi dimg viée ham néng

du va dang chay tuén hoan

© Let the oil temperature go down to 40°C and start the flushing again. The job is ready

when after 4 hours of flushing no particles can be found in the mesh 100.

QUALITY, ASSURA ICE PROCEDURE [Boc. No. PCD-PIP-07

[Revisor 200]

FLUSHING PROCEDURE I

‘SAIGON SHIPYARD

Ha nhiét d6 dau xuéng du6i 40°C va khéi déng lai vide stic ria. Céng vige sic niva hoan

thanh sau 4 gid hoat dong ma khéng c6 bui nhé dinh trén lu6i 100.

6) Disassembly of the flushing arrangement:

Théo may sic riva

‘© Disconnect the power supply

Ngat nguén dién cung cap.

‘© Empty the flushing tank to clean barrels.

Vé sinh sach bén chita dau stic riva.

6. Flushing LFO system oY

Stic ria hé théng LFO

Flushing piping with diesel oil

Stic niva bang dau diese!

1) Double-check all connections and venting devices. Inspect the flushing tank, clean it and fill

it with clean flushing oil. Check that there are no leaks.

Kiém tra cdn than cdc vi tri néi va dung cu théng gid. Kiém tra bén chita déu sic ria, vé

sinh bén va cép déu suc riva. Kiém tra dam bao kh6ng cé r6 1.

2) Start by slowly filling the pipes with flushing oil. Only run the pump short periods of time.

‘Check the flushing oil level in the flushing tank and check for leaks.

Bat dau cap dau suc rita tir tir vao hé théng. Chi nén chay bom trong khoang thoi gian —

ng&n. Kiém tra mire dau trong bén chia va kiém tra sw ro 11 tén hé théng.

3) Begin flushing using a mesh of size 30. When the mesh stays almost clean, go on to a mesh

size 60. And finally to size 100. During the flushing, genSUPy hammer the welding seams.

Flushing tank openings have to be covered during the flushing, In order to avoid water in the

oil, the flushing tank has to be drained regularly.

Bat ddu sic riva sir dung loai 1u6i 30. Khi l6i 30 luén sach, chuyén sang str dung loai lui

60. Cudi cng str dung loai Iur6i 100. Trong qué trinh stic rita, ding bia g6 nhe cdc duéng

han. Bén chia déu suc ria phai duge che day trong qué trinh hoat dong. Cha y trong dau

6 nurée, bén chia phai thudng xuyén xa can.

4) The flushing is ready if, after three hours continuous circulation mesh 100 is free of any

sand, metal, dirt or other harmful particles.

Qué trinh stic rita hoan thanh néu sau 3 gid hoat déng tudn hoan voi iudi 100 ma khéng cO

eat, manh kim logi, cn ban hoée cée vat lisu gay hai khdc.

SIZ QUALITY ASSURANCE PROCEDURE

LL FLUSHING PROCEDURE

5) When the flushing has been approved, drain the whole system. Use oil barrels or similar to

store the flushing oil in. DO NOT LET THE OIL LEAK ONTO THE GROUND!

Khi qua trinh sic nva duge chép thuan, thao xa hé théng. Str dung cae loai thing dung dau

hod tuong tu dé cét gite ddu vao kho. KHONG BUOC DE DAU CHAY RA SAN NHAI

6) Open a flange connection and inspect the cleaning,

Théo céc ché néi mat bich va kiém tra vi6e vé sinh.

7. Flushing HFO-piping system

Suc riva hé hé thong 6ng HFO

\~ 14) Fabricate and arrange all needed flushing equipment. The flushing pump must have a large

pumping capacity. All steel flushing equipment must be cleaned with pickling solution. All

flushing hoses must be of a suitable diameter for the pump's capacity or of the same

diameter as the piping.

Ché tao va bé tri tét cé cdc dung cu sic rita can ding. Bom sic rita phai cd céng suat lon.

Cée dung cu ste ria bang s&t thép phai duoc vé sinh, xtr ly axit. Cac éng mém ding cho

vibe sic ria phai c6 kich thuéc hop ly so v6i Ivu lugng ola bom hode tuong ty kich thuée

ctia duéng dng.

Install the flushing filter and hose to the end of the pipeline.

LAp dat Iu6i loc ste rira va 6ng mém & cudi dudng éng.

Install a mesh of size 30 inside the flushing filter first.

Dau tién lp dat loai luéi 30 bén trong bé6 loc.

Inspect the cleaning of the tank, close the ouSUPet valve and fill the tank with flushing

Fa

3)

e

4)

LFO. Use enough oil for the flushing process.

Kiém tra cong viée vé sinh bén chita, déng cae van xd ra va dé déu suc rita FO véo bén.

Si dung dit déu cho qué trinh sie ria.

Open the tank ouSUPet valve and fill the piping. Check that there are no leaks.

M6 van duéng ra ctia bén va dé ddu vao éng. Kiém tra khéng 06 r6 1.

Start the flushing pump, vent the air and make a note of the pressure in the flushing filter,

when the pressure rises it will indicate the intervals for cleaning the flushing filter mesh.

Check that there are no leaks,

Khéi déng bom stc rita, théng gié va ghi lai 4p suét trong b6 loc suc rika. Khi ap suat tang

Jén ching e6i loc stic rita bi nghet. Kiém tra khong 06 ro 1.

7) During the flushing, check:

Trong khi sic riva, cén kiém tra:

5)

6)

PCD-PIP-OF

‘QUALITY ASSURANCE PROCEDURE

FLUSHING PROCEDURE

© The LFO level in flushing tank. Make sure the tank openings are covered.

Marc du LFO trong bén chita dau. Che déy bén chia khi dang hoat dong.

‘That there are no leaks.

Bam bao kh6ng c6 16 1h.

The flushing mesh(s) every 3 hours.

Ludi loc sau mdi 3 gid.

GenSUPy hammer the welding seams with a small hammer.

°

°

°

G6 nhe dung han bang baa nhé.

© Pump cavitation and temperatures.

Bom bj hut va nhiét do. ‘

© Pressure.

Ap suat.

8) When flushing filter mesh 30 is almost clean, change to mesh 60 and consequentially,

when mesh 60 is almost clean, change to mesh 100.

Khi lam sach gan hét voi loai Iu6i loc 30, chuyén sang loai Iu6i 60 va tiép tuc, khi lam sach

ht véi logi ludi 60, chuyén sang loai lui 100.

9) The flushing is ready if after 3 hours continuous flushing using mesh 100 the mesh is free

of dirt or harmful particles such as sand, metal or welding slag. The person responsible for

the flushing and commissioning must approve the cleaning.

Qué trinh stic rtva hoan tét néu sau 3 gid hoat déng lién tuc voi loai ludi 100 ma khéng dinh

can ban hoe nhing manh nhé co hai nhu cat, thép, xT han, Ngudi chju tréch nhiém chinh >

vé viée stic riva va chay thir hé théng phai chap thudn miic d6 sach.

40)If the piping will be kept dry for a longer period of time, mix the flushing oil with lube oll and

circulate it the last few hours of the flushing process. This will give protection to the pipes.

Néu éng sé cét git trong thai gian dai, thi ta pha ln déu suc rita voi dau béi tron va chay

tudn hoan sau vai gid cla qui trinh sie riva. Viéc nay sé gitip bao vé éng.

11)Close the flushing tank ouSUPet valve, drain the piping and inspect the cleaning. Do not let

flushing oil leak onto the ground or the concrete floor.

Déng van xa cia bén sic riva, lam khé éng va kiém tra d6 sach. Khéng duoc dé déu sdc

rita tran ra san, dat.

8. Cleaning and flushing of Gas system

Stic ria va lam sach hé théng Gas

Gas pipe can be made of carbon steel or stainless steel pipes require less work, e.g., the

pickling containing rinsing is not required, which saves time.

PCD-PiP-O7

‘QUALITY ASSURANCE PROCEDURE

Lie FLUSHING PROCEDURE

Ong gas ¢6 thé duoc lam bang thép cacbon hoae thép kh6ng ri nham giém thidu céng viée,

khéng phai yu cdu xt ly axit, ti6t ki6m thoi gian.

8.1 TIG welded carbon steel piping

Han dng thép cacbon bang hén tig

a) Removing of slag, rust and scaling with tools (steel brush, hammer etc...) and grind the

flange.

Lam sach xi, gi va vy bang nhiing céng cu nhu (ban chai thép, bila w..) va mai gitla gée

canh.

b) Visual inspection

kiém tra bang mat.

©) Washing with alkaline solution in hot water at 80°C for degreasing.

Rita sach bang dung dich kiém & nhiét a6 80 °C dé tay déu me.

d) Pickling (containing neutralizing / rinsing of piping and blowing with air, 1.5 times

nominal pressure)

Xi? ly axit (bao gém trung hoa / sie rita duong éng va théi khi, gdp 1.5 lan dp sudt lam

viéc)

@) Fresh water flushing for long pipe lines.

Stic ria bang nuéc sach cho duéng éng dai.

f) Blowing with air after erection of the pipe system.

Théi bang khi sau khi lp rap hé théng dung éng.

g) Pressure and leak tests.

Thir &p Ive va r6 11.

h) Filling the lines with Nitrogen in the pressure of 0.5 bar in order to prevent corrosion.

C&p khi Nite vao duéng éng véi 4p jue 0.5 bar dé ngan nga su an mén.

8.2 Tig welded stainless steel piping

Han 6ng thép kh6ng ri bang han tig

a) Visual inspection

Kiém tra bang mat thuéng.

b) Pickling and passivation according.

Xérly axit va chéng oxi hod hop ly.

c) Blowing with compressed air.

Théi bang khi nén

d) Pressure and leak tests.

Tht &p lye va r6 ri

‘QUALITY ASSURANCE PROCEDURE

FLUSHING PROCEDURE

e) Filling the lines with N2 if flammable mixture is possible.

Cép khi Ne néu hén hop ¢6 kha nang chay

9, Flushing of cooling water system

Suc riva hé théng nwée lam mat

9.1 Expansion pipes

Ong gian nov

The expansion pipes are to be flushed with water unit they are clean from debris. pe

Drain the expansion system and clean the bottom of the expansion tanks carefully. ;

Dang nue sach stic rita can ban cho éng gian né

9.2 Pipes line of cooling system

Dweng 6ng cia hé théng lam mat

Before flushing with water starts, bigger pipes are to be cleaned by hand. The pipes of

radiators need not to be flushed. Disconnect therefore the pipes of radiators and build a

pipe loop as show in sketch below. The flushing is to be done with an external flushing

pump arrangement (e.g. by using the fire water pump) having adequate flow capacity and

equipped with strainers collecting the debris coming from the pipes during the flushing

procedure.

Truéc khi sic rita bat dau voi nuéc, nhéing 6ng 06 dung kinh I6n phai dugc vé sinh bang)

fay. B6 phan tan nhiét khéng can sac riva. Théo roi éng c&e éng néi véi b6 phan tan nhiét,

dau néi éng voi nhau & vi tri thdp. bé tri bom sic ria (chang han ding bom ctru hoa) co

céng sudt déng chay pha hop dé siic rira va duge trang bj luéi loc gom rac tle duéng éng

trong qué trinh stic rira.

9.3 The whole cooling radiator system

B6 phan tan nhigét

When the pipes between connect to radiators are clean, re-connect the pipe to the

tadiators. Install running filter on HT and LT-inlet pipes to the engine. Fill up the whole

system with untreated water. Run until the engine is warm, and then shut down the engine.

Check the running in fiter. If no debris is found in the filter nor in the expansion tanks the

system can be considered as clean. Drain all water from the system and refill it with

chemically treated water. Remove the running-in fiter at the first 50 hours service interval

of the engine.

SI

‘QUALITY ASSURANCE PROCEDURE Doc. No. = PCD-PIP-07

[Revision = 00

FLUSHING PROCEDURE 10 |

SAIGOX SHIPYARD Page No. 14of 14

Sau khi hé théng éng néi v6i b6 phan tan nhiét duge vé sinh, néi céc éng voi bé phén tan

nhiét. Lép dét lu6i loc hoat déng tai dung éng vao HT(high temperature-nhiét d6 cao) va

LT( low tomperature-nhiét d6 thdp ) clia may. 86 day toan b6 hé théng voi nube chua xir

ly. Hoat déng hé théng dén khi may 4m, sau dé tét may. Kiém tra sy hoat déng cia lui

loc. Néu khéng nhin théy rac trén l6i loc va trén bé phan gién né thi hé théng da sach. Xa

hét nuée trong hé théng va lép lai voi nuéc chia hod chét xt ly. Théo lur6i loc sau khi may

hoat dong 50 gio.

V. APPLIED FORMS

1, Internal Quality Inspection & Checking Application List.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Intergard 263: Epoxy Tie CoatDocument4 pagesIntergard 263: Epoxy Tie Coatcmc261185No ratings yet

- Reasons For Dry-Docking?Document3 pagesReasons For Dry-Docking?cmc261185No ratings yet

- Piping System Hydraulic Test Procedure R0Document6 pagesPiping System Hydraulic Test Procedure R0cmc261185No ratings yet

- Pipe Spool Welding RecordDocument47 pagesPipe Spool Welding Recordcmc261185No ratings yet

- Pipe Spools Fabrication RecordDocument56 pagesPipe Spools Fabrication Recordcmc261185No ratings yet

- EFD-015 - General Valve List - 200731Document3 pagesEFD-015 - General Valve List - 200731cmc261185No ratings yet

- Fan Catalog OnishiDocument15 pagesFan Catalog Onishicmc261185No ratings yet

- EFD-018 - Butterfly Valve List With Limit Switch - 200731.Document2 pagesEFD-018 - Butterfly Valve List With Limit Switch - 200731.cmc261185No ratings yet

- RMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air ConditionerDocument21 pagesRMH-LC-ACV-DOC-006 RC Equipment Selection Seawater Cooled Package Air Conditionercmc261185No ratings yet

- Bang Gia THANH LÝ Hang Ton 2020 06, G I Khách Hàng 2Document16 pagesBang Gia THANH LÝ Hang Ton 2020 06, G I Khách Hàng 2cmc261185No ratings yet

- Osaka 2018 PDFDocument148 pagesOsaka 2018 PDFcmc261185No ratings yet

- PK'G No. Description Q'Ty Unit Weight PK'G#1-1 300KGS: M/T Claxton Bay (Hmd-2138)Document8 pagesPK'G No. Description Q'Ty Unit Weight PK'G#1-1 300KGS: M/T Claxton Bay (Hmd-2138)cmc261185No ratings yet