Professional Documents

Culture Documents

Prepared By: Certified By: Witnessed by

Prepared By: Certified By: Witnessed by

Uploaded by

Sudhir Kotkar0 ratings0% found this document useful (0 votes)

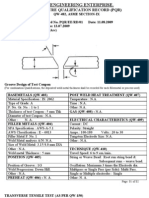

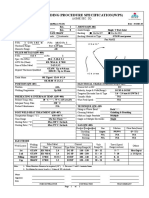

28 views1 pageThis document summarizes the variables used to weld test coupons for PQR number TME 000. It lists the process, consumable, current, and voltage used for the barrier layer and subsequent layers of the weld. It also provides information on the materials used, including their specifications, sizes, heat/lot numbers, and manufacturer. Chemical compositions and location measurements for various elements are presented for the consumable materials. The document was prepared, certified, and witnessed by welding personnel.

Original Description:

Original Title

ANNEXURE-1 wps

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes the variables used to weld test coupons for PQR number TME 000. It lists the process, consumable, current, and voltage used for the barrier layer and subsequent layers of the weld. It also provides information on the materials used, including their specifications, sizes, heat/lot numbers, and manufacturer. Chemical compositions and location measurements for various elements are presented for the consumable materials. The document was prepared, certified, and witnessed by welding personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

28 views1 pagePrepared By: Certified By: Witnessed by

Prepared By: Certified By: Witnessed by

Uploaded by

Sudhir KotkarThis document summarizes the variables used to weld test coupons for PQR number TME 000. It lists the process, consumable, current, and voltage used for the barrier layer and subsequent layers of the weld. It also provides information on the materials used, including their specifications, sizes, heat/lot numbers, and manufacturer. Chemical compositions and location measurements for various elements are presented for the consumable materials. The document was prepared, certified, and witnessed by welding personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

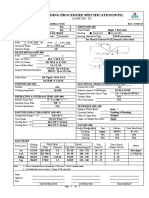

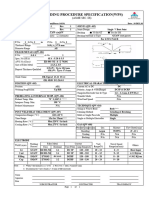

ANNEXURE - 1

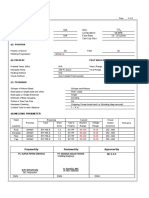

Record Of Actual Variables Used to Weld Test Coupons

PQR NO: TME 000

PASS/LAYER PROCESS CONSUMABLE CURRENT VOLTAGE

NO. AWS CLASS SIZE (mm) (amps) (volts)

Barrier Layer SMAW ENiCrMo-10 3.15 90 22-26

Subsequent SMAW ENiCrMo-10 4.00 110 23-28

Layer

Subsequent SMAW ENiCrMo-10 4.00 110 23-28

Layer

NOTE:- Materials used to weld the test coupon

HEAT/LOT

SR. NO. SPECIFICATION SIZE IN mm MAKE T.C. NO

NO.

1 SA 240 GR 316L 300X300X6 00000 ABC 0000

2 ENiCrMo-10 Ø3.15 000000 ABC 000

3 ENiCrMo-10 Ø4.0 000000 ABC 0000

Location C S P Mn Si Cr Mo Cu Fe

2.5 mm

3.0 mm

Location V Co W Ni

2.5 mm

3.0 mm

ENiCrMo-10 Confirms at 2.5 mm and above from Fusion Line and 3.5 mm from weld interface vide report

no : Q-000 Dtd: 00/00/0000

ENiCrMo-10 Confirms at 3.5 mm and above from Fusion Line and 3.5 mm from weld interface vide report

no : Q-000 Dtd: 00/00/0000

Prepared By: Certified By: Witnessed By:

Engineer (Welding) Head Welding

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Self Declaration Shop PDFDocument2 pagesSelf Declaration Shop PDFSudhir Kotkar0% (2)

- Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- PQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- Audco India Limited Welding Procedure Specification: LAB-005R1Document3 pagesAudco India Limited Welding Procedure Specification: LAB-005R1sudeep_singh1No ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Welding Procedure Specification (WPS) : CÓDIGO: AC-FT-018 Versión: 01 FECHA: 24-05-2019 Página: 1 de 1Document2 pagesWelding Procedure Specification (WPS) : CÓDIGO: AC-FT-018 Versión: 01 FECHA: 24-05-2019 Página: 1 de 1cesarNo ratings yet

- 0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableDocument3 pages0361TQ BS EN 60332-1-2 BS 638: Orange Welding CableFacundo ArlistanNo ratings yet

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- TA - 4271 17-185 (PO-9) 2nd MockupDocument5 pagesTA - 4271 17-185 (PO-9) 2nd MockupAgni DuttaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WG-WPS-0099 Rev 2Document1 pageWG-WPS-0099 Rev 2mb.pipingNo ratings yet

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- PQR PDFDocument2 pagesPQR PDFNjoku ChijiokeNo ratings yet

- Hasil Uji Kubikel 20KV PLTMH Besai KemuDocument22 pagesHasil Uji Kubikel 20KV PLTMH Besai KemulutfiNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- Material 1.4057 PDFDocument3 pagesMaterial 1.4057 PDFengfaridmalkNo ratings yet

- Ec-2692-220-2 - Void 4SDocument3 pagesEc-2692-220-2 - Void 4SMatheus Fabrício TeixeiraNo ratings yet

- UGINEDocument1 pageUGINEjesusNo ratings yet

- Sandvik 253MA Data Sheet PDFDocument10 pagesSandvik 253MA Data Sheet PDFTee Klong RungNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Increased Safety Stator Winding Temperature Sensors: Specification and Order OptionsDocument2 pagesIncreased Safety Stator Winding Temperature Sensors: Specification and Order Optionsswapneel_kulkarniNo ratings yet

- NZTM-Q29 - Roll Cage Tube SpecificationDocument1 pageNZTM-Q29 - Roll Cage Tube SpecificationDavid TurnerNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- 074 - ANPAM EnggDocument1 page074 - ANPAM EnggvinuNo ratings yet

- 4 - PREPARATION OF WPS - StudentDocument22 pages4 - PREPARATION OF WPS - Studentrazlan ghazaliNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + 304L)Document3 pagesPurchase Spec. For Plates-Weld Overlay (CS + 304L)Daison PaulNo ratings yet

- WPS & PQR - LTM - QW - PipeDocument7 pagesWPS & PQR - LTM - QW - PipeKAMALNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Din 2393-2Document0 pagesDin 2393-2Yalavarthi ChandrasekharNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Tubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)Document2 pagesTubo 2 STD P265 Dual Charpy Ec H. R56612 (13.726)alexis garciaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- 028120-SPL-003 Pipeline Material Rev. DDocument36 pages028120-SPL-003 Pipeline Material Rev. DRokan PipelineNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- MT 14 465 T1 Report Supplier 1 48.3mm TubeDocument1 pageMT 14 465 T1 Report Supplier 1 48.3mm TubeHaseeb KhanNo ratings yet

- Datasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Document9 pagesDatasheet-Sandvik-Saf-31803-En-V2018-07-20 11 - 04 Version 1Gonzalo AlarciaNo ratings yet

- Pwps / WPQ / Wopq Data SheetDocument14 pagesPwps / WPQ / Wopq Data SheetGurbir SinghNo ratings yet

- WPARDocument2 pagesWPARSc TanNo ratings yet

- JSPL Line-2 Erection BOMDocument11 pagesJSPL Line-2 Erection BOMRakesh Karan SinghNo ratings yet

- Slip StreamDocument1 pageSlip StreamvietsdsNo ratings yet

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 pagesSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- 011 WPS ASME TOP F 2022 - Rev.0Document8 pages011 WPS ASME TOP F 2022 - Rev.0megantara maromNo ratings yet

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- QW-483 (Yellow) PQR No.: Tme 355Document1 pageQW-483 (Yellow) PQR No.: Tme 355Sudhir KotkarNo ratings yet

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- QW-483 (Black) PQR No.: Tme 356Document1 pageQW-483 (Black) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- QW-483 (Green) PQR No.: Tme 356Document1 pageQW-483 (Green) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- Wps 1Document1 pageWps 1Sudhir KotkarNo ratings yet

- Quotation: Sr. No. Item Description Quantity Unit Rate AmountDocument1 pageQuotation: Sr. No. Item Description Quantity Unit Rate AmountSudhir KotkarNo ratings yet

- Quote FormatDocument1 pageQuote FormatSudhir KotkarNo ratings yet

- Shop Act PDFDocument2 pagesShop Act PDFSudhir KotkarNo ratings yet

- Quotation: Shree EnterprisesDocument1 pageQuotation: Shree EnterprisesSudhir KotkarNo ratings yet

- QW-483 (BACK) PQR No.: Tme 356Document1 pageQW-483 (BACK) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument26 pages1 Input Data: WWW - Hilti.inSudhir KotkarNo ratings yet

- Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- PQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Document1 pagePQR No: Tme 000 Pass/Layer NO. Process Consumable Current (Amps) Voltage (Volts) Aws Class SIZE (MM)Sudhir KotkarNo ratings yet

- SelfDeclaration Shop PDFDocument2 pagesSelfDeclaration Shop PDFSudhir KotkarNo ratings yet

- SelfDeclaration ShopDocument2 pagesSelfDeclaration ShopSudhir KotkarNo ratings yet