Professional Documents

Culture Documents

ASMT-C-795 Cloride Content SS PDF

ASMT-C-795 Cloride Content SS PDF

Uploaded by

susantaCopyright:

Available Formats

You might also like

- Astm A923 23Document7 pagesAstm A923 23danielrelva100% (1)

- Astm A143a143m.20Document4 pagesAstm A143a143m.20safak kahramanNo ratings yet

- Astm A143Document4 pagesAstm A143asdrecv100% (1)

- Astm G48Document11 pagesAstm G48thedreampower100% (4)

- ASTM C795 Insulation Material For Austenistic SteelDocument3 pagesASTM C795 Insulation Material For Austenistic SteelAbass100% (2)

- ASTM - Tratamientos de PasivacionDocument7 pagesASTM - Tratamientos de PasivacionFrank Herrera RodríguezNo ratings yet

- Astm G 48Document9 pagesAstm G 48nisha_khanNo ratings yet

- Cameroon KoleDocument1 pageCameroon KoleSamNo ratings yet

- C795-08 (2013) Standard Specification For Thermal Insulation For Use in Contact With Austenitic SDocument4 pagesC795-08 (2013) Standard Specification For Thermal Insulation For Use in Contact With Austenitic Snguyen100% (1)

- Astm C795Document4 pagesAstm C795Nacer Kisy100% (1)

- Astm C795 08Document2 pagesAstm C795 08marcelo barrosNo ratings yet

- Thermal Insulation For Use in Contact With Austenitic Stainless SteelDocument4 pagesThermal Insulation For Use in Contact With Austenitic Stainless SteelDave Le Khac DuyenNo ratings yet

- A 923 - 01 Qtkymy0wmqDocument7 pagesA 923 - 01 Qtkymy0wmqPRASANTH PRASANTHNo ratings yet

- C-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingDocument7 pagesC-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingYogalingam ArumugamNo ratings yet

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- A 923Document9 pagesA 923John P KNo ratings yet

- Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsDocument10 pagesDetecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsBaskar VNo ratings yet

- Astm A293-2022Document10 pagesAstm A293-2022CarlosNo ratings yet

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocument7 pagesAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloNo ratings yet

- Astm - A 975Document7 pagesAstm - A 975victorNo ratings yet

- Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsDocument9 pagesDetecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsmaheshNo ratings yet

- Astm A 143 - 03Document3 pagesAstm A 143 - 03Glenys MuñozNo ratings yet

- Astm A967 01Document3 pagesAstm A967 01tecnicostratadosNo ratings yet

- Astm A967Document7 pagesAstm A967Luciano Grassi Kuyven100% (1)

- Flex Gabion Standard ASTM A975-97Document7 pagesFlex Gabion Standard ASTM A975-97Moh Ragil SodikinNo ratings yet

- Astm 143Document3 pagesAstm 143JH_ProjectNo ratings yet

- Astm A967 01Document6 pagesAstm A967 01tecnicostratadosNo ratings yet

- Che Ical Passiv T On Treatmen S or Stain Ess Steel Parts: M A I T F LDocument7 pagesChe Ical Passiv T On Treatmen S or Stain Ess Steel Parts: M A I T F LÖzgür ÇalışkanNo ratings yet

- ASTM A-967-13 Pasivado Inoxidable PDFDocument7 pagesASTM A-967-13 Pasivado Inoxidable PDFmagierezNo ratings yet

- Astm A 923-2014Document9 pagesAstm A 923-2014Mohammed AliNo ratings yet

- Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsDocument9 pagesDetecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsIsmail Tp100% (1)

- Astm A 143 A143m-2007Document3 pagesAstm A 143 A143m-2007Fabio SegattoNo ratings yet

- Nonstructural Steel Framing Members: Standard Specification ForDocument6 pagesNonstructural Steel Framing Members: Standard Specification Forthienbinh.ngnNo ratings yet

- A 950 - A 950M - 99 (Reapproved 2003) PDFDocument5 pagesA 950 - A 950M - 99 (Reapproved 2003) PDFhectoriturbeNo ratings yet

- Testing Cellular Glass Insulation Block: Standard Test Methods ofDocument4 pagesTesting Cellular Glass Insulation Block: Standard Test Methods ofMina RemonNo ratings yet

- C795Document3 pagesC795dinhtung2210No ratings yet

- Boiler WaterDocument6 pagesBoiler WaterAamir NaweedNo ratings yet

- Astm A 967 2005Document7 pagesAstm A 967 2005Marco VeraNo ratings yet

- Copper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDocument4 pagesCopper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDennise ChicaizaNo ratings yet

- Astm A923-2006 PDFDocument10 pagesAstm A923-2006 PDFDhamuNo ratings yet

- ASTM G 48 - 00 - Rzq4ltawDocument10 pagesASTM G 48 - 00 - Rzq4ltawSamuel EduardoNo ratings yet

- Safeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and Procedure For Detecting EmbrittlementDocument4 pagesSafeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and Procedure For Detecting EmbrittlementLucas O. AquinoNo ratings yet

- Measurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method ForDocument5 pagesMeasurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method Formohammed karasnehNo ratings yet

- Hot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceDocument11 pagesHot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceProduction DepartmentNo ratings yet

- D807-05 Standard Practice For Assessing The Tendency of Industrial Boiler Waters To Cause Embrittlement (USBM1 Embrittlement Detector Method)Document6 pagesD807-05 Standard Practice For Assessing The Tendency of Industrial Boiler Waters To Cause Embrittlement (USBM1 Embrittlement Detector Method)ericNo ratings yet

- Steel Sheet, Carbon, Metallic-And Nonmetallic-Coated For Cold-Formed Framing MembersDocument6 pagesSteel Sheet, Carbon, Metallic-And Nonmetallic-Coated For Cold-Formed Framing Membersvuqar0979No ratings yet

- ASTM A123 Galv. DFT RequirementDocument8 pagesASTM A123 Galv. DFT Requirementshoaib1985No ratings yet

- Astm G 47 - 98 - RZQ3LTK4Document6 pagesAstm G 47 - 98 - RZQ3LTK4Samuel EduardoNo ratings yet

- Industrial Anodizing Co Inc A967Document9 pagesIndustrial Anodizing Co Inc A967Daryna KupriianovaNo ratings yet

- Cold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceDocument5 pagesCold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion Resistancewatt_hrNo ratings yet

- Astm C665Document5 pagesAstm C665archwilfredNo ratings yet

- ASTM C764 Mineral Fiber Loose-Fill InsulationDocument5 pagesASTM C764 Mineral Fiber Loose-Fill InsulationMike DukasNo ratings yet

- G 48 - 99 - RZQ4LTK5QQDocument9 pagesG 48 - 99 - RZQ4LTK5QQCordova RaphaelNo ratings yet

- Astm A502 1993Document4 pagesAstm A502 1993Jesse ChenNo ratings yet

- ASTM G35 - 98 (Reapproved 2010)Document3 pagesASTM G35 - 98 (Reapproved 2010)Ali Ali Asjari100% (1)

- Astm B633-19Document8 pagesAstm B633-19sharma.sumeet2290No ratings yet

- IND TB009 Stress Corrosion Cracking of Austenitic Stainless SteelDocument2 pagesIND TB009 Stress Corrosion Cracking of Austenitic Stainless SteelSoren KjaerNo ratings yet

- E1010 16 PDFDocument4 pagesE1010 16 PDFFrancisco PizarroNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Finish Paint Inspection Report: ND ST ND RDDocument2 pagesFinish Paint Inspection Report: ND ST ND RDsusantaNo ratings yet

- BS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress ReportDocument1 pageBS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress Reportsusanta100% (1)

- Deepak Garg 2019.02.1 3 12:01:33 +05'30': Written by Checked byDocument2 pagesDeepak Garg 2019.02.1 3 12:01:33 +05'30': Written by Checked bysusantaNo ratings yet

- Deepak Garg 2019.02.1 3 11:59:07 +05'30': Written by Checked byDocument2 pagesDeepak Garg 2019.02.1 3 11:59:07 +05'30': Written by Checked bysusantaNo ratings yet

- Heat Transfer CompoundDocument2 pagesHeat Transfer CompoundsusantaNo ratings yet

- BS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress ReportDocument1 pageBS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress ReportsusantaNo ratings yet

- Insulation Schedule Panipat Hgu Reformer: Date:01/11/2019Document3 pagesInsulation Schedule Panipat Hgu Reformer: Date:01/11/2019susantaNo ratings yet

- Design Area Design Area For Units Subcontractor ScopeDocument6 pagesDesign Area Design Area For Units Subcontractor ScopesusantaNo ratings yet

- Description Mark Nos Qty Steel WT Total WT Reformer-1Document18 pagesDescription Mark Nos Qty Steel WT Total WT Reformer-1susantaNo ratings yet

- VRMP Projects - #973 Hgu Reformer Insulation Monthly Completion Plan Project: Reformer Works - HGU-EPCC 6, HPCL, VIZAGDocument1 pageVRMP Projects - #973 Hgu Reformer Insulation Monthly Completion Plan Project: Reformer Works - HGU-EPCC 6, HPCL, VIZAGsusantaNo ratings yet

- Product Data Sheet TIC 9061 Heat Transfer Cement: DescriptionDocument2 pagesProduct Data Sheet TIC 9061 Heat Transfer Cement: DescriptionsusantaNo ratings yet

- Loid Seal 94ADocument1 pageLoid Seal 94AsusantaNo ratings yet

- Introduction To Joining: Joining-Understanding The Basics F.C. Campbell, Editor All Rights ReservedDocument10 pagesIntroduction To Joining: Joining-Understanding The Basics F.C. Campbell, Editor All Rights ReservedKeiNo ratings yet

- Gate 2011 Chemical SyllabusDocument2 pagesGate 2011 Chemical SyllabusVenkyNo ratings yet

- 10em Chem 1 Foundation Chap-1Document46 pages10em Chem 1 Foundation Chap-1Legendary MathematicianNo ratings yet

- Wall Mounted Split Type Air Conditioner: ManualDocument8 pagesWall Mounted Split Type Air Conditioner: ManualMoody MoodyNo ratings yet

- Milling Speeds and Feeds PDFDocument1 pageMilling Speeds and Feeds PDFrobNo ratings yet

- Mems and Nems: The Physics of The Microworld Is Dominated by Surface EffectsDocument39 pagesMems and Nems: The Physics of The Microworld Is Dominated by Surface EffectsroshanNo ratings yet

- Thermal Expansion CalculationsDocument36 pagesThermal Expansion CalculationsAhmad MuzammilNo ratings yet

- 5.00 FD An1 s1 CE Chemistry 23-24Document4 pages5.00 FD An1 s1 CE Chemistry 23-24imsNo ratings yet

- Worksheet (Metals and Non Metals) Subject-Science Grade - ViiiDocument4 pagesWorksheet (Metals and Non Metals) Subject-Science Grade - Viiikatira rashmiNo ratings yet

- Normal Laboratory ValuesDocument2 pagesNormal Laboratory ValuesSBNo ratings yet

- Link Seal ManualDocument28 pagesLink Seal ManualAurva KapoorNo ratings yet

- TIBCDocument2 pagesTIBCFatma Gemala100% (1)

- MODULE 2 ClimatologyDocument23 pagesMODULE 2 ClimatologyRAKSHITHA JAVAGALNo ratings yet

- Kerosine: Standard Specification ForDocument3 pagesKerosine: Standard Specification ForDavid CazorlaNo ratings yet

- 2017 - Green Synthesis of Graphene From Recycled PET Bottle WastesDocument12 pages2017 - Green Synthesis of Graphene From Recycled PET Bottle WastesViviane Zorio PeixotoNo ratings yet

- sp001 5thedition ChecklistsDocument14 pagessp001 5thedition ChecklistsJavier Mauricio Higuera MoraNo ratings yet

- Lithium Battery Storage and HandlingDocument9 pagesLithium Battery Storage and HandlingAhmed HemdanNo ratings yet

- Data SheetDocument3 pagesData Sheetashv1972No ratings yet

- Carbohydrates: There Are Three Classes of Carbohydrates: 1. Monosaccharides 2.disaccharides 3.polysaccharidesDocument3 pagesCarbohydrates: There Are Three Classes of Carbohydrates: 1. Monosaccharides 2.disaccharides 3.polysaccharidesselvasrijaNo ratings yet

- Cement Carb 5Document6 pagesCement Carb 5neyzaNo ratings yet

- International Standard: Safety of Primary and Secondary Lithium Cells and Batteries During TransportDocument7 pagesInternational Standard: Safety of Primary and Secondary Lithium Cells and Batteries During Transportp sangeerthNo ratings yet

- MS 01 180Document88 pagesMS 01 180DucVikingNo ratings yet

- Shafts and Associated Parts: Prof. Dr. Özgen Ümit ÇolakDocument14 pagesShafts and Associated Parts: Prof. Dr. Özgen Ümit ÇolakMücahit EzelNo ratings yet

- Spray Paint Booths Purchasing GuideDocument18 pagesSpray Paint Booths Purchasing Guidefurtan100% (1)

- Up PDFDocument242 pagesUp PDFMandal Ji TeloNo ratings yet

- International - Standard ISO 14175Document3 pagesInternational - Standard ISO 14175Geom_MengoliNo ratings yet

- Lithological Terminology and DefinitionsDocument3 pagesLithological Terminology and DefinitionsJonathan ShimNo ratings yet

- Glossary RubberDocument12 pagesGlossary RubbersabtonluckyNo ratings yet

- Natural Toxins: 1. Toxic Phenolic SubstancesDocument12 pagesNatural Toxins: 1. Toxic Phenolic SubstancesMohamed Bayoumi mohamed100% (1)

ASMT-C-795 Cloride Content SS PDF

ASMT-C-795 Cloride Content SS PDF

Uploaded by

susantaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASMT-C-795 Cloride Content SS PDF

ASMT-C-795 Cloride Content SS PDF

Uploaded by

susantaCopyright:

Available Formats

Designation: C 795 – 08

Standard Specification for

Thermal Insulation for Use in Contact with Austenitic

Stainless Steel1

This standard is issued under the fixed designation C 795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This specification covers non-metallic thermal insula- 3.1 Definitions—Terminology C 168 applies to the terms

tion for use in contact with austenitic stainless steel piping and used in this specification.

equipment. In addition to meeting the requirements specified in 3.2 Definitions of Terms Specific to This Standard:

their individual material specifications, issued under the juris- 3.2.1 basic material specification—any of the material

diction of ASTM Committee C16, these insulations must pass specifications for homogeneous insulation covered in any of

the preproduction test requirements of Test Method C 692, for the pertinent Annual Book of ASTM Standards.

stress corrosion effects on austenitic stainless steel, and the 3.2.2 lot—a lot shall be defined in accordance with Practice

confirming quality control, chemical requirements, when tested C 390 by agreement between the purchaser and the manufac-

in accordance with the Test Methods C 871. turer.

1.2 The values stated in inch-pound units are to be regarded 3.2.3 stress corrosion cracking (SCC)—the failure of metal,

as standard. The values given in parentheses are mathematical taking the form of cracks that potentially occur under the

conversions to SI units that are provided for information only combined influence of certain corrosive environments and

and are not considered standard. applied or residual stresses.

1.3 This standard does not purport to address all of the 3.2.4 wicking-type insulation—insulation material that, by

safety concerns, if any, associated with its use. It is the virtue of its physical characteristics, permits a wetting liquid to

responsibility of the user of this standard to establish appro- infiltrate it by capillary attraction.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4. Significance and Use

4.1 Stress corrosion cracking of austenitic stainless steel is a

2. Referenced Documents metallurgical phenomenon. One cause of stress corrosion

2.1 ASTM Standards:2 cracking is the presence of contaminants in water solution,

C 168 Terminology Relating to Thermal Insulation which can be concentrated at the stressed surface by evapora-

C 390 Practice for Sampling and Acceptance of Thermal tion of the water.

Insulation Lots 4.2 There is an apparent correlation between stress corro-

C 692 Test Method for Evaluating the Influence of Thermal sion cracking of austenitic stainless steel and the use of

Insulations on External Stress Corrosion Cracking Ten- insulation which either contains water-leachable chloride or, by

dency of Austenitic Stainless Steel reason of its water absorptivity, acts as a vehicle through which

C 871 Test Methods for Chemical Analysis of Thermal chlorides from outside the system are concentrated at the

Insulation Materials for Leachable Chloride, Fluoride, surface of the stainless steel.3,4,5

Silicate, and Sodium Ions 4.3 Studies have shown that insulation containing certain

water-soluble compounds have the capacity to retard or prevent

1

This specification is under the jurisdiction of ASTM Committee C16 on

3

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on Schaffer, L. D., and Klapper, J. A., “Investigation of the Effects of Wet,

Homogeneous Inorganic Thermal Insulations. Chloride-Bearing, Thermal Insulation on Austenitic Stainless Steel,” Report No.

Current edition approved Oct. 15, 2008. Published November 2008. Originally ESI-25-(a)-1, Oak Ridge National Laboratory, and Ebasco Services Inc., November

approved in 1977. Last previous edition approved in 2003 as C 795 – 03. 1, 1961.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Dana, A. W., Jr., “Stress-Corrosion Cracking of Insulated Austenitic Stainless

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Steel,” ASTM Bulletin, October 1957.

5

Standards volume information, refer to the standard’s Document Summary page on Louthan, M. R., Jr., “Initial Stages of Stress Corrosion Cracking in Austenitic

the ASTM website. Stainless Steels,” Corrosion, NACE, September 1965.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

--`,,````,```,,``,``,,,`,,,```,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=Petroliam Nasional Berhad/4397000001

No reproduction or networking permitted without license from IHS Not for Resale, 04/20/2009 20:29:36 MDT

C 795 – 08

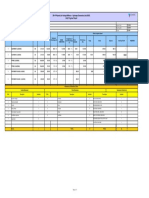

FIG. 1 Acceptability of Insulation Material on the Basis of the Plot Points of the (Cl + F) and the (Na + SiO3) Analyses.

stress corrosion. Numerous materials thought to inhibit stress the extractable ions and plotting them on the Fig. 1 acceptabil-

corrosion cracking have been tried with varying degrees of ity graph. Fluoride has been added to chloride in Section 13

success. An inhibiting compound commonly used is sodium and on Fig. 1 to be consistent with the other standards.

silicate. Present knowledge indicates that the sodium silicate 4.6 Physical and chemical changes can occur when thermal

dissociates in the presence of water, leaving the silicate ion to insulation, various binders, or adhesives, or a combinations

form a protective mechanism that inhibits or prevents the thereof, are heated. Insulation materials are often exposed to

chloride ion from attacking the stainless steel. Under adverse process temperatures that are sufficient to cause changes.

environmental conditions, this protective agent will possibly be Various compounds thermally decompose increasing the solu-

leached from the product with time and permanent protection bility of some ions that leach out when exposed to water. Other

is not afforded. compounds have the potential to become less soluble after

4.4 Test Method C 692 contains a procedure for determining thermal exposure.

whether or not stress corrosion cracking will occur with a given 4.7 The inhibitory qualities of sodium silicate compounds

thermal insulation. The procedure is used to evaluate insulation have been found to be different for different molar ratios of

--`,,````,```,,``,``,,,`,,,```,,-`-`,,`,,`,`,,`---

materials have the potential to inhibit, to be passive, or actively sodium to silicate. The current specifications treat them as

contribute to stress corrosion cracking of austenitic stainless being added together for a total ppm value.6

steels. 4.8 A variety of acids and ionic chemical solutions are

4.5 Research has indicated that in addition to the halide ion known to induce metal pitting, hydrogen embrittlement, inter-

chloride, fluoride ions have the potential to induce SCC in the granular corrosion and stress corrosion cracking on sensitized

absence of inhibiting ions.6 Two widely used insulation speci- austenitic stainless steel. The results of Test Methods C 692

fications that are similar to C 795 and are specific to SCC allow corrosion test are expected to indicate if there is an untested

the use of the same Test Methods C 692 and C 871 for agent in the insulation that will induce cracking.

evaluation of insulation materials. Both specifications require

fluoride ions to be included with chloride ions when evaluating 5. Ordering Information

5.1 The requirements of this specification shall be stated by

6

Whorlow, Kenneth M., Woolridge, Edward and Hutto, Francis B., Jr., “Effect of the purchaser for the particular insulation and material appli-

Halogens and Inhibitors on the External Stress Corrosion Cracking of Type 304

Austenitic Stainless Steel”; STP 1320 Insulation Materials: Testing and Applica-

cation specified. The purchaser shall specify the type, grade,

tions, Third Volume, Ronald S. Graves and Robert R. Zarr, editors, ASTM West class, dimensions, quantity, and other requirements as available

Conshohocken, PA, 1997 page 485 . in the basic material specification for a particular insulation.

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=Petroliam Nasional Berhad/4397000001

No reproduction or networking permitted without license from IHS Not for Resale, 04/20/2009 20:29:36 MDT

C 795 – 08

6. Composition sample is taken shall be of the same formulation, made by the

6.1 The material shall conform to the established require- same production processes and from the same kind, nature, and

ments of the basic material specification. quality of ingredients as those that will be employed for

production of thermal insulation under this specification.

7. Physical and Chemical Requirements 12.2 The corrosion test shall be conducted in accordance

7.1 The physical requirements shall conform to the require- with the method presented in Test Method C 692. At the end of

ments of the basic material specification. The chemical require- the test time, none of the prepared coupons of stainless steel

ments shall conform to the requirements of Section 13 of this shall show a crack when examined in accordance with Test

specification. Method C 692.

12.3 The test procedure need not be repeated for subsequent

8. Dimensions and Permissible Variations orders using the same production process and the same kind,

8.1 The dimensions and permissible variations shall con- nature, and quality of ingredients unless so required. The

form to the requirements of the basic material specification. manufacturer shall keep records of actual numerical results of

the tests available for review on request by those concerned.

9. Workmanship, Finish, and Appearance

9.1 The workmanship, finish, and appearance shall conform 13. Chemical Analysis

to the requirements of the basic material specification. 13.1 A chemical analysis shall be performed on the insula-

tion material in accordance with Test Methods C 871 and, in

10. Sampling addition, the manufacturer shall demonstrate that his current

10.1 The unit sample shall be of sufficient size to perform product has passed the preproduction corrosion test in accor-

the preproduction corrosion test and chemical analysis tests dance with Test Method C 692.

specified in this specification. The samples shall be of sufficient 13.1.1 An acceptable proportion of sodium plus silicate ions

size to ensure an acceptable level of confidence that the test to the chloride plus fluoride ions as found by leaching from the

results represent the characteristics of the product being insulation is shown in Fig. 1 and was arrived at empirically.

purchased. Sample size shall be in accordance with Practice Other insulation compositions, whose chemical analysis falls

C 390. outside of the acceptance area shown in Fig. 1, are possibly

acceptable; however, their efficacy shall be determined in

11. Acceptance and Retests accordance with Test Method C 692 and subsequently moni-

11.1 Acceptance—All specimens in a lot sampling shall tored in accordance with Test Methods C 871.

meet the chemical requirements of this specification. If the 13.2 pH—The pH of the leach water extracted, in accor-

average analysis of the two specimens taken from any sample dance with Test Method C 871, shall be measured using a pH

fails to conform to the requirements of this specification, the lot meter and probe and shall have a pH no greater than 12.5 at

represented by that sample shall be rejected. 77°F (25°C).

11.2 Retest—At the option of the supplier, each individual 13.3 The specific material supplied shall be analyzed in

unit of supply (that is, carton, bag, roll, sheet, drum, and so accordance with Test Methods C 871 for the following leach-

forth) in rejected lots are allowed to be retested, in accordance able ions: chloride, fluoride, sodium, and silicate. The “plot

with Test Methods C 871, at the supplier’s expense, by testing point” of these analyses shall fall in the acceptable area of Fig.

samples taken at random from the unit of supply in accordance 1.

with this specification. Unless otherwise agreed upon between 13.4 The minimum allowable value of sodium plus silicate

the purchaser and the manufacturer, the resubmitted material shall be 50 ppm. There is no minimum limit on chloride plus

shall require the same number of samples to be tested as fluoride. Extrapolating the chloride plus fluoride level below

required for the initial submittal. If the average analysis of the 10 ppm on Fig. 1 is considered to be in the acceptable area

two specimens taken from each sample fails to conform to the when the sodium and silicate is above 50 ppm.

requirements of this specification, the unit of supply repre-

sented by that sample shall be rejected. For other than chemical 14. Handling and Application

analysis or stress corrosion tests, the number of tests and retests 14.1 See applicable ASTM specifications for handling and

shall be as specified in the basic material specification. application.

12. Preproduction Corrosion Test 15. Keywords

12.1 A corrosion test shall be performed as a preproduction 15.1 austenitic stainless steel; chloride; fluoride; pH; sili-

test by each manufacturer. The production lot from which the cate; sodium; stress corrosion cracking; thermal insulation

--`,,````,```,,``,``,,,`,,,```,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=Petroliam Nasional Berhad/4397000001

No reproduction or networking permitted without license from IHS Not for Resale, 04/20/2009 20:29:36 MDT

C 795 – 08

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,,````,```,,``,``,,,`,,,```,,

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=Petroliam Nasional Berhad/4397000001

No reproduction or networking permitted without license from IHS Not for Resale, 04/20/2009 20:29:36 MDT

You might also like

- Astm A923 23Document7 pagesAstm A923 23danielrelva100% (1)

- Astm A143a143m.20Document4 pagesAstm A143a143m.20safak kahramanNo ratings yet

- Astm A143Document4 pagesAstm A143asdrecv100% (1)

- Astm G48Document11 pagesAstm G48thedreampower100% (4)

- ASTM C795 Insulation Material For Austenistic SteelDocument3 pagesASTM C795 Insulation Material For Austenistic SteelAbass100% (2)

- ASTM - Tratamientos de PasivacionDocument7 pagesASTM - Tratamientos de PasivacionFrank Herrera RodríguezNo ratings yet

- Astm G 48Document9 pagesAstm G 48nisha_khanNo ratings yet

- Cameroon KoleDocument1 pageCameroon KoleSamNo ratings yet

- C795-08 (2013) Standard Specification For Thermal Insulation For Use in Contact With Austenitic SDocument4 pagesC795-08 (2013) Standard Specification For Thermal Insulation For Use in Contact With Austenitic Snguyen100% (1)

- Astm C795Document4 pagesAstm C795Nacer Kisy100% (1)

- Astm C795 08Document2 pagesAstm C795 08marcelo barrosNo ratings yet

- Thermal Insulation For Use in Contact With Austenitic Stainless SteelDocument4 pagesThermal Insulation For Use in Contact With Austenitic Stainless SteelDave Le Khac DuyenNo ratings yet

- A 923 - 01 Qtkymy0wmqDocument7 pagesA 923 - 01 Qtkymy0wmqPRASANTH PRASANTHNo ratings yet

- C-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingDocument7 pagesC-1767 Standard Specification For Stainless Steel Jacketing For Insulation1e - Insulation CladdingYogalingam ArumugamNo ratings yet

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- A 923Document9 pagesA 923John P KNo ratings yet

- Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsDocument10 pagesDetecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsBaskar VNo ratings yet

- Astm A293-2022Document10 pagesAstm A293-2022CarlosNo ratings yet

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocument7 pagesAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloNo ratings yet

- Astm - A 975Document7 pagesAstm - A 975victorNo ratings yet

- Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsDocument9 pagesDetecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsmaheshNo ratings yet

- Astm A 143 - 03Document3 pagesAstm A 143 - 03Glenys MuñozNo ratings yet

- Astm A967 01Document3 pagesAstm A967 01tecnicostratadosNo ratings yet

- Astm A967Document7 pagesAstm A967Luciano Grassi Kuyven100% (1)

- Flex Gabion Standard ASTM A975-97Document7 pagesFlex Gabion Standard ASTM A975-97Moh Ragil SodikinNo ratings yet

- Astm 143Document3 pagesAstm 143JH_ProjectNo ratings yet

- Astm A967 01Document6 pagesAstm A967 01tecnicostratadosNo ratings yet

- Che Ical Passiv T On Treatmen S or Stain Ess Steel Parts: M A I T F LDocument7 pagesChe Ical Passiv T On Treatmen S or Stain Ess Steel Parts: M A I T F LÖzgür ÇalışkanNo ratings yet

- ASTM A-967-13 Pasivado Inoxidable PDFDocument7 pagesASTM A-967-13 Pasivado Inoxidable PDFmagierezNo ratings yet

- Astm A 923-2014Document9 pagesAstm A 923-2014Mohammed AliNo ratings yet

- Detecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsDocument9 pagesDetecting Detrimental Intermetallic Phase in Duplex Austenitic/Ferritic Stainless SteelsIsmail Tp100% (1)

- Astm A 143 A143m-2007Document3 pagesAstm A 143 A143m-2007Fabio SegattoNo ratings yet

- Nonstructural Steel Framing Members: Standard Specification ForDocument6 pagesNonstructural Steel Framing Members: Standard Specification Forthienbinh.ngnNo ratings yet

- A 950 - A 950M - 99 (Reapproved 2003) PDFDocument5 pagesA 950 - A 950M - 99 (Reapproved 2003) PDFhectoriturbeNo ratings yet

- Testing Cellular Glass Insulation Block: Standard Test Methods ofDocument4 pagesTesting Cellular Glass Insulation Block: Standard Test Methods ofMina RemonNo ratings yet

- C795Document3 pagesC795dinhtung2210No ratings yet

- Boiler WaterDocument6 pagesBoiler WaterAamir NaweedNo ratings yet

- Astm A 967 2005Document7 pagesAstm A 967 2005Marco VeraNo ratings yet

- Copper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDocument4 pagesCopper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDennise ChicaizaNo ratings yet

- Astm A923-2006 PDFDocument10 pagesAstm A923-2006 PDFDhamuNo ratings yet

- ASTM G 48 - 00 - Rzq4ltawDocument10 pagesASTM G 48 - 00 - Rzq4ltawSamuel EduardoNo ratings yet

- Safeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and Procedure For Detecting EmbrittlementDocument4 pagesSafeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and Procedure For Detecting EmbrittlementLucas O. AquinoNo ratings yet

- Measurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method ForDocument5 pagesMeasurement of Corrosion Potentials of Aluminum Alloys: Standard Test Method Formohammed karasnehNo ratings yet

- Hot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceDocument11 pagesHot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceProduction DepartmentNo ratings yet

- D807-05 Standard Practice For Assessing The Tendency of Industrial Boiler Waters To Cause Embrittlement (USBM1 Embrittlement Detector Method)Document6 pagesD807-05 Standard Practice For Assessing The Tendency of Industrial Boiler Waters To Cause Embrittlement (USBM1 Embrittlement Detector Method)ericNo ratings yet

- Steel Sheet, Carbon, Metallic-And Nonmetallic-Coated For Cold-Formed Framing MembersDocument6 pagesSteel Sheet, Carbon, Metallic-And Nonmetallic-Coated For Cold-Formed Framing Membersvuqar0979No ratings yet

- ASTM A123 Galv. DFT RequirementDocument8 pagesASTM A123 Galv. DFT Requirementshoaib1985No ratings yet

- Astm G 47 - 98 - RZQ3LTK4Document6 pagesAstm G 47 - 98 - RZQ3LTK4Samuel EduardoNo ratings yet

- Industrial Anodizing Co Inc A967Document9 pagesIndustrial Anodizing Co Inc A967Daryna KupriianovaNo ratings yet

- Cold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceDocument5 pagesCold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion Resistancewatt_hrNo ratings yet

- Astm C665Document5 pagesAstm C665archwilfredNo ratings yet

- ASTM C764 Mineral Fiber Loose-Fill InsulationDocument5 pagesASTM C764 Mineral Fiber Loose-Fill InsulationMike DukasNo ratings yet

- G 48 - 99 - RZQ4LTK5QQDocument9 pagesG 48 - 99 - RZQ4LTK5QQCordova RaphaelNo ratings yet

- Astm A502 1993Document4 pagesAstm A502 1993Jesse ChenNo ratings yet

- ASTM G35 - 98 (Reapproved 2010)Document3 pagesASTM G35 - 98 (Reapproved 2010)Ali Ali Asjari100% (1)

- Astm B633-19Document8 pagesAstm B633-19sharma.sumeet2290No ratings yet

- IND TB009 Stress Corrosion Cracking of Austenitic Stainless SteelDocument2 pagesIND TB009 Stress Corrosion Cracking of Austenitic Stainless SteelSoren KjaerNo ratings yet

- E1010 16 PDFDocument4 pagesE1010 16 PDFFrancisco PizarroNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Finish Paint Inspection Report: ND ST ND RDDocument2 pagesFinish Paint Inspection Report: ND ST ND RDsusantaNo ratings yet

- BS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress ReportDocument1 pageBS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress Reportsusanta100% (1)

- Deepak Garg 2019.02.1 3 12:01:33 +05'30': Written by Checked byDocument2 pagesDeepak Garg 2019.02.1 3 12:01:33 +05'30': Written by Checked bysusantaNo ratings yet

- Deepak Garg 2019.02.1 3 11:59:07 +05'30': Written by Checked byDocument2 pagesDeepak Garg 2019.02.1 3 11:59:07 +05'30': Written by Checked bysusantaNo ratings yet

- Heat Transfer CompoundDocument2 pagesHeat Transfer CompoundsusantaNo ratings yet

- BS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress ReportDocument1 pageBS-VI Projects For Panipat Refinery - Hydrogen Generation Unit (HGU) Daily Progress ReportsusantaNo ratings yet

- Insulation Schedule Panipat Hgu Reformer: Date:01/11/2019Document3 pagesInsulation Schedule Panipat Hgu Reformer: Date:01/11/2019susantaNo ratings yet

- Design Area Design Area For Units Subcontractor ScopeDocument6 pagesDesign Area Design Area For Units Subcontractor ScopesusantaNo ratings yet

- Description Mark Nos Qty Steel WT Total WT Reformer-1Document18 pagesDescription Mark Nos Qty Steel WT Total WT Reformer-1susantaNo ratings yet

- VRMP Projects - #973 Hgu Reformer Insulation Monthly Completion Plan Project: Reformer Works - HGU-EPCC 6, HPCL, VIZAGDocument1 pageVRMP Projects - #973 Hgu Reformer Insulation Monthly Completion Plan Project: Reformer Works - HGU-EPCC 6, HPCL, VIZAGsusantaNo ratings yet

- Product Data Sheet TIC 9061 Heat Transfer Cement: DescriptionDocument2 pagesProduct Data Sheet TIC 9061 Heat Transfer Cement: DescriptionsusantaNo ratings yet

- Loid Seal 94ADocument1 pageLoid Seal 94AsusantaNo ratings yet

- Introduction To Joining: Joining-Understanding The Basics F.C. Campbell, Editor All Rights ReservedDocument10 pagesIntroduction To Joining: Joining-Understanding The Basics F.C. Campbell, Editor All Rights ReservedKeiNo ratings yet

- Gate 2011 Chemical SyllabusDocument2 pagesGate 2011 Chemical SyllabusVenkyNo ratings yet

- 10em Chem 1 Foundation Chap-1Document46 pages10em Chem 1 Foundation Chap-1Legendary MathematicianNo ratings yet

- Wall Mounted Split Type Air Conditioner: ManualDocument8 pagesWall Mounted Split Type Air Conditioner: ManualMoody MoodyNo ratings yet

- Milling Speeds and Feeds PDFDocument1 pageMilling Speeds and Feeds PDFrobNo ratings yet

- Mems and Nems: The Physics of The Microworld Is Dominated by Surface EffectsDocument39 pagesMems and Nems: The Physics of The Microworld Is Dominated by Surface EffectsroshanNo ratings yet

- Thermal Expansion CalculationsDocument36 pagesThermal Expansion CalculationsAhmad MuzammilNo ratings yet

- 5.00 FD An1 s1 CE Chemistry 23-24Document4 pages5.00 FD An1 s1 CE Chemistry 23-24imsNo ratings yet

- Worksheet (Metals and Non Metals) Subject-Science Grade - ViiiDocument4 pagesWorksheet (Metals and Non Metals) Subject-Science Grade - Viiikatira rashmiNo ratings yet

- Normal Laboratory ValuesDocument2 pagesNormal Laboratory ValuesSBNo ratings yet

- Link Seal ManualDocument28 pagesLink Seal ManualAurva KapoorNo ratings yet

- TIBCDocument2 pagesTIBCFatma Gemala100% (1)

- MODULE 2 ClimatologyDocument23 pagesMODULE 2 ClimatologyRAKSHITHA JAVAGALNo ratings yet

- Kerosine: Standard Specification ForDocument3 pagesKerosine: Standard Specification ForDavid CazorlaNo ratings yet

- 2017 - Green Synthesis of Graphene From Recycled PET Bottle WastesDocument12 pages2017 - Green Synthesis of Graphene From Recycled PET Bottle WastesViviane Zorio PeixotoNo ratings yet

- sp001 5thedition ChecklistsDocument14 pagessp001 5thedition ChecklistsJavier Mauricio Higuera MoraNo ratings yet

- Lithium Battery Storage and HandlingDocument9 pagesLithium Battery Storage and HandlingAhmed HemdanNo ratings yet

- Data SheetDocument3 pagesData Sheetashv1972No ratings yet

- Carbohydrates: There Are Three Classes of Carbohydrates: 1. Monosaccharides 2.disaccharides 3.polysaccharidesDocument3 pagesCarbohydrates: There Are Three Classes of Carbohydrates: 1. Monosaccharides 2.disaccharides 3.polysaccharidesselvasrijaNo ratings yet

- Cement Carb 5Document6 pagesCement Carb 5neyzaNo ratings yet

- International Standard: Safety of Primary and Secondary Lithium Cells and Batteries During TransportDocument7 pagesInternational Standard: Safety of Primary and Secondary Lithium Cells and Batteries During Transportp sangeerthNo ratings yet

- MS 01 180Document88 pagesMS 01 180DucVikingNo ratings yet

- Shafts and Associated Parts: Prof. Dr. Özgen Ümit ÇolakDocument14 pagesShafts and Associated Parts: Prof. Dr. Özgen Ümit ÇolakMücahit EzelNo ratings yet

- Spray Paint Booths Purchasing GuideDocument18 pagesSpray Paint Booths Purchasing Guidefurtan100% (1)

- Up PDFDocument242 pagesUp PDFMandal Ji TeloNo ratings yet

- International - Standard ISO 14175Document3 pagesInternational - Standard ISO 14175Geom_MengoliNo ratings yet

- Lithological Terminology and DefinitionsDocument3 pagesLithological Terminology and DefinitionsJonathan ShimNo ratings yet

- Glossary RubberDocument12 pagesGlossary RubbersabtonluckyNo ratings yet

- Natural Toxins: 1. Toxic Phenolic SubstancesDocument12 pagesNatural Toxins: 1. Toxic Phenolic SubstancesMohamed Bayoumi mohamed100% (1)