Professional Documents

Culture Documents

Pki Series I-Joists Pr-L315 Pinkwood LTD

Pki Series I-Joists Pr-L315 Pinkwood LTD

Uploaded by

Abdurrahman CinarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pki Series I-Joists Pr-L315 Pinkwood LTD

Pki Series I-Joists Pr-L315 Pinkwood LTD

Uploaded by

Abdurrahman CinarCopyright:

Available Formats

PKI Series I-Joists PR-L315

PinkWood Ltd. Revised February 3, 2020

Products: PKI Series I-Joists

PinkWood Ltd., 5929 6th St. NE, Calgary, Alberta, Canada T2K 5R5

(403) 279-3700

www.pinkwood.ca

1. Basis of the product report:

• 2018, 2015, and 2012 International Building Code (IBC): Sections 104.11 Alternative

materials and 2303.1.2 Prefabricated wood I-joists

• 2018 and 2015 International Residential Code (IRC): Sections R104.11 Alternative

materials, R502.1.2, and R802.1.8 (2018 IRC only) Prefabricated wood I-joists

• 2012 IRC: Sections R104.11 Alternative materials and R502.1.4 Prefabricated wood I-

joists

• ASTM D5055-13e1, D5055-13, and D5055-09 recognized by the 2018 IBC and IRC,

2015 IBC and IRC, and 2012 IBC and IRC, respectively

• APA Reports T2014M-11, T2014M-19, T2015M-01A, T2015M-09, T2016M-09, T2016M-

14, T2016M-17, T2016M-38, T2016M-45, T2016M-48, T2016M-51, T2017M-34,

T2019M-24, T2019M-32, and T2019M-54, and other qualification data

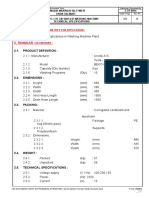

2. Product description:

PKI10, PKI20, PKI23, PKI35Plus, PKI40, and PKI50 Series I-joists, as described in Table 1,

are made with lumber flanges and an OSB web in accordance with the in-plant

manufacturing standard approved by APA.

3. Design properties:

Tables 2 and 3 list the design properties for PKI10, PKI20, PKI23, PKI35Plus, PKI40, and

PKI50 Series I-joists. The allowable spans for PKI Series I-joists covered by this report shall

be in accordance with the recommendations provided by the manufacturer

(www.pinkwood.ca).

4. Product installation:

PKI10, PKI20, PKI23, PKI35Plus, PKI40, and PKI50 Series I-joists shall be installed in

accordance with the recommendations provided by the manufacturer (see link above).

Permissible web holes and cantilever reinforcements shall be in accordance with the

recommendations provided by the manufacturer.

5. Fire-rated assemblies:

Fire-rated assemblies shall be constructed in accordance with the recommendations

provided by the manufacturer (see link above), APA Product Report PR-S315, or APA Fire-

Rated Systems, Form W305 (www.apawood.org/resource-library).

6. Limitations:

a) PKI10, PKI20, PKI23, PKI35Plus, PKI40, and PKI50 Series I-joists shall be designed in

accordance with the code using the design properties specified in this report.

b) PKI10, PKI20, PKI23, PKI35Plus, PKI40, and PKI50 Series I-joists are limited to dry

service conditions where the average equilibrium moisture content of sawn lumber is

less than 16 percent.

c) PKI10, PKI20, PKI23, PKI35Plus, PKI40, and PKI50 Series I-joists are produced at the

PinkWood Ltd. facility in Calgary, Alberta, Canada under a quality assurance program

audited by APA.

© 2020 APA - The Engineered Wood Association 02-03

APA Product Report PR-L315

Revised February 3, 2020 Page 2 of 6

d) This report is subject to re-examination in one year.

7. Identification:

The PKI Series prefabricated wood I-joists described in this report are identified by a label

bearing the manufacturer's name (PinkWood Ltd.) and/or trademark, the APA assigned plant

number (1113), the I-joist depth and series, the APA logo, the report number PR-L315, and

a means of identifying the date of manufacture.

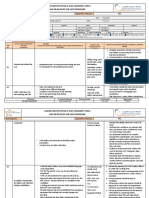

Table 1. Description of PKI Series I-Joists(a)

Flanges Web

Joist

Joist Series Depths Dimension Thickness

(in.) Material Material

Depth (in.) Width (in.) (in.)

Proprietary

PKI10 9-1/2 - 14 1-1/2 2-1/2 OSB 3/8

SPF

Proprietary

PKI20 9-1/2 - 16 1-1/2 2-1/2 OSB 3/8

SPF

Proprietary

PKI23 9-1/2 - 16 1-1/2 2-1/2 OSB 7/16

SPF

Proprietary

SPF and

proprietary

PKI35Plus 9-1/2 - 16 1-1/2 3-1/2 OSB 3/8

Douglas

Fir-Larch

(North)

Proprietary

9-1/2 - 16 1-1/2 3-1/2 OSB 3/8

SPF

PKI40

Proprietary

18 - 24 1-1/2 3-1/2 OSB 7/16

SPF

Proprietary

PKI50 11-7/8 - 24 1-1/2 3-1/2 OSB 7/16

SPF

(a) Referenced dimensions are nominal. Tolerances are as specified in the plant quality manual.

© 2020 APA - The Engineered Wood Association 02-03

APA Product Report PR-L315

Revised February 3, 2020 Page 3 of 6

Table 2. Design Properties (Allowable Stress Design) for PKI Series I-Joists(a)

Joist Joist EI (b) M (c) V (d) VLC (e) K (f)

Depth (in.) Series (106lbf-in.2) (lbf-ft) (lbf) (lbf/ft) (106lbf)

9-1/2 168 2,365 1,260 2,000 4.94

11-7/8 PKI10 286 3,100 1,485 2,000 6.18

14 420 3,720 1,680 2,000 7.28

9-1/2 193 2,810 1,260 2,000 4.94

11-7/8 327 3,755 1,485 2,000 6.18

PKI20

14 479 4,405 1,680 2,000 7.28

16 652 5,060 1,870 2,000 8.32

9-1/2 208 3,330 1,585 2,000 4.94

11-7/8 352 4,320 1,805 2,000 6.18

PKI23

14 515 5,200 2,005 2,000 7.28

16 700 6,030 2,190 2,000 8.32

9-1/2 234 3,395 1,260 2,000 4.94

11-7/8 396 4,395 1,485 2,000 6.18

PKI35Plus

14 580 5,270 1,680 2,000 7.28

16 787 5,990 1,870 2,000 8.32

9-1/2 328 5,390 1,340 2,000 4.94

11-7/8 553 6,970 1,625 2,000 6.18

14 807 8,395 1,875 2,000 7.28

16 1,092 9,730 2,115 2,000 8.32

PKI40

18 1,421 11,005 2,535 1,800 9.36

20 1,799 12,175 2,680 1,600 10.40

22 2,224 13,335 2,815 1,300 11.44

24 2,698 14,480 2,945 1,100 12.48

11-7/8 565 7,955 2,135 2,000 6.18

14 824 9,200 2,280 2,000 7.28

16 1,115 10,655 2,415 2,000 8.32

18 PKI50 1,453 12,770 2,535 1,800 9.36

20 1,839 14,175 2,680 1,600 10.40

22 2,273 14,590 2,815 1,300 11.44

24 2,757 15,845 2,945 1,100 12.48

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 lbf = 4.448 N.

(a) The tabulated values are allowable design values for normal duration of load. All values, except for EI,

K, and VLC shall be permitted to be adjusted for other load durations as permitted by the code.

(b) Bending stiffness (EI) of the I-joist.

(c) Moment capacity (M) of the I-joist, which shall not be increased by any repetitive member use factor.

(d) Shear capacity (V) of the I-joist.

(e) Uniform vertical load capacity (VLC) of the I-joist.

(f) Coefficient of shear deflection (K). For calculating uniform load and center point load deflections of an I-

joist in a simple-span application, use Equations 1 and 2.

5 𝜔𝐿4 𝜔𝐿2

Uniform Load: δ= + [1]

384 𝐸𝐼 𝐾

𝑃𝐿3 2 𝑃𝐿

Center-Point Load: δ= + [2]

48 𝐸𝐼 𝐾

Where: = calculated deflection (in.), = uniform load (lbf/in.)

P = concentrated load (lbf), L = design span (in.)

EI = bending stiffness of the I-joist (lbf-in.2), and K = coefficient of shear deflection (lbf)

© 2020 APA - The Engineered Wood Association 02-03

APA Product Report PR-L315

Revised February 3, 2020 Page 4 of 6

Table 3. Reaction Capacities (Allowable Stress Design) for PKI Series I-Joists(a,b,c,d)

End Reaction(lbf) Intermediate Reaction (lbf)

Flange

1-1/2 in. or 2-1/2 in.(e) 3-1/2 in. or 4 in.(f) 3-1/2 in. 5-1/2 in.

Joist Bearing

Joist Series Brg. Length Brg. Length Brg. Length Brg. Length

Depth (in.) Capacity

w/o Brg. w/Brg. w/o Brg. w/Brg. w/o Brg. w/Brg. w/o Brg. w/Brg.

(lbf/in.)

Stiffeners Stiffeners Stiffeners Stiffeners Stiffeners Stiffeners Stiffeners Stiffeners

9-1/2 900 1,140 1,110 1,260 2,195 2,280 2,450 2,520

11-7/8 PKI10 900 1,275 1,160 1,485 2,195 2,485 2,525 2,810 955

14 900 1,395 1,200 1,680 2,195 2,665 2,585 2,960

9-1/2 970 1,140 1,110 1,260 2,195 2,375 2,450 2,635

11-7/8 970 1,275 1,160 1,485 2,330 2,525 2,595 2,830

PKI20 955

14 970 1,395 1,200 1,680 2,455 2,665 2,725 3,005

16 970 1,510 1,240 1,870 2,570 2,795 2,850 3,175

9-1/2 1,050 1,430 1,350 1,500 2,410 2,770 2,850 3,210

11-7/8 1,050 1,470 1,435 1,680 2,410 2,770 2,850 3,280

PKI23 1,180

14 1,050 1,505 1,485 1,845 2,410 2,770 2,850 3,340

16 1,050 1,540 1,500 2,000 2,410 2,770 2,850 3,400

9-1/2 900 1,140 1,110 1,260 2,195 2,280 2,450 2,520

11-7/8 900 1,275 1,160 1,485 2,195 2,485 2,525 2,810

PKI35Plus 1,380

14 900 1,395 1,200 1,680 2,195 2,665 2,585 2,960

16 900 1,510 1,240 1,865 2,195 2,880 2,645 3,105

9-1/2 1,185 1,340 1,305 1,340 2,900 3,095 2,940 3,195

11-7/8 1,245 1,510 1,595 1,625 3,025 3,340 3,120 3,515

14 1,280 1,660 1,595 1,875 3,085 3,565 3,280 3,805

16 1,295 1,800 1,595 2,115 3,145 3,775 3,435 4,080

PKI40 1,705

18 1,310 2,060 1,680 2,550 2,850 4,285 3,435 4,970

20 1,310 2,185 1,680 2,640 2,850 4,410 3,435 4,970

22 1,310 2,310 1,680 2,735 2,850 4,530 3,435 4,970

24 1,310 2,440 1,680 2,830 2,850 4,640 3,435 4,970

11-7/8 1,245 1,510 1,595 1,625 3,025 3,340 3,120 3,515

14 1,280 1,660 1,595 1,875 3,085 3,565 3,280 3,805

16 1,295 1,800 1,595 2,115 3,145 3,775 3,435 4,080

18 PKI50 1,310 2,060 1,680 2,550 2,850 4,285 3,435 4,970 1,995

20 1,310 2,185 1,680 2,640 2,850 4,410 3,435 4,970

22 1,310 2,310 1,680 2,735 2,850 4,530 3,435 4,970

24 1,310 2,440 1,680 2,830 2,850 4,640 3,435 4,970

See footnotes on the next page.

© 2020 APA - The Engineered Wood Association 02-03

APA Product Report PR-L315

Revised February 3, 2020 Page 5 of 6

Footnotes to Table 3:

For SI: 1 inch = 25.4 mm, 1 lbf = 4.448 N, 1 lbf/in. = 0.175kN/m

(a)

Reaction capacity shall be limited by the flange bearing capacity or the bearing capacity of the support material, whichever is less. The flange bearing capacity, per inch of bearing

length, is based on the allowable compression perpendicular-to-grain of the I-joist flange, accounting for eased edges.

(b)

Reaction capacity is for normal duration of load and shall be permitted to be adjusted for other load durations provided that the adjusted reaction capacity is not greater than the

flange bearing capacity or the bearing capacity of the support material, which shall not be increased for any load durations.

(c)

Reaction capacity shall be permitted to be increased over that tabulated for the minimum bearing length by linear interpolation of the reaction capacity between the minimum and

maximum bearing lengths. Extrapolation beyond the minimum and maximum bearing lengths is beyond the scope of this table.

(d)

Bearing stiffeners shall be installed in accordance with the recommendations provided by the manufacturer.

(e)

Bearing length = 2-1/2 in. for 18-in. to 24-in. deep PKI40 and PKI50 I-joist series. Bearing length = 1-1/2 in. for all other cases.

(f)

Bearing length = 3-1/2 in. for PKI23 I-joist series. Bearing length = 4 in. for all other cases.

© 2020 APA - The Engineered Wood Association 02-03

APA Product Report PR-L315

Revised February 3, 2020 Page 6 of 6

APA –The Engineered Wood Association is an approved national standards developer

accredited by American National Standards Institute (ANSI). APA publishes ANSI standards

and Voluntary Product Standards for wood structural panels and engineered wood products.

APA is an accredited certification body under ISO/IEC 17065 by Standards Council of Canada

(SCC), an accredited inspection agency under ISO/IEC 17020 by International Code Council

(ICC) International Accreditation Service (IAS), and an accredited testing organization under

ISO/IEC 17025 by IAS. APA is also an approved Product Certification Agency, Testing

Laboratory, Quality Assurance Entity, and Validation Entity by the State of Florida, and an

approved testing laboratory by City of Los Angeles.

APA – THE ENGINEERED WOOD ASSOCIATION

HEADQUARTERS

7011 So. 19th St. ▪ Tacoma, Washington 98466

Phone: (253) 565-6600 ▪ Fax: (253) 565-7265 ▪ Internet Address: www.apawood.org

PRODUCT SUPPORT HELP DESK

(253) 620-7400 ▪ E-mail Address: help@apawood.org

DISCLAIMER

APA Product Report is a trademark of APA – The Engineered Wood Association, Tacoma,

Washington. The information contained herein is based on the product evaluation in accordance

with the references noted in this report. Neither APA, nor its members make any warranty,

expressed or implied, or assume any legal liability or responsibility for the use, application of, and/or

reference to opinions, findings, conclusions, or recommendations included in this report. Consult

your local jurisdiction or design professional to assure compliance with code, construction, and

performance requirements. Because APA has no control over quality of workmanship or the

conditions under which engineered wood products are used, it cannot accept responsibility for

product performance or designs as actually constructed.

© 2020 APA - The Engineered Wood Association 02-03

You might also like

- Fireproofing SpecificationDocument48 pagesFireproofing SpecificationEsteban Castellano100% (12)

- INTERCHANGE 2 - RQUIZ UNITS 13 & 14 - Revisión Del IntentoDocument5 pagesINTERCHANGE 2 - RQUIZ UNITS 13 & 14 - Revisión Del IntentoAURA ARTEAGA100% (4)

- Bells Adjustment Inventory MaterialsDocument13 pagesBells Adjustment Inventory MaterialsArpitha Rao100% (16)

- Ki208 Ki209 Installation Manual PDFDocument26 pagesKi208 Ki209 Installation Manual PDFjackcastelNo ratings yet

- Raiseboring Drill PipesDocument16 pagesRaiseboring Drill Pipesmanuel_plfNo ratings yet

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Document3 pagesHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- Roseburg RFPI® Series I-Joists PR-L259 Roseburg Forest Products CompanyDocument9 pagesRoseburg RFPI® Series I-Joists PR-L259 Roseburg Forest Products CompanyImerNo ratings yet

- Pipe Supports z4Document5 pagesPipe Supports z4alla malikNo ratings yet

- Product End of Life (Eol) Notice: SB300 Micro ATX Board, Sandy Bridge PlatformDocument2 pagesProduct End of Life (Eol) Notice: SB300 Micro ATX Board, Sandy Bridge PlatformWaleed MareeNo ratings yet

- Daily Plan 12 April 2022Document16 pagesDaily Plan 12 April 2022Alfrid ImanuelNo ratings yet

- Kalesnikoff Cross-Laminated Timber Kalesnikoff Mass Timber IncDocument7 pagesKalesnikoff Cross-Laminated Timber Kalesnikoff Mass Timber IncciviliiiNo ratings yet

- BCI Series I-Joists PR-L323 Boise Cascade Wood Products, LLCDocument5 pagesBCI Series I-Joists PR-L323 Boise Cascade Wood Products, LLCImerNo ratings yet

- SpecifierGuide PKJoists CDN v2 Updated 23-06Document7 pagesSpecifierGuide PKJoists CDN v2 Updated 23-06vikas.gautamNo ratings yet

- Singlemode Specifications White Paper PDFDocument2 pagesSinglemode Specifications White Paper PDFQuintal ConfortoNo ratings yet

- Industrial Dehumidifier Flc-Series: Technical SpecificationDocument3 pagesIndustrial Dehumidifier Flc-Series: Technical SpecificationAmmad FazilNo ratings yet

- Uygulama / Responsibilities For Application: 2. Tanimlar / DefinitionsDocument7 pagesUygulama / Responsibilities For Application: 2. Tanimlar / Definitionsmajstor70No ratings yet

- 74821000250SPC0008 - 2 - Support SpecDocument62 pages74821000250SPC0008 - 2 - Support SpecEduardo RateikeNo ratings yet

- IMI Group Requirements PCB Suppliers v2016.1Document10 pagesIMI Group Requirements PCB Suppliers v2016.1sudar1477No ratings yet

- AJS Series I-Joists PR-L310 Boise Cascade Wood Products, LLCDocument8 pagesAJS Series I-Joists PR-L310 Boise Cascade Wood Products, LLCImerNo ratings yet

- 1MRG042112 - en Relion - 670 - 650 - Series - SAM600-IO - Version - 2Document26 pages1MRG042112 - en Relion - 670 - 650 - Series - SAM600-IO - Version - 2Papun Kumar SwainNo ratings yet

- Lubricación Fittings & AccesoriosDocument1 pageLubricación Fittings & AccesoriosRafael JaraNo ratings yet

- Cisco 300 Series Switches Cisco Small Business: Product PresentationDocument38 pagesCisco 300 Series Switches Cisco Small Business: Product PresentationNhan PhanNo ratings yet

- Corrigendum and Revised Price BidDocument58 pagesCorrigendum and Revised Price BidPiyush MahanaNo ratings yet

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDocument6 pagesR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Protfolio Selection Group 2Document7 pagesProtfolio Selection Group 2Dulon DuttaNo ratings yet

- 072-Lightning Protection-Holcim Narogong-6 Apr 2018 PDFDocument2 pages072-Lightning Protection-Holcim Narogong-6 Apr 2018 PDFAvid Abu FatihNo ratings yet

- Fkur Bio Flex Bio Based Biodegradable MultifacetedDocument10 pagesFkur Bio Flex Bio Based Biodegradable MultifacetedShruti SinghNo ratings yet

- R2B-P3-206-02-K-ET-00005 Rev.1 - ENGDocument40 pagesR2B-P3-206-02-K-ET-00005 Rev.1 - ENGarturovcamposNo ratings yet

- Hobart Subarc CatalogDocument2 pagesHobart Subarc CatalogwiNo ratings yet

- Ad 24Document61 pagesAd 24IhsanNo ratings yet

- Structural Analysis - 17 Storey Apartment Building PDFDocument107 pagesStructural Analysis - 17 Storey Apartment Building PDFSimon ManansalaNo ratings yet

- IAB080316 Roof AgreementDocument21 pagesIAB080316 Roof AgreementwalekadebaNo ratings yet

- Presentation Slides - Mark VIEDocument33 pagesPresentation Slides - Mark VIEolegprikhodko2809100% (1)

- Especificación de PinturaDocument52 pagesEspecificación de Pinturadiana laura felix garciaNo ratings yet

- Gland Seal Water SPOOL 1.5": AREA: 3510Document12 pagesGland Seal Water SPOOL 1.5": AREA: 3510JHONATAN RODRIGUEZ VENTONo ratings yet

- VK3502 Quick Response Upright Sprinkler K8.0 (115) : 1. Product IdentificationDocument16 pagesVK3502 Quick Response Upright Sprinkler K8.0 (115) : 1. Product Identificationyjayasanka588No ratings yet

- Assembly ListDocument1 pageAssembly Listionescugabriel10No ratings yet

- 390F L ExcavatorDocument2 pages390F L Excavatorisaac989No ratings yet

- Technical Information ASSET DOC LOC 1543385Document21 pagesTechnical Information ASSET DOC LOC 1543385Alfonso ChNo ratings yet

- Marking Specification For Piping Material IdentificationDocument22 pagesMarking Specification For Piping Material IdentificationarturovcamposNo ratings yet

- KI-202, KI-203, KI-204, KI-205, KI-206 and KI-207 NAV IndicatorDocument30 pagesKI-202, KI-203, KI-204, KI-205, KI-206 and KI-207 NAV IndicatorWimpie Deysel100% (1)

- Irn - GEMSCAB INDUSTRIES LTD - OMTECH ONGC CGS BOKARO 22 23 064 - 9152022 - 9222022ICSE-1250Document1 pageIrn - GEMSCAB INDUSTRIES LTD - OMTECH ONGC CGS BOKARO 22 23 064 - 9152022 - 9222022ICSE-1250QAQC OmtechNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Technical Bulletin For Kwik BoltDocument3 pagesTechnical Bulletin For Kwik BoltAbu Hena Mostofa KamalNo ratings yet

- Report Klinik Aminah MedikaDocument58 pagesReport Klinik Aminah Medikaadhi nathaNo ratings yet

- Cac+ Rac Submittal-A4848Document179 pagesCac+ Rac Submittal-A4848MUBASHIRNo ratings yet

- SHOPPING LA MOLINA LOUVERS 150922 - SubmittalDocument7 pagesSHOPPING LA MOLINA LOUVERS 150922 - SubmittalEduhar Jesus Vasquez FernandezNo ratings yet

- United States Patent: (10) Patent No.: US 6,957,339 B2Document43 pagesUnited States Patent: (10) Patent No.: US 6,957,339 B2Alex MungaiNo ratings yet

- Uitm Adv NetworkDocument18 pagesUitm Adv Networknadiashining_star_56No ratings yet

- Boq - 12jku0190, Mi - MCP - Ancol1 - IbDocument3 pagesBoq - 12jku0190, Mi - MCP - Ancol1 - IbIr VanNo ratings yet

- mc560mm Rev2 - tcm3 102129Document313 pagesmc560mm Rev2 - tcm3 102129lupin30000No ratings yet

- United States Patent: (10) Patent N0.: (45) Date of PatentDocument23 pagesUnited States Patent: (10) Patent N0.: (45) Date of Patentmaulik_20_8No ratings yet

- Proteccion Conta Incendios Hdpe - KWH PipeDocument8 pagesProteccion Conta Incendios Hdpe - KWH PipeYHASMANI SOTELO GARCIANo ratings yet

- 042519-Window SprinklersDocument10 pages042519-Window SprinklersVINOD PAULNo ratings yet

- Brother DCP j100 j105 j132w j152w j172w j200 j245 Parts ManualDocument31 pagesBrother DCP j100 j105 j132w j152w j172w j200 j245 Parts Manuallyndell culturaNo ratings yet

- Mve SC Series Spec SheetDocument2 pagesMve SC Series Spec SheetБранко ЛуковићNo ratings yet

- Uygulama: 2.1. Product DefinitionDocument3 pagesUygulama: 2.1. Product DefinitionEl BashaNo ratings yet

- SNI 4096 2007 EngDocument16 pagesSNI 4096 2007 EngCtr YlNo ratings yet

- Om - Maintenance Building 1 National Power Corporation 7Document7 pagesOm - Maintenance Building 1 National Power Corporation 7ramilreyesNo ratings yet

- Compliance: With IEC EN 61508:2010Document7 pagesCompliance: With IEC EN 61508:2010Mohamed OmarNo ratings yet

- 229 Gs Pulling Tool Pws DsheetDocument1 page229 Gs Pulling Tool Pws DsheetMehdi SoltaniNo ratings yet

- Profile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997From EverandProfile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997No ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- SR-103 APA System Report 103 Use of Wood Structural Panels For Energy-Heel Trusses PDFDocument12 pagesSR-103 APA System Report 103 Use of Wood Structural Panels For Energy-Heel Trusses PDFAbdurrahman CinarNo ratings yet

- W345 APA Performance Rated Rim Boards PDFDocument9 pagesW345 APA Performance Rated Rim Boards PDFAbdurrahman CinarNo ratings yet

- S700 - APA Simple Solutions LVL Beams & Headers PDFDocument2 pagesS700 - APA Simple Solutions LVL Beams & Headers PDFAbdurrahman CinarNo ratings yet

- SR-102 APA System Report 102 APA Simplified Wall Bracing Method PDFDocument15 pagesSR-102 APA System Report 102 APA Simplified Wall Bracing Method PDFAbdurrahman CinarNo ratings yet

- A Guide For Builders, Designers and Plan Reviewers: IRC Wall BracingDocument63 pagesA Guide For Builders, Designers and Plan Reviewers: IRC Wall BracingAbdurrahman CinarNo ratings yet

- Mat 107 Understanding Braced Wall Lines 2018 IrcDocument95 pagesMat 107 Understanding Braced Wall Lines 2018 IrcAbdurrahman CinarNo ratings yet

- Grevious Lateral DesignDocument20 pagesGrevious Lateral DesignAbdurrahman CinarNo ratings yet

- ANSI 405-2018 Standard For Adhesives For Use in Structural Glued Laminated Timber PDFDocument16 pagesANSI 405-2018 Standard For Adhesives For Use in Structural Glued Laminated Timber PDFAbdurrahman CinarNo ratings yet

- Glulam Floor Beams PDFDocument20 pagesGlulam Floor Beams PDFAbdurrahman CinarNo ratings yet

- 5 (Azemin Et Al 2017) Discriminating Factors For Ficus Deltoidea Jack Varieties by HPTLC Coupled With ChemometricsDocument11 pages5 (Azemin Et Al 2017) Discriminating Factors For Ficus Deltoidea Jack Varieties by HPTLC Coupled With ChemometricsAcik AyieNo ratings yet

- 234348199-Plasma-Spray-Coating - 2024-02-23T001110.506Document153 pages234348199-Plasma-Spray-Coating - 2024-02-23T001110.506hinhhits07No ratings yet

- Hunter Tire ChangerDocument4 pagesHunter Tire Changertayyab abbasNo ratings yet

- How To Check Who Are Important People in Your Life, What They Teach You About and Your Past Life Connection With ThemDocument5 pagesHow To Check Who Are Important People in Your Life, What They Teach You About and Your Past Life Connection With ThemDana-Zaza BajicNo ratings yet

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (18) Spacer and Vibration Damper InstallationDocument14 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (18) Spacer and Vibration Damper Installationmohammed tofiqNo ratings yet

- National Compassionate, Respectful and Caring Orientation: Federal Ministry of HealthDocument54 pagesNational Compassionate, Respectful and Caring Orientation: Federal Ministry of Healthtatu100% (1)

- Course Name: Graduate Seminar II Course Code: CR HRS: 2 Instructor: Dawit Amogne Course DescriptionDocument3 pagesCourse Name: Graduate Seminar II Course Code: CR HRS: 2 Instructor: Dawit Amogne Course DescriptionDAWIT AMOGNENo ratings yet

- Statement FebruaryDocument20 pagesStatement Februarysergio andres gutierrez leonNo ratings yet

- Strategic Planning at Sports Organizations: PHD Radovan IliDocument9 pagesStrategic Planning at Sports Organizations: PHD Radovan IliJam MendezNo ratings yet

- 7H0011X0 W&C Tech Handbook Sec 04Document5 pages7H0011X0 W&C Tech Handbook Sec 04Ferran MunyósNo ratings yet

- Rubrics For Class DebateDocument2 pagesRubrics For Class DebateJhun Verano Labrador Jr.No ratings yet

- 50 Sample Is T QB ProblemsDocument19 pages50 Sample Is T QB Problemssupermary405No ratings yet

- Characteristics of CultureDocument2 pagesCharacteristics of CultureBeyoung GamefightNo ratings yet

- Mixture and AlligationDocument42 pagesMixture and AlligationOliver ZadeNo ratings yet

- Five Ways To Drive Experience Led Growth in BankingDocument9 pagesFive Ways To Drive Experience Led Growth in Bankingitzel riveraNo ratings yet

- 2022 Liugong Overseas Warranty Administration General Version) - V2-Final Updated Oct 22Document70 pages2022 Liugong Overseas Warranty Administration General Version) - V2-Final Updated Oct 22frannnnsNo ratings yet

- SOP+ TECNAM P MentorDocument3 pagesSOP+ TECNAM P MentorjonathanaldazmNo ratings yet

- WELD-Electrical Characteristics of An Arc (With Diagram) - MetallurgyDocument4 pagesWELD-Electrical Characteristics of An Arc (With Diagram) - MetallurgypeterNo ratings yet

- Physics Letters B: Rabin Banerjee, Bibhas Ranjan Majhi, Elias C. VagenasDocument4 pagesPhysics Letters B: Rabin Banerjee, Bibhas Ranjan Majhi, Elias C. VagenasahndrashNo ratings yet

- Ch12 The Art of Modelling With SpreadsheetDocument16 pagesCh12 The Art of Modelling With Spreadsheetrajkzo100% (1)

- University of Caloocan City Biglang Awa St. Cor. 11 Avenue Catleya Caloocan City, PhilippinesDocument3 pagesUniversity of Caloocan City Biglang Awa St. Cor. 11 Avenue Catleya Caloocan City, PhilippinesElliorb Yseer NlaatacarNo ratings yet

- 5V/-12V/-15V or Adjustable, High-Efficiency, Low I DC-DC InvertersDocument12 pages5V/-12V/-15V or Adjustable, High-Efficiency, Low I DC-DC InverterscarcavaNo ratings yet

- ExampleDocument2 pagesExampleWarley RochaNo ratings yet

- PSpice TutorialDocument5 pagesPSpice Tutorialchaitanya100% (1)

- Fireworks and Dream Weaver CS3 Under UbuntuDocument2 pagesFireworks and Dream Weaver CS3 Under UbuntuMucahit YilmazNo ratings yet

- Analisa Kelayakan Investasi Pembangunan Ruko Di Kota SurakartaDocument10 pagesAnalisa Kelayakan Investasi Pembangunan Ruko Di Kota SurakartaDante Wahyudariyan DanteNo ratings yet

- Revision of Syzygium IndochinaDocument98 pagesRevision of Syzygium IndochinasasiNo ratings yet