Professional Documents

Culture Documents

AEG Freezer Repair Manual

AEG Freezer Repair Manual

Uploaded by

sidrana7Copyright:

Available Formats

You might also like

- ATI 630 - Technical-Manual TRANSFER PDFDocument88 pagesATI 630 - Technical-Manual TRANSFER PDFpablo86% (7)

- Daikin Print Part ListDocument4 pagesDaikin Print Part ListPriesilia Presley100% (2)

- CELAIR Owner's ManualDocument24 pagesCELAIR Owner's Manualvisio2004100% (1)

- Maytag Neptune StackDocument132 pagesMaytag Neptune StackdanfurlanoNo ratings yet

- Zanussi Zte 285Document67 pagesZanussi Zte 285Augusto Vieira100% (2)

- Technical Training Pointer: For Immediate Attention of Your Service DepartmentDocument21 pagesTechnical Training Pointer: For Immediate Attention of Your Service DepartmentmoiNo ratings yet

- Led Monitor: Service ManualDocument16 pagesLed Monitor: Service ManualabdelkaderNo ratings yet

- Vc9808+ ManualDocument3 pagesVc9808+ ManualJose Dario Soto ParisNo ratings yet

- Mitsubishi U100 ManuaDocument90 pagesMitsubishi U100 Manuapepe1bmNo ratings yet

- Vanguard Twin Cylinder Ohv LC Briggs & StrattonDocument85 pagesVanguard Twin Cylinder Ohv LC Briggs & StrattonKenn Ferro100% (1)

- 07 Kfr-60gw-Na10 Kf-60gw-Na10 Service ManualDocument41 pages07 Kfr-60gw-Na10 Kf-60gw-Na10 Service ManualPedja BekicNo ratings yet

- Mpez-6 Installation Manual - Inline 201007Document8 pagesMpez-6 Installation Manual - Inline 201007api-244989438No ratings yet

- Omegas Plus: Software ManualDocument40 pagesOmegas Plus: Software ManualВіктор ЛялькаNo ratings yet

- Split-Type Air Conditioner: Basic: AQ09RAN (X) SER Model: AQ07 SER Model Code: AQ07TSBN (X) SERDocument56 pagesSplit-Type Air Conditioner: Basic: AQ09RAN (X) SER Model: AQ07 SER Model Code: AQ07TSBN (X) SERСергей Брегеда0% (1)

- Samsung CM1069 Service ManualDocument43 pagesSamsung CM1069 Service ManualKeetykat100% (1)

- Service ManualDocument183 pagesService ManualAnonymous ajQr0qXNo ratings yet

- LG Split Type Air Conditioner Complete Service Manual PDFDocument74 pagesLG Split Type Air Conditioner Complete Service Manual PDFCapitanSalamiNo ratings yet

- Cooling Brochure - September 2008Document16 pagesCooling Brochure - September 2008monique5617No ratings yet

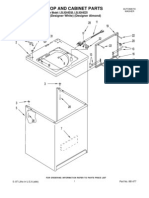

- Whirlpool LSL9244EQ0 Repair Part ListDocument14 pagesWhirlpool LSL9244EQ0 Repair Part ListkenygomezNo ratings yet

- Asko dw20 Dishwasher SerDocument40 pagesAsko dw20 Dishwasher SerChad HenkeNo ratings yet

- Pioneer Gm-A6604 Crt5455Document31 pagesPioneer Gm-A6604 Crt5455boroda2410No ratings yet

- Whirlpool Akm613ix 01Document6 pagesWhirlpool Akm613ix 01Tamo NekoNo ratings yet

- Air Conditioner With Refrigerant R134aDocument178 pagesAir Conditioner With Refrigerant R134aArierep OdariesmeNo ratings yet

- Philips Sdi-Pdp s42sd Yd09 S42ax Yd02 S50hw-Yd01 Repair-ManualDocument64 pagesPhilips Sdi-Pdp s42sd Yd09 S42ax Yd02 S50hw-Yd01 Repair-Manualronald stewNo ratings yet

- Manual AC CompressorDocument56 pagesManual AC CompressorGerman Diego Salazar RosasNo ratings yet

- Design Symbols of Spark PlugsDocument2 pagesDesign Symbols of Spark Plugsbrandon999No ratings yet

- Washing Machine AEG Electrolux ManualDocument40 pagesWashing Machine AEG Electrolux ManualPaulWhitcombe75% (4)

- AF210 Service ManualDocument17 pagesAF210 Service ManualUEENo ratings yet

- EcoTEC Installation and ServicingDocument56 pagesEcoTEC Installation and ServicingMaria Harris100% (1)

- Samsung Washing MachineDocument28 pagesSamsung Washing MachineandreNo ratings yet

- Tensioning Issues On Chevrolet/Daewoo 16V Petrol EnginesDocument4 pagesTensioning Issues On Chevrolet/Daewoo 16V Petrol EnginesChristobal EngelbreitNo ratings yet

- 7 Fridges MinDocument28 pages7 Fridges MinAbdel Hafid LahrecheNo ratings yet

- Service Manual: Chest FreezerDocument21 pagesService Manual: Chest FreezerPedro IzquierdoNo ratings yet

- Master Part September 2021Document2,002 pagesMaster Part September 2021Amrul RamziNo ratings yet

- Manual Refrigerador LGDocument113 pagesManual Refrigerador LGchristian Ramirez DuranNo ratings yet

- WN DS70 Diesel Vibratory RammerDocument3 pagesWN DS70 Diesel Vibratory RammerMolie1979No ratings yet

- MS Gree Aircon Midwall Service Manual PDFDocument55 pagesMS Gree Aircon Midwall Service Manual PDFMacSparesNo ratings yet

- Samsung Microwave TrainingDocument23 pagesSamsung Microwave Trainingbody2030No ratings yet

- SM Auhf12lal Aohb12lall 10 en PDFDocument25 pagesSM Auhf12lal Aohb12lall 10 en PDFpepondeAviles100% (1)

- Fisher-Paykel Disk Was Her Service ManualDocument27 pagesFisher-Paykel Disk Was Her Service ManualjtabelingNo ratings yet

- Electrolux - 1 PDFDocument62 pagesElectrolux - 1 PDFfredjbps@gmail.comNo ratings yet

- Harley Sensor and Motor CodesDocument7 pagesHarley Sensor and Motor Codesmarcus9patricNo ratings yet

- Mig 250c ManualDocument18 pagesMig 250c ManualBondan PratamaNo ratings yet

- Mitsubishi Service ManualDocument48 pagesMitsubishi Service Manualrxp2007No ratings yet

- Ww70j4213iw DC68-03506M-04 SP FQDocument56 pagesWw70j4213iw DC68-03506M-04 SP FQErrorry Jeckson100% (1)

- Automatic Transaxle: SectionDocument754 pagesAutomatic Transaxle: SectionElias SerranoNo ratings yet

- Bosch General Full Manual (90008171786)Document40 pagesBosch General Full Manual (90008171786)Basil Polychronopulos100% (1)

- Delonghi MAgnifica EAM3200Document136 pagesDelonghi MAgnifica EAM3200Claudiu PavelNo ratings yet

- Danfoss Compressors R-134aDocument6 pagesDanfoss Compressors R-134afaizan abbasiNo ratings yet

- SM 25Document144 pagesSM 25Jan Svein HammerNo ratings yet

- SECOP XV Compressor InverterDocument26 pagesSECOP XV Compressor InverterrazvanmstancescuNo ratings yet

- D14131WFDocument47 pagesD14131WFNasir KhanNo ratings yet

- XR 0013 02 Carlyle Conversion GuideDocument36 pagesXR 0013 02 Carlyle Conversion Guidedaniel anayaNo ratings yet

- V236BJ1 P01 InnoLuxDocument29 pagesV236BJ1 P01 InnoLuxAnonymous PDNToMmNmRNo ratings yet

- Service Manual: DryersDocument50 pagesService Manual: DryersnassimNo ratings yet

- Dishwashers: Service ManualDocument37 pagesDishwashers: Service ManualLuc-iano VaderNo ratings yet

- MAN205-0061000EN Rev RDocument139 pagesMAN205-0061000EN Rev RConstantin ZamfirNo ratings yet

- Service Manual: WashingDocument37 pagesService Manual: WashingwidhiantoNo ratings yet

- Mpe Installation, Use and Maintenance ManualDocument56 pagesMpe Installation, Use and Maintenance ManualapeirotanNo ratings yet

- Electrolux CuorseDocument118 pagesElectrolux CuorseDiogo Silva100% (1)

- Solar Cell Efficiency Mapping by LBICDocument6 pagesSolar Cell Efficiency Mapping by LBICSupriya Rai0% (1)

- Design and Simulation of A 100W Pure SinDocument4 pagesDesign and Simulation of A 100W Pure SinZeeshan Khan100% (1)

- Baldor 20H Series ManualDocument99 pagesBaldor 20H Series ManualLODELBARRIO RDNo ratings yet

- Magnetostatics BahanDocument11 pagesMagnetostatics BahanBaho Kristanti HutagalungNo ratings yet

- Vlsi DesignDocument31 pagesVlsi Designajas777BNo ratings yet

- SDVH 20: LVDT Linear Position SensorsDocument4 pagesSDVH 20: LVDT Linear Position Sensorsعلی ربانیNo ratings yet

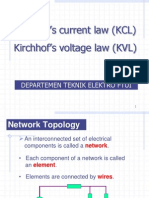

- KCL KVLDocument23 pagesKCL KVLquick_badNo ratings yet

- Xapp024.pdfxilinx XC 3000Document11 pagesXapp024.pdfxilinx XC 3000Rohith RajNo ratings yet

- Applies To:: Curtis PMC 1228 Controller Flash CodesDocument1 pageApplies To:: Curtis PMC 1228 Controller Flash Codesmg victorNo ratings yet

- Zero Speed Switch Working Principle Instrumentation ToolsDocument3 pagesZero Speed Switch Working Principle Instrumentation Toolsersanjeeb_456100% (1)

- Daewoo cn-071Document49 pagesDaewoo cn-071Joel Jácome SantosNo ratings yet

- P2N2222A Amplifier Transistors: NPN SiliconDocument8 pagesP2N2222A Amplifier Transistors: NPN SiliconJuan RamírezNo ratings yet

- Class 12th Physics Sample PaperDocument5 pagesClass 12th Physics Sample PaperAashika DhareNo ratings yet

- Hyundai Led4 InstruccionesDocument5 pagesHyundai Led4 InstruccionesEncep ZaenalNo ratings yet

- 9AKK107318 EN 05-2018 - 20847 - ABB - Technical - Note - IEC - 60034 - 2 - 1 PDFDocument2 pages9AKK107318 EN 05-2018 - 20847 - ABB - Technical - Note - IEC - 60034 - 2 - 1 PDFLeon de RuijterNo ratings yet

- Fast Decoupled State Estimation For Distribution Networks Considering Branch Ampere MeasurementsDocument4 pagesFast Decoupled State Estimation For Distribution Networks Considering Branch Ampere MeasurementsJesus Ortiz LNo ratings yet

- Ps I Unit 2 PPT 2021Document72 pagesPs I Unit 2 PPT 2021Vaishnavi NarreNo ratings yet

- EENGDocument4 pagesEENGrbNo ratings yet

- 700 Welding Soldering UnitDocument3 pages700 Welding Soldering UnitXtians SanchezNo ratings yet

- 1PH813 BeDocument124 pages1PH813 BeRMK BrothersNo ratings yet

- Appendix 1 Transistor)Document6 pagesAppendix 1 Transistor)Achik SniperNo ratings yet

- EPIP20-LT User Manual NewDocument5 pagesEPIP20-LT User Manual NewDeibis Francisco Paredes HurtadoNo ratings yet

- BernardDocument20 pagesBernardandy131078No ratings yet

- The Child-Langmuir Law and AnalyticalDocument14 pagesThe Child-Langmuir Law and AnalyticalVadimJabotinskiNo ratings yet

- Smoke Detector CircuitDocument7 pagesSmoke Detector CircuitAKSHARA SAJEEVNo ratings yet

- Shenzhen Tuofeng Semiconductor Technology Co., LTD: SMD Type MosfetDocument4 pagesShenzhen Tuofeng Semiconductor Technology Co., LTD: SMD Type MosfetАндрей ПоляковNo ratings yet

- Amr - PHD Thesis UCLA 2012 High Frequency Multiphase Clock Generation Using Multipath Oscillators and ApplicationsDocument143 pagesAmr - PHD Thesis UCLA 2012 High Frequency Multiphase Clock Generation Using Multipath Oscillators and ApplicationszhangwenNo ratings yet

- Design of An Electrical Installation of A Storey Building: January 2020Document12 pagesDesign of An Electrical Installation of A Storey Building: January 2020SUNIDHI VERMANo ratings yet

- The Simulation Meteor Shower LED Based On W79E2051 OneDocument2 pagesThe Simulation Meteor Shower LED Based On W79E2051 OneLaurentiu IacobNo ratings yet

AEG Freezer Repair Manual

AEG Freezer Repair Manual

Uploaded by

sidrana7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AEG Freezer Repair Manual

AEG Freezer Repair Manual

Uploaded by

sidrana7Copyright:

Available Formats

SERVICE MANUAL

REFRIGERATION

REFRIGERATORS

© Electrolux Home Products S.p.A. NO FROST

Spares Operations Italy Publication no. TOTAL

Corso lino Zanussi, 30

I - 33080 Porcia (PN)

with

599 38 47-44

Fax +39 0434 394096 ERF2050

EN electronic

S.O.I. DIGITS

Edition: 11.2006

AEG styling

FACTORY: HUY

- ITZAA 1/44 599 38 47-44

CONTENT

1 INTRODUCTION ....................................................................................................................................... 5

2 AIR CIRCULATION.................................................................................................................................... 7

3 REFRIGERATION CIRCUIT...................................................................................................................... 8

4 ELECTRIC WIRING................................................................................................................................... 9

5 COMPONENTS ....................................................................................................................................... 11

5.1 Control panel ................................................................................................................................... 11

5.2 Electronic boards ............................................................................................................................. 12

5.2.1 Power board ERF2050 ........................................................................................................... 13

5.2.2 Display board ERF2000.......................................................................................................... 16

5.3 Cooler compartment ........................................................................................................................ 17

5.3.1 Temperature sensor ............................................................................................................... 18

5.3.2 Door switch ............................................................................................................................. 18

5.3.3 Air flow regulator (damper) ..................................................................................................... 19

5.3.4 Carbon air filter ....................................................................................................................... 19

5.3.5 LED lighting (optional depending on the models) ................................................................... 20

5.4 Freezer compartment ...................................................................................................................... 21

5.4.1 Cold module............................................................................................................................ 22

5.4.2 Thermal switches.................................................................................................................... 22

5.4.3 Cold module fan...................................................................................................................... 23

5.4.4 Defrosting heater .................................................................................................................... 23

5.4.5 Temperature sensor ............................................................................................................... 24

5.4.6 Door switch ............................................................................................................................. 25

5.5 Compressor compartment ............................................................................................................... 25

6 MAIN FUNCTIONS .................................................................................................................................. 26

6.1 Normal ............................................................................................................................................. 26

6.2 Normal with first switching on or power failure ................................................................................ 27

6.3 Defrosting ........................................................................................................................................ 28

6.4 Flow chart for the defrosting management ...................................................................................... 29

6.5 FROSTMATIC Function (rapid freezing) ......................................................................................... 30

6.6 COOLMATIC Function (rapid cooling)............................................................................................. 30

6.7 HOLIDAY Function (valid only for the cooler) .................................................................................. 30

6.8 Malfunctioning of cooler air temperature sensor.............................................................................. 31

6.9 Malfunctioning of freezer temperature sensor ................................................................................. 32

7 ALARMS .................................................................................................................................................. 33

7.1 Freezer compartment temperature alarm ........................................................................................ 33

8 ACCESSIBILITY ...................................................................................................................................... 34

8.1 Freezer compartment ...................................................................................................................... 34

8.1.1 Battery evaporator .................................................................................................................. 34

8.2 Control panel ................................................................................................................................... 38

8.3 Cooler compartment accessibility .................................................................................................... 40

8.3.1 Air flow regulator (damper) ..................................................................................................... 40

8.3.2 LED lighting (optional depending on the models) ................................................................... 41

9 TROUBLESHOOTING............................................................................................................................. 42

9.1 Excessive ice formation on the battery : .......................................................................................... 42

9.2 Failed defrosting: ............................................................................................................................. 42

- ITZAA 2/44 599 38 47-44

10 DISPLAY SYMBOLS ............................................................................................................................... 43

10.1 Cooler compartment ....................................................................................................................... 43

10.2 Freezer compartment ..................................................................................................................... 44

- ITZAA 3/44 599 38 47-44

- ITZAA 4/44 599 38 47-44

1 INTRODUCTION

This manual describes the TOTAL NO FROST refrigerators with ERF2050 DIGITS electronic AEG styling pro-

duced in the Nyíregyháza factory (HUY).

These models feature:

- Total No Frost (no frost freezer, refrigerator no frost)

- free standing

- single-compressor

- electronic control (electronic board ERF2021)

- digit display AEG styling

- air flow regulator (damper)

- LED lighting (optional depending on the model)

They are appliances (CBNF 350, CBNF 390 e CBNF 395) with the following PNCs:

PNC MODEL BRAND

925034004 S75358KG3 AEG-Electrolux

925034005 S75358KG3 AEG-Electrolux

925034006 S75350KG3 AEG-Electrolux

925034007 S75358KG3 AEG-Electrolux

925034026 S75340KG6 AEG-Electrolux

925034027 S75348KG6 AEG-Electrolux

925034030 S75348KG6 AEG-Electrolux

925034203 S75398KG3 AEG-Electrolux

925034204 S75398KG3 AEG-Electrolux

925034205 S75390KG3 AEG-Electrolux

925034206 S75398KG3 AEG-Electrolux

925034226 S75388KG6 AEG-Electrolux

925034228 S75388KG6 AEG-Electrolux

925034402 S75408KG AEG-Electrolux

925034403 S75400KG AEG-Electrolux

The controls of the appliance are inserted into the work top.

The power control board is ERF2050.

The user interface board is ERF2000 (DIGIT display) with AEG styling.

Since it is a single-compressor, it is not possible to switch off only one of the two compartments.

The temperatures regulation is the following:

• from +8 to +2 °C for the cooler

• from -15 to -24 °C for the freezer

The DIGIT display enables to show the temperatures of the two compartments.

- ITZAA 5/44 599 38 47-44

The appliance has the following functions:

• rapid freezing

• rapid cooling

• freezer temperature alarm

• cooler compartment holiday

The appliance consists of the following compartments:

• freezer;

• cooler;

The evaporating circuit consists of:

• cold module (freezer compartment);

Key:

A = control panel

B = cooler compartment (No Frost)

C = cold module

D = freezer compartment (No Frost)

- ITZAA 6/44 599 38 47-44

2 AIR CIRCULATION

Unlike in the PARTIAL NO FROST refrigerator, in the TOTAL type the cooler and the freezer communicate

each other, therefore, the battery evaporator cools both compartments.

The cold produced by the battery evaporator in the freezer compartment, is distributed by the fan F placed be-

hind the cold module.

Cooler compartment air flow: the cold air is pushed by the fan into the foamed duct and exits from the air flow

regulator (damper) E located in the rear part of the diffuser-lamp holder.

The air returns in the freezer compartment by means of some foamed ducts entering the air vent grids G.

Freezer compartment air flow: the cold air is pushed into the compartment through the air screen and returns

into the cold module through the front air vent grid.

In case of opening of the freezer or cooler door the fan stops.

To simulate the door closed use a magnet and put it next to the reed element located in

the electronic board or push the freezer door button.

- ITZAA 7/44 599 38 47-44

3 REFRIGERATION CIRCUIT

Key:

1. compressor;

2. condenser;

3. anti-condensation coil;

4. dehydrator filter;

5. capillary;

6. battery evaporator (freezer compartment);

7. exchanger.

- ITZAA 8/44 599 38 47-44

4 ELECTRIC WIRING

(Check the specific diagram for each model!)

- ITZAA 9/44 599 38 47-44

Key:

1. connection box

3. compressor

5. motor protector

9. defrosting heater

13. lamp

16. freezer door switch

19. ON/OFF switch

24. fan

26. safety thermal switch (+40 °C)

27. defrosting cut-out switch (+8 °C)

41. electronic board ERF 2050

52. air flow regulator (damper)

56. cooler air temperature sensor (cable colour: brown)

57. freezer air temperature sensor (cable colour: white)

67. LED electronic board (optional)

a. yellow-green

b. brown

c. blue

d. white

e. black

- ITZAA 10/44 599 38 47-44

5 COMPONENTS

5.1 Control panel

Key:

Cooler compartment

A. ON/OFF button

B. cooler temperature increase button (+)

C. cooler temperature displaying

D. cooler temperature decrease button (-)

E. COOLMATIC function button (rapid cooling)

F. COOLMATIC function pilot lamp (rapid cooling)

Freezer compartment

G. FROSTMATIC function pilot lamp (rapid freezing)

H. FROSTMATIC function button (rapid freezing)

I. freezer temperature increase button (+)

J. freezer temperature displaying

K. freezer temperature decrease button (-)

L. alarm deactivation button

M. alarm pilot lamp

- ITZAA 11/44 599 38 47-44

5.2 Electronic boards

The electronic board of the appliance consists of:

1. power board ERF2050

2. display board ERF2000

The two electronic boards are connected by means of a flat cable with a connector; therefore, the two boards

are available singularly as spare part.

- ITZAA 12/44 599 38 47-44

5.2.1 Power board ERF2050

- View of the electronic board (side of components):

1. earth contact

2. free

3. line

4. compressor

5. neutral

6. lamp neutral

7. lamp

8. defrosting heater neutral

9. defrosting heater

1. fan line

2. fan neutral

- ITZAA 13/44 599 38 47-44

1. free

2. free

3. LED light board (+) (optional)

4. LED light board (-) (optional)

5. damper

6. damper

7. damper

8. damper

1. free

2. free

1. cooler air temperature sensor

2. cooler air temperature sensor

3. free

4. free

5. freezer air temperature sensor

6. freezer air temperature sensor

- ITZAA 14/44 599 38 47-44

1. free

2. free

3. free

4. free

1. free

2. free

3. freezer door switch

4. freezer door switch

- ITZAA 15/44 599 38 47-44

5.2.2 Display board ERF2000

Key:

SW1 = reed element

SW3 = cooler temperature increase button (+)

SW4 = cooler temperature decrease button (-)

SW5 = COOLMATIC function button (rapid cooling)

SW7 = freezer temperature increase button (+)

SW8 = freezer temperature decrease button (-)

SW9 = FROSTMATIC function button (rapid freezing)

SW10 = alarm deactivation button

DISP1 = cooler display

DISP2 = freezer display

LD2 = + sign pilot lamp

LD3 = COOLMATIC function pilot lamp (rapid cooling)

LD5 = - sign pilot lamp

LD6 = FROSTMATIC function pilot lamp (rapid freezing)

LD7 = alarm pilot lamp

- ITZAA 16/44 599 38 47-44

5.3 Cooler compartment

Key:

1. cooler door magnet

2. display board reed element

3. air flow regulator (damper)

4. carbon air filter

5. LED lighting (optional depending on the model)

A. cooler air temperature sensor

- ITZAA 17/44 599 38 47-44

5.3.1 Temperature sensor

1 NTC sensor detects the temperature of the cooler:

• cooler air temperature sensor (placed inside the right air vent grid)

The cooler air temperature sensor is used both to control the appliance by means of the air flow regulator

(damper) and to display the cooler compartment temperature.

The sensor A has the foamed cable inside the cabinet, therefore it is not replaceable (for further information

please see Service Bulletin 599374122).

5.3.2 Door switch

The battery evaporator defrosting is driven by the electronic board and depends also on the detection of the

opening of the doors.

The detection of the opening of the cooler door is carried out by means of:

• magnetic switch for the cooler door control (located on the display board inserted into the work top)

The magnetic switch for the cooler door control is activated by a magnet located inside the cooler door.

The magnetic switch controls also the switching on of the lamp and of the LED lighting if featured (optional de-

pending on the models).

- ITZAA 18/44 599 38 47-44

5.3.3 Air flow regulator (damper)

The temperature regulation of the cooler compartment occurs by means of the passage or not of cold air from

the damper, which can have only 2 fixed positions, opened or closed.

The air flow regulator (damper) 1 is located inside the diffuser lamp holder 2.

The damper consists of a door and a stepping motor and it is connected to the electric wiring by means of a 4-

pole connector.

5.3.4 Carbon air filter

The carbon air filter 1 is located inside the door 2 indicated in the figure.

The door must be always closed during the operation of the appliance.

- ITZAA 19/44 599 38 47-44

5.3.5 LED lighting (optional depending on the models)

The LED lighting is obtained by means of a electronic board ERFL100.

The electronic board is placed inside the air diffuser and is connected to the electric wiring through a 3-pole

connector.

The voltage of the electronic board is 18 VDC (direct current).

- ITZAA 20/44 599 38 47-44

5.4 Freezer compartment

1. freezer door button

2. cold module

A. freezer air temperature sensor

- ITZAA 21/44 599 38 47-44

5.4.1 Cold module

1. thermal switches

2. cold module fan

3. cold module defrosting heater

5.4.2 Thermal switches

The thermal cut-outs are positioned in direct contact with the battery evaporator.

They switch off the defrosting heater respectively at:

• +8 °C cut-out defrosting switch (wire colour: black - blue)

• +40 °C cut-out safety switch (wire colour: black - white)

TYPE OF THERMAL OVERLOAD CUT-IN TEMPERATURE

CUT-OUT OPENING CLOSING

DEFROSTING + 8 °C - 5 °C

SAFETY + 40 °C + 30 °C

- ITZAA 22/44 599 38 47-44

5.4.3 Cold module fan

The fan is located behind the cold module.

The air is intaken by the fan, therefore, in case of its replacement, ensure that the air is forced towards the cell

bottom.

The fan has the following characteristics:

- voltage 240 V

- power 3,1 W

- speed 2000 rpm

The fan stops in case of opening of the freezer door or of the cooler door.

To simulate the door closed, use a magnet and put it next to the magnetic sensor

located on the electronic board or push the freezer door button.

5.4.4 Defrosting heater

The defrosting heater is used to defrost the ice that has accumulated on the battery evaporator.

The balancing heater has the following values:

- power 240 W

- voltage 240 V

- resistance 240 Ohm

- ITZAA 23/44 599 38 47-44

5.4.5 Temperature sensor

1 NTC sensor detects the temperature of the freezer compartment:

• freezer air temperature sensor (located inside the freezer cell)

The freezer air temperature sensor is used both to control the appliance by means of the fan and the compres-

sor and to display the freezer compartment temperature.

The sensor S has the foamed cable inside the cabinet, therefore it is not replaceable (for further information

please see Service Bulletin 599374122).

- ITZAA 24/44 599 38 47-44

5.4.6 Door switch

The battery evaporator defrosting is driven by the electronic board and depends also on the detection of the

opening of the freezer door by means of:

• a button for the freezer door control (located on the left side of the cold module).

Freezer door button

5.5 Compressor compartment

Key:

A. connections box

B. compressor

The connections box is located in the compressor compartment to connect the various electrical components.

- ITZAA 25/44 599 38 47-44

6 MAIN FUNCTIONS

6.1 Normal

Warning: Unplug the appliance before operating.

In case of first switching on with a freezer compartment temperature higher than 10 °C, the appliance operates

with a test cycle (for the factory) for a maximum time of about 1,5 hours.

In this period do not check the correct functioning of the appliance, since the loads are activated only for internal

check (compressor, fan and defrosting heater).

When the appliance is off then:

• the compressor is off

• the displays are off

Pushing the ON/OFF button, the displays switch on with the following displaying:

• + symbol on cooler display

• flashing digits of the freezer

• freezer compartment temperature alarm (buzzer active)

Push the alarm deactivation button to deactivate the buzzer.

Regulate the temperatures of the compartments so as to set the following values:

• about +5 °C in the cooler

• about -18 °C in the freezer

In NOFROST freezers, the humidity inside the freezer compartment accumulates on the evaporator battery

thanks to the air circulation, thus preventing the formation of frost on food.

During normal operation time the electronic board powers the compressor (3) and the fan (24) circuits.

The fan is activated or deactivated with a 2 minute delay compared to the compressor.

The operation time which corresponds to the interval between the following defrosting lasts about 14 hours with

normal opening of the door (it can last up to 72 hours if the doors are never opened!).

The arrows in the picture indicate the current path.

- ITZAA 26/44 599 38 47-44

6.2 Normal with first switching on or power failure

In case of fault when the appliance is switched on for the first time or in case of a power failure, one of the two

conditions described below occurs:

1. If the internal temperature is higher or the same as the sensor cut-in temperature (CUT-IN), when the power

is restored, the electronic board activates the compressor and the fan till the set temperature is reached and

after 5 hours the electronic board activates the defrosting procedure (after the compressor cut-out)

2. If the internal temperature is lower than the sensor cut-in temperature (CUT-IN), when the power is restored,

the compressor functions in thermostatic conditions and after 5 hours the electronic board activates the de-

frosting procedure (after the compressor cut-out)

The electronic board activates, in any case, the defrosting procedure 5 hours after the first switching on and

after a power failure.

- ITZAA 27/44 599 38 47-44

6.3 Defrosting

All the humidity in the compartment accumulates on the evaporator, which is the coldest part of the compart-

ment; periodically, about every 14 hours with normal door opening (up to 72 hours if the doors never open!), it

is then necessary to defrost the ice on the battery.

The defrosting starts after the compressor cut-out or if the compressor is on after 2,5 hours max.

The electronic board immediately disconnects the circuit which powers the compressor (3) after 2 minutes the

fan (24), waits 3 minutes and then it powers the circuit of the defrosting heater (9) for a minimum time of about

20 minutes.

The heat generated by the defrosting heater does not affect the freezer compartment temperature or the food

packages temperature, because the thermal energy is consumed in the defrosting process of the evaporator

ice.

After 20 minutes, the electronic board checks the state of the thermal switch (27) every minute to detect the

cut-out.

When the defrosting switch cuts-out, and anyway after 20 minutes, the electronic board switches the compres-

sor on (3) with a 5 minute delay.

After 3 minute delay, when the air is already cold, the fan switches on too (24).

If for any reason, the defrosting cut-out switch (27) does not switch on and the battery temperature rises up to

40 °C, the defrosting heater (9) will be switched off by the safety thermal switch (26).

If 1 hour after the starting of the defrosting, the thermal switches did not cut out, the electronic board switches

the defrosting heater off and continues its operation.

The arrows in the picture indicate the current path.

- ITZAA 28/44 599 38 47-44

6.4 Flow chart for the defrosting management

START

More than 5 h elapsed after power on &

compressor off or compressor on for more

than 2,5 h?

no

yes

DEFROSTING

Resetting door accumulated timer

no

More than 14 h elapsed after

SUPER function activated?

the last defrosting?

no yes

yes

More than 14 h elapsed after the last

defrosting & cooler or freezer door is open DEFROSTING

from more than 6 minutes?

yes

no

More than 14 h elapsed after the last

defrosting & comp on for more than 2,5 h?

yes

no

More than 30 h elapsed after the last

defrosting & cooler or freezer door is open

from more than 1 minute?

yes

no

More than 72 h elapsed after the last

defrosting?

no yes

DEFROSTING

- ITZAA 29/44 599 38 47-44

6.5 FROSTMATIC Function (rapid freezing)

The FROSTMATIC function (rapid freezing) is activated by pushing the relative button, therefore:

• The pilot lamp relative to the FROSTMATIC function lights up;

• The compressor operates in thermostatic conditions and not continuously (like the temperature knob was

on max. position) for a duration of about 52 hours, and then it deactivates automatically.

To deactivate the FROSTMATIC function push the relative button.

With the FROSTMATIC function some fixed defrosting can occur anyway depending on how much time has

elapsed after the last defrosting.

6.6 COOLMATIC Function (rapid cooling)

The COOLMATIC function (rapid cooling) is activated by pushing the relative button, therefore:

• The pilot lamp relative to the COOLMATIC function lights up;

• The compressor operates in thermostatic conditions and not continuously (like the temperature knob was

on max. position) for a duration of about 6 hours, and then it deactivates automatically.

To deactivate the COOLMATIC function push the relative button.

6.7 HOLIDAY Function (valid only for the cooler)

The HOLIDAY function is activated when the customer does not want to use temporary the cooler.

In this case it is not necessary to leave the cooler door open, because a 15 °C temperature is automatically set

to avoid the formation of bad odours inside.

To activate the HOLIDAY function push button + (temperature increase) till letter H is shown in the cooler dis-

play.

Obviously the cooler must be empty because the 15 °C temperature does not allow the preservation of the most

common food.

- ITZAA 30/44 599 38 47-44

6.8 Malfunctioning of cooler air temperature sensor

If during the normal operation a failure occurs to the cooler NTC temperature sensor (the signal coming from

the sensor is out of range), then:

• The display shows cooler temperature sensor faulty.

• The air flow regulator (damper) operates as follows:

- open when the compressor is on

- closed when the compressor is off.

• The defrosting procedure is activated every about 10 hours.

When the sensor operates again normally, the above described conditions terminate.

Characteristics of the NTC sensor:

- ITZAA 31/44 599 38 47-44

6.9 Malfunctioning of freezer temperature sensor

If during the normal operation a failure occurs to the freezer NTC temperature sensor (the signal coming from

the sensor is out of range), then:

• The display shows freezer temperature sensor faulty.

• The appliance operates with preset cycle when the compressor is powered for 40 minutes and

remains off for 40 minutes alternatively.

• The defrosting procedure is activated every about 10 hours.

Characteristics of the NTC sensor:

- ITZAA 32/44 599 38 47-44

7 ALARMS

7.1 Freezer compartment temperature alarm

When the freezer compartment reaches -11 °C, the temperature alarm activates:

• The display digits flash.

• The temperature alarm pilot lamp light up.

• The buzzer sounds.

Push the alarm deactivation button to deactivate the buzzer.

When normal conditions are reset (after a power failure):

• The acoustic signal deactivates.

• The temperature alarm pilot lamp remains on.

• The display digits still flash.

Pushing the alarm deactivation button:

• The highest temperature reached in the freezer compartment is displayed for 5 minutes.

• The alarm pilot lamp switches off.

• The display digits do not flash anymore.

- ITZAA 33/44 599 38 47-44

8 ACCESSIBILITY

8.1 Freezer compartment

Warning: Disconnect the appliance from the electric power before operating with the

appliance.

8.1.1 Battery evaporator

To access the battery evaporator and its components (fan, defrosting heater, door switch, and thermal switch-

es) perform the following operations in sequence:

a. Remove the freezer drawers.

b. Detach the fan and defrosting heater connectors located inside the connections box (compressor compart-

ment).

c. Cut the wiring fixing tie.

d) Lean the appliance on the rear side (condenser e) Insert a screwdriver into the right hook and

side). release it.

f) Insert a blade inside the F slot and release the g) View of the internal hook.

internal hook.

- ITZAA 34/44 599 38 47-44

h) Lift and pull the air vent grid. i) Unscrew the 2 fixing screws of the air diffuser.

l) Cut the air diffuser pulling and lifting it up. m) Remove the 2 fixing screws of the cold module.

n) Pull backward the cold module support releasing o) View of the rear water drain duct.

the rear water drain duct.

- ITZAA 35/44 599 38 47-44

p) Release the left hook of the defrosting heater. q) Release the right hook of the defrosting heater.

r) Cut the wiring tie of the thermal switches and s) Remove the sealing rubber.

release them from the evaporator.

Note:

The defrosting and cut-out thermal switches (+8 /

+40°C) are connected together, therefore they are

not available as single spare parts.

t) Remove the wiring fixing tie. u) Unplug the connector of the thermal switches.

- ITZAA 36/44 599 38 47-44

v) The heater is fitted to the evaporator by means of w) Remove the fan extracting it from the evaporator

the aluminium ties. support.

In case of replacement of the fan, it is necessary to ensure that the fan draws in air.

x) To remove the freezer door switch. y) Release the door button hook and simultane-

ously pull it backward.

- ITZAA 37/44 599 38 47-44

8.2 Control panel

Warning: Unplug the appliance before operating.

To access the control panel and its components (power/display boards and electric connectors) perform the

following operations:

a) Unscrew the 2 fixing screws of the control panel b) Release the 2 hooks of the control panel insert-

locating under the upper hinges. ing a screwdriver into both its sides.

c) Pull backward the control panel. d) It is possible to access the connectors of the

electronic boards.

- ITZAA 38/44 599 38 47-44

e) View of the electronic board connectors.

- ITZAA 39/44 599 38 47-44

8.3 Cooler compartment accessibility

Warning: Disconnect the appliance from the electric power before operating with the

appliance.

8.3.1 Air flow regulator (damper)

To access the air diffuser and its components (air flow regulator damper and lamp holder) perform the following

operations in sequence:

a) Open the air carbon filter door, release and b) Unscrew the 2 front fixing screws of the lamp

remove it. holder.

c) Uunscrew the 2 upper fixing screws of the lamp d) View of the lamp holder.

holder.

- ITZAA 40/44 599 38 47-44

e) The damper is fitted with 2 screws and is con-

nected to the electric wiring by means of a 4-pole

connector.

8.3.2 LED lighting (optional depending on the models)

To gain access to the LED board, perform the following operations:

a) Remove the LED cover releasing the 2 side b) Remove the LED electronic board releasing the

hooks. upper and lower hooks.

c) View of the 3-pole connector of the LED elec-

tronic board.

- ITZAA 41/44 599 38 47-44

9 TROUBLESHOOTING

Warning: Unplug the appliance before operating.

9.1 Excessive ice formation on the battery :

If the rubber valve remains open, the humid air outside the freezer compartment is ducted inside and it accu-

mulates too much ice on the battery.

The valve remains open if there are foreign bodies or if it looses elasticity; therefore, in the first case the foreign

bodies must be removed, while in the latter the rubber valve must be replaced.

9.2 Failed defrosting:

In case of failed defrosting, the possible causes are:

Sequence POSSIBLE HOW TO CONTROL SOLUTION

no CAUSES

1. The defrosting Unplug the appliance, remove If the resistance value does not

heater is inter- the connector of the heater and correspond to the technical data,

rupted verify with the tester the correct replace the heater

resistance value to the connec-

tor clamps

2. One or both Frost the battery, then detach If the resistance value does not

switches of the the power plug of the appliance, correspond to 0 (zero Ohm)

thermal protectors remove the connector of the replace the thermal switches

are open thermal switches and verify with assembly

the tester the correct resistance

value to the connector clamps

- ITZAA 42/44 599 38 47-44

10 DISPLAY SYMBOLS

10.1 Cooler compartment

DISPLAY DIGITS DESCRIPTION

It indicates the cooler temperature with normal function

NOT FLASHING

[from +2 to +8]

It indicates the HOLIDAY function of the cooler compart-

NOT FLASHING

ment [15 °C]

It indicates the malfunctioning of cooler air temperature

NOT FLASHING

sensor

It indicates incompatibility between the electronic boards

NOT FLASHING

Remedy: check the spare part nos. of the electronic boards

It indicates eeprom parameter writing/reading error

NOT FLASHING Remedy: replace both electronic boards (power and dis-

play)

- ITZAA 43/44 599 38 47-44

10.2 Freezer compartment

DISPLAY DIGITS DESCRIPTION

It indicates the freezer temperature with normal function

NOT FLASHING

[from -15 to -24]

It indicates the malfunctioning of freezer air temperature

NOT FLASHING

sensor

It indicates incompatibility between the electronic boards

NOT FLASHING

Remedy: check the spare part nos. of the electronic boards

It indicates eeprom parameter writing/reading error

NOT FLASHING Remedy: replace both electronic boards (power and dis-

play)

- ITZAA 44/44 599 38 47-44

You might also like

- ATI 630 - Technical-Manual TRANSFER PDFDocument88 pagesATI 630 - Technical-Manual TRANSFER PDFpablo86% (7)

- Daikin Print Part ListDocument4 pagesDaikin Print Part ListPriesilia Presley100% (2)

- CELAIR Owner's ManualDocument24 pagesCELAIR Owner's Manualvisio2004100% (1)

- Maytag Neptune StackDocument132 pagesMaytag Neptune StackdanfurlanoNo ratings yet

- Zanussi Zte 285Document67 pagesZanussi Zte 285Augusto Vieira100% (2)

- Technical Training Pointer: For Immediate Attention of Your Service DepartmentDocument21 pagesTechnical Training Pointer: For Immediate Attention of Your Service DepartmentmoiNo ratings yet

- Led Monitor: Service ManualDocument16 pagesLed Monitor: Service ManualabdelkaderNo ratings yet

- Vc9808+ ManualDocument3 pagesVc9808+ ManualJose Dario Soto ParisNo ratings yet

- Mitsubishi U100 ManuaDocument90 pagesMitsubishi U100 Manuapepe1bmNo ratings yet

- Vanguard Twin Cylinder Ohv LC Briggs & StrattonDocument85 pagesVanguard Twin Cylinder Ohv LC Briggs & StrattonKenn Ferro100% (1)

- 07 Kfr-60gw-Na10 Kf-60gw-Na10 Service ManualDocument41 pages07 Kfr-60gw-Na10 Kf-60gw-Na10 Service ManualPedja BekicNo ratings yet

- Mpez-6 Installation Manual - Inline 201007Document8 pagesMpez-6 Installation Manual - Inline 201007api-244989438No ratings yet

- Omegas Plus: Software ManualDocument40 pagesOmegas Plus: Software ManualВіктор ЛялькаNo ratings yet

- Split-Type Air Conditioner: Basic: AQ09RAN (X) SER Model: AQ07 SER Model Code: AQ07TSBN (X) SERDocument56 pagesSplit-Type Air Conditioner: Basic: AQ09RAN (X) SER Model: AQ07 SER Model Code: AQ07TSBN (X) SERСергей Брегеда0% (1)

- Samsung CM1069 Service ManualDocument43 pagesSamsung CM1069 Service ManualKeetykat100% (1)

- Service ManualDocument183 pagesService ManualAnonymous ajQr0qXNo ratings yet

- LG Split Type Air Conditioner Complete Service Manual PDFDocument74 pagesLG Split Type Air Conditioner Complete Service Manual PDFCapitanSalamiNo ratings yet

- Cooling Brochure - September 2008Document16 pagesCooling Brochure - September 2008monique5617No ratings yet

- Whirlpool LSL9244EQ0 Repair Part ListDocument14 pagesWhirlpool LSL9244EQ0 Repair Part ListkenygomezNo ratings yet

- Asko dw20 Dishwasher SerDocument40 pagesAsko dw20 Dishwasher SerChad HenkeNo ratings yet

- Pioneer Gm-A6604 Crt5455Document31 pagesPioneer Gm-A6604 Crt5455boroda2410No ratings yet

- Whirlpool Akm613ix 01Document6 pagesWhirlpool Akm613ix 01Tamo NekoNo ratings yet

- Air Conditioner With Refrigerant R134aDocument178 pagesAir Conditioner With Refrigerant R134aArierep OdariesmeNo ratings yet

- Philips Sdi-Pdp s42sd Yd09 S42ax Yd02 S50hw-Yd01 Repair-ManualDocument64 pagesPhilips Sdi-Pdp s42sd Yd09 S42ax Yd02 S50hw-Yd01 Repair-Manualronald stewNo ratings yet

- Manual AC CompressorDocument56 pagesManual AC CompressorGerman Diego Salazar RosasNo ratings yet

- Design Symbols of Spark PlugsDocument2 pagesDesign Symbols of Spark Plugsbrandon999No ratings yet

- Washing Machine AEG Electrolux ManualDocument40 pagesWashing Machine AEG Electrolux ManualPaulWhitcombe75% (4)

- AF210 Service ManualDocument17 pagesAF210 Service ManualUEENo ratings yet

- EcoTEC Installation and ServicingDocument56 pagesEcoTEC Installation and ServicingMaria Harris100% (1)

- Samsung Washing MachineDocument28 pagesSamsung Washing MachineandreNo ratings yet

- Tensioning Issues On Chevrolet/Daewoo 16V Petrol EnginesDocument4 pagesTensioning Issues On Chevrolet/Daewoo 16V Petrol EnginesChristobal EngelbreitNo ratings yet

- 7 Fridges MinDocument28 pages7 Fridges MinAbdel Hafid LahrecheNo ratings yet

- Service Manual: Chest FreezerDocument21 pagesService Manual: Chest FreezerPedro IzquierdoNo ratings yet

- Master Part September 2021Document2,002 pagesMaster Part September 2021Amrul RamziNo ratings yet

- Manual Refrigerador LGDocument113 pagesManual Refrigerador LGchristian Ramirez DuranNo ratings yet

- WN DS70 Diesel Vibratory RammerDocument3 pagesWN DS70 Diesel Vibratory RammerMolie1979No ratings yet

- MS Gree Aircon Midwall Service Manual PDFDocument55 pagesMS Gree Aircon Midwall Service Manual PDFMacSparesNo ratings yet

- Samsung Microwave TrainingDocument23 pagesSamsung Microwave Trainingbody2030No ratings yet

- SM Auhf12lal Aohb12lall 10 en PDFDocument25 pagesSM Auhf12lal Aohb12lall 10 en PDFpepondeAviles100% (1)

- Fisher-Paykel Disk Was Her Service ManualDocument27 pagesFisher-Paykel Disk Was Her Service ManualjtabelingNo ratings yet

- Electrolux - 1 PDFDocument62 pagesElectrolux - 1 PDFfredjbps@gmail.comNo ratings yet

- Harley Sensor and Motor CodesDocument7 pagesHarley Sensor and Motor Codesmarcus9patricNo ratings yet

- Mig 250c ManualDocument18 pagesMig 250c ManualBondan PratamaNo ratings yet

- Mitsubishi Service ManualDocument48 pagesMitsubishi Service Manualrxp2007No ratings yet

- Ww70j4213iw DC68-03506M-04 SP FQDocument56 pagesWw70j4213iw DC68-03506M-04 SP FQErrorry Jeckson100% (1)

- Automatic Transaxle: SectionDocument754 pagesAutomatic Transaxle: SectionElias SerranoNo ratings yet

- Bosch General Full Manual (90008171786)Document40 pagesBosch General Full Manual (90008171786)Basil Polychronopulos100% (1)

- Delonghi MAgnifica EAM3200Document136 pagesDelonghi MAgnifica EAM3200Claudiu PavelNo ratings yet

- Danfoss Compressors R-134aDocument6 pagesDanfoss Compressors R-134afaizan abbasiNo ratings yet

- SM 25Document144 pagesSM 25Jan Svein HammerNo ratings yet

- SECOP XV Compressor InverterDocument26 pagesSECOP XV Compressor InverterrazvanmstancescuNo ratings yet

- D14131WFDocument47 pagesD14131WFNasir KhanNo ratings yet

- XR 0013 02 Carlyle Conversion GuideDocument36 pagesXR 0013 02 Carlyle Conversion Guidedaniel anayaNo ratings yet

- V236BJ1 P01 InnoLuxDocument29 pagesV236BJ1 P01 InnoLuxAnonymous PDNToMmNmRNo ratings yet

- Service Manual: DryersDocument50 pagesService Manual: DryersnassimNo ratings yet

- Dishwashers: Service ManualDocument37 pagesDishwashers: Service ManualLuc-iano VaderNo ratings yet

- MAN205-0061000EN Rev RDocument139 pagesMAN205-0061000EN Rev RConstantin ZamfirNo ratings yet

- Service Manual: WashingDocument37 pagesService Manual: WashingwidhiantoNo ratings yet

- Mpe Installation, Use and Maintenance ManualDocument56 pagesMpe Installation, Use and Maintenance ManualapeirotanNo ratings yet

- Electrolux CuorseDocument118 pagesElectrolux CuorseDiogo Silva100% (1)

- Solar Cell Efficiency Mapping by LBICDocument6 pagesSolar Cell Efficiency Mapping by LBICSupriya Rai0% (1)

- Design and Simulation of A 100W Pure SinDocument4 pagesDesign and Simulation of A 100W Pure SinZeeshan Khan100% (1)

- Baldor 20H Series ManualDocument99 pagesBaldor 20H Series ManualLODELBARRIO RDNo ratings yet

- Magnetostatics BahanDocument11 pagesMagnetostatics BahanBaho Kristanti HutagalungNo ratings yet

- Vlsi DesignDocument31 pagesVlsi Designajas777BNo ratings yet

- SDVH 20: LVDT Linear Position SensorsDocument4 pagesSDVH 20: LVDT Linear Position Sensorsعلی ربانیNo ratings yet

- KCL KVLDocument23 pagesKCL KVLquick_badNo ratings yet

- Xapp024.pdfxilinx XC 3000Document11 pagesXapp024.pdfxilinx XC 3000Rohith RajNo ratings yet

- Applies To:: Curtis PMC 1228 Controller Flash CodesDocument1 pageApplies To:: Curtis PMC 1228 Controller Flash Codesmg victorNo ratings yet

- Zero Speed Switch Working Principle Instrumentation ToolsDocument3 pagesZero Speed Switch Working Principle Instrumentation Toolsersanjeeb_456100% (1)

- Daewoo cn-071Document49 pagesDaewoo cn-071Joel Jácome SantosNo ratings yet

- P2N2222A Amplifier Transistors: NPN SiliconDocument8 pagesP2N2222A Amplifier Transistors: NPN SiliconJuan RamírezNo ratings yet

- Class 12th Physics Sample PaperDocument5 pagesClass 12th Physics Sample PaperAashika DhareNo ratings yet

- Hyundai Led4 InstruccionesDocument5 pagesHyundai Led4 InstruccionesEncep ZaenalNo ratings yet

- 9AKK107318 EN 05-2018 - 20847 - ABB - Technical - Note - IEC - 60034 - 2 - 1 PDFDocument2 pages9AKK107318 EN 05-2018 - 20847 - ABB - Technical - Note - IEC - 60034 - 2 - 1 PDFLeon de RuijterNo ratings yet

- Fast Decoupled State Estimation For Distribution Networks Considering Branch Ampere MeasurementsDocument4 pagesFast Decoupled State Estimation For Distribution Networks Considering Branch Ampere MeasurementsJesus Ortiz LNo ratings yet

- Ps I Unit 2 PPT 2021Document72 pagesPs I Unit 2 PPT 2021Vaishnavi NarreNo ratings yet

- EENGDocument4 pagesEENGrbNo ratings yet

- 700 Welding Soldering UnitDocument3 pages700 Welding Soldering UnitXtians SanchezNo ratings yet

- 1PH813 BeDocument124 pages1PH813 BeRMK BrothersNo ratings yet

- Appendix 1 Transistor)Document6 pagesAppendix 1 Transistor)Achik SniperNo ratings yet

- EPIP20-LT User Manual NewDocument5 pagesEPIP20-LT User Manual NewDeibis Francisco Paredes HurtadoNo ratings yet

- BernardDocument20 pagesBernardandy131078No ratings yet

- The Child-Langmuir Law and AnalyticalDocument14 pagesThe Child-Langmuir Law and AnalyticalVadimJabotinskiNo ratings yet

- Smoke Detector CircuitDocument7 pagesSmoke Detector CircuitAKSHARA SAJEEVNo ratings yet

- Shenzhen Tuofeng Semiconductor Technology Co., LTD: SMD Type MosfetDocument4 pagesShenzhen Tuofeng Semiconductor Technology Co., LTD: SMD Type MosfetАндрей ПоляковNo ratings yet

- Amr - PHD Thesis UCLA 2012 High Frequency Multiphase Clock Generation Using Multipath Oscillators and ApplicationsDocument143 pagesAmr - PHD Thesis UCLA 2012 High Frequency Multiphase Clock Generation Using Multipath Oscillators and ApplicationszhangwenNo ratings yet

- Design of An Electrical Installation of A Storey Building: January 2020Document12 pagesDesign of An Electrical Installation of A Storey Building: January 2020SUNIDHI VERMANo ratings yet

- The Simulation Meteor Shower LED Based On W79E2051 OneDocument2 pagesThe Simulation Meteor Shower LED Based On W79E2051 OneLaurentiu IacobNo ratings yet