Professional Documents

Culture Documents

A-2 Test Data For Materials Description A B C: Column AS Column AT Column AU

A-2 Test Data For Materials Description A B C: Column AS Column AT Column AU

Uploaded by

Jitu PatelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A-2 Test Data For Materials Description A B C: Column AS Column AT Column AU

A-2 Test Data For Materials Description A B C: Column AS Column AT Column AU

Uploaded by

Jitu PatelCopyright:

Available Formats

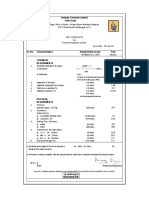

A-2 TEST DATA FOR MATERIALS

Description Cement Admixture 20mm agg. 10mm agg. Sand Limits

a Fineness 1.90 - - - - <10%

b Initial setting Time 182 - - - - >30 min.

c Final setting Time 257 - - - - <600 min.

Comp.Strength 3 Days 27.49 - - - - 23N/mm2

d 7 Days 49.29 - - - - 33N/mm2

28 Days 51.83 - - - - 43N/mm2

e Specific gravity SSD 3.15 1.103 2.735 2.711 2.621 -

f Water absorption - - 0.46% 0.74% 1.33% <2%

g AIV - - 19.64 - <30%

h Flakiness - - 31.2 - <35%

i Zone of sand - - - - II -

j Fineness Modulus of Sand - - - - 2.72 2 to 3.5%

k Silt content - - - - 1.15 <3%

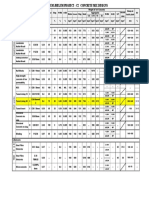

3) All in % Passing Percentage of Different Fraction Spec. As per

Aggregate IS Sieve

I II III 35 % 26 % 39 % IS-383

Mid Limit

Combined % passing Lower Uper

size(mm) CA FA CA FA

limit limit

31.50 100 100 100 35.00 26.00 39.00 100.00 100 100 100

26.50 96.67 100 100 33.83 26.00 39.00 98.83 95.00 90 100

19.00 57.43 100 100 20.10 26.00 39.00 85.10 85.00 75 95

9.50 1.98 76.89 100 0.69 19.99 39.00 59.68 60.00 50 70

4.75 0.15 1.76 98.83 0.05 0.46 38.54 39.05 42.50 30 55

0.600 0.00 0.78 44.99 0.00 0.20 17.55 17.75 19.00 8 30

0.150 0.00 0.70 2.63 0.00 0.182 1.03 1.21 5.00 0 10

0.075 0.00 0.00 1.05 0.00 0 0.41 0.41 1.00 0 2

120.00

100.00

80.00

60.00

% Passing

Column AS

40.00 Column AT

20.00 Column AU

0.00

0.10 1.00 10.00 100.00

1

IS Sieve Size in mm

Contractor's Representative Consultent's Representative

A-3

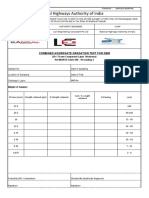

TARGET STRENGTH FOR MIX PROPORTIONING :- 52 N / mm 2 (AS PER MORTH TABLE 1700-5 )

fck + (1.65* s) :- 40+(1.65*6.5)= 51 N/mm2 (AS PER IRC-44 CLAUSE 4.2.2 Table-4)

TARGET FLEXURAL STRENGTH FOR MIX PROPORTIONING

fck + (1.65* s) :- 4.5 + (1.65*0.4) = 5.2

fck +0.55 :- 4.5+0.55 = 5.1

A-4 SELECTION OF WATER-CEMENT RATIO

Based on experience, adopt water-cement ratio 0.350

0.35 = 0.45 hence O.K

A-5 SELECTION OF WATER CONTENT

From Table-2 IS 10262:2009, Maximum water content for 20 mm aggregate = 186 kg / m 3

As High Range water reducing and super plasticizer is used, water content can be reduced up to 30 percent

Based on trial with High Range water reducing and super plasticizer water content rduction of . 24.70 % has been ahived

Hence the arrived water content = { 186.00-(186x24.70 %) }

= 140 kg/m3

A-6 CALCULATION OF CEMENT CONTENT

Water- cement ratio = 0.35

Cement content Water content / Water-Cement ratio

=

= 410 kg / m3

Minimum cement content = 360 kg / m 3 < 400 kg / m3

A-7 PROPORTION OF VOLUME OF COARSE AGGREGATE AND FINE AGGREGATE CONTENT

Fine Aggregate have been considered, for satisfying the all in aggregate gradation and for getting the cohesiveness of mix and the required slump

Therefore volume of coarse aggregate CA 1 = = 0.40 or 25%

Therefore volume of coarse aggregate CA 11 = 0.20 or 15%

Therefore volume of coarse aggregate CA 111 = 0.10 25%

Volume of Fine aggregate FA = Sand or 35%

=

Admixture dosage by weight of cement % kg / m3

= 0.90 ٪ ≈ 3.69

A-8 MIX CALCULATION

a) Volume Of Concrete = 1 m3

b) Volume Of Cement = (Mass of Cement / Specific gravity of Cement) x ( 1/1000 )

= ( 410 / 3.15 x / 1000

= 0.130 m3

c) Volume Of Water = (Mass of Water / Specific gravity of Water) x ( 1/1000 )

= ( 144.00 / 1 ) x 1 / 1000 )

= 0.144 m3

d) Volume Of Admixture = (Mass of Admixture / Specific gravity of Admixturer) x ( 1/1000 )

= ( 3.69 / 1.103 x ( 1 / 1000 )

= 0.003 m3

Contractor's Representative Consultent's Representative

e) Volume Of All in aggregate = {a-( b+c+d )}

= { 1 - ( 0.130 0.144 + 0.0030 ) }

= 0.723 m3

f) Mass of Coarse aggregate (CA 1) = ( Volume of all in aggregate X Volume of Coarse aggregate X

Specific gravity of Coarse aggregate X1000)

= ( 0.723 x 0.25 x 2.735 x 1000 )

= 494.351 kg /m3

g) Mass of Coarse aggregate (CA 11) = ( Volume of all in aggregate X Volume of Coarse aggregate X

Specific gravity of Coarse aggregate X1000)

( 0.723 x 0.15 x 2.785 x 1000 )

= 302.033 kg /m3

g) Mass of Coarse aggregate (CA 111) = ( Volume of all in aggregate X Volume of Coarse aggregate X

Specific gravity of Coarse aggregate X1000)

( 0.723 x 0.25 x 2.776 x 1000 )

= 501.762 kg /m3

g) Mass of fine aggregate = ( Volume of all in aggregate X Volume of Fine aggregate X

Specific gravity of fine aggregate X 1000)

= ( 0.723 x 0.35 x 2.634 x 1000 )

= 666.534 kg /m3

A-9 MIX PROPORTION FOR 1 M3 IN SSD CONDITION

Water(Kg) Cement (Kg) 40 mm agg.( Kg) 20 mm agg.( Kg) 10 mm agg. (Kg) Sand (Kg) Admixtuer (Kg)

144.00 410 494.351 302.033 501.76 666.53 3.690

0.351 1 1.206 0.737 1.224 1.626 0.009

A-10 MIX PROPORTIONS FOR 1 m3 IN DRY CONDITION

Water(Kg) Cement (Kg) 26.5 mm agg.( Kg) 10 mm agg. (Kg) Sand (Kg) Admixtuer (Kg)

3.21 3.81 9.92

157 410 695.579 510.74 736.275 3.600

0.393 1 1.739 1.277 1.841 0.009

A-11 MIX PROPORTION FOR 0.027M3(CUBE CASTING)

Water(Kg) Cement (Kg) 26.5 mm agg.( Kg) 10 mm agg. (Kg) Sand (Kg) Admixtuer (Kg)

3.403 9.720 16.981 12.504 18.133 0.087

Sample No-1 Sample No-2 Sample No-3

Initial Slump mm

:- 70 70 75

After 30 minutes:- mm

40 45 40

After 60 minutes mm

:- 20 30 25

Remarks :- Visual observation for the mix is cohesive cube casting done

A-12 CUBE STRENGTH

Admixt Slump (mm) Visual

28 days Compressive

Grade of Concrete Mix ure After 90 Observation for 7 days Compressive strength N/mm2 Remarks

Stength N/mm2

(%) minutes the mix

0.90 25 Cohesive 46.88 56.30

OK

A-13 FLEXURAL STRENGTH

Admixt Slump (mm) Visual

28 days Compressive

Grade of Concrete Mix ure After 90 Observation for 7 days Compressive strength N/mm2 Remarks

Stength N/mm2

(%) minutes the mix

0.90 25 Cohesive 6.04 7.09

OK

Contractor's Representative Consultent's Representative

You might also like

- Cigre TB 623Document95 pagesCigre TB 623Chris Parkinson100% (3)

- Automatic-M25 Concrete Mix Design As Per Is Code - Excel SheetDocument50 pagesAutomatic-M25 Concrete Mix Design As Per Is Code - Excel Sheetshaik saifulla lNo ratings yet

- 11 KV Ue Heat Shrink Indoor Gtp-1987 R-0Document1 page11 KV Ue Heat Shrink Indoor Gtp-1987 R-0Prasad Yeluripati0% (1)

- National Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Document37 pagesNational Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Rahul Goyal100% (2)

- Principles of Fracture MechanicsDocument49 pagesPrinciples of Fracture MechanicsgodzillafoodNo ratings yet

- International Standard ReferenceDocument14 pagesInternational Standard ReferenceKARTHIGEYAN.RNo ratings yet

- Waffle SlabsDocument14 pagesWaffle SlabsRaju Shrestha50% (2)

- Moisture Correction..02Document2 pagesMoisture Correction..02Er Dnyaneshwar PatilNo ratings yet

- Blending For DLCDocument12 pagesBlending For DLCAjit P. SinghNo ratings yet

- KCC PQC Mix BlendingDocument2 pagesKCC PQC Mix BlendingQuality JamNo ratings yet

- Concrete Mix Design of M-15 (PCC)Document141 pagesConcrete Mix Design of M-15 (PCC)Abhishek SinghNo ratings yet

- Ambuja Cements Limited Unit: DadriDocument1 pageAmbuja Cements Limited Unit: DadriVishal Sharma100% (1)

- Copy of Aggregate Gradation-06-09-2022Document8 pagesCopy of Aggregate Gradation-06-09-2022Bagish Upadhyay UpadhyayNo ratings yet

- Concrete Requisition: Sign of P&M Sign of QC Sign of Project Manager Sign of Site Incharge Incharge EngineerDocument11 pagesConcrete Requisition: Sign of P&M Sign of QC Sign of Project Manager Sign of Site Incharge Incharge EngineerGino BrownNo ratings yet

- M25 Mix Design 100 Recycled AggregateDocument9 pagesM25 Mix Design 100 Recycled AggregateRakesh ReddyNo ratings yet

- Bridge Design Format For Rural Road NQM Project AssamDocument35 pagesBridge Design Format For Rural Road NQM Project Assamarif ahmedNo ratings yet

- BS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesDocument10 pagesBS 1881-116-1983 - Testing Concrete Part 116 - Method For Determination of Compressive Strength of Concrete CubesSarifNo ratings yet

- RMC Plant Calibration 18 Sept. 2021Document4 pagesRMC Plant Calibration 18 Sept. 2021SUNIL JHILMILNo ratings yet

- Soil GSB WMM by Sand Replacement MethodDocument1 pageSoil GSB WMM by Sand Replacement MethodBrahammanand BairwaNo ratings yet

- Blending WMMDocument2 pagesBlending WMMPrasanna S Kulkarni100% (1)

- JMF For BC MixDocument3 pagesJMF For BC MixRakesh DaveNo ratings yet

- Mix DesignDocument1 pageMix Designfaizankhan23No ratings yet

- M45Document6 pagesM45Prakash HitechNo ratings yet

- Concrete Mix Design For - M5: (As Per IS 10262-2019)Document8 pagesConcrete Mix Design For - M5: (As Per IS 10262-2019)mahesh naikNo ratings yet

- Compressive Strength of AAC BlockDocument11 pagesCompressive Strength of AAC BlockImran KhanNo ratings yet

- Test Reports PDFDocument25 pagesTest Reports PDFAbdelhamid ElgasaierNo ratings yet

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNo ratings yet

- Fine Aggregate - M-SandDocument1 pageFine Aggregate - M-SandSudhir Mishra100% (1)

- M25 (PPC)Document2 pagesM25 (PPC)Jagdev GuleriaNo ratings yet

- Mix Design As Per IS 10262-2019Document18 pagesMix Design As Per IS 10262-2019Suchitra PandaNo ratings yet

- DBM Job MixDocument3 pagesDBM Job MixSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- 12 Volumetric AnalysisDocument1 page12 Volumetric AnalysisjitendraNo ratings yet

- Mix Design PQC m40 Opc 53Document7 pagesMix Design PQC m40 Opc 53Dipayan Misra100% (1)

- Silt Factor For Scour Calculation AroundDocument7 pagesSilt Factor For Scour Calculation AroundPrem Dheep100% (1)

- Sieve Analysis of Coarse AggDocument10 pagesSieve Analysis of Coarse AggcaddNo ratings yet

- S 7232 Snow-Boots - SpecsDocument22 pagesS 7232 Snow-Boots - SpecsAshish RawatNo ratings yet

- Cube Test ReportDocument1 pageCube Test ReportSurajit SahaNo ratings yet

- 02 - Part A - Earth WorkDocument32 pages02 - Part A - Earth Workkartick adhikaryNo ratings yet

- Amendment No. 1 November 2019 TO Is 16715: 2018 Ultrafine Ground Granulated Blast Furnace Slag - SpecificationDocument2 pagesAmendment No. 1 November 2019 TO Is 16715: 2018 Ultrafine Ground Granulated Blast Furnace Slag - SpecificationdivithNo ratings yet

- Pumpable Concrete Proposed Combined Aggregates Grading LimitsDocument4 pagesPumpable Concrete Proposed Combined Aggregates Grading LimitsAndrew MwambaNo ratings yet

- Design Mix M 25 PPC - CP2659-41Document2 pagesDesign Mix M 25 PPC - CP2659-41Sathish AnandakumarNo ratings yet

- Combine Flakiness & Elongation TestDocument1 pageCombine Flakiness & Elongation TestFariha AzadNo ratings yet

- SCC m55 Birla Sakthi (Scc-081)Document6 pagesSCC m55 Birla Sakthi (Scc-081)sooricivilNo ratings yet

- D) Gradation of Coarse AggregateDocument6 pagesD) Gradation of Coarse Aggregatechitranjan4kumar-8No ratings yet

- Test of Sand QualityDocument4 pagesTest of Sand QualityJamaludin100% (1)

- IVS Industries M35 50% Crushed Sand GGBSDocument8 pagesIVS Industries M35 50% Crushed Sand GGBSImran KhanNo ratings yet

- Analysis of Road ItemDocument15 pagesAnalysis of Road ItemSHAILENDRANo ratings yet

- Mix Design and Pie Chart RepresentationDocument40 pagesMix Design and Pie Chart RepresentationKuldeep ChakerwartiNo ratings yet

- 42 DBM GradationDocument2 pages42 DBM GradationPrasanna S Kulkarni100% (2)

- 5.fineness of CementDocument2 pages5.fineness of CementRahul Sharma100% (1)

- Inspection Format RoadDocument61 pagesInspection Format Roaddhiraj dNo ratings yet

- Mix Design Calculations - DCIPL M40.Document14 pagesMix Design Calculations - DCIPL M40.AmirNo ratings yet

- Filter Media & Back FillDocument4 pagesFilter Media & Back FillMurthy Babu100% (1)

- Test For Water Bound Macadam Base (WBM) Grade 3 (Sive Analysis of Aggregate)Document9 pagesTest For Water Bound Macadam Base (WBM) Grade 3 (Sive Analysis of Aggregate)Athul Matter LabNo ratings yet

- Design Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutDocument3 pagesDesign Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutMuneer HaiderNo ratings yet

- Paver Block DesignDocument1 pagePaver Block DesignSonti KumarNo ratings yet

- WMM ResultDocument2 pagesWMM Resultbrajesh kumar100% (1)

- Construct BC DBMDocument159 pagesConstruct BC DBMMohd AliNo ratings yet

- Sector Project-Package A:Mahua-Chuwahi RoadDocument6 pagesSector Project-Package A:Mahua-Chuwahi RoadVIMAL TIWARINo ratings yet

- 1 WMM Mix DesignDocument24 pages1 WMM Mix Designyuva_86No ratings yet

- Contractor: G R Infraprojects Ltd. Coating and Stripping of Bitumen Aggregate MixturesDocument1 pageContractor: G R Infraprojects Ltd. Coating and Stripping of Bitumen Aggregate MixturesjitendraNo ratings yet

- M-25 Design MixDocument7 pagesM-25 Design MixAbhishek GoundNo ratings yet

- Grain Size Analysis: Axis TitleDocument4 pagesGrain Size Analysis: Axis Titleajit karandikar100% (1)

- Mix Design For M-35 Pile: Sieve AnalysisDocument5 pagesMix Design For M-35 Pile: Sieve AnalysisAbhinandan JasrotiaNo ratings yet

- Autodesk Robot Structural Analysis Professional 2019 Author: File: Address: Project: StructureDocument4 pagesAutodesk Robot Structural Analysis Professional 2019 Author: File: Address: Project: StructureJocNo ratings yet

- US20010024927A1Document7 pagesUS20010024927A1MahnooshNo ratings yet

- Is 800-2007 (WSD) Crane-1 SpanDocument3 pagesIs 800-2007 (WSD) Crane-1 SpanSuryaSinghNo ratings yet

- Quick Wiring Diagrams - Switches & ReceptaclesDocument8 pagesQuick Wiring Diagrams - Switches & ReceptaclesJon Ricciardi100% (1)

- WK - 14 - Introduction To Design of Built-Up SectionDocument39 pagesWK - 14 - Introduction To Design of Built-Up SectionLilyNo ratings yet

- NR/L2/OHS/00130 Issue 1 Creating A Site of Work Segregated From The RailwayDocument18 pagesNR/L2/OHS/00130 Issue 1 Creating A Site of Work Segregated From The RailwayrimacalNo ratings yet

- Simply Supported Reinforced Concrete Beam Analysis and Design (ACI 318-14)Document33 pagesSimply Supported Reinforced Concrete Beam Analysis and Design (ACI 318-14)Anonymous ARMtmNKL100% (1)

- 3 4 PDFDocument3 pages3 4 PDFMarjoko SantosoNo ratings yet

- Perspective View 1: Proposed St. Anthony de Padua ChapelDocument1 pagePerspective View 1: Proposed St. Anthony de Padua ChapelAyson Nacino Dela CruzNo ratings yet

- ThesisBlandon Jan2008 PDFDocument418 pagesThesisBlandon Jan2008 PDFTheo Alejandro Rojas VivarNo ratings yet

- VARCO October 2013Document48 pagesVARCO October 2013Pumper MagazineNo ratings yet

- V-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkDocument5 pagesV-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkWidya PrasetyaNo ratings yet

- S.P.Catalog TNT600I600GS-3 2020-Ver 200908Document97 pagesS.P.Catalog TNT600I600GS-3 2020-Ver 200908Rjay HayNo ratings yet

- 12L204 X Présentation1Document1 page12L204 X Présentation1suvraNo ratings yet

- John Deere 24 Skid Steer Loader Parts ManualDocument10 pagesJohn Deere 24 Skid Steer Loader Parts ManualiloNo ratings yet

- Explosivo PartesDocument2 pagesExplosivo PartesJOSE INESNo ratings yet

- Lvl30 - Hvac: Refer To The Attached CommentsDocument1 pageLvl30 - Hvac: Refer To The Attached CommentsAnonymous NR3qZ30No ratings yet

- FDI Policy Lao - pdr-1 2010Document35 pagesFDI Policy Lao - pdr-1 2010toulao60No ratings yet

- 3 CP For Bim Esubmission Cs v1-1Document93 pages3 CP For Bim Esubmission Cs v1-1PTchong100% (1)

- LEED V4.1 Score CardDocument1 pageLEED V4.1 Score CardAsad YousafNo ratings yet

- Delhi HaatDocument24 pagesDelhi HaatShubh Katiyar92% (12)

- Brushbond Cool Coat PDFDocument2 pagesBrushbond Cool Coat PDFtrading materialNo ratings yet

- Tutorial Material For Mandatory Basic Safety Training Course (Construction Work)Document22 pagesTutorial Material For Mandatory Basic Safety Training Course (Construction Work)Nirajan MarwaitNo ratings yet

- Lecture 7Document27 pagesLecture 7Tayyab ZafarNo ratings yet

- List of RFI-RFA PENDING MAR 6, 2024Document1 pageList of RFI-RFA PENDING MAR 6, 2024jsla1983.const2No ratings yet

- SB DatasheetDocument4 pagesSB DatasheetMohammad AnwarNo ratings yet