Professional Documents

Culture Documents

STPS40L45C: Low Drop Power Schottky Rectifier

STPS40L45C: Low Drop Power Schottky Rectifier

Uploaded by

sasan hatamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STPS40L45C: Low Drop Power Schottky Rectifier

STPS40L45C: Low Drop Power Schottky Rectifier

Uploaded by

sasan hatamiCopyright:

Available Formats

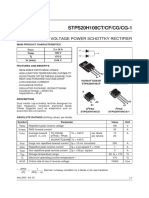

STPS40L45C

Low drop power Schottky rectifier

Datasheet - production data

Description

A1

K Dual center tap Schottky barrier rectifier designed

A2 for high frequency switched mode power supplies

and DC to DC converters.

K Packaged in TO-220AB, TO-247 and D2PAK

these devices are intended for use in low voltage,

high frequency inverters, free-wheeling and

polarity protection applications.

A2

A1

Table 1. Device summary

D2PAK

STPS40L45CG IF(AV) 2 x 20 A

VRRM 45 V

Tj (max) 150° C

VF(max) 0.49 V

A2

A2 K

A1 K A1

TO-220AB TO-247

STPS40L45CT STPS40L45CW

Features

Low forward voltage drop meaning very small

conduction losses

Low switching losses allowing high frequency

operation

Avalanche capability specified

October 2013 DocID6857 Rev 5 1/11

This is information on a product in full production. www.st.com

Characteristics STPS40L45C

1 Characteristics

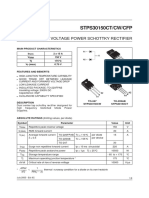

Table 2. Absolute Ratings (limiting values, per diode)

Symbol Parameter Value Unit

VRRM Repetitive peak reverse voltage 45 V

IF(RMS) Forward rms current 30 A

Tc =130° C Per diode 20

IF(AV) Average forward current A

= 0.5 Per device 40

IFSM Surge non repetitive forward current tp = 10 ms Sinusoidal 220 A

IRRM Repetitive peak reverse current tp = 2 µs square F = 1 kHz 2 A

IRSM Non repetitive peak reverse current tp = 100 µs square 3 A

PARM Repetitive peak avalanche power tp = 1 µs Tj = 25° C 8100 W

Tstg Storage temperature range -65 to + 150 °C

Tj (1)

Maximum operating junction temperature 150 °C

dV/dt Critical rate of rise of reverse voltage 10000 V/µs

1.

dPtot

---------------

dTj

-------------------------

1

Rth j – a

- condition to avoid thermal runaway for a diode on its own heatsink

Table 3. Thermal resistances

Symbol Parameter Value Unit

Per diode 1.5

Rth (j-c) Junction to case °C/W

Total 0.8

Rth(c) Coupling 0.1 °C/W

When the diodes 1 and 2 are used simultaneously:

Tj(diode 1) = P(diode1) x Rth(j-c)(Per diode) + P(diode2) x Rth(c).

Table 4. Static electrical characteristics (per diode)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

Tj = 25° C 0.6 mA

IR(1) Reverse leakage current VR = VRRM

Tj = 125° C 140 280 mA

Tj = 25° C IF = 20 A 0.53

Tj = 125° C IF = 20 A 0.42 0.49

VF(1.) Forward voltage drop V

Tj = 25° C IF = 40 A 0.69

Tj = 125° C IF = 40 A 0.6 0.7

1. Pulse test: tp = 380 µs, < 2%

To evaluate the conduction losses use the following equation:

P = 0.28 x IF(AV) + 0.0105 IF2(RMS)

2/11 DocID6857 Rev 5

STPS40L45C Characteristics

Figure 1. Average forward power dissipation Figure 2. Average forward current versus

versus average forward current (per diode) ambient temperature ( = 0.5, per diode)

PF(av)(W) IF(av)(A)

16 22

δ = 0.1 δ = 0.2 δ = 0.5 20

14

δ = 0.05 18 Rth(j-a)=Rth(j-c)

12 16

10 14

δ=1 12

8

10 Rth(j-a)=15°C/W

6 8

T

4 6 T

4

2 IF(av) (A) δ=tp/T tp 2 Tamb(°C)

δ=tp/T tp

0 0

0 2 4 6 8 10 12 14 16 18 20 22 24 0 25 50 75 100 125 150

Figure 3. Normalized avalanche power derating Figure 4. Normalized avalanche power derating

versus pulse duration versus junction temperature

PARM(tp) PARM(Tj)

PARM(1 µs) PARM(25 °C)

1 1.2

0.1 0.8

0.6

0.01 0.4

0.2

tp(µs) Tj(°C)

0.001 0

0.01 0.1 1 10 100 1000 25 50 75 100 125 150

Figure 5. Non repetitive surge peak forward Figure 6. Relative variation of thermal

current versus overload duration (maximum impedance junction to case versus pulse

values, per diode) duration

IM(A) Zth(j-c)/Rth(j-c)

250 1.0

225

200 0.8

175

δ = 0.5

150 0.6

Tc=25°C

125

100 0.4 δ = 0.2

75 Tc=75°C

δ = 0.1 T

50 IM 0.2

t Tc=125°C

25 t(s) Single pulse tp(s)

δ=0.5 δ=tp/T tp

0 0.0

1E-3 1E-2 1E-1 1E+0 1E-4 1E-3 1E-2 1E-1 1E+0

DocID6857 Rev 5 3/11

11

Characteristics STPS40L45C

Figure 7. Reverse leakage current versus Figure 8. Junction capacitance versus reverse

reverse voltage applied (typical values, per voltage applied (typical values, per diode)

diode)

C(nF)

IR(mA)

10.0

1E+3 F=1MHz

Tj=25°C

Tj=150°C

1E+2

Tj=125°C

1E+1 1.0

Tj=75°C

1E+0

1E-1 Tj=25°C

VR(V)

0.1

VR(V) 1 10 100

1E-2

0 5 10 15 20 25 30 35 40 45

Figure 9. Forward voltage drop versus forward Figure 10. Thermal resistance junction to

current (maximum values, per diode) ambient versus copper surface under tab

IFM(A) Rth(j-a) (°C/W)

1000 80

70 Epoxy printed circuit board FR4,

copper thickness: 35 µm

60

100 Typical values 50

Tj=150°C

40

Tj=125°C

30

10

Tj=75°C 20

Tj=25°C

10 S(Cu) (cm²)

VFM(V)

1 0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 0 5 10 15 20 25 30 35 40

4/11 DocID6857 Rev 5

STPS40L45C Package Information

2 Package Information

Epoxy meets UL94,V0

Cooling method: by conduction (C)

Recommended torque value: 0.4 to 0.6 N·m (TO-220AB)

Recommended torque value: 0.55, 1.0 N·m maximum (TO-247)

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK® is an ST trademark.

Figure 11. TO-220AB dimension definitions

E A

Resin gate

∅P F

0.5 mm max.

protrusion(1)

Q

H1

D D1

L20 L30

b1 L1 J1

L

b

e Resin gate c

0.5 mm max.

protrusion(1)

e1

(1) Resin gate position accepted in each of the two

position shown as well as the symmetrical opposites

DocID6857 Rev 5 5/11

11

Package Information STPS40L45C

Table 5. TO-220AB dimension values

Dimensions

Ref. Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.17 0.18

b 0.61 0.88 0.024 0.035

b1 1.14 1.70 0.045 0.067

c 0.48 0.70 0.019 0.027

D 15.25 15.75 0.60 0.62

D1 1.27 typ. 0.05 typ.

E 10 10.40 0.39 0.41

e 2.40 2.70 0.094 0.106

e1 4.95 5.15 0.19 0.20

F 1.23 1.32 0.048 0.052

H1 6.20 6.60 0.24 0.26

J1 2.40 2.72 0.094 0.107

L 13 14 0.51 0.55

L1 3.50 3.93 0.137 0.154

L20 16.40 typ. 0.64 typ.

L30 28.90 typ. 1.13 typ.

P 3.75 3.85 0.147 0.151

Q 2.65 2.95 0.104 0.116

6/11 DocID6857 Rev 5

STPS40L45C Package Information

Figure 12. D2PAK dimension definitions

E

C2

L2

D

L

L3

A1

B2

C R

B

A2

M

* V2

* FLAT ZONE NO LESS THAN 2mm

Table 6. D2PAK dimension values

Dimensions

Ref. Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.173 0.181

A1 2.49 2.69 0.098 0.106

A2 0.03 0.23 0.001 0.009

B 0.70 0.93 0.027 0.037

B2 1.14 1.70 0.045 0.067

C 0.45 0.60 0.017 0.024

C2 1.23 1.36 0.048 0.054

D 8.95 9.35 0.352 0.368

E 10.00 10.40 0.393 0.409

G 4.88 5.28 0.192 0.208

L 15.00 15.85 0.590 0.624

L2 1.27 1.40 0.050 0.055

L3 1.30 1.75 0.051 0.069

M 2.29 2.79 0.090 0.110

R 0.40 typ. 0.016 typ.

V2 0° 8° 0° 8°

DocID6857 Rev 5 7/11

11

Package Information STPS40L45C

Figure 13. D2PAK footprint (dimensions in mm)

16.90

12.2 5.08

2.54

1.60

3.50

9.75

Figure 14. TO-247 dimension definitions

A Heat-sink plane

E

∅P

S ∅R

L2

L1

L b1

b2

1 2 3 3 2 1

b c

A1 BACK VIEW

e

8/11 DocID6857 Rev 5

STPS40L45C Package Information

Table 7. TO-247 dimension values

Dimensions

Ref. Millimeters Inches

Min. Typ. Max. Min. Typ Max.

A 4.85 5.15 0.191 0.203

A1 2.20 2.60 0.086 0.102

b 1.00 1.40 0.039 0.055

b1 2.00 2.40 0.078 0.094

b2 3.00 3.40 0.118 0.133

c 0.40 0.80 0.015 0.031

D(1) 19.85 20.15 0.781 0.793

E 15.45 15.75 0.608 0.620

e 5.30 5.45 5.60 0.209 0.215 0.220

L 14.20 14.80 0.559 0.582

L1 3.70 4.30 0.145 0.169

L2 18.50 typ. 0.728 typ.

P (2)

3.55 3.65 0.139 0.143

R 4.50 5.50 0.177 0.217

S 5.30 5.50 5.70 0.209 0.216 0.224

1. Dimension D plus gate protrusion does not exceed 20.5 mm

2. Resin thickness around the mounting hole is not less than 0.9 mm

DocID6857 Rev 5 9/11

11

Ordering Information STPS40L45C

3 Ordering Information

Table 8. Ordering information

Order code Marking Package Weight Base qty Delivery mode

STPS40L45CG STPS40L45CG D2PAK 1.8g 500 Tape and reel

STPS40L45CT STPS40L45CT TO-220AB 2g 50 Tube

STPS40L45CW STPS40L45CW TO-247 4.4g 30 Tube

4 Revision history

Table 9. Document revision history

Date Revision Description of Changes

Jul-2003 4A Previous version

30-Oct-2013 5 Updated Package information section

10/11 DocID6857 Rev 5

STPS40L45C

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

ST PRODUCTS ARE NOT DESIGNED OR AUTHORIZED FOR USE IN: (A) SAFETY CRITICAL APPLICATIONS SUCH AS LIFE

SUPPORTING, ACTIVE IMPLANTED DEVICES OR SYSTEMS WITH PRODUCT FUNCTIONAL SAFETY REQUIREMENTS; (B)

AERONAUTIC APPLICATIONS; (C) AUTOMOTIVE APPLICATIONS OR ENVIRONMENTS, AND/OR (D) AEROSPACE APPLICATIONS

OR ENVIRONMENTS. WHERE ST PRODUCTS ARE NOT DESIGNED FOR SUCH USE, THE PURCHASER SHALL USE PRODUCTS AT

PURCHASER’S SOLE RISK, EVEN IF ST HAS BEEN INFORMED IN WRITING OF SUCH USAGE, UNLESS A PRODUCT IS

EXPRESSLY DESIGNATED BY ST AS BEING INTENDED FOR “AUTOMOTIVE, AUTOMOTIVE SAFETY OR MEDICAL” INDUSTRY

DOMAINS ACCORDING TO ST PRODUCT DESIGN SPECIFICATIONS. PRODUCTS FORMALLY ESCC, QML OR JAN QUALIFIED ARE

DEEMED SUITABLE FOR USE IN AEROSPACE BY THE CORRESPONDING GOVERNMENTAL AGENCY.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2013 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

DocID6857 Rev 5 11/11

11

You might also like

- STPS20L45C: Low Drop Power Schottky RectifierDocument9 pagesSTPS20L45C: Low Drop Power Schottky RectifierFabio SantanaNo ratings yet

- STPS40170C High Voltage Power Schottky Rectifier Diode PDFDocument8 pagesSTPS40170C High Voltage Power Schottky Rectifier Diode PDFHưng HQNo ratings yet

- STPS640C: Power Schottky RectifierDocument8 pagesSTPS640C: Power Schottky RectifierMax TeleNo ratings yet

- STPS3045C: Power Schottky RectifierDocument13 pagesSTPS3045C: Power Schottky RectifierАлександр ШустовNo ratings yet

- STPS30H100C: 100 V Power Schottky RectifierDocument12 pagesSTPS30H100C: 100 V Power Schottky RectifierPablo AllosiaNo ratings yet

- Hoja ValiosaDocument18 pagesHoja Valiosacarlosjamal95No ratings yet

- 14731Document7 pages14731NORBERTO NEGRETENo ratings yet

- STPS20H 100CTDocument7 pagesSTPS20H 100CTManuel G Medina LopezNo ratings yet

- Schott yDocument8 pagesSchott yDinalba(Formación) El Espíritu Santo ObraNo ratings yet

- Stps 40170 CDocument15 pagesStps 40170 CotnielsaririNo ratings yet

- STPS1545CT/CF/CG: Power Schottky RectifierDocument8 pagesSTPS1545CT/CF/CG: Power Schottky RectifiersuppoNo ratings yet

- STPS20H100C: 100 V Power Schottky RectifierDocument17 pagesSTPS20H100C: 100 V Power Schottky RectifierMiguel GuzmanNo ratings yet

- Probador CCFL-CreatronicaDocument6 pagesProbador CCFL-CreatronicasanlugoNo ratings yet

- STPS80L60CY-ST Diode Kep PDFDocument3 pagesSTPS80L60CY-ST Diode Kep PDFHưng HQNo ratings yet

- STPS20H100CT/CF/CG/CG-1: High Voltage Power Schottky RectifierDocument7 pagesSTPS20H100CT/CF/CG/CG-1: High Voltage Power Schottky RectifierVicente MiróNo ratings yet

- STTH6003: High Frequency Secondary RectifierDocument9 pagesSTTH6003: High Frequency Secondary RectifierTudor ApostuNo ratings yet

- stps20s100cfp SCHOTTKY DIODEDocument7 pagesstps20s100cfp SCHOTTKY DIODEANDREASBOULNo ratings yet

- Stps 30170 CDocument9 pagesStps 30170 CKichin_ANo ratings yet

- STPS15L60C: DescriptionDocument8 pagesSTPS15L60C: DescriptioncqlNo ratings yet

- Byv44 Series PDFDocument7 pagesByv44 Series PDFdraNo ratings yet

- Sf20a400hpi 1Document5 pagesSf20a400hpi 1Federico JaureguiberryNo ratings yet

- Stps 10120 CDocument9 pagesStps 10120 CLEWIS RODRIGUEZNo ratings yet

- Stps 60 H 100 CDocument9 pagesStps 60 H 100 CLexi SNo ratings yet

- STTH1602C: DescriptionDocument15 pagesSTTH1602C: DescriptionAndrea MartinezNo ratings yet

- High Frequency DiodeDocument12 pagesHigh Frequency DiodeCarlos IbaNo ratings yet

- STPS745: Main Product CharacteristicsDocument9 pagesSTPS745: Main Product CharacteristicsQadash NeharaNo ratings yet

- STPS10170C: High Voltage Power Schottky RectifierDocument10 pagesSTPS10170C: High Voltage Power Schottky RectifierRicky Maulana FirdausNo ratings yet

- Borro ToDocument9 pagesBorro TomaugrysNo ratings yet

- STTH6003TV/CW: High Frequency Secondary RectifierDocument7 pagesSTTH6003TV/CW: High Frequency Secondary Rectifierruslan savcaNo ratings yet

- STTH2002C: High Efficiency Ultrafast DiodeDocument16 pagesSTTH2002C: High Efficiency Ultrafast DiodeAseng saputraNo ratings yet

- STTH6003TVPDF 231209 185115Document7 pagesSTTH6003TVPDF 231209 185115Denilson BonifacioNo ratings yet

- STPS80H100CY Schottky RectifierDocument10 pagesSTPS80H100CY Schottky RectifierAnonymous oyUAtpKNo ratings yet

- STPS1045D Eng TdsDocument8 pagesSTPS1045D Eng Tdsjohn9999_502754No ratings yet

- Stps1045b-Y - Schottky DiodeDocument7 pagesStps1045b-Y - Schottky DiodePradeep JaganjyothiNo ratings yet

- WS1219PT W03010560aDocument6 pagesWS1219PT W03010560amimramesNo ratings yet

- STPS10L60CF/CFP: Power Schottky RectifierDocument5 pagesSTPS10L60CF/CFP: Power Schottky RectifierHector Alberto SanchezNo ratings yet

- STPS2045CTCFCGCFPCRDocument8 pagesSTPS2045CTCFCGCFPCROmaraye JoshuaNo ratings yet

- Diodo Rectificador DualDocument5 pagesDiodo Rectificador DualHeriberto VivasNo ratings yet

- STPS20H100C: 100 V, 20 A Power Schottky RectifierDocument19 pagesSTPS20H100C: 100 V, 20 A Power Schottky RectifierTodor NakovNo ratings yet

- STPS80170C: 170 V Power Schottky RectifierDocument9 pagesSTPS80170C: 170 V Power Schottky Rectifiern tanevarNo ratings yet

- Trial TVDocument18 pagesTrial TVronal lopezNo ratings yet

- Data Sheet: BYV42E, BYV42EB SeriesDocument9 pagesData Sheet: BYV42E, BYV42EB SeriesAnthony AndreyNo ratings yet

- STPS30H100CT - DiodoDocument6 pagesSTPS30H100CT - DiodoroberthNo ratings yet

- Stpr620Ct/Cf/Cfp: Ultra Fast Recovery Rectifier DiodesDocument7 pagesStpr620Ct/Cf/Cfp: Ultra Fast Recovery Rectifier DiodestouchmemoryNo ratings yet

- STTH 602 CDocument9 pagesSTTH 602 COmar MelchorNo ratings yet

- STPSC20H12C: 1200 V Power Schottky Silicon Carbide DiodeDocument10 pagesSTPSC20H12C: 1200 V Power Schottky Silicon Carbide DiodeshivguptaNo ratings yet

- Low Drop Power Schottky Rectifier: FeaturesDocument7 pagesLow Drop Power Schottky Rectifier: Featuresyuly paola perea mesaNo ratings yet

- STTH 100 W 06 CDocument8 pagesSTTH 100 W 06 CSandro SachserNo ratings yet

- TN6050-12PI: 60 A, 1200 V Standard SCRDocument11 pagesTN6050-12PI: 60 A, 1200 V Standard SCRluis lopezNo ratings yet

- Stps 30100 STDocument9 pagesStps 30100 STDerkis MarcanoNo ratings yet

- Stps 20 S 100 CDocument12 pagesStps 20 S 100 CEnrico RotaNo ratings yet

- Aukc S A0000240024 1Document5 pagesAukc S A0000240024 1ghbtechabasNo ratings yet

- stps1045b Eng TdsDocument8 pagesstps1045b Eng Tdsjohn9999_502754No ratings yet

- Datasheet Diode Power Schottky Rectifier STPS80L60CY PDFDocument4 pagesDatasheet Diode Power Schottky Rectifier STPS80L60CY PDFHưng HQNo ratings yet

- tn4050hp 12gy tr-2935903Document11 pagestn4050hp 12gy tr-2935903chawkigenieNo ratings yet

- STTH3002CDocument8 pagesSTTH3002Celad kotlovskiNo ratings yet

- Rectifier Diodes BYV32E, BYV32EB Series Ultrafast, Rugged: Features Symbol Quick Reference DataDocument7 pagesRectifier Diodes BYV32E, BYV32EB Series Ultrafast, Rugged: Features Symbol Quick Reference Datajose luisNo ratings yet

- BR 211140Document7 pagesBR 211140Felipe SoffiattiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- MGD623SDocument2 pagesMGD623SMindSet MarcosNo ratings yet

- User Manual: Router Control SystemDocument54 pagesUser Manual: Router Control Systemjhon hernandezNo ratings yet

- Voltage+Regulation (20 Files Merged)Document20 pagesVoltage+Regulation (20 Files Merged)muhammadtahahussian474No ratings yet

- Intel Desktop Borad D915GVWB Product GuideDocument64 pagesIntel Desktop Borad D915GVWB Product GuideArcangelo DI BATTISTANo ratings yet

- Philips FW650C PDFDocument10 pagesPhilips FW650C PDFSamvel YesayanNo ratings yet

- Pyramid DC Power SupplyDocument5 pagesPyramid DC Power SupplyGerardo HernándezNo ratings yet

- MSP 430 FR 6820Document160 pagesMSP 430 FR 6820dbmNo ratings yet

- GT Virtual UART 64 Driver Installation InstructionsDocument11 pagesGT Virtual UART 64 Driver Installation InstructionsLio SnNo ratings yet

- TS906C2 Diodo 12V - 12VDocument4 pagesTS906C2 Diodo 12V - 12VSergio GarciaNo ratings yet

- Spectrum Master Ms2760A: Ultraportable Mmwave Spectrum AnalyzerDocument2 pagesSpectrum Master Ms2760A: Ultraportable Mmwave Spectrum AnalyzerPablo Pereyra SagárnagaNo ratings yet

- Mvi56e MCM MCMXT Um001Document209 pagesMvi56e MCM MCMXT Um001Israel100% (1)

- NPN Silicon Epitaxial Planar Transistor: Semtech Electronics LTDDocument2 pagesNPN Silicon Epitaxial Planar Transistor: Semtech Electronics LTDalexjcc10No ratings yet

- PCB AssemblyDocument16 pagesPCB Assemblynirvan93100% (1)

- IMXRT1050CECDocument93 pagesIMXRT1050CECjxjinNo ratings yet

- Systemmonitoring PerformanceDocument59 pagesSystemmonitoring Performanceakkati123No ratings yet

- J2534 Diagnostic Tool Software:: Vehicle Communication Interfaces (VCI)Document1 pageJ2534 Diagnostic Tool Software:: Vehicle Communication Interfaces (VCI)Hikmah Jevie YusriNo ratings yet

- Diploma in Computer Application (Second Semester) Examination, February 2019Document3 pagesDiploma in Computer Application (Second Semester) Examination, February 2019Kamta Prasad PatelNo ratings yet

- LabInstr EE320L Lab9Document8 pagesLabInstr EE320L Lab9MjdNo ratings yet

- Chapter No 6 McqsDocument9 pagesChapter No 6 McqsCh Adnan AslamNo ratings yet

- Iec 60287-3-1 1999-05Document38 pagesIec 60287-3-1 1999-05MalinduNo ratings yet

- Delos Reyes - Precious Melody-Part 2Document16 pagesDelos Reyes - Precious Melody-Part 2Melody Delos ReyesNo ratings yet

- Java Programming: From Problem Analysis To Program Design, 3eDocument41 pagesJava Programming: From Problem Analysis To Program Design, 3eTsuna RinkuNo ratings yet

- 1073 AshrafDocument70 pages1073 Ashrafkroto iusNo ratings yet

- Ilovepdf MergedDocument746 pagesIlovepdf MergedVansh JainNo ratings yet

- Nursing Informatics 9Document36 pagesNursing Informatics 9Rachelle Anne Delcarmen SarteNo ratings yet

- Raspberry Pi Pico EssentialsDocument25 pagesRaspberry Pi Pico Essentials李小华No ratings yet

- 2015 Logik 31-S 33-S GBDocument2 pages2015 Logik 31-S 33-S GBAbdurrhman Al ShukhryNo ratings yet

- ZXSDR A8612 Product DescriptionDocument15 pagesZXSDR A8612 Product DescriptionbbpncbNo ratings yet

- Astable Multi Vibrator: Prior To The Lab SessionDocument5 pagesAstable Multi Vibrator: Prior To The Lab SessionRiya Saluja100% (1)

- ps2 HMMDocument484 pagesps2 HMMAndrew ParkerNo ratings yet