Professional Documents

Culture Documents

Environment Basic Material Temp. (°C) Max. Piping Velocity (M/S) Remarks

Environment Basic Material Temp. (°C) Max. Piping Velocity (M/S) Remarks

Uploaded by

mohsenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environment Basic Material Temp. (°C) Max. Piping Velocity (M/S) Remarks

Environment Basic Material Temp. (°C) Max. Piping Velocity (M/S) Remarks

Uploaded by

mohsenCopyright:

Available Formats

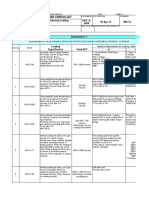

Document Responsibility: Materials Engineering Standards Committee SAES-L-132

Issue Date: 24 August 2016

Next Planned Update: 24 August 2019 Materials Selection for Pipelines, Piping, and Process Equipment

Max. Piping

Temp.

Environment Basic Material Velocity Remarks

(°C)

(m/s)

Only for dedicated, non-corrosive

Galvanized steel Ambient 2.25

systems (SAES-B-017)

Carbon steel,

cement lined or Ambient 3.0 See SAES-H-002

FBE coated

Type 6Mo Ambient 10.0 Welded with Alloy 625 filler wire

25Cr Duplex Ambient 10.0 FPREN ≥ 42

For Fire Sprinkler system in Light

UL Listed CPVC Ambient 2.4 Hazardous Occupancies

(SAES-S-050)

Fire control, RTR

1 - 93 5.0 SAES-B-017 and SAES-L-610

dedicated (epoxy resin)

(seawater/utility),

underground HDPE 1 - 60 5.0 SAES-B-017 and 01-SAMSS-051

piping

Fire control, RTR

1 - 93 5.0 See SAES-S-040

non-dedicated / (epoxy resin)

utility distribution,

underground HDPE 1 - 60 5.0 See SAES-S-040

piping

PVC 1 - 60 5.0 See SAES-S-040

Utility water RTR Base case (par. 4.3)

1 - 93 5.0

(raw) (epoxy resin) SAES-L-610

PVC 1 - 60 5.0 Base case (par. 4.3)

CPVC 1 - 80 5.0 Base case (par. 4.3)

Base case (par. 4.3)

HDPE 1 - 60 5.0 See SAES-S-040 &

01-SAMSS-051

For storage tanks only

Carbon steel with

- - See 32-SAMSS-005 and

elastomeric lining

01-SAMSS-041

Carbon steel,

cement lined or 1 - 120 3.0 See SAES-H-002

FBE coated

Copper 1 - 99 1.2

Treated sewage RTR Base case (par. 4.3)

1 - 70 5.0

effluent (TSE) (epoxy resin) SAES-L-610

PVC 1 - 60 5.0 Base case (par. 4.3)

Saudi Aramco: Company General Use

Page 23 of 26

You might also like

- Saes-H-002 - ArmacoDocument29 pagesSaes-H-002 - ArmacoVenkat Gokila DT100% (1)

- Pre-Purchase Final Report Sea LightDocument46 pagesPre-Purchase Final Report Sea LightCESAR VIECNTE100% (1)

- Encyclopedia of Korean Folk BeliefsDocument167 pagesEncyclopedia of Korean Folk BeliefsAria7No ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- References ASEAN2Document3 pagesReferences ASEAN2M IrwaniNo ratings yet

- Incest 5Document239 pagesIncest 5Dana Simireanu Dana33% (9)

- 100 QuestionsDocument44 pages100 QuestionsLara Knezić100% (1)

- SAES-L-136 Pipe, Flange and Fitting Material RequirementsDocument8 pagesSAES-L-136 Pipe, Flange and Fitting Material RequirementsnavaronefraNo ratings yet

- Saes L 136Document8 pagesSaes L 136Abdul Ahad LoneNo ratings yet

- InternalDocument2 pagesInternalSUNIL RAJPUTNo ratings yet

- Saes L 132 PDFDocument14 pagesSaes L 132 PDFsamsurendran_mech4020No ratings yet

- Saes L 110Document12 pagesSaes L 110Karu 2No ratings yet

- Saes S 040Document22 pagesSaes S 040Mohammed YousufNo ratings yet

- Saes L 610Document7 pagesSaes L 610imadz853No ratings yet

- VVACT0008 SourServiceDocument1 pageVVACT0008 SourServicewolverulNo ratings yet

- Saes S 050Document17 pagesSaes S 050Hamza ChNo ratings yet

- Esab, OK Autrod 12.22 (1222252800)Document1 pageEsab, OK Autrod 12.22 (1222252800)RodrigoNo ratings yet

- Saes L 610Document7 pagesSaes L 610Abdullah RiazNo ratings yet

- Piping Class: PROJ: 2963 REV: 2 DOC: PPAG-100-ET-C-012Document7 pagesPiping Class: PROJ: 2963 REV: 2 DOC: PPAG-100-ET-C-012Santiago GarciaNo ratings yet

- Saes L 133Document17 pagesSaes L 133Ahmed Kabel100% (1)

- Piping Class - F1E0U2Document3 pagesPiping Class - F1E0U2AMBYNo ratings yet

- 32 Samss 004Document6 pages32 Samss 004Sajad AbdulNo ratings yet

- Saes L 136Document7 pagesSaes L 136Ahmed KabelNo ratings yet

- Saes L 136Document8 pagesSaes L 136kartik_harwani4387No ratings yet

- Piping Class: PROJ: 2963 REV: 1 DOC: PPAG-100-ET-C-009Document5 pagesPiping Class: PROJ: 2963 REV: 1 DOC: PPAG-100-ET-C-009Santiago GarciaNo ratings yet

- Excerpt From ASME IXDocument1 pageExcerpt From ASME IXhanz bermejoNo ratings yet

- Saic S 4057Document5 pagesSaic S 4057Engr IrfanNo ratings yet

- New Revision of SAES-S-040Document22 pagesNew Revision of SAES-S-040luke luckyNo ratings yet

- Saes S 040Document22 pagesSaes S 040nadeem shaikhNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System SpecificationPrasanna UmapathyNo ratings yet

- SAE AMS5628F Steel, Corrosion-Resistant, Bars, Wire, Forgings, and Tubing 16Cr-2.5Ni (SAE 51431) (Composition Similar To UNS S43100)Document13 pagesSAE AMS5628F Steel, Corrosion-Resistant, Bars, Wire, Forgings, and Tubing 16Cr-2.5Ni (SAE 51431) (Composition Similar To UNS S43100)loebNo ratings yet

- Sa 387Document6 pagesSa 387Pavul RajNo ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationAwais CheemaNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System SpecificationZubair RaoofNo ratings yet

- Saes L 132Document16 pagesSaes L 132Ali Aldubaikhi100% (1)

- TDZ AlloyDocument1 pageTDZ AlloyIan MacMoyNo ratings yet

- Saic L 2015Document8 pagesSaic L 2015Engr IrfanNo ratings yet

- Sa 387 2019Document6 pagesSa 387 2019CK CkkouNo ratings yet

- AW - Datasheet - ALLOY 20 CB 3Document2 pagesAW - Datasheet - ALLOY 20 CB 3.xNo ratings yet

- Materials System SpecificationDocument12 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- D9 Ppag-100-Et-C-025-3 PDFDocument5 pagesD9 Ppag-100-Et-C-025-3 PDFSantiago GarciaNo ratings yet

- Microsoft Word - 2028B - Rev - 0Document10 pagesMicrosoft Word - 2028B - Rev - 0Padmanabhan VenkateshNo ratings yet

- Ams 5678F 2007Document9 pagesAms 5678F 2007zveryuga6350% (2)

- Raven 405FS TDS 060520 V.5.5Document4 pagesRaven 405FS TDS 060520 V.5.5Larry Wayne Sumpter, JrNo ratings yet

- D7 Ppag-100-Et-C-034-2 PDFDocument7 pagesD7 Ppag-100-Et-C-034-2 PDFSantiago GarciaNo ratings yet

- Industrial Codes PipingDocument5 pagesIndustrial Codes PipingmetinNo ratings yet

- Saes B 018Document15 pagesSaes B 018drbabithameringeorgemdsorthoNo ratings yet

- PGRAL-100-ET-C-007 - B - PIPING CLASS - A3 - ASME 150lb PDFDocument7 pagesPGRAL-100-ET-C-007 - B - PIPING CLASS - A3 - ASME 150lb PDFcasandraNo ratings yet

- 15.4 000 7 SP 004Document7 pages15.4 000 7 SP 004Sumantra ChattopadhyayNo ratings yet

- Saep 310Document39 pagesSaep 310Noura KhaledNo ratings yet

- Inspection 2Document1 pageInspection 2Iftikhar AhmedNo ratings yet

- Pipe Coat & LiningDocument22 pagesPipe Coat & Liningjadav parixeet100% (3)

- Saes L 100Document12 pagesSaes L 100samsurendran_mech4020No ratings yet

- Saic L 2115Document4 pagesSaic L 2115khuram shahzadNo ratings yet

- 1Document2 pages1Sam JoseNo ratings yet

- Saep 310Document38 pagesSaep 310paul cafeNo ratings yet

- Control of Retained Delta Ferrite in Type 410 Stainless SteelDocument7 pagesControl of Retained Delta Ferrite in Type 410 Stainless SteelEnp JgcNo ratings yet

- Engineering StandardDocument18 pagesEngineering Standardsunil601No ratings yet

- Saes L 109Document16 pagesSaes L 109Abdullah RiazNo ratings yet

- 02 Samss 009Document13 pages02 Samss 009YOUSUF KHANNo ratings yet

- Service Advisory - Corrosive Sulfur in Power Bushings: Product Group Insulation & ComponentsDocument2 pagesService Advisory - Corrosive Sulfur in Power Bushings: Product Group Insulation & ComponentsCarlos CastellonNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material Specificationvsraju2No ratings yet

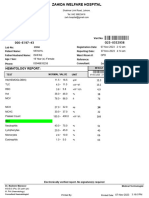

- Hematology Report:: MRN: Visit NoDocument1 pageHematology Report:: MRN: Visit Nojuniadsheikh6No ratings yet

- Physics of Everyday Phenomena A Conceptual Introduction To Physics 8th Edition Griffith Test BankDocument14 pagesPhysics of Everyday Phenomena A Conceptual Introduction To Physics 8th Edition Griffith Test Bankdavidhallwopkseimgc100% (32)

- 6 - DNV - Composites Repair JIP - New Approach To Repair of FPSO's Without Hot Work Using Glueing PolymersDocument31 pages6 - DNV - Composites Repair JIP - New Approach To Repair of FPSO's Without Hot Work Using Glueing PolymersAnonymous 19QCaJNo ratings yet

- JNTUH R09 Percentage & Credits Calculator-1Document16 pagesJNTUH R09 Percentage & Credits Calculator-1msg2dpNo ratings yet

- LDPDocument46 pagesLDPSoundradevi ArumugamNo ratings yet

- Pre-Embalming Observations: Arteries Injected: Veins Drained: Disinfection: (Check Appropriate Areas)Document2 pagesPre-Embalming Observations: Arteries Injected: Veins Drained: Disinfection: (Check Appropriate Areas)May MontanoNo ratings yet

- Chen 2013Document16 pagesChen 2013Alexandru ArcireNo ratings yet

- Tech Talk Liquid Filtration Pressure DropDocument1 pageTech Talk Liquid Filtration Pressure DropAzmi AhmadNo ratings yet

- Prepared by - Snehal ChintalaDocument78 pagesPrepared by - Snehal ChintalaSnehal ChintalaNo ratings yet

- Msds UreaDocument5 pagesMsds UreaHunterlan Register FilanNo ratings yet

- Content Expectations: Quick Response PDCA Assignment / Breakdown Factor Tree Analysis 5 Why Analysis PDCADocument31 pagesContent Expectations: Quick Response PDCA Assignment / Breakdown Factor Tree Analysis 5 Why Analysis PDCAdysonNo ratings yet

- PINKBAR Inspector SheetDocument2 pagesPINKBAR Inspector SheetdharmaNo ratings yet

- HP 245 G6 Notebook PC: Maintenance and Service GuideDocument106 pagesHP 245 G6 Notebook PC: Maintenance and Service GuideStevenson QuinteroNo ratings yet

- Push Pull (Cascade) DespieceDocument20 pagesPush Pull (Cascade) DespieceAntonio Vargas ZarateNo ratings yet

- ULMA Advanced Forged Solutions Corporate BrochureDocument8 pagesULMA Advanced Forged Solutions Corporate Brochureaan alfianNo ratings yet

- Edible PackagingDocument7 pagesEdible Packagingyouthsafetyinitiative244No ratings yet

- Ariens Model 921013 Deluxe 30 Snow Blower Operator ManualDocument46 pagesAriens Model 921013 Deluxe 30 Snow Blower Operator ManualTim MckennaNo ratings yet

- 1.8 Anchor Systems Indd 2009Document80 pages1.8 Anchor Systems Indd 2009ihpeter100% (1)

- Contemporary PAR Lesson 4Document23 pagesContemporary PAR Lesson 4.....No ratings yet

- PPDocument15 pagesPPdana angela hernandezNo ratings yet

- The Blessed TrinityDocument2 pagesThe Blessed TrinityPatNo ratings yet

- Pathophysiology Cardiac ArrestDocument1 pagePathophysiology Cardiac ArrestPATHOSHOPPE100% (2)

- MPD and MPK Series Midi Io Details 02Document3 pagesMPD and MPK Series Midi Io Details 02Jorge David Monroy PerezNo ratings yet

- Clean and GreenDocument9 pagesClean and GreenDanny Dancel100% (1)

- User S Manual Bedienungsanleitung: Version 1.0 October 1998Document32 pagesUser S Manual Bedienungsanleitung: Version 1.0 October 1998Ojit QuizonNo ratings yet