Professional Documents

Culture Documents

Minimum Quality Assurance Testing Requirements Asphalt Concrete Pavement - Eps Spec 3.50, Managed Qa (Projects With Maximum Specific Gravity Testing)

Minimum Quality Assurance Testing Requirements Asphalt Concrete Pavement - Eps Spec 3.50, Managed Qa (Projects With Maximum Specific Gravity Testing)

Uploaded by

Sami AjOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Minimum Quality Assurance Testing Requirements Asphalt Concrete Pavement - Eps Spec 3.50, Managed Qa (Projects With Maximum Specific Gravity Testing)

Minimum Quality Assurance Testing Requirements Asphalt Concrete Pavement - Eps Spec 3.50, Managed Qa (Projects With Maximum Specific Gravity Testing)

Uploaded by

Sami AjCopyright:

Available Formats

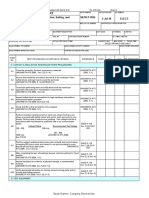

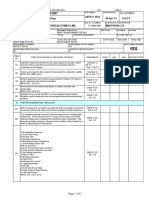

MINIMUM QUALITY ASSURANCE TESTING REQUIREMENTS ASPHALT CONCRETE

PAVEMENT - EPS SPEC 3.50, MANAGED QA

(Projects with Maximum Specific Gravity Testing)

TEST STANDARD MINIMUM ATT- DATA

MQA/17 FREQUENCY SHEETS

SAMPLING 1

Five per each Lot (full

1. Mix ATT-37 Production)

2. Cores (Obtained by Contractor) MAT 6-82

ATT-56 Each Lot

Stratified Random Test Sites for ACP Projects

One per Segment

Coring (Monitor Contractor’s Coring) ATT-5

As required for

ATT-38 Correction Factor

3. Aggregate

2

MIX TESTING One per Segment for MAT 6-79

ATT-12 Part II or each QA Acceptance MAT 6- 98

1. Asphalt Content ATT-74 Lot MAT 6- 99

MAT 6- 100

2. Correction Factor, Extracted Asphalt Content ATT-12 Part III As specified in MAT 6-101

ATT-12 Part III MAT 6-75

ATT-74 As specified in ATT-74 MAT 6-99

3. Correction Factor, Ignition Asphalt Content Part II

1

4. Mix Moisture Content ATT-15 Five tests per Lot MAT 6-80

(Full Production)

1

ATT-13 Five tests per Lot MAT 6-80

5. Field Formed Marshall Briquettes (Full Production)

1

6. Maximum Specific Gravity of Bituminous Mixes ASTM D2041 Five tests per Lot

(Gmm) (Full Production)

AGGREGATE TESTING

ATT-26 Each sample, QA MAT 6-80

1. Extraction or Ignition Sieve Analysis Acceptance Lot

MAT 6-75

2. Correction Factor Aggregate Sieve Analysis ATT-26 As required MAT 6-25

OTHER RELATED TESTING

ATT-7 Each core or formed MAT 6-80

1. Density Immersion Method, Saturated Surface Dry specimen

2. Voids Calculations, Cores or Formed Specimens ATT-36 and Each core or formed MAT 6-80

specimen MAT 6-79

% by Gmm (See Note 3)

3. Percent Compaction, Asphalt Concrete Pavement

ATT-67 One per Segment MAT 6-79

PAVEMENT SURFACE See Contract Each Sublot Contractor to test and

1. Smoothness Testing using IRI Criteria Documents report

Paving Guidelines & Each Lane·Km MAT 6-95

2. Segregation Segregation Rating

Manual

Revised December 2019 Appendix B.01a

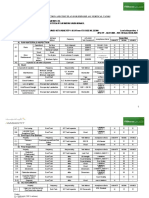

REPORTING Email completed Asphalt Mix Design & JMF Summary Sheet to

Project Sponsor and Surface Engineering section at

trans.constructqa@gov.ab.ca. Provide written documentation to

1. All Approved Asphalt Mix Designs and Changes in Job Contractor for approved designs and JMF changes. Included copies of all

Mix Formula mix designs and JMF approvals in Final Details.

2. Lot Paving Report Complete MAT 6-78 Lot Paving Report. Submit on a weekly basis to

Project Sponsor and to trans.constructqa@gov.ab.ca. Use appropriate Lot

Paving Report form complete with Gmm Air Voids.

3. Pavement Smoothness & Segregation IRI reports to be submitted to trans.constructqa@gov.ab.ca include .ppf

data files, ProVAL reports (.pdf) and payment assessment spreadsheets

(.xls) as outlined in CB #25 Pavement Smoothness Testing Using IRI

Criteria.

Include MAT 6-95s in Final Details as outlined in Engineering

Consultant Guidelines for Highway and Bridge Projects - Volume 2,

Construction Contract Administration. Email early submission copy of

Final Details ACP EPS to trans.constructqa@gov.ab.ca within one

month of paving completion.

1

Note: One sample for the first two hours of production; one immediately after, remaining samples at random over the rest of the day. Full

production is considered when a Lot has more than eight hours of plant production.

2

Note: On QC Acceptance Lots a minimum of 1 asphalt content test on loose mix using test procedures specified in Table 3.50.4. TEST

METHODS ON MANAGED QA PROJECTS

3

Note: Marshall air voids determined by Maximum Specific Gravity (G mm) are to be reported for information only and not to be

used for specification compliance.

Where: Gmm = Maximum specific gravity, and

Gmb = Bulk Specific Gravity of Marshall or core specimen

Note: Density is a synonymous term often used within industry in place of Specific Gravity.

Testing requirements as per MQA specifications are briefly summarized as follows:

On all Lots (QA Acceptance or QC Acceptance) the Consultant is to sample loose mix from behind the

paver to form Marshall briquettes and determine Maximum Specific Gravity (G mm).

For each sampling instance, the Consultant shall split and retain a minimum 5000 g sample for the

Contractor for determination of Maximum Specific Gravity.

Marshall air voids determined by Maximum Specific Gravity (G mm) are to be reported for

information only and not to be used for specification compliance.

Contractor to obtain all core samples at site locations determined by the Consultant.

Materials processing and QA testing is to be done in a laboratory facility (mobile or stationary) that is no

further than one hour from the project.

Contractor quality control test results for asphalt content and gradation will be used for conditional

acceptance of most Lots. For these QC Acceptance Lots the Consultant is to do a minimum of one asphalt

content test per Lot on loose mix using the specified test procedures. For QA Acceptance Lots, report

only the QA test results on the Lot Paving Report. For QC Acceptance Lots, report all available QA

results and the QC test results for asphalt content and gradation. Indicate on the Lot Paving Report which

are QC and which are QA.

On QC Acceptance Lots the Target Asphalt Content is to be used to determine air voids.

The minimum number of QA Lots in which full QA testing is completed is outlined in section 3.50.1.2

Definitions of Specification 3.50 ACP-EPS.

Revised December 2019 Appendix B.01a

You might also like

- 238 PDFDocument9 pages238 PDFcarlosNo ratings yet

- SDBC Design CalculationsDocument30 pagesSDBC Design Calculationsakst1976200095% (19)

- M80Document3 pagesM80FRANZ RICHARD SARDINAS MALLCO100% (2)

- Ollessos Technical Training Institute Proposeed Three Storey Building For Civil Engineering DepartmentDocument89 pagesOllessos Technical Training Institute Proposeed Three Storey Building For Civil Engineering DepartmentCarol SoiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistm4metzNo ratings yet

- Fresh Concrete Lab ReportsDocument66 pagesFresh Concrete Lab ReportsShuaib IsmailNo ratings yet

- Lab Report 5Document7 pagesLab Report 5enieynazNo ratings yet

- B.02 Superpave QA OutlineDocument2 pagesB.02 Superpave QA OutlineSami AjNo ratings yet

- Appendix B: Highway Construction Administration FormsDocument46 pagesAppendix B: Highway Construction Administration FormsSami AjNo ratings yet

- Minimum Quality Assurance Testing Requirements Hot In-Place Recycled Asphalt Concrete Pavement (Hir)Document2 pagesMinimum Quality Assurance Testing Requirements Hot In-Place Recycled Asphalt Concrete Pavement (Hir)Sami AjNo ratings yet

- B.06 GBC QA OutlineDocument1 pageB.06 GBC QA OutlineSami AjNo ratings yet

- R4 Materials and Testing M 6 1Document2 pagesR4 Materials and Testing M 6 1sangumangNo ratings yet

- Ce Const2 Al 59 Conductor 2011 PDFDocument3 pagesCe Const2 Al 59 Conductor 2011 PDFPRAGATHI REDDYNo ratings yet

- B.05 Grading QA OutlineDocument1 pageB.05 Grading QA OutlineSami AjNo ratings yet

- Learn To Speak Japanese FastDocument3 pagesLearn To Speak Japanese FastPisey2014No ratings yet

- Contractor Test Report Client Hot Mix Asphalt Analysis Marshall Method AASHTO T 245, T 164, T 209 & ASTM D 6927 Rashid Contracting Est. Saudi AramcoDocument1 pageContractor Test Report Client Hot Mix Asphalt Analysis Marshall Method AASHTO T 245, T 164, T 209 & ASTM D 6927 Rashid Contracting Est. Saudi Aramcoعباس حمزة الحسينNo ratings yet

- Design of Bituminous Mixtures: Test Procedure ForDocument40 pagesDesign of Bituminous Mixtures: Test Procedure ForAlhilali ZiyadNo ratings yet

- Design of Bituminous Mixtures: Test Procedure ForDocument40 pagesDesign of Bituminous Mixtures: Test Procedure ForNor NadiaNo ratings yet

- S 2400 Hot Mix Asphalt ConcreteDocument8 pagesS 2400 Hot Mix Asphalt ConcreteChaudary Azhar SaleemNo ratings yet

- Saudi Aramco Test ReportDocument11 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Practice For Superpave Warm Mix Asphalt (Wma) Mix DesignDocument6 pagesPractice For Superpave Warm Mix Asphalt (Wma) Mix DesignEdil AlmendrasNo ratings yet

- Minimum Quality Assurance Testing Requirements Cold In-Place Recycled (Cir)Document1 pageMinimum Quality Assurance Testing Requirements Cold In-Place Recycled (Cir)Sami AjNo ratings yet

- Method Statement On Asphalt PavementDocument30 pagesMethod Statement On Asphalt PavementHayle Dela CruzNo ratings yet

- Inspection Testing Plan Guidelines Roadworks 1705928555Document29 pagesInspection Testing Plan Guidelines Roadworks 1705928555foureight48No ratings yet

- Item # Material and Tests Estimated Number, "N" Unit Price, "P" ($)Document4 pagesItem # Material and Tests Estimated Number, "N" Unit Price, "P" ($)rmdarisaNo ratings yet

- R4 Materials and Testing M 6 3Document3 pagesR4 Materials and Testing M 6 3sangumangNo ratings yet

- Component Rework Continuation Sheet: Buddha Air (P) LTDDocument1 pageComponent Rework Continuation Sheet: Buddha Air (P) LTDcyderNo ratings yet

- Mastic-Mix DesignDocument10 pagesMastic-Mix DesignVaasu KotyadaNo ratings yet

- QAP Overall ProjectDocument2 pagesQAP Overall ProjectGangadhar GangaNo ratings yet

- Maximum Specific Gravity Bituminous Paving Mixture: As Per ASTM D-2041Document19 pagesMaximum Specific Gravity Bituminous Paving Mixture: As Per ASTM D-2041jjksite voyantsNo ratings yet

- Qap Dross ShedDocument21 pagesQap Dross ShedSasanka SekharNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Research Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDADocument4 pagesResearch Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDAAyush GoyalNo ratings yet

- Weekly Check: AIRBUS A320-214 & A320-232 Maintenance Check ListDocument5 pagesWeekly Check: AIRBUS A320-214 & A320-232 Maintenance Check ListMuskan GuptaNo ratings yet

- ITP-001 Rev. 00 - AGV - TANK - NESMADocument2 pagesITP-001 Rev. 00 - AGV - TANK - NESMAgayas416No ratings yet

- TC No. 03 2022Document83 pagesTC No. 03 2022Muskmelon gamerNo ratings yet

- Recommended Performance Guideline Micro Surfacing: NoticeDocument17 pagesRecommended Performance Guideline Micro Surfacing: NoticeRaAl GaRuNo ratings yet

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289No ratings yet

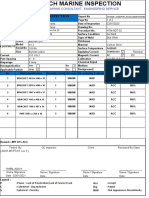

- Magnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceDocument4 pagesMagnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceSulthan HanifNo ratings yet

- SATR-P-3417 Rev 7 FinalDocument6 pagesSATR-P-3417 Rev 7 FinalzhangNo ratings yet

- Saic M 1006Document2 pagesSaic M 1006Hussain Nasser Al- NowiesserNo ratings yet

- QAP - Block With Geogrid RE Wall - JSCDocument2 pagesQAP - Block With Geogrid RE Wall - JSCswapan.boseNo ratings yet

- 1 Lot 1a Vol 2 of 10 235Document1 page1 Lot 1a Vol 2 of 10 235dana setiawanNo ratings yet

- SPP 103 - (R03) Export Crude Oil Analysis ProcedureDocument13 pagesSPP 103 - (R03) Export Crude Oil Analysis ProceduresalemNo ratings yet

- API 579 BlueDocument65 pagesAPI 579 BlueMohamed Alkhiat100% (2)

- Satr-P-3912 Transformer InsulationDocument8 pagesSatr-P-3912 Transformer InsulationSurendren R100% (1)

- Appendix BDocument1 pageAppendix BDelta akathehuskyNo ratings yet

- Saudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: MV Cablebus Continuity and Insulation Resistance Testing SATR-P-3233 3-Jul-18 Electkarthi51289No ratings yet

- Tendernotice 3Document9 pagesTendernotice 3rxrahul9334No ratings yet

- Item 346: Item 346 Is A For Stone-Matrix Asphalt (SMA) and Asphalt Rubber Stone-Matrix (SMAR) MixturesDocument34 pagesItem 346: Item 346 Is A For Stone-Matrix Asphalt (SMA) and Asphalt Rubber Stone-Matrix (SMAR) MixturesLam Dao PhucNo ratings yet

- Codeware, Inc.: Sarasota, FL, USADocument20 pagesCodeware, Inc.: Sarasota, FL, USAVenkatesan ManikandanNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Qa - 4 Component Installation Sheet - HD785-7Document4 pagesQa - 4 Component Installation Sheet - HD785-7Fajar SuryaNo ratings yet

- Specifications For Manufactured Materials: 1. Product Description 1.1. DescriptionDocument9 pagesSpecifications For Manufactured Materials: 1. Product Description 1.1. Descriptionعبدالحميد علبNo ratings yet

- Survey (TB) - S60MC-C Derate NOx Group 7-v4-1 (5955)Document9 pagesSurvey (TB) - S60MC-C Derate NOx Group 7-v4-1 (5955)SorinNo ratings yet

- Standard SpecificationDocument3 pagesStandard SpecificationDanilo DinglasaNo ratings yet

- QCR RegisteregisterDocument19 pagesQCR Registeregisterchitranjan4kumar-8No ratings yet

- Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Electkarthi51289No ratings yet

- Concrete Property Suite of TestsDocument2 pagesConcrete Property Suite of TestsJuan CamposNo ratings yet

- Shell Owner ForumDocument17 pagesShell Owner ForumvizadNo ratings yet

- Heavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUSDocument1 pageHeavy-Duty Diesel Engine Test Category For API CI-4 and CI-4 PLUSsreehariNo ratings yet

- 002 EiaabDocument269 pages002 EiaabSami AjNo ratings yet

- Equipment Checklist FM 1-T180: Moisture-Density Relations of Soils Using A 4.54Kg or 10lb Rammer and A 457mm or 18in DropDocument2 pagesEquipment Checklist FM 1-T180: Moisture-Density Relations of Soils Using A 4.54Kg or 10lb Rammer and A 457mm or 18in DropSami AjNo ratings yet

- Procedure Checklist FM 1 T-180: Moisture-Density Relations of Soils Using A 4.54 KG (10 LB) RammerDocument2 pagesProcedure Checklist FM 1 T-180: Moisture-Density Relations of Soils Using A 4.54 KG (10 LB) RammerSami AjNo ratings yet

- A.c03 Damage Claim Letter BDocument1 pageA.c03 Damage Claim Letter BSami AjNo ratings yet

- Procedure Checklist FM 1-R 090EW - Sampling of Earthwork: P F N/A A. Stockpiles (Manual Sampling - Board/Shovel Method)Document1 pageProcedure Checklist FM 1-R 090EW - Sampling of Earthwork: P F N/A A. Stockpiles (Manual Sampling - Board/Shovel Method)Sami AjNo ratings yet

- A.c02 Damage Claim Letter ADocument1 pageA.c02 Damage Claim Letter ASami AjNo ratings yet

- Utility Accident Report: To: From: Project Sponsor Consultant's RepresentativeDocument3 pagesUtility Accident Report: To: From: Project Sponsor Consultant's RepresentativeSami AjNo ratings yet

- A.15 Project Completion Health and Safety ReviewDocument2 pagesA.15 Project Completion Health and Safety ReviewSami AjNo ratings yet

- A.c04 Damage Claim Letter CDocument1 pageA.c04 Damage Claim Letter CSami AjNo ratings yet

- Old As03 Accident Motor Veh Collisions in Work Zones (Aug 2014)Document4 pagesOld As03 Accident Motor Veh Collisions in Work Zones (Aug 2014)Sami AjNo ratings yet

- A.24 Earth Borrow Letter of UnderstandingDocument1 pageA.24 Earth Borrow Letter of UnderstandingSami AjNo ratings yet

- As05 Accident Notification (3rd Party)Document2 pagesAs05 Accident Notification (3rd Party)Sami AjNo ratings yet

- As01 Saftey TAS OHS ReviewDocument2 pagesAs01 Saftey TAS OHS ReviewSami Aj0% (1)

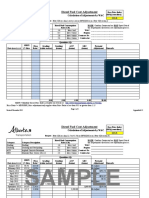

- Diesel Fuel Cost Adjustment: Calculation of Adjustments by WACDocument2 pagesDiesel Fuel Cost Adjustment: Calculation of Adjustments by WACSami AjNo ratings yet

- A.s02 Traffic Accommodation Strategy Component ChecklistDocument2 pagesA.s02 Traffic Accommodation Strategy Component ChecklistSami AjNo ratings yet

- A.16 Conditional Construction Completion Certificate (CCCC)Document1 pageA.16 Conditional Construction Completion Certificate (CCCC)Sami AjNo ratings yet

- DAILY COMPACTION REPORT - Cold In-Place Recycling (CIR) : Cir Mix Cir PavementDocument2 pagesDAILY COMPACTION REPORT - Cold In-Place Recycling (CIR) : Cir Mix Cir PavementSami AjNo ratings yet

- A.25 Payment Anti-Strip AdditiveDocument2 pagesA.25 Payment Anti-Strip AdditiveSami AjNo ratings yet

- Daily Report - Granular Base Course: Compaction - Control Strip MethodDocument2 pagesDaily Report - Granular Base Course: Compaction - Control Strip MethodSami AjNo ratings yet

- B.12 Daily Comp Report GradingDocument2 pagesB.12 Daily Comp Report GradingSami AjNo ratings yet

- LOT PAVING REPORT - QA Testing Using Maximum Specific GravitiesDocument1 pageLOT PAVING REPORT - QA Testing Using Maximum Specific GravitiesSami AjNo ratings yet

- Superpave Lot Paving Report: Gyratory Formed Specimens MIX Lot Pavement and Compaction DataDocument2 pagesSuperpave Lot Paving Report: Gyratory Formed Specimens MIX Lot Pavement and Compaction DataSami AjNo ratings yet

- T S R T.S.R.: (Dd-Mmm-Year)Document2 pagesT S R T.S.R.: (Dd-Mmm-Year)Sami AjNo ratings yet

- Sieve Analysis Lab ReportDocument3 pagesSieve Analysis Lab ReportJelaiza Guias100% (1)

- Particle Size Analysis of SoilsDocument6 pagesParticle Size Analysis of SoilsKaty PerryNo ratings yet

- Aggregate Shape Test (Flakiness Index & Elongation Index) Group 5 - Section 7Document9 pagesAggregate Shape Test (Flakiness Index & Elongation Index) Group 5 - Section 7Beman EasyNo ratings yet

- Test DirDocument13 pagesTest DirAhmedMahirNo ratings yet

- USP-NF Microcrystalline CelluloseDocument3 pagesUSP-NF Microcrystalline CelluloseVõ Đức TrọngNo ratings yet

- Effects of Soil Particle Size On The Adsorption, Distribution, and Migration Behaviors of Heavy Metal (Loid) S in Soil - A ReviewDocument20 pagesEffects of Soil Particle Size On The Adsorption, Distribution, and Migration Behaviors of Heavy Metal (Loid) S in Soil - A ReviewhuangxiaofengNo ratings yet

- Repair Lab JUDocument78 pagesRepair Lab JUnira365No ratings yet

- Pundra University of Engineering & Technology: Laboratory ManualDocument8 pagesPundra University of Engineering & Technology: Laboratory ManualMd. AsaduzzamanNo ratings yet

- QAQCDocument56 pagesQAQCRavindra Babu Sivapu100% (1)

- Irs 1Document15 pagesIrs 1vpmohammed100% (1)

- CMT Lab Report 3Document10 pagesCMT Lab Report 3HAZEL SANDRONo ratings yet

- 3480-Article Text-6540-1-10-20210306Document6 pages3480-Article Text-6540-1-10-20210306TECH MACNo ratings yet

- Use of Waste Tyre Rubber in A Partial Replacement of Aggregate in ConcreteDocument54 pagesUse of Waste Tyre Rubber in A Partial Replacement of Aggregate in ConcreteDurgesh PardeshiNo ratings yet

- 2.0 Basic Characteristic of Soil: Method For Soil ClassificationDocument46 pages2.0 Basic Characteristic of Soil: Method For Soil ClassificationCtnurtasnim Mat ZukiNo ratings yet

- Lab Manual Highway & TrafficDocument59 pagesLab Manual Highway & TrafficfateenhananeyNo ratings yet

- University of Engineering and Technology LHR, (NWL Campus) Lab Manual Subject: Plain Reinforcement ConcreteDocument57 pagesUniversity of Engineering and Technology LHR, (NWL Campus) Lab Manual Subject: Plain Reinforcement ConcreteNoman AliNo ratings yet

- ASTM C110 - Ensaios Físicos Da Cal VirgemDocument25 pagesASTM C110 - Ensaios Físicos Da Cal VirgemThamirisAgmNo ratings yet

- The Effects of Waste Glass Powder Usage On PolymerDocument5 pagesThe Effects of Waste Glass Powder Usage On PolymerDer FamousNo ratings yet

- 〈786〉 PARTICLE SIZE DISTRIBUTION ESTIMATION BY ANALYTICAL SIEVINGDocument4 pages〈786〉 PARTICLE SIZE DISTRIBUTION ESTIMATION BY ANALYTICAL SIEVINGPhuong DangNo ratings yet

- Work Instruction: Sieve Analysis - Mechanical MethodDocument3 pagesWork Instruction: Sieve Analysis - Mechanical MethodCris LegaspiNo ratings yet

- Tutorial MaterialDocument12 pagesTutorial MaterialYamada Takeshi100% (2)

- Minerals 08 00237Document12 pagesMinerals 08 00237حسام رسميNo ratings yet

- 7 Lab Tests On Aggregate To Check Quality For Use in Road WorkDocument32 pages7 Lab Tests On Aggregate To Check Quality For Use in Road Workkumar814.dkNo ratings yet

- AggregatesDocument44 pagesAggregatesCIVIL ENGINEERINGNo ratings yet

- Principles of Geotechnical Engineering 9th Edition Das Sobhan Solution ManualDocument17 pagesPrinciples of Geotechnical Engineering 9th Edition Das Sobhan Solution Manualevelyn100% (31)

- Consmat Lab Manual 2016 PDFDocument57 pagesConsmat Lab Manual 2016 PDFAngelito RamosNo ratings yet

- My Creat 9.5mm To 19mm New Import Dubai StoneDocument1 pageMy Creat 9.5mm To 19mm New Import Dubai Stonesujanislam811No ratings yet