Professional Documents

Culture Documents

WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32

WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32

Uploaded by

Teddy MatthewOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32

WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32

Uploaded by

Teddy MatthewCopyright:

Available Formats

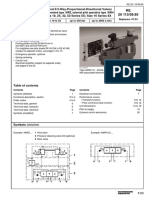

Directional spool valve electrically WK

operated type WE6 series 32 420 970

NS6 up to 35 MPa up to 80 dm 3/min 05.2018

DATA SHEET - OPERATION MANUAL

APPLICATION

Directional spool valves type WE6… electrically

operated are intended for change in direction of fluid

flow in a hydraulic system and thus it allows to

change direction of movement of a receiver - mostly

piston rod of a cylinder or hydraulic motor as well to

use functions: on and off. These directional spool

valves are used for subplate mounting in any position

in a hydraulic system.

The product is compliant with the regulations of

directive 2014/35/UE.

DESCRIPTION OF OPERATION

4WE6 E -32/G24NZ4

a b

A P B

5 4 T 2 1 3

Main elements of directional spool valve type WE6… When the situation is anticipated, directional spool valve

are: housing (1), solenoids (3), control spool (2), must be mounted in the way as to be available.

centering springs (4) and manual overrides (5). The

spool (2) is shifted when it is moved into one of end Version WE6…/OF…- only for spools:

positions by the force of solenoid (3) affecting it. The A, C, D, EA, GA, HA, JA, MA, EB, GB, HB,

return of the spool into neutral position and centering JB, MB. 2-position directional spool valve

are secured by the centering springs (4). The shape of without return springs with detent. The

the spool (control edge spacing) affects the spool (2) is positioned and supported

configuration of connections among the ports: A, B, P with detent (6), and its shift results from

and T. Function of ports: supplying voltage to one solenoid (3).

P - supply port

T - oil return to the tank

A, B - ports for a receiver 6

In case of emergency, the spool can be shifted

manually by means of the override (5) - only for

version with manual override.

Type WE6s32 -1- WK 420 970 05.2018

DESCRIPTION OF OPERATION

Version WE6…/O… - only for spools: A, Directional control valve type WE6… is also available in

C, D, EA, GA, HA, JA, MA, EB, GB, HB, JB, MB. versions with optional equipment: manual operation

2-position directional spool valve without lever (8) - version WE6.../...H… - see page 10 to 11;

return springs. The spool is positioned and manual operation lever with a lock (9) - version

supported with attached solenoid. There is WE6.../...HF… - see page 12 to 15 or/and inductive

no neutral position as the spool is not sensor of spool position control (10) type S - version

positioned. WE6.../...- S - see page 18 to 20; inductive sensor of spool

7 Version WE6…/…B… - directional spool position control (11) type M - version WE6.../...- M - see

valve designation like that, has throttle page 21 to 23.

insert (7) in port P.

WE6.../...H... WE6.../... HF...

P

WE6.../...- S WE6.../...- M

8 9

10 11

TECHNICAL DATA

Hydraulic fluid mineral oil

Required fluid cleanliness class ISO 4406 class 20/18/15

o

Nominal fluid viscosity 37 mm 2/s at temperature 55 C

Viscosity range 2,8 up to 380 mm 2/s

recommended 40 oC up to 55 o C

Fluid temperature range (in a tank)

max -20 o C up to +70 oC

Ambient temperature range - 20 oC up to +50 oC

ports P, A, B 35 MPa

Maximum operating pressure

port T 21 MPa

Flow section for spool W in central position

3 % nominal flow

(diagrams on page 5)

with 1 solenoid WE6...- 1,5 kg WE6...H...- 2,8 kg

Weight

with 2 solenoids WE6...- 2,1 kg WE6...H...- 3,4 kg

DC AC AC

(plug-in connector with rectifier) direct supply

Supply voltage of solenoids

12V 24V 110V 230V-50Hz 220V- 50Hz 110V- 50Hz 230V- 50Hz

Supply voltage tolerance ±10% ±10%

Power requirement (DC) 30 W _

Holding power (AC) _ 50 VA

Switch-on power (AC) _ 300 VA

ON up to 60 ms ON up to 40 ms

Switching time

OFF up to 40 ms OFF up to 25 ms

Maximum switching frequency 15000 on/h 12000 on/h

Degree of protection IP 65

Solenoid coil temperature max 150 oC

WK 420 970 05.2018 -2- Type WE6s32

INSTALLATION AND OPERATION REQUIREMENTS

1. Only fully functional and operational valve, properly following must be checked:

connected to electrical installation must be used. • condition of the electrical connection

Connecting or disconnecting the valve to an electrical • proper working of the valve

installation must only be carried out by qualified • cleanliness of the hydraulic fluid

personnel. 7. Due to heating of solenoid coils to high temp., the

2. Ground connection ( ) must be connected with valve shall be placed in such way to eliminate the risk

protective earth wire (PE ) in supply system according of accidental contact with solenoid during operation

to appropriate instructions. or to apply suitable covers acc. to European

3. Solenoid plug shall precisely adhere to socket and shall standards: PN - EN ISO 13732 - 1 and PN - EN 4413.

be secured with thread bolt screwed in securely in a 8. In order to provide proper tightness of the valve

place. It is forbidden to operate the valve if the connection to the hydraulic system, one should keep

tightness and suitable clamp of cable in the plug gland the dimensions of the sealing rings, tightening

are not ensured. torques values and valve operation parameters,

4. For the …W230 - 50… versions, simultaneous joining specified in this Data Sheet - Operation Manual.

of two solenoids of the same valve should not be 9. Valve with spool position sensor is adjusted at factory

permitted (partial overriding of the valve can overheat and it is not allowed to change its settings. In case of

and damage the winding coils). any damages of the sensor or valve one must

5. During the period of operation must be kept fluid change complete valve. Inductive sensors cannot be

viscosity acc. to requirements defined in this Data Sheet joined in series.

- Operation Manual 10. A person that operates the valve must be thoroughly

6. In order to ensure failure free and safe operation the familiar with this Data Sheet - Operation Manual.

PERFORMANCE CURVES

o

measured at viscosity ν = 41 mm 2/s and temperature t = 50 C

Flow resistance curves

characteristic curves Δp (Q) for directional spool valve type spool symbol performance diagram number

WE6... for various spool types shifted positions flow direction

diagrams according

8 5 3 1 to pages 5, 6 P → A P → B A → T B →T

6 7

A, B 3 3 - -

1,2 C 1 1 3 1

2 D, Y 5 5 3 3

1,0 E 3 3 1 1

4

F 2 3 3 5

0,8 G 7 7 6 6

Δ p [MPa]

H 2 4 2 2

0,6 J 1 1 2 1

L, W 1 1 2 2

M 2 4 3 3

0,4

P 2 3 3 5

U 3 1 3 3

0,2

D1 5 - - 5

Y1 - 5 5 -

0 10 20 30 40 50 60 70 80 central position flow direction

3 diagram according P → A A →T

Q [dm /min] to page 5 P → B P → T B →T B → A

G - 8 - -

Type WE6s32 -3- WK 420 970 05.2018

PERFORMANCE CURVES

o

measured at viscosity ν = 41 mm 2/s and temperature t = 50 C

Operating limits

characteristic curves p-Q for directional spool symbol performance

spool valve type WE6... with DC solenoids diagrams according diagram number

for various spool types to pages 5, 6

35 E, EA/O, EB/O, MA/O, MB/O,

1

1 EA/OF, EB/OF, MA/OF, MB/OF

30

4 3 H, M, L, U, JA/O, JB/O, C/OF,

p [MPa]

20 2

D/OF, JA/OF, JB/OF, HA/OF, 2

10 HB/OF

10 5

C/O, D/O 3

C, D, Y 4

0 10 20 30 40 50 60 70 80

A, B 5

Q [dm 3/min]

A/O 6

35

J 7

30

7 G 8

p [MPa]

20 F, P 9

9 8 6 D1, Y1 10

10 GA/O, GB/O, GA/OF, GB/OF 11

11

0 10 20 30 40 50 60 70 80

Q [dm 3/min]

characteristic curves p-Q for directional spool valve

type WE6... with AC solenoids with direct supply for

various spool types

35

5 1 spool symbol performance

30 diagrams according diagram number

2

25 to pages 5, 6

3 C, D, H, D/O, HA/O, HB/O,

p [MPa]

20

4 EA/O, EB/O, JA/O, JB/O, D/OF,

15 1

HA/OF, HB/OF, EA/OF, EB/OF,

10 JA/OF, JB/OF, C/OF

5 W 2

E, MA/O, MB/O, MA/OF, MB/OF 3

0 10 20 30 40 50 60 70 80 L 4

Q [dm 3 /min] G 5

35 J

8 6

30 M 7

6

25 A 8

GA/O, GB/O, GA/OF, GB/OF

p [MPa]

20 9

7

15

10

9

5

0 10 20 30 40 50 60 70 80

Q [dm 3 /min]

NOTES:

Above operating limits are related to symmetrical flow T (applied to directional control valves with 4 service

through all ports i.e. if the oil flows from port P to port ports). Degree of asymmetry affects adversely the

A, then the same flow rate is from port B to port parameters.

WK 420 970 05.2018 -4- Type WE6s32

DIAGRAMS

Diagrams for 3-position Diagrams for 2-position directional spool valves

directional spool valves versions with positions a, 0 versions with positions 0, b

A B A B A B

WE6.../... a a 0 b b WE6...A /... a a 0 WE6...B/... 0 b b

P T P T P T

A B A B

WE6...A /O...* a a 0 b WE6...B/O...* a 0 b b

P T P T

A B A B

WE6...A /OF...* a a 0 b WE6...B/OF...* a 0 b b

P T P T

A B A B A B

WE6.../...H... a a 0 b b WE6...A /...H... a a 0 WE6...B/...H... 0 b b

P T P T P T

A B A B A B

WE6.../...HF... a a 0 b b WE6...A /...HF... a a 0 WE6...B/...HF... 0 b b

P T P T P T

A B A B A B

WE6.../... - S... a a 0 b WE6...A /... - S... a 0 WE6...B/... - S... 0 b

b

P T P T P T

A BG G A B

WE6...A /... - M a 0 WE6...B/... - M 0 b

Diagrams for spools P T P T

working and working working and working working and working

indirect positions positions indirect positions positions indirect positions positions

A B A B A B A B A B A B

a 0 b a 0 b a 0 a 0 0 b 0 b

P T P T P T P T P T P T

E EA EB

F FA FB

G GA GB

H HA HB

J JA JB

L LA LB

M MA MB

P PA PB

U UA UB

W** WA** WB**

NOTES:

(*) - versions available only for spools - diagrams: EA, GA, HA, JA, MA, EB, GB, HB, JB, MB

(**) - flow section for spool W in central position - 3 % nominal flow

Type WE6s32 -5- WK 420 970 05.2018

DIAGRAMS

Diagrams for 2-position

directional spool valves

versions with positions a, b

A B A B

WE6.../... a a b WE6.../... a b b

P T P T

A B

WE6.../O...* a a b b

P T

A B

WE6.../OF...* a a b b

P T

A B A B

WE6.../...H... a a b WE6.../...H... a b b

P T P T

A B

WE6.../O...H...* a a b b

P T

A B

WE6.../OF...H...* a a b b

P T

A B A B

WE6.../... - S... a b WE6.../... - S... a b

P T P T

A BG G A B

WE6.../... - M a b WE6.../... - M a b

P T P T

NOTE:

(*) - versions available only for spools - diagrams: A, C, D

Diagrams for spools

working and working working and working

indirect positions positions indirect positions positions

A B A B A B A B

a b a b a b a b

P T P T P T P T

A B

A B A B A B A B

a b a b a b a b

P T P T P T P T

D Y

D1 Y1

WK 420 970 05.2018 -6- Type WE6s32

OVERALL AND CONNECTION DIMENSIONS

version WE6.../...Z4... (electrical connection type ISO 4400)

O 9,4

15

4 counterbores

O 5,3

4 holes

2,5

a b

H

57

49

42

23

5 1 3 6 4 2 45

8 154

45

A B

32,5

31

O

P

0,75

40,5 17

73 8,7

9 154

7 218

Option of connection ...Z4... (ISO 4400) dimension H 1 - Solenoid on side a

plug-in connector type supply voltage DC 2 - Solenoid on side b

ISO 4400 (DIN 43650 - A)

86 3 - Plug-in connector on side a - ISO 4400 type (DIN 43650 - A)

12V, 24V, 110V

plug-in connector type 4 - Plug-in connector on side b - ISO 4400 type (DIN 43650 - A)

supply voltage AC

ISO 4400 (DIN 43650 - A) 93 5 - Plug-in connector - ISO 4400 type (DIN 43650 - A) with

110V, 220V, 230V

with rectifier rectifier

6 - O-ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

7 - Directional spool valve dimension with 2 solenoids

on side a, b:

• 3-position springs centered (spool diagrams: E, F, G, H, J,

L, M, P, U, W - according to page 5

10

O

M5 depth 10 - 4 holes

7,6 (max) - 4 holes (P, T, A, B) • 2-position without return springs

• 2-position without springs and with detent

T (versions WE6.../O...; .../OF...; spool diagrams: A, C, D, EA,

GA, HA, JA, MA, EB, GB, HB, JB, MB - acc. to pages 5, 6)

45 (min)

A B

31,75

32,5

8 - Directional spool valve dimension with 1 solenoid - on side a

26,55

• 2-position springs centered

P (spool diagrams: A, C, D, D1, EA, FA, GA, HA, JA, LA, MA,

PA, UA, WA - according to pages 5, 6)

16,25

0,75

5,95

10,3 9 - Directional spool valve dimension with 1 solenoid - on side b

19 • 2-position springs centered

27,8 (spool diagrams: B, Y, Y1, EB, FB, GB, HB, JB, LB, MB, PB,

UB, WB - according to pages 4, 5

40,5 17

10 - Porting pattern of the subplate surface compliant

73 (min) with ISO 4401 standard;

r 0,01/100

0,63

designation ISO 4401-03-02-0-94 (CETOP 03);

fixing screws M5 x 50 - 10.9 in accordance with

PN - EN ISO 4762 - pcs 4/set; tightening torque Md = 9 Nm

11 - Subplate surface required

11

Type WE6s32 -7- WK 420 970 05.2018

OVERALL AND CONNECTION DIMENSIONS

versions: WE6.../...G12...J...; ...G24...J... (electrical connection type AMP Junior Timer)

1 3 O 9,4 2

O

4 counterbores

5,3

2,5

a 4 holes b

71

49

42

23

154 45

45

A B

32,5

31

O

P

40,5 17

0,75

73 8,7

154

218

NOTES: 1 - Solenoid on side a

Description of other elements of the valve drawing; 2 - Solenoid on side b

porting pattern and requirements of surface state of the 3 - Connector type AMP Junior Timer male 2-pole

subplate - as in version WE6…/…Z4…, see page 7 (plug-in connectors not shown in the drawing

must be ordered separately - Data Sheet WK 499 963)

versions: WE6.../...G12...D...; G24...D... (electrical connection type Deutsch)

1 3 O 9,4 2

O

4 counterbores

5,3

2,5

a 4 holes b

64,5

49

42

23

156 45

T

45

A B

32,5

31

P

0,75

40,5 17

73 8,7

156

221

1 - Solenoid on side a

NOTES: 2 - Solenoid on side b

Description of other elements of the valve drawing; 3 - Deutsch DT04 - 2P type connector

porting pattern and requirements of surface state of the (plug-in connectors Deutsch DT06 - 2S type not shown

subplate - as in version WE6…/…Z4…, see page 7 in the drawing must be ordered separately - Data Sheet

WK 499 963)

WK 420 970 05.2018 -8- Type WE6s32

OVERALL AND CONNECTION DIMENSIONS

version WE6.../...W230 - 50...Z4... (AC solenoids; electrical connection type ISO 4400)

1 3 4 2

15

2,5

a b

81

49

64 64 45

202

146

T

A B

45

73

146

NOTES: 1 - AC solenoid (with direct supply) from the a side

• other dimensions, description of other elements of the 2 - AC solenoid (with direct supply) from the b side

valve drawing; porting pattern and requirements of the NOTE:

surface state of the subplate - as in version WE6.../...Z4… simultaneous joining of two solenoids of the same

with DC solenoids, see page 7 valve should not be permitted (partial overriding of

• details of the WE6.../...W230 - 50...H Z4... version (with a the valve can overheat and damage the winding coils)

manual control lever) - as in version WE6.../...H Z4... with 3 - Plug-in connector on side a - type ISO 4400

DC solenoids, see page 10 - 11 (DIN 43650 - A)

4 - Plug-in connector on side b - type ISO 4400

(DIN 43650 - A)

Type WE6s32 -9- WK 420 970 05.2018

OVERALL AND CONNECTION DIMENSIONS

3-position versions WE6.../...H Z4...; .../...HS Z4...

2-position versions WE6.../O...H Z4...; .../OF... H Z4...

WE6.../O...HS Z4...; .../OF...HS Z4...

8 9 16° 16°

working motion = = working motion

= =

idle movement idle movement 18,5

a 0 b

O 16

OO O 6

°

16

9,4 - 4 counterbores

5,3 - 4 holes

16°

30°

~147

2,5

a b

~102

70,5

H

57

49

49

42

23

1 3 7 11 5 4 2

T

A B

32,5

45

31

P

O

0,75

40,5 17

72,5 31 73

249 6

Option of connection ...Z4... (ISO 4400) dimension H 1 - Solenoid on side a

plug-in connector type supply voltage DC 2 - Solenoid on side b

ISO 4400 (DIN 43650 - A)

86 3 - Plug-in connector on side a - type ISO 4400 (DIN 43650 - A)

12V, 24V, 110V

plug-in connector type 4 - Plug-in connector on side b - type ISO 4400 (DIN 43650 - A)

supply voltage AC

ISO 4400 (DIN 43650 - A) 93 5 - O-ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

110V, 220V, 230V

with rectifier 6 - Directional spool valve dimension with 2 solenoids

on side a, b:

NOTES:

• 3-position springs centered

• versions WE6.../...H...;…HS…; …O…H…; …OF…H…;

versions WE6.../...H...; ...HS... (spool diagrams: E, F, G, H, J,

…O…HS…; …OF…HS… with other electrical

L, M, P, U, W - according to page 5

connections, see page 16

• 2-position without return springs

• porting pattern and requirements of surface state of the

versions WE6.../O...H...; .../O...HS...

subplate - as in version WE6.../...Z4..., see page 7

• 2-position without springs and with detent

versions WE6.../OF...H... .../OF...HS...

(spool diagrams: A, C, D - according to page 6)

7 - Manual control lever

NOTES: 8 - Manual control lever positions in versions:

The valve is switched by the manual control lever - item 7, return WE6.../...H... WE6.../O...H... .../OF...H...

of the lever to the initial (neutral) state occurs automatically. After 9 - Manual control lever positions in versions:

switching the valve by using the solenoid - item 1or 2, the lever - WE6.../...HS... WE6.../O...HS... .../OF...HS...

item 7 remains inactive.

WK 420 970 05.2018 - 10 - Type WE6s32

OVERALL AND CONNECTION DIMENSIONS

2-position versions WE6.../...H Z4...; ...HS Z4...

9 10 11 12

16° 16°

working motion

a

= = idle movement

b (0) a (0) b

18,5 18,5

O 16

O 6

30

16

°

O

°

9,4

16°

O

4 counterbores

30°

~147

5,3

4 holes

a b

~102

70,5

H

2,5

49

49

42

23

1 3 8 11 5 11 4 2 45

186 7

31 72,5

45

A

32,5

B

31

O

P

0,75

40,5 17

72,5 31 73

6 186

Option of connection ...Z4... (ISO 4400) dimension H 1 - Solenoid on side a

plug-in connector type supply voltage DC 2 - Solenoid on side b

ISO 4400 (DIN 43650 - A)

86 3 - Plug-in connector on side a - type ISO 4400 (DIN 43650 - A)

12V, 24V, 110V

plug-in connector type 4 - Plug-in connector on side b - type ISO 4400 (DIN 43650 - A)

supply voltage AC 5 - O-ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

ISO 4400 (DIN 43650 - A) 93

110V, 220V, 230V 6 - Directional spool valve dimension with 1 solenoid - on side a,

with rectifier

2-position with return spring (spool diagrams: A, C, D,

NOTES: D1, EA, FA, GA, HA, JA, LA, MA, PA, UA, WA - according to

• versions WE6.../...H...; …HS… with other electrical pages 5, 6)

connections, see page 16 7 - Directional spool valve dimension with 1 solenoid - on side b,

• porting pattern and requirements of surface state of the 2-position with return spring (spool diagrams: B, Y, Y1,

subplate - as in version WE6.../...Z4..., see page 7 EB, FB, GB, HB, JB, LB, MB, PB, UB, WB - according to

pages 5, 6

8 - Manual control lever

9 - Manual control lever positions in versions:

WE6.../...H... with 1 solenoid - on side a

10 - Manual control lever positions in versions:

NOTES: WE6.../...HS... with 1 solenoid - on side a

The valve is switched by the manual control lever - item 8 11 - Manual control lever positions in versions:

return of the lever to the initial (neutral) state occurs WE6.../...H... with 1 solenoid - on side b

automatically. After switching the valve by using the 12 - Manual control lever positions in versions:

solenoid - item 1, 2, the lever - item 8 remains inactive. WE6.../...HS... with 1 solenoid - on side b

Type WE6s32 - 11 - WK 420 970 05.2018

OVERALL AND CONNECTION DIMENSIONS

3-position versions WE6.../...HF Z4...

16° 16°

= =

working motion

idle movement

a

= =

0 b

working motion

idle movement

18,5

O20

OO

~6

7 unlocked position

locked position 16

8 OO

9,4 - 4 counterbores

5,3 - 4 holes

11

~150

2,5

a b

70,5

H

49

49

42

23

1 3 11 5 4 2 45

T

A B 32,5

45

31

P

O

0,75

40,5 17

72,5 31 73

249 6

Option of connection ...Z4... (ISO 4400) dimension H

plug-in connector type supply voltage DC

ISO 4400 (DIN 43650 - A)

86

12V, 24V, 110V

plug-in connector type

supply voltage AC

ISO 4400 (DIN 43650 - A) 93

110V, 220V, 230V

with rectifier

NOTES:

• versions WE6.../...HF... with other electrical connections,

see page 17 1 - Solenoid on side a

• porting pattern and requirements of surface state of the 2 - Solenoid on side b

subplate - as in version WE6.../...Z4..., see page 7 3 - Plug-in connector on side a - type ISO 4400 (DIN 43650 - A)

4 - Plug-in connector on side b - type ISO 4400 (DIN 43650 - A)

NOTES:

The valve is switched by the manual control lever - item 7, return 5 - O-ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

of the lever to the initial (neutral) state occurs automatically. In 6 - Directional spool valve dimension with 2 solenoids

order for the lever - item 7 to remain in switched position, one on side a, b: 3-position springs centered

should move the lock sleeve - item 8 to the lower position until it version WE6.../...HF... (spool diagrams: E, F, G, H, J, L, M, P,

stops. U, W - according to page 5

After switching the valve by using the solenoid - item 1or 2, the 7 - Manual control lever

lever - item 7 remains inactive. 8 - Manual control lever lock sleeve

WK 420 970 05.2018 - 12 - Type WE6s32

OVERALL AND CONNECTION DIMENSIONS

3-position versions WE6.../...HSF Z4...

working motion

idle movement

unlocked position

locked position

15°

~6 18,5

OO

°

OO

16

=

b 20

9,4 - 4 counterbores

0 16

16°

5,3 - 4 holes

O

=

30°

11

=

~ 125

2,5

~ 96

H1

H2

70,5

movement

working

motion

49

49

42

idle

23

11 45

7 1 8 3 5 4 2

52

32,5

A B

45

31

P

O

0,75

40,5 17

72,5 31 73

249 6

dimension

Option of connection ...Z4... (ISO 4400)

H1 H2

plug-in connector type supply voltage DC

ISO 4400 (DIN 43650 - A) 87 86

12V, 24V, 110V

plug-in connector type supply voltage AC

ISO 4400 (DIN 43650 - A) 110V, 220V, 230V 94 93

with rectifier

NOTES:

• versions WE6.../...HSF... with other electrical

connections, see page 17 1 - Solenoid on side a

• porting pattern and requirements of surface state of the 2 - Solenoid on side b

subplate - as in version WE6.../...Z4..., see page 7 3 - Plug-in connector on side a - type ISO 4400 (DIN 43650 - A)

NOTES: 4 - Plug-in connector on side b - type ISO 4400 (DIN 43650 - A)

The valve is switched by the manual control lever - item 7, return 5 - O-ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

of the lever to the initial (neutral) state occurs automatically. In 6 - Directional spool valve dimension with 2 solenoids

order for the lever - item 7 to remain in switched position, one on side a, b: 3-position springs centered

should move the lock sleeve - item 8 to the lower position until it version WE6.../...HF... (spool diagrams: E, F, G, H, J, L, M, P,

stops. U, W - according to page 5

After switching the valve by using the solenoid - item 1or 2, the 7 - Manual control lever

lever - item 7 remains inactive. 8 - Manual control lever lock sleeve

Type WE6s32 - 13 - WK 420 970 05.2018

OVERALL AND CONNECTION DIMENSIONS

2-position versions WE6...A/...HF Z4...; ...B/...HF Z4...

working motion

16°

= = idle movement 16°

18,5 18,5

O 20

a b (0)

unlocked

a (0) b

O 16

8 position

locked O 11

~6

position

9

O 5,3

O9,4

4 counterbores

~150

4 holes

2,5

a b

70,5

H

49

49

42

23

1 3 11 5 4 2 45

186 7

31 72,5

45

A

32,5

B

31

P

O

0,75

40,5 17

72,5 31 73

6 186

Option of connection ...Z4... (ISO 4400) dimension H

plug-in connector type supply voltage DC

86

ISO 4400 (DIN 43650 - A) 12V, 24V, 110V

plug-in connector type

supply voltage AC

ISO 4400 (DIN 43650 - A) 93

110V, 220V, 230V

with rectifier 1 - Solenoid on side a

NOTES: 2 - Solenoid on side b

3 - Plug-in connector on side a - type ISO 4400 (DIN 43650 - A)

• versions WE6...A/...HF...; …B/…HF… with other

4 - Plug-in connector on side b - type ISO 4400 (DIN 43650 - A)

electrical connections, see page 17

5 - O-ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

• porting pattern and requirements of surface state of the 6 - Directional spool valve dimension with 1 solenoid - on side a,

subplate - as in version WE6.../...Z4..., see page 7 2-position with return spring - version WE6...A/...HF...

NOTES: (spool diagrams: EA, FA, GA, HA, JA, LA, MA, PA, UA, WA -

The valve is switched by the manual control lever - item 8, return according to page 5)

of the lever to the initial (neutral) state occurs automatically. In 7 - Directional spool valve dimension with 1 solenoid - on side b,

order for the lever - item 8 to remain in switched position, one 2-position with return spring - version WE6...B/...HF...

should move the lock sleeve - item 9 to the lower position until it (spool diagrams: EB, FB, GB, HB, JB, LB, MB, PB, UB, WB -

stops. according to page 5

After switching the valve by using the solenoid - item 1or 2, the 8 - Manual control lever

lever - item 8 remains inactive. 9 - Manual control lever lock sleeve

WK 420 970 05.2018 - 14 - Type WE6s32

OVERALL AND CONNECTION DIMENSIONS

2-position versions WE6...A/...HSF Z4...; ...B/...HSF Z4...

15°

unlocked position 18,5

idle

movement locked position

~6 O 9,4

4 counterbores

18,5

OO20

b (0)

O a (0) 16

= =°

O

16

5,3

16°

30°

a 4 holes 11

2,5

b

~ 105

H

76

working

motion

49

49

42

23

11 7 45

8 1 9 3 5 4 2

58

186 7

31 72,5

45

32,5

A B

31

O

P

0,75

40,5 17

72,5 31 73

6 186

Option of connection ...Z4... (ISO 4400) dimension H

plug-in connector type supply voltage DC

ISO 4400 (DIN 43650 - A)

86

12V, 24V, 110V

plug-in connector type

supply voltage AC

ISO 4400 (DIN 43650 - A) 93

110V, 220V, 230V

with rectifier 1 - Solenoid on side a

NOTES: 2 - Solenoid on side b

3 - Plug-in connector on side a - type ISO 4400 (DIN 43650 - A)

• versions WE6...A/...HSF...; …B/…HSF… with other

4 - Plug-in connector on side b - type ISO 4400 (DIN 43650 - A)

electrical connections, see page 17

5 - O-ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

• porting pattern and requirements of surface state of the 6 - Directional spool valve dimension with 1 solenoid - on side a,

subplate - as in version WE6.../...Z4..., see page 7 2-position with return spring - version WE6...A/...HSF...

NOTES: (spool diagrams: EA, FA, GA, HA, JA, LA, MA, PA, UA, WA -

The valve is switched by the manual control lever - item 8, return according to page 5)

of the lever to the initial (neutral) state occurs automatically. In 7 - Directional spool valve dimension with 1 solenoid - on side b,

order for the lever - item 8 to remain in switched position, one 2-position with return spring - version WE6...B/...HSF...

should move the lock sleeve - item 9 to the lower position until it (spool diagrams: EB, FB, GB, HB, JB, LB, MB, PB, UB, WB -

stops. according to page 5

After switching the valve by using the solenoid - item 1or 2, the 8 - Manual control lever

lever - item 8 remains inactive. 9 - Manual control lever lock sleeve

Type WE6s32 - 15 - WK 420 970 05.2018

OVERALL AND CONNECTION DIMENSIONS

versions: WE6.../...H...G12...J...; ...H...G24...J...; ...HS...G12...J...; ...HS...G24...J...

(electrical connection type AMP Junior Timer)

6 1 2 5 3

a b

71,5

72,5 <31> <73>

186

249

NOTES: 1 - Solenoid on side a

•other dimensions, description of elements of the valve 2 - Solenoid on side b

drawing as in version WE6.../...H...Z4... - see page 10 3 - 2-poles male AMP Junior Timer type connector

•porting pattern and requirements of surface state of the (plug-in connectors not shown in the drawing must be

subplate - as in version WE6.../...Z4... - see page 7 ordered separately - Data Sheet WK 499 963)

4 - Versions: …H…G12…J…; … H…G24…J…

5 - Versions: …HS…G12…J…; … HS…G24…J…

versions: WE6.../...H...G12..D...; ...H...G24...D...; ...HS...G12...D...; ...HS...G24...D...

(electrical connection type Deutsch)

6 1 2 5 3

a b

64,5

74 <31> <73>

188

252

NOTES: 1 - Solenoid on side a

•other dimensions, description of elements of the valve 2 - Solenoid on side b

drawing as in version WE6.../...H...Z4... - see page 10 3 - Deutsch DT04 - 2P type connector

•porting pattern and requirements of surface state of the (plug-in connectors Deutsch DT06 - 2S type not shown

subplate - as in version WE6.../...Z4... - see page 7 in the drawing must be ordered separately - Data Sheet

WK 499 963)

4 - Versions: …H…G12…D…; … H…G24…D…

5 - Versions: …HS…G12…D…; … HS…G24…D…

WK 420 970 05.2018 - 16 - Type WE6s32

OVERALL AND CONNECTION DIMENSIONS

versions: WE6.../...HF...G12...J...; ...HF...G24...J...; ...HSF...G12...J...; ...HSF...G24...J...

(electrical connection type AMP Junior Timer)

6 1 3 5 2

a b

71,5

72,5 <31> <73>

186

249

NOTES: 1 - Solenoid on side a

•other dimensions, description of elements of the valve 2 - Solenoid on side b

drawing as in versions: WE6.../...HF...Z4... ; …HSF…Z4… 3 - 2-poles male AMP Junior Timer type connector

see pages 12 to 15 (plug-in connectors not shown in the drawing must be

•porting pattern and requirements of surface state of the ordered separately - Data Sheet WK 499 963)

subplate - as in version WE6.../...Z4... - see page 7 4 - Versions: …HF…G12…J…; … HF…G24…J…

5 - Versions: …HSF…G12…J…; … HSF…G24…J…

versions: WE6.../...HF...G12...D...; ...HF...G24...D...; ...HSF...G12...D...; ...HSF...G24...D...

(electrical connection type Deutsch)

6 1 3 5 2

a b

64,5

74 <31> <73>

188

252

NOTES: 1 - Solenoid on side a

•other dimensions, description of elements of the valve 2 - Solenoid on side b

drawing as in versionS: WE6.../...HF...Z4...; …HSF…Z4… 3 - Deutsch DT04 - 2P type connector

- see pages 12 to 15 (plug-in connectors Deutsch DT06 - 2S type not shown

•porting pattern and requirements of surface state of the in the drawing must be ordered separately - Data Sheet

subplate - as in version WE6.../...Z4... - see page 7 WK 499 963)

4 - Versions: …HF…G12…D…; … HF…G24…D…

5 - Versions: …HSF…G12…D…; … HSF…G24…D…

Type WE6s32 - 17 - WK 420 970 05.2018

ACCESSORIES

Spool position switch type S

Additional technical data

Switch type PNP inductive proximity switch

Range of supply voltage for switch 10 - 30V DC

Max load current 200 mA

Connection type of switch switch with M12x1 external thread; male connection; 4 contacts (pins)

Degree of protection IP 65

Weight of directional valve

with 1 solenoid and 1 switch 2,1 kg

with 2 solenoids and 1 switch 2,7 kg

with 2 solenoids and 2 switches 3,3 kg

Diagrams of electrical connection of inductive switch type S

type S1 type S2 contact allocation (pins of

switch connector)

1 1

+

+

200 mA 200 mA 2 1

4 10-30V DC 2

10-30V DC

3 3

_ _ 3 4

Diagrams for directional control valves and initial positions of switches

initial position of inductive switch type S depending on the spool position diagram for

0 - off neutral state on output coctact directional valve

1 - on state on uotput contact

3-position version

position monitored a and b position monitored 0

switch type S1 switch type S1

switch 1 switch 1

pin 4 pin 4

on side a 0 on side a 0

switch 1 switch 1

pin 4 on side b pin 4

on side b 0 0

100 50 0 50 100 100 50 0 50 100

a spool position [%] b a spool position [%] b A B

a 0 b

switch type S2 switch type S2

P T

switch 1 switch 1

pin 2

pin 2

on side a 0 on side a 0

switch 1 switch 1

pin 2 on side b pin 2

on side b 0 0

100 50 0 50 100 100 50 0 50 100

a spool position [%] b a spool position [%] b

WK 420 970 05.2018 - 18 - Type WE6s32

ACCESSORIES

Spool position switch type S

initial position of inductive switch depending on the spool position diagram for

directional valve

2-position versions WE6...A... (positions: a, 0)

solenoid and switch on side a

position monitored a position monitored 0

switch 1 switch 1 A B

type S1 pin 4 type S1 pin 4

0 0 a 0

1 1 P T

switch pin 2 switch pin 2

type S2 0 type S2 0

0 50 100 0 50 100

0 spool position [%] a 0 spool position [%] a

2-position versions WE6...B... (positions: 0, b)

solenoid and switch on side b

position monitored 0 position monitored b

switch switch 1 A B

1

type S1 pin 4 type S1 pin 4

0 0 0 b

1 1 P T

switch switch pin 2

pin 2

type S2 0 type S2 0

0 50 100 0 50 100

0 spool position [%] b 0 spool position [%] b

2-position versions WE6A...; ...C...; ...D...; .../O...; .../OF...

A B

switch on side a

a b

position monitored b P T

position monitored a

A B

switch 1 switch 1 a

pin 4 type S1 pin 4 b

type S1 0

0 P T

1 1

switch pin 2 switch pin 2 A B

type S2 0 type S2 0

a b

0 50 100 0 50 100

b spool position [%] a P T

b spool position [%] a

2-position versions WE6B...; ...Y...

switch on side b

position monitored a position monitored b

A B

switch 1 switch 1

pin 4 type S1 pin 4 a b

type S1

0 0

P T

1 1

switch pin 2 switch pin 2

type S2 0 type S2 0

0 50 100 0 50 100

a spool position [%] b a spool position [%] b

Type WE6s32 - 19 - WK 420 970 05.2018

ACCESSORIES

Spool position switch type S 5

Overall dimensions

version with 2 solenoids and 2 switches

70 (min)

M12 x 1

2,5

b

103

a

57,5

49

23

72,5 30 73 6 45

1 278

version with 1 solenoid and 1 switch

2 184

T

45

A B

31

O

P

0,75

40,5 17

8,7

3 184

version with 2 solenoids and 1 switch

NOTES:

a b •directional valve with spool position

switch is adjusted; any adjustments

can be made only by the manufacturer

•in case of a faulty switch or valve

complete directional valve must

4 248 be changed

NOTE: other elements of the valve drawing; porting pattern and requirements of surface state of the subplate acc. to

page 7

1 - Dimension of directional valve with 2 solenoids - on B, Y, EB, FB, GB, HB, JB, LB, MB, PB, UB, WB

side a, b and 2 position switches - acc. to pages 5, 6)

•3-position, springs centered 4 - Dimension of directional valve with 2 solenoids - on side

versions WE6.../...S1...; ...S2... (spool diagrams: a, b and 1 position switch on side a

E, F, G, H, J, L, M, P, U, W - acc. to page 5) • 2-position, without spring return

2 - Dimension of directional control valve with versions WE6.../O...S1...; ...S2...

1 solenoid - on side a and 1 position switch • 2-position, without spring return, with detent

• 2-position, with return spring versions WE6.../OF...S1...; ...S2...

versions WE6.../...S1...; ...S2... (spool diagrams: (spool diagrams: A, C, D - acc. to page 6)

A, C, D, EA, FA, GA, HA, JA, LA, MA, PA, UA, WA 5 - Distance for mounting plug-in connector and cable of

- acc. to pages 5, 6) switch (plug-in connectors not showed in the drawing

3 - Dimension of directional valve with 1 solenoid - on must be ordered separately according to data sheet

side b and 1 position switch WK 499 963)

• 2-position, with return spring 6 - O - ring 9,25 x 1,78 - pcs 4/set (P, T, A, B)

versions WE6.../...S1... ...S2... (spool diagrams:

WK 420 970 05.2018 - 20 - Type WE6s32

ACCESSORIES

Spool position sensor type M

(only for 2-position versions with return spring)

Technical data

Type of spool position sensor inductive sensor type M with two alternative PNP type outputs

+20%

Supply voltage range of the sensor 24 VDC -10%

Max sensor load current 400 mA

Sensor connection type external thread M12 x1; 4 poles (pins)

Degree of protection IP 65

Weight (directional valve with switch) 1,8 kg

WARNING: M type inductive sensors must not be connected serially.

Diagrams of electrical connection

contact allocation

1 (pins of sensor connector)

3 2 1

PNP

4

3 4

2

Diagrams for directional valves and status of sensors

status of sensor type M depending on position of the spool diagram for

0 - off, neutral, potential-free state at the output contact directional valve

1 - on, voltage state at the output contact

2-position versions WE6...A... (positions: a, 0)

solenoid on side a and sensor on side b

position monitored a position monitored 0

1 1

contact 2 contact 2 A BG

0 0

a 0

1 1

contact 4 contact 4 P T

0 0

0 50 100 0 50 100

0 spool position [%] a 0 spool position [%] a

2-position versions WE6...B... (positions: 0, b)

solenoid on side b and sensor on side a

position monitored 0 position monitored b

1 1 G A B

contact 2 contact 2

0 0 0 b

1 P T

1

contact 4 contact 4 0

0

0 50 100 0 50 100

0 spool position [%] b 0 spool position [%] b

Type WE6s32 - 21 - WK 420 970 05.2018

ACCESSORIES

Spool position sensor type M

(only for 2-position versions with return spring)

Diagrams for directional valves and status of sensors

status of sensor type M depending on position of the spool diagram for

0 - off, neutral, potential-free state at the output contact directional valve

1 - on, voltage state at the output contact

2-position versions WE6A...; ...C...; ...D...; ...D1...

sensor on side b

position monitored a position monitored b

1 A BG

1

contact 2 contact 2 a b

0 0

1 P T

1

contact 4 0 contact 4

0

0 50 100 0 50 100

b spool position [%] a b spool position [%] a

2-position versions WE6B...; ...Y...; ...Y1...

sensor on side a

position monitored a position monitored b

1 1 G A B

contact 2 contact 2

0 0 a b

1 P T

1

contact 4 contact 4 0

0

0 50 100 0 50 100

a spool position [%] b 0 spool position [%] a

WK 420 970 05.2018 - 22 - Type WE6s32

ACCESSORIES

Spool position sensor type M

(only for 2-position versions with return spring)

Overall dimensions

version with solenoid on side a and sensor type M

15

M12 x 1

2,5

a

86

49

23

1

73

4

2 153 96 (max) 70 (min)

T

45

A B

32,5

31

45

O

40,5 17

0,75

version with solenoid on side a and sensor type M

73

3 153

NOTE: other elements of the valve drawing; porting pattern and requirements of surface state of the subplate acc. to

page 7

1 - O-ring 9,25 x 1,78 - pcs 4/set (P,T, A, B) NOTES:

2 - Dimension of directional valve 2-position, with return spring •directional valve with spool position

with 1 solenoid - on side a and switch type M sensor is adjusted; any adjustments

(spool diagrams: A, C, D, D1, EA, FA, GA, HA, JA, LA, MA, PA, UA, WA can be made only by the manufacturer

- acc. to pages 5, 6) •in case of a faulty sensor or valve

3 - Dimension of directional valve 2-position, with return spring complete directional valve must

with 1 solenoid - on side b and switch type M be changed

(spool diagrams: B, Y, Y1, EB, FB, GB, HB, JB, LB, MB, PB, UB, WB

- acc. to pages 5, 6)

4 - Distance for mounting plug-in connector and cable of

switch (plug-in-connectors not showed in the drawing

must be ordered separately according to data sheet WK 499 963)

Type WE6s32 - 23 - WK 420 970 05.2018

HOW TO ORDER

WE 6

Number of service ports

3-way - only for spools A, B =3

4-way - for the other spools =4

Nominal size (NS)

NS6 =6

Spool symbol

spool diagrams - according to pages 5, 6

Series number

(30 - 39) - connection and installation dimensions unchanged = 3X

series 32 = 32

Spool centering/positioning

spring centering = no designation

without springs return* =O

without springs return with detent* = OF

NOTE:

(*) - options available only for versions with spools: A, C, D, EA, GA, HA, JA, MA,

EB, GB, HB, JB, MB)

Supply voltage for solenoids

12V DC = G12

24V DC = G24

110V DC = G110

110V AC 50Hz (plug-in connector with rectifier) = W110R

220V AC 50Hz (plug-in connector with rectifier) = W220R

230V AC 50Hz (plug-in connector with rectifier) = W230R

230V AC 50 Hz (direct supply with AC current) = W230-50

Manual override

solenoids with manual override =N

solenoids without manual override (only for version with

inductive sensor type M) = no designation

Manual lever control

no manual control lever = no designation

with a manual control lever positioned vertically =H

with a manual control lever positioned vertically with lock sleeve = HF

with a manual control lever positioned at an angle = HS

with a manual control lever positioned at an angle with lock sleeve = HSF

NOTES:

options with a manual control lever (...H...; ...HS...; ...HF...; ...HSF...) for versions:

WE6 ...A/O...; ...A/OF...; ...B/O...; ...B/OF... z suwakami EA, GA, HA, JA, MA, EB, GB, HB, JB, MB

available after consultation with the manufacturer

Electrical connection

plug-in connector type ISO 4400 (DIN 43650 - A) without LED = Z4

plug-in connector type ISO 4400 (DIN 43650 - A) with LED = Z4L

without plug-in connector, with 2-poles male AMP Junior Timer type connector

(exists for ...G12...; ...G24... options only) =J

without plug-in connector, with Deutsch type connector

exists for ...G12...; ...G24... options only) =D

WK 420 970 05.2018 - 24 - Type WE6s32

HOW TO ORDER

* Further requirements in clear text

(to be agreed with the manufacturer)

Monitored position of the spool

without spool position monitoring = no designation

monitored position 0 - zero (3- position and 2- position versions

with positions (a, 0) or (0, b)) =0

monitored position a (2- position versions with positions (a, 0) or (a, b)) =A

monitored position b (2- position versions with positions (0, b) or (a, b) =B

monitored position a and b (3- position versions) = AB

Spool position sensor

withoutspool position sensor = no designation

spool position switch type S1 = S1

spool position switch type S2 = S2

spool position sensor type M (only for 2-positions versions with return spring) =M

NOTE:

Optional versions with a spool position sensor and a manual control lever (options ...H...; ...HS...;

...HF...; ...HSF...) available after consultation with the manufacturer.

Sealing

NBR (for fluids on mineral oil base) = no designation

FKM (for fluids on phosphate ester base) =V

Throttle insert (in port P)

without throttle insert = no designation

throttle insert φ 0,8 = B 08

throttle insert φ 1,0 = B 10

throttle insert φ 1,2 = B 12

NOTES:

Directional spool valve should be ordered according to the above coding.

The symbols in bold are the preferred versions available in short delivery time.

Coding example: 4WE6 E - 32/G24 N Z4 B08 - S1 - AB

Type WE6s32 - 25 - WK 420 970 05.2018

EXAMPLE OF APPLICATION

IN HYDRAULIC SYSTEM

A B

P T 4WE6 J...

SUBPLATES AND FIXING SCREWS

Subplates must be ordered according to catalogue Subplates and screws fixing directional valve M5 x 50 - 10,9

sheet WK 496 480. Subplate symbols: in accordance with PN - EN ISO 4762 - pcs 4/set must be

G 341/01 - threaded connections G 1/4 ordered separately.

G 342/01 - threaded connections G 3/8 Tightening torque Md = 9 Nm.

G 502/01 - threaded connections G 1/2

G 341/02 - threaded connections M14 x 1,5

G 342/02 - threaded connections M16 x 1,5

NOTE:

Subplate symbol in bold is the preferred

version available in short delivery time.

PONAR Wadowice S.A.

ul. Wojska Polskiego 29

34-100 Wadowice

tel. +48 33 488 21 00

fax .+48 33 488 21 03

www.ponar-wadowice.pl

WK 420 970 05.2018 - 26 - Type WE6s32

You might also like

- JRC Jqx-30aDocument44 pagesJRC Jqx-30aTeddy MatthewNo ratings yet

- Service Training 2005Document76 pagesService Training 2005Heidi Cuevas Venegas100% (1)

- Compact Power Packs: Functional DescriptionDocument16 pagesCompact Power Packs: Functional DescriptionRaúl FigueroaNo ratings yet

- Hyster Spreader Parte Electrica PDFDocument47 pagesHyster Spreader Parte Electrica PDFFredy VelazquezNo ratings yet

- Enterprise IT at CiscoDocument3 pagesEnterprise IT at CiscoroyalmechnoNo ratings yet

- Integrating C# With Embedded SystemDocument47 pagesIntegrating C# With Embedded SystemRaghav ShettyNo ratings yet

- ICT101 Lecture 1 IntroductionDocument42 pagesICT101 Lecture 1 IntroductionOguntoye Yusuf100% (2)

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document22 pagesWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Рома БлошенкоNo ratings yet

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоNo ratings yet

- Weh22s13 enDocument32 pagesWeh22s13 engerin123456789No ratings yet

- WE10 S 15 XDocument12 pagesWE10 S 15 Xargo_arjieantoNo ratings yet

- WE-6-50B huadeDocument10 pagesWE-6-50B huadeLuis JesusNo ratings yet

- Solenoid Poppet Valve - 2/2-, 3/2-And 3/4-Way Construction - Q 40 L/min - P 350 BarDocument2 pagesSolenoid Poppet Valve - 2/2-, 3/2-And 3/4-Way Construction - Q 40 L/min - P 350 BarTruong KhacNo ratings yet

- REXROTH 4wrz 16 5x-6x Series PDFDocument20 pagesREXROTH 4wrz 16 5x-6x Series PDFمحمدلمينابراهيمالموريتاني100% (1)

- wh22 enDocument12 pageswh22 enam0626554No ratings yet

- 4/3 and 4/2 Directional Spool Valves, ISO Size 02: 1 DescriptionDocument5 pages4/3 and 4/2 Directional Spool Valves, ISO Size 02: 1 DescriptionDark CenobiteNo ratings yet

- Re29061 4WREEDocument18 pagesRe29061 4WREEManuel VizcarraNo ratings yet

- WSP22 3 - 400 P 120801 enDocument4 pagesWSP22 3 - 400 P 120801 enDavid AltarribaNo ratings yet

- Ervice AND Arts AnualDocument78 pagesErvice AND Arts AnualMelanie GerdesNo ratings yet

- PLL 1764Document13 pagesPLL 1764Marisabel Barrientos carreraNo ratings yet

- 2/2 4/4 Solenoid Directional Seat Valve, ISO Size 03: 1 DescriptionDocument8 pages2/2 4/4 Solenoid Directional Seat Valve, ISO Size 03: 1 DescriptionWilliam RodrigoNo ratings yet

- Bomba Paul 50 NGDocument4 pagesBomba Paul 50 NGLucía Salazar de TeránNo ratings yet

- D05 Directional Control Valves EngineeringDocument11 pagesD05 Directional Control Valves EngineeringVentas Control HidráulicoNo ratings yet

- 4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsDocument4 pages4-Port, Spool Type, Directional Control Valves With Hand Lever Actuation and Wide Variety of Spool Types With Spring-Centered, Spring-Offset and De-Tent ArrangementsSiddharth GajjarNo ratings yet

- Manual: Original InstructionsDocument70 pagesManual: Original InstructionsMelanie GerdesNo ratings yet

- Ervice AND Arts AnualDocument76 pagesErvice AND Arts AnualMelanie Gerdes100% (1)

- SDE060 Uk-Kbs 216701Document4 pagesSDE060 Uk-Kbs 216701Sergio Belmar CrisostoNo ratings yet

- E5213 0 01 13 - 4we6dDocument2 pagesE5213 0 01 13 - 4we6dardossantosNo ratings yet

- Ervice AND Arts AnualDocument74 pagesErvice AND Arts AnualMelanie GerdesNo ratings yet

- Ervice AND Arts AnualDocument72 pagesErvice AND Arts AnualMelanie Gerdes100% (1)

- WSP22G Ona3 - 400 P 120801 e 01Document4 pagesWSP22G Ona3 - 400 P 120801 e 01Eng-Mohammed SalemNo ratings yet

- Steering Mode Selection Valve With Electromechanical Detent LF1 - 1STR3 (SMV2.0) Patent PendingDocument10 pagesSteering Mode Selection Valve With Electromechanical Detent LF1 - 1STR3 (SMV2.0) Patent PendingRusmiyanto YantoNo ratings yet

- Re29105 2018-12Document20 pagesRe29105 2018-12emreali1No ratings yet

- Re18302 07 - VS311 312 315Document8 pagesRe18302 07 - VS311 312 315diegokatoNo ratings yet

- HD3 AbcoDocument2 pagesHD3 AbcoDanielEscobarMontecinosNo ratings yet

- WK 421 180 Directional Spool ValvesDocument18 pagesWK 421 180 Directional Spool ValvesРома БлошенкоNo ratings yet

- Solenoid Operated Poppet Valve NG6Document4 pagesSolenoid Operated Poppet Valve NG6Irmad RusdianaNo ratings yet

- Directional Controls Dg4V4-01: 1 Design Flows To 115 L/Min (30 Usgpm) 315 Bar (4570 Psi)Document18 pagesDirectional Controls Dg4V4-01: 1 Design Flows To 115 L/Min (30 Usgpm) 315 Bar (4570 Psi)VadimNo ratings yet

- 4V200 Series Solenoid Valve, Pneumatic Control Valve: - 2 10 08 B AC220V W - 4VDocument5 pages4V200 Series Solenoid Valve, Pneumatic Control Valve: - 2 10 08 B AC220V W - 4VMohammed YousifNo ratings yet

- MVHF DBL334eDocument2 pagesMVHF DBL334eGOOGLE DISKNo ratings yet

- Directional Spool Valves, Direct Operated, With Solenoid ActuationDocument20 pagesDirectional Spool Valves, Direct Operated, With Solenoid ActuationSaber LeffiNo ratings yet

- Datablad Ex-Ventiler HA4047Document6 pagesDatablad Ex-Ventiler HA4047nadmyrNo ratings yet

- Solenoid Operated Directional Valve HWE Series: Ordering CodeDocument1 pageSolenoid Operated Directional Valve HWE Series: Ordering CodeSebastian Vega VelizNo ratings yet

- Eaton VickerDocument605 pagesEaton VickerServices Solution100% (1)

- HAWE - MVGDocument15 pagesHAWE - MVGSsaannddyy SandyNo ratings yet

- D7700H en PDFDocument11 pagesD7700H en PDFY.EbadiNo ratings yet

- 4 KB 111Document3 pages4 KB 111swarajdesh251044No ratings yet

- 2/2 Cartridge Spool Valve, Size 5: 1 DescriptionDocument4 pages2/2 Cartridge Spool Valve, Size 5: 1 Descriptiondumass27No ratings yet

- sv08-20 27feb2022 16-50Document5 pagessv08-20 27feb2022 16-50Cesar LimaNo ratings yet

- A4VGDocument68 pagesA4VGИгорь ИгорьNo ratings yet

- Amca L Mov e 06 02Document2 pagesAmca L Mov e 06 02manjappahNo ratings yet

- 4wre 6-10 Sew1xDocument12 pages4wre 6-10 Sew1x2267airportNo ratings yet

- Ws32gna - 400 P 121200 e 03Document4 pagesWs32gna - 400 P 121200 e 03Eng-Mohammed SalemNo ratings yet

- Rexroth 811405144 DatasheetDocument8 pagesRexroth 811405144 Datasheetteknoplastik.techNo ratings yet

- WSP22G Ola1 - 400 P 120601 e 01Document4 pagesWSP22G Ola1 - 400 P 120601 e 01Eng-Mohammed SalemNo ratings yet

- Ficha Tecnica Valvulas Proporcionales Direccionales Directas Sin Feedback 4WRA6-XE ATEX-II2G CETOP3-NG6 Bosch RexrothDocument12 pagesFicha Tecnica Valvulas Proporcionales Direccionales Directas Sin Feedback 4WRA6-XE ATEX-II2G CETOP3-NG6 Bosch RexrothJHONATAN ANDRES SANCHEZNo ratings yet

- HR A6ve250hzDocument5 pagesHR A6ve250hzMichail ArmitageNo ratings yet

- Valvula Cetop 03Document4 pagesValvula Cetop 03Jesús Guirao ValeroNo ratings yet

- SD 11 eDocument12 pagesSD 11 eseaqu3stNo ratings yet

- Ekomat - WE4 10 Englisch PDFDocument10 pagesEkomat - WE4 10 Englisch PDFharianaNo ratings yet

- HPVG Datenblatt en Final KleinDocument63 pagesHPVG Datenblatt en Final Klein1989vasu.pNo ratings yet

- Vickers DG4V-3-6C Electrovalve PDFDocument16 pagesVickers DG4V-3-6C Electrovalve PDFSteven EsquivelNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Arriel 2 Nbrochure 1Document1 pageArriel 2 Nbrochure 1Teddy MatthewNo ratings yet

- Argus Radar X-Band Technical User Manual PDFDocument98 pagesArgus Radar X-Band Technical User Manual PDFTeddy MatthewNo ratings yet

- JRC Jqe-3a PDFDocument30 pagesJRC Jqe-3a PDFTeddy MatthewNo ratings yet

- Argus Radar X-Band Technical User Manual Lampiran PDFDocument37 pagesArgus Radar X-Band Technical User Manual Lampiran PDFTeddy MatthewNo ratings yet

- Different Types of ShipDocument6 pagesDifferent Types of ShipJason DiCaprioNo ratings yet

- Theta76Processor EL V1-0Document31 pagesTheta76Processor EL V1-0MarcelinoMorillasCeciliaNo ratings yet

- Ray SplatDocument9 pagesRay SplatMark Anthony Rodado MuncadaNo ratings yet

- Victor A. Skormin (Auth.) - Introduction To Process Control - Analysis, Mathematical Modeling, Control and Optimization (2016, Springer International Publishing)Document265 pagesVictor A. Skormin (Auth.) - Introduction To Process Control - Analysis, Mathematical Modeling, Control and Optimization (2016, Springer International Publishing)Wouter Plessers100% (1)

- 1828 1Document16 pages1828 1Hamid NaveedNo ratings yet

- Gas Insulated Substation (GIS) Versus Air Insulated Substation (AIS) - EEP PDFDocument8 pagesGas Insulated Substation (GIS) Versus Air Insulated Substation (AIS) - EEP PDFAnonymous oZdAPQdIJNo ratings yet

- Tara Apartments HousingDocument22 pagesTara Apartments Housing10Aboli MahajanNo ratings yet

- Geronimo Z. Velasco - IOMDocument4 pagesGeronimo Z. Velasco - IOMGazelle Joy UlalanNo ratings yet

- 25724-830-V1A-MHCB-00049 Inf. TecnicaDocument3 pages25724-830-V1A-MHCB-00049 Inf. TecnicaNelson Cuevas AvendanoNo ratings yet

- Work, Energy, Power & MachinesDocument54 pagesWork, Energy, Power & MachinesYvonne NtinyariNo ratings yet

- C 8 F 390 Dae 8790 EcbDocument13 pagesC 8 F 390 Dae 8790 Ecbjaafar abdullahNo ratings yet

- UTP OTC PRICE Cust Cross Reference Records AccessDocument7 pagesUTP OTC PRICE Cust Cross Reference Records AccessvenkchNo ratings yet

- O Ring Stretch & Fill & SqueezeDocument9 pagesO Ring Stretch & Fill & SqueezeGaurav MahajanNo ratings yet

- Amaia Trece - CheckListDocument32 pagesAmaia Trece - CheckListDick Anthony MabaoNo ratings yet

- SL No:30 Date: 07.10.2020: Process - Planning To Design Version - 1.0Document4 pagesSL No:30 Date: 07.10.2020: Process - Planning To Design Version - 1.0Varunn VelNo ratings yet

- DS TMTT 50 en Us 16241Document2 pagesDS TMTT 50 en Us 16241heroNo ratings yet

- Conergy C 160P: Photovoltaic Modules - Technical DataDocument1 pageConergy C 160P: Photovoltaic Modules - Technical DataAndréDiasNo ratings yet

- CYME Solar Impact Study ModulesDocument8 pagesCYME Solar Impact Study ModulesclicknagpalNo ratings yet

- Effectiveness of Durian Peel As Biomass BriquetteDocument103 pagesEffectiveness of Durian Peel As Biomass BriquetteEvan Kristofer De Castro100% (2)

- CP Sanitary Fitting & Fixture QtyDocument1 pageCP Sanitary Fitting & Fixture QtyJyoti SarkarNo ratings yet

- The New Firewall Forward Camshaft: PointDocument1 pageThe New Firewall Forward Camshaft: PointAndri OdeNo ratings yet

- Maulana Abul Kalam Azad University of Technology, West BengalDocument1 pageMaulana Abul Kalam Azad University of Technology, West Bengalbiswajit dasNo ratings yet

- Euronorm 2-80Document16 pagesEuronorm 2-80Phung Tuan AnhNo ratings yet

- AVR ProDocument19 pagesAVR Proabhay2703No ratings yet

- 3.4 - Burning in A KilnDocument4 pages3.4 - Burning in A KilnIrshad Hussain100% (1)

- ENGLISHDocument13 pagesENGLISHpierocarnelociNo ratings yet

- Modeling and Control of Two Axis Gimbal System With Dynamic UnbalanceDocument3 pagesModeling and Control of Two Axis Gimbal System With Dynamic UnbalanceFaisal Khan JadoonNo ratings yet