Professional Documents

Culture Documents

9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE Reply

9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE Reply

Uploaded by

ANIL PLAMOOTTILCopyright:

Available Formats

You might also like

- GE 6107 OED Answers CompilationDocument84 pagesGE 6107 OED Answers Compilationjikjik70% (10)

- Design of Small Diameter Frictional Piles and Cases StudyDocument71 pagesDesign of Small Diameter Frictional Piles and Cases StudyLeung Liang50% (2)

- MP0150-CSCEC-QF-006 Master Document RegisterDocument4 pagesMP0150-CSCEC-QF-006 Master Document Registerigul2572No ratings yet

- BLDG - Revised Inspection and Test PlanDocument23 pagesBLDG - Revised Inspection and Test Plan124th EAGLECOM KimJaveroNo ratings yet

- Eqt Summary-22.07.2019Document2 pagesEqt Summary-22.07.2019Biplab MondalNo ratings yet

- Ahw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Document6 pagesAhw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Parag Lalit SoniNo ratings yet

- 12282A - Expansion Joints DatasheetDocument1 page12282A - Expansion Joints DatasheetGaurav TripathiNo ratings yet

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutDocument7 pages9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- PSR&LLDocument15 pagesPSR&LLZain AbidiNo ratings yet

- Skid Packages - TQ-4-Consolidated - Alshirawi UpdatedDocument6 pagesSkid Packages - TQ-4-Consolidated - Alshirawi Updatedyadav yadavNo ratings yet

- TVS Jupiter RMC - 19.3.19Document60 pagesTVS Jupiter RMC - 19.3.19vinodNo ratings yet

- DRP001 Puc Hyo A60 160P 014a 0001 Com R6 - Te 9586 - 87 - 90 - 91Document16 pagesDRP001 Puc Hyo A60 160P 014a 0001 Com R6 - Te 9586 - 87 - 90 - 91John AlmasNo ratings yet

- MDRDocument81 pagesMDRFerdie OS100% (3)

- EPCI YY Document Numbering System (From PHE On 02-Apr-2018)Document25 pagesEPCI YY Document Numbering System (From PHE On 02-Apr-2018)BTJT-B BTJT-ANo ratings yet

- 04351-En-30 SC and KF DiagramDocument1 page04351-En-30 SC and KF Diagramjefry sitorusNo ratings yet

- C.7wy0.wh.74.22.20205.uag Eiz102 S01 R00Document1 pageC.7wy0.wh.74.22.20205.uag Eiz102 S01 R00JC DC AcostaNo ratings yet

- Pm210011-Nui900-Ese-00001 - 02 - Nui-Material Technical Submittal Panel Boards (Nesma United Industry)Document154 pagesPm210011-Nui900-Ese-00001 - 02 - Nui-Material Technical Submittal Panel Boards (Nesma United Industry)Partha SundarNo ratings yet

- Imir 1714Document1 pageImir 1714abhijit007beraNo ratings yet

- Taper BlockDocument2 pagesTaper BlockVKL QualityNo ratings yet

- Ethylene Crackers-102-ModelDocument12 pagesEthylene Crackers-102-ModelWaleed EL-sheshtawyNo ratings yet

- Construction Quality Control Form No. PR 808-14-O24 SUBC. No. - Sheet: - ofDocument1 pageConstruction Quality Control Form No. PR 808-14-O24 SUBC. No. - Sheet: - ofMathias OnosemuodeNo ratings yet

- F08941C-C01-0402 - 1 Limestone Powder Feeding System P&idDocument1 pageF08941C-C01-0402 - 1 Limestone Powder Feeding System P&idAnindya ananda putriNo ratings yet

- Expansion Joint For EvaporateurDocument2 pagesExpansion Joint For EvaporateurLAKHTIRINo ratings yet

- Owner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument2 pagesOwner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- Imir 004Document5 pagesImir 004aakashNo ratings yet

- A07 Za e 7009632 - BBG - 00Document25 pagesA07 Za e 7009632 - BBG - 00babjihanumanthuNo ratings yet

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Document4 pagesWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoNo ratings yet

- Response Submittal - GD01-PIV-ALG-MAT-ARC-0033-01 - Roof Access Hatch & LadderDocument117 pagesResponse Submittal - GD01-PIV-ALG-MAT-ARC-0033-01 - Roof Access Hatch & LadderAhmadMughalNo ratings yet

- Owner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument1 pageOwner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- IVR-8117994011-01 - Rev.00Document6 pagesIVR-8117994011-01 - Rev.00Abhay KarandeNo ratings yet

- 000 SLT2101316 Pe PiDocument27 pages000 SLT2101316 Pe PijaidikarimNo ratings yet

- OAS-VD-055PPBXII-IE-LST-0001 - Fire - Gas IO Assignment List - REV 0 IFA ADocument7 pagesOAS-VD-055PPBXII-IE-LST-0001 - Fire - Gas IO Assignment List - REV 0 IFA AAhmad RezaNo ratings yet

- Iso TemplateDocument4 pagesIso TemplateMark Darrel AranasNo ratings yet

- Ethylene Crackers-101 - ModelDocument12 pagesEthylene Crackers-101 - ModelWaleed EL-sheshtawyNo ratings yet

- Butadiene Unit 101 - ModelDocument5 pagesButadiene Unit 101 - ModelWaleed EL-sheshtawyNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Tsr-Sd22e Bd106 TurrbocharrgeDocument2 pagesTsr-Sd22e Bd106 Turrbocharrgedwi supraptoNo ratings yet

- Sky Mqap1Document1 pageSky Mqap1Kumara SubramanianNo ratings yet

- Ga 157393Document2 pagesGa 157393bao nguyen phanNo ratings yet

- IBR Valves Schedule: Thermax LTD., PuneDocument3 pagesIBR Valves Schedule: Thermax LTD., PuneGuitarist Ratan DebnathNo ratings yet

- NBC Jaf GQC RT A 150,151,152,153Document4 pagesNBC Jaf GQC RT A 150,151,152,153Akansha SharmaNo ratings yet

- State of Qatar: Floor and Wall-Mounted Remote Indicator Lamp Typical Fixing Detail For Detectors in Raised 2 3 4 5Document1 pageState of Qatar: Floor and Wall-Mounted Remote Indicator Lamp Typical Fixing Detail For Detectors in Raised 2 3 4 5MadhankumarNo ratings yet

- Operating Conditions Units Max Norm Min: FCI Steam Trap Specification SheetDocument3 pagesOperating Conditions Units Max Norm Min: FCI Steam Trap Specification SheetHayder HusseinNo ratings yet

- National Iranian Oil Company: Central Treatment and Export Plant (Ctep)Document8 pagesNational Iranian Oil Company: Central Treatment and Export Plant (Ctep)iman tabataba'iNo ratings yet

- Form Report Baja Pipa NewDocument48 pagesForm Report Baja Pipa NewRiza ahmad Sofikul IrfanNo ratings yet

- Qualified Welder ListDocument1 pageQualified Welder ListErwin Timbayo SuleNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- CPP NGCP INCR & LBE Log AS of 17 May 2020Document42 pagesCPP NGCP INCR & LBE Log AS of 17 May 2020deva017No ratings yet

- GRP Drainage Piping System FabricationDocument5 pagesGRP Drainage Piping System FabricationkahootNo ratings yet

- Commercial Bid Form For Supply of Various Process Piping Materials For Ppu-Vt-1st Reduce PriceDocument24 pagesCommercial Bid Form For Supply of Various Process Piping Materials For Ppu-Vt-1st Reduce PriceKasarachi AmadiNo ratings yet

- Scaffolding Rental - One Oasis Cdo BLDG 2Document3 pagesScaffolding Rental - One Oasis Cdo BLDG 2Ronell SolijonNo ratings yet

- Instrument CableDocument29 pagesInstrument Cablegalih santoso100% (1)

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- Inspection and Test PlanDocument1 pageInspection and Test PlanMohsin MohdNo ratings yet

- Vsup2-0511 (Vi) Wac 01Document12 pagesVsup2-0511 (Vi) Wac 01JENNNo ratings yet

- ITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFDocument3 pagesITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFGordon LongforganNo ratings yet

- Component Supply Chain Chart (CSCC)Document1 pageComponent Supply Chain Chart (CSCC)arunNo ratings yet

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Document5 pagesKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriNo ratings yet

- Anpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRDocument1 pageAnpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRjefry sitorusNo ratings yet

- Demo Project EPLAN Electric P8: Circuit Diagram Control CubicleDocument40 pagesDemo Project EPLAN Electric P8: Circuit Diagram Control CubicleKuenley TiNy OndeNo ratings yet

- Evaporation Pond Reply by SEZADDocument17 pagesEvaporation Pond Reply by SEZADANIL PLAMOOTTILNo ratings yet

- 6.3.10 Ex Certified Equipment Complaince: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.10 Ex Certified Equipment Complaince: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- C10A GMRHPB Foundations Coating InspectionDocument1 pageC10A GMRHPB Foundations Coating InspectionANIL PLAMOOTTILNo ratings yet

- C07A Ymkmdc Foundations: Jithraj Anil.P.K. Ganesh ArunachalamDocument1 pageC07A Ymkmdc Foundations: Jithraj Anil.P.K. Ganesh ArunachalamANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- 6.2.2 Inspection, Measuring and Testing Equipment: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.2.2 Inspection, Measuring and Testing Equipment: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Rev A1: Oman Tank Terminal Company (Ottco)Document2 pagesRev A1: Oman Tank Terminal Company (Ottco)ANIL PLAMOOTTILNo ratings yet

- 6.3.6 Independent Testing Agency: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.6 Independent Testing Agency: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.3.2 Material Receiving Inspection: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.2 Material Receiving Inspection: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.3.4 Final Inspection and Test: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.4 Final Inspection and Test: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Reference Documents: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageReference Documents: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- 5.4 QC Inspectors: Ras Markaz Crude Oil Park Project (Phase1)Document1 page5.4 QC Inspectors: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 9686 6120 PR Po0101Document1 page9686 6120 PR Po0101ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document1 pageRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document1 pageRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.2.7 Anchor / Thrust Blocks: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.2.7 Anchor / Thrust Blocks: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Never Drop The Pipe Into The TrenchDocument1 pageNever Drop The Pipe Into The TrenchANIL PLAMOOTTILNo ratings yet

- Abbreviations:: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageAbbreviations:: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 9686 6130 FQ 000 0003Document2 pages9686 6130 FQ 000 0003ANIL PLAMOOTTILNo ratings yet

- 焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0Document1 page焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0ANIL PLAMOOTTILNo ratings yet

- Pqr 实验计划/Pqr Test Plan: Project InformationDocument1 pagePqr 实验计划/Pqr Test Plan: Project InformationANIL PLAMOOTTILNo ratings yet

- Journal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFDocument6 pagesJournal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFmasgrahaNo ratings yet

- MGT-300 EVO - GBDocument2 pagesMGT-300 EVO - GBDago SaenzNo ratings yet

- 100 Pitanja Za Engleski Jezik 2Document14 pages100 Pitanja Za Engleski Jezik 2xujianchentkNo ratings yet

- Mapping Personality Traits of Doctors With Big 5 Personality DimensionsDocument5 pagesMapping Personality Traits of Doctors With Big 5 Personality DimensionsUGCJOURNAL PUBLICATIONNo ratings yet

- Training EvaluationDocument11 pagesTraining EvaluationcupidshruNo ratings yet

- 2008JCECapillary PDFDocument4 pages2008JCECapillary PDFshaileshNo ratings yet

- SeminarDocument2 pagesSeminarAerone SebastianNo ratings yet

- Chemistry Everyday LifeDocument52 pagesChemistry Everyday LifeSunilDuttB100% (1)

- FINS 3635 Short Computer Assignment-2017-2Document1 pageFINS 3635 Short Computer Assignment-2017-2joannamanngoNo ratings yet

- Palliative Care Practice and Associated Factors Among Nurses Working in Jimma University Medical Center South-West Ethiopia, 2017Document8 pagesPalliative Care Practice and Associated Factors Among Nurses Working in Jimma University Medical Center South-West Ethiopia, 2017Diani Rista SariNo ratings yet

- CV Nurul Rachma PutriDocument2 pagesCV Nurul Rachma PutrispongeraputNo ratings yet

- Cartridge Pneumatic StarterDocument15 pagesCartridge Pneumatic StarterKleberNo ratings yet

- Math Worksheet - 3Document4 pagesMath Worksheet - 3Abinaya ParthasarathyNo ratings yet

- IBM Integration Bus: MQ Flexible Topologies: Configuring MQ Nodes Using MQ Connection PropertiesDocument53 pagesIBM Integration Bus: MQ Flexible Topologies: Configuring MQ Nodes Using MQ Connection PropertiesdivaNo ratings yet

- Computer Fundamentals (ALL in ONE)Document818 pagesComputer Fundamentals (ALL in ONE)Arya BhattNo ratings yet

- Resume Jigar JayswalDocument2 pagesResume Jigar JayswaljigarjayswalNo ratings yet

- Process LayoutDocument32 pagesProcess LayoutMaryem Hassani100% (3)

- ReadmeDocument16 pagesReadmeroniellialvesNo ratings yet

- What Do You Know About JobsDocument2 pagesWhat Do You Know About JobsMónicaNo ratings yet

- 5 - Defining Your MessageDocument8 pages5 - Defining Your MessageLe SamirNo ratings yet

- Understanding Psychological Test ScoresDocument2 pagesUnderstanding Psychological Test ScoresJohn F. LeporeNo ratings yet

- People Pleasing Patterns Are Learned When Needs Are Not Met PDFDocument10 pagesPeople Pleasing Patterns Are Learned When Needs Are Not Met PDFPamela RodriguezNo ratings yet

- Heat Engine & IC EnginesDocument26 pagesHeat Engine & IC EnginesVeeresh Kumar G BNo ratings yet

- Riding 2002Document69 pagesRiding 2002Elmira RomanovaNo ratings yet

- Eltek Flatpack 1 How To GuideDocument18 pagesEltek Flatpack 1 How To GuidePankaj Jaswal100% (1)

- Model-View-Controller (MVC) Design PatternDocument17 pagesModel-View-Controller (MVC) Design PatternTamiltamil TamilNo ratings yet

- Anava Hoyt (Lama)Document7 pagesAnava Hoyt (Lama)Diana Putri AriniNo ratings yet

- Freedom Notes Class 11Document2 pagesFreedom Notes Class 11vsurendar159No ratings yet

9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE Reply

9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE Reply

Uploaded by

ANIL PLAMOOTTILOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE Reply

9686-PO0025-CPP-PL-001 - Honeywell Reply Confirmance For PL 26-Dec-2020 - CPPE Reply

Uploaded by

ANIL PLAMOOTTILCopyright:

Available Formats

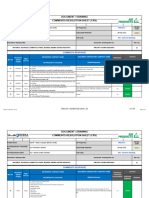

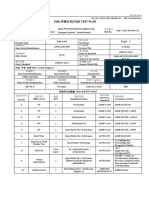

RAS MARKAZ CRUDE OIL PARK PROJECT

PUNCH LIST

Item

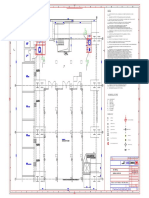

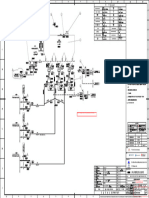

Punch List No. 9686-PO0025-CPP-PL-001 TGS System Date 22-Dec-20

Description

Company OTTCO P.O. No. CPP-RM-PO-0025 Contract No.

Contractor CPP P.O. Item No. Project No.

Vendor/Sub Vendor Honeywell Tag No.

Remarks VERIFIED BY

Action

Category/ Inititaed Close-out CPP (Mech)

Sl.No Discipline Photograph Description of item or Pending points taken Result CPP Engg EPC

Component by/Date Date Vendor Response Inspector VENDOR COMPANY

by/Date Response CONTRACTOR

Resposne

Line number 2 of BoM: Flange 6" ANSI 300RF, AISI

316 for 990 according to BoM quantity of material

to be 3 while quantity of actual presented material

was 1

- Page number 6 of drawing number 9620-51- Ordered quantity was 3 no, but seems 2 flanges have misplaced but under

PO0025-0001 to be update according to actual investigation. It may be 1 of the reason we have concerned to CPP that

appearance of material factory can’t hold the materials for long time so might have happened

that 2 flanges for this ordered were dispatched to other customer/client.

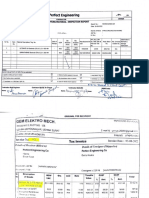

CPP Procurement CPP Procurement

Visual inspection/ Having said we have immediately raised new PO to factory for 2 Flanges

1 Visual 12/23/2020 Honeywell have accepted have accepted

flange (please see attached PO) & once those are available will be shipped out

vendor resposne vendor resposne

separately may be by/before Jan’21 end.

In current shipment, Honeywell will not invoice for this 2 short supply

flanges.

Line number 7 of BoM: VITO Flange NPS 6" ANSI

150 RF acc. ASME 16.5 with threaded G1/2

according to BoM quantity of material to be 3 while

quantity of actual presented material was 1

Ordered quantity was 3 no, but seems 2 flanges have misplaced but under

investigation. It may be 1 of the reason we have concerned to CPP that

factory can’t hold the materials for long time so might have happened

that 2 flanges for this ordered were dispatched to other customer/client.

CPP Procurement CPP Procurement

Visual inspection/ Having said we have immediately raised new PO to factory for 2 Flanges

2 Quantity 12/23/2020 Honeywell have accepted have accepted

flange (please see attached PO) & once those are available will be shipped out

vendor resposne vendor resposne

separately may be by/before Jan’21 end.

In current shipment, Honeywell will not invoice for this 2 short supply

flanges.

Termination details of actual mounted terminal box

on the radar gauge is not according to darawing

CPPE has cleared on

Nov 16, 2020.

We have submitted the drawing on 10-Nov-2020 & haven’t received the

CPP procurement

commented/approved drawing to do the revised submission & was

Documention/ shall expdite further

3 Functional test 12/23/2020 Honeywell informed to CPP team couple of times. Anyways this point is related to Refer CPPE response

terminalbox with

drawing revision & same shall be rectified once we receive Enraf GAD &

vendor/company

termination drawing returned from CPP.

whether they

received or not

since the radar gauge is designed for using in the

pipe and not for open area, and given this fact that

test is done on test bench on open area,

undersigned inspector cannot verify if measured

and read level and changing in the level is

according to project specification or not. Supplied Radar is for Still Well application & meets the Project Noted.This shall be

specifications & requirements. further verified

during SAT. Any non

Procedure to functional test the Radar @ Enraf Factory is on Test bench & compliance

by moving object this is also mentioned in the FAT Procedure. This identified during

functional test procedure is standard & applicable for all projects to SAT shall be in

Functionl test/

4 Functional test 12/23/2020 Honeywell verify the Radars are communicating with the CIU888 & readings are Refer CPPE response honeywell

radar gauge

available on EntisPro system. However all 3 Radars are tested for responsibility to

accuracy on the calibration bench & calibration certificate for all 3 Radars resolve it.

is submitted with CPP.

CPP QA shall advise

Having said & as clarified above the Antenna is for Still well application & further & get

meets the functional & accuracy requirements. company approval

FORM No:9686-QAQC-FRM--0035 Rev-03

Since no any certified calibrated thermometer was

present dung the test undersigned inspector can

not verify if read value is correct or not.

As per the FAT procedure the Temperature reading is verified in the

HART SmartView & Entis System, same is demonstrated by our Enraf FAT

team. Purpose is readings should be same/similar in Entis System & HART Noted. approved

Smartview. There is no Thermometer & hence it is not mentioned as part FAT procedure shall

of FAT procedure. be followed during

Functionl test/

5 Visual No photo 12/23/2020 Honeywell Temperature Probe is standard function of 766 unit & Honeywell takes Refer CPPE response inspection.

radar gauge

the responsibility of its functionality, accuracy. CPP QA shall advise

further & get

We, Honeywell, confirm that all Enraf materials manufactured against this company approval

order meets the Project requirements & we take the responsibility to

demonstrate the functionality, accuracy during the SAT.

test of optional water probe, is not done due to

lack of water tank on the Honeywell building.

We understand this couldn’t be demonstrated, but could have been

possible if TPI visit was happened in the timing suggested from 9am till

5:30pm. After 4pm if TPI is visiting it is difficult to accommodate most of

the test as in the FAT room Water is not allowed & once the factory

timing is closed normally 5:30pm it is not possible to arrange. We

CPP QA shall advise

Functionl test/ managed to complete the FAT with the revised timing. However water Verified Honeywell

6 Functional test No photo 12/23/2020 Honeywell further & get

radar gauge probe is standard function of 766 unit & Honeywell takes the COC

company approval

responsibility of its functionality, accuracy.

We, Honeywell, confirm that all Enraf materials manufactured against this

order meets the Project requirements & we take the responsibility to

demonstrate the functionality, accuracy during the SAT.

Cat. A To be completed prior to dispatch.

Ahmad Yamoudi Mahesh Narawade, Dated: 06-Jan-2021

Cat. B To be attended at site prior to pre-com/com. Punch list originator (Name/Sign And Date) Vendor Representative (Name/Sign And Date)

FORM No:9686-QAQC-FRM--0035 Rev-03

You might also like

- GE 6107 OED Answers CompilationDocument84 pagesGE 6107 OED Answers Compilationjikjik70% (10)

- Design of Small Diameter Frictional Piles and Cases StudyDocument71 pagesDesign of Small Diameter Frictional Piles and Cases StudyLeung Liang50% (2)

- MP0150-CSCEC-QF-006 Master Document RegisterDocument4 pagesMP0150-CSCEC-QF-006 Master Document Registerigul2572No ratings yet

- BLDG - Revised Inspection and Test PlanDocument23 pagesBLDG - Revised Inspection and Test Plan124th EAGLECOM KimJaveroNo ratings yet

- Eqt Summary-22.07.2019Document2 pagesEqt Summary-22.07.2019Biplab MondalNo ratings yet

- Ahw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Document6 pagesAhw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Parag Lalit SoniNo ratings yet

- 12282A - Expansion Joints DatasheetDocument1 page12282A - Expansion Joints DatasheetGaurav TripathiNo ratings yet

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutDocument7 pages9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- PSR&LLDocument15 pagesPSR&LLZain AbidiNo ratings yet

- Skid Packages - TQ-4-Consolidated - Alshirawi UpdatedDocument6 pagesSkid Packages - TQ-4-Consolidated - Alshirawi Updatedyadav yadavNo ratings yet

- TVS Jupiter RMC - 19.3.19Document60 pagesTVS Jupiter RMC - 19.3.19vinodNo ratings yet

- DRP001 Puc Hyo A60 160P 014a 0001 Com R6 - Te 9586 - 87 - 90 - 91Document16 pagesDRP001 Puc Hyo A60 160P 014a 0001 Com R6 - Te 9586 - 87 - 90 - 91John AlmasNo ratings yet

- MDRDocument81 pagesMDRFerdie OS100% (3)

- EPCI YY Document Numbering System (From PHE On 02-Apr-2018)Document25 pagesEPCI YY Document Numbering System (From PHE On 02-Apr-2018)BTJT-B BTJT-ANo ratings yet

- 04351-En-30 SC and KF DiagramDocument1 page04351-En-30 SC and KF Diagramjefry sitorusNo ratings yet

- C.7wy0.wh.74.22.20205.uag Eiz102 S01 R00Document1 pageC.7wy0.wh.74.22.20205.uag Eiz102 S01 R00JC DC AcostaNo ratings yet

- Pm210011-Nui900-Ese-00001 - 02 - Nui-Material Technical Submittal Panel Boards (Nesma United Industry)Document154 pagesPm210011-Nui900-Ese-00001 - 02 - Nui-Material Technical Submittal Panel Boards (Nesma United Industry)Partha SundarNo ratings yet

- Imir 1714Document1 pageImir 1714abhijit007beraNo ratings yet

- Taper BlockDocument2 pagesTaper BlockVKL QualityNo ratings yet

- Ethylene Crackers-102-ModelDocument12 pagesEthylene Crackers-102-ModelWaleed EL-sheshtawyNo ratings yet

- Construction Quality Control Form No. PR 808-14-O24 SUBC. No. - Sheet: - ofDocument1 pageConstruction Quality Control Form No. PR 808-14-O24 SUBC. No. - Sheet: - ofMathias OnosemuodeNo ratings yet

- F08941C-C01-0402 - 1 Limestone Powder Feeding System P&idDocument1 pageF08941C-C01-0402 - 1 Limestone Powder Feeding System P&idAnindya ananda putriNo ratings yet

- Expansion Joint For EvaporateurDocument2 pagesExpansion Joint For EvaporateurLAKHTIRINo ratings yet

- Owner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument2 pagesOwner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- Imir 004Document5 pagesImir 004aakashNo ratings yet

- A07 Za e 7009632 - BBG - 00Document25 pagesA07 Za e 7009632 - BBG - 00babjihanumanthuNo ratings yet

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Document4 pagesWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoNo ratings yet

- Response Submittal - GD01-PIV-ALG-MAT-ARC-0033-01 - Roof Access Hatch & LadderDocument117 pagesResponse Submittal - GD01-PIV-ALG-MAT-ARC-0033-01 - Roof Access Hatch & LadderAhmadMughalNo ratings yet

- Owner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument1 pageOwner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- IVR-8117994011-01 - Rev.00Document6 pagesIVR-8117994011-01 - Rev.00Abhay KarandeNo ratings yet

- 000 SLT2101316 Pe PiDocument27 pages000 SLT2101316 Pe PijaidikarimNo ratings yet

- OAS-VD-055PPBXII-IE-LST-0001 - Fire - Gas IO Assignment List - REV 0 IFA ADocument7 pagesOAS-VD-055PPBXII-IE-LST-0001 - Fire - Gas IO Assignment List - REV 0 IFA AAhmad RezaNo ratings yet

- Iso TemplateDocument4 pagesIso TemplateMark Darrel AranasNo ratings yet

- Ethylene Crackers-101 - ModelDocument12 pagesEthylene Crackers-101 - ModelWaleed EL-sheshtawyNo ratings yet

- Butadiene Unit 101 - ModelDocument5 pagesButadiene Unit 101 - ModelWaleed EL-sheshtawyNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Tsr-Sd22e Bd106 TurrbocharrgeDocument2 pagesTsr-Sd22e Bd106 Turrbocharrgedwi supraptoNo ratings yet

- Sky Mqap1Document1 pageSky Mqap1Kumara SubramanianNo ratings yet

- Ga 157393Document2 pagesGa 157393bao nguyen phanNo ratings yet

- IBR Valves Schedule: Thermax LTD., PuneDocument3 pagesIBR Valves Schedule: Thermax LTD., PuneGuitarist Ratan DebnathNo ratings yet

- NBC Jaf GQC RT A 150,151,152,153Document4 pagesNBC Jaf GQC RT A 150,151,152,153Akansha SharmaNo ratings yet

- State of Qatar: Floor and Wall-Mounted Remote Indicator Lamp Typical Fixing Detail For Detectors in Raised 2 3 4 5Document1 pageState of Qatar: Floor and Wall-Mounted Remote Indicator Lamp Typical Fixing Detail For Detectors in Raised 2 3 4 5MadhankumarNo ratings yet

- Operating Conditions Units Max Norm Min: FCI Steam Trap Specification SheetDocument3 pagesOperating Conditions Units Max Norm Min: FCI Steam Trap Specification SheetHayder HusseinNo ratings yet

- National Iranian Oil Company: Central Treatment and Export Plant (Ctep)Document8 pagesNational Iranian Oil Company: Central Treatment and Export Plant (Ctep)iman tabataba'iNo ratings yet

- Form Report Baja Pipa NewDocument48 pagesForm Report Baja Pipa NewRiza ahmad Sofikul IrfanNo ratings yet

- Qualified Welder ListDocument1 pageQualified Welder ListErwin Timbayo SuleNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- CPP NGCP INCR & LBE Log AS of 17 May 2020Document42 pagesCPP NGCP INCR & LBE Log AS of 17 May 2020deva017No ratings yet

- GRP Drainage Piping System FabricationDocument5 pagesGRP Drainage Piping System FabricationkahootNo ratings yet

- Commercial Bid Form For Supply of Various Process Piping Materials For Ppu-Vt-1st Reduce PriceDocument24 pagesCommercial Bid Form For Supply of Various Process Piping Materials For Ppu-Vt-1st Reduce PriceKasarachi AmadiNo ratings yet

- Scaffolding Rental - One Oasis Cdo BLDG 2Document3 pagesScaffolding Rental - One Oasis Cdo BLDG 2Ronell SolijonNo ratings yet

- Instrument CableDocument29 pagesInstrument Cablegalih santoso100% (1)

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- Inspection and Test PlanDocument1 pageInspection and Test PlanMohsin MohdNo ratings yet

- Vsup2-0511 (Vi) Wac 01Document12 pagesVsup2-0511 (Vi) Wac 01JENNNo ratings yet

- ITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFDocument3 pagesITP For Ball Valves - (ON-OFF) - 32 Inch NGL Pipeline PDFGordon LongforganNo ratings yet

- Component Supply Chain Chart (CSCC)Document1 pageComponent Supply Chain Chart (CSCC)arunNo ratings yet

- KG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Document5 pagesKG98 2 ONT OMF in 7861 DW 178 R0 Pressure Transmitter GA Drawing (Code 1)Madheswaran DharmapuriNo ratings yet

- Anpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRDocument1 pageAnpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRjefry sitorusNo ratings yet

- Demo Project EPLAN Electric P8: Circuit Diagram Control CubicleDocument40 pagesDemo Project EPLAN Electric P8: Circuit Diagram Control CubicleKuenley TiNy OndeNo ratings yet

- Evaporation Pond Reply by SEZADDocument17 pagesEvaporation Pond Reply by SEZADANIL PLAMOOTTILNo ratings yet

- 6.3.10 Ex Certified Equipment Complaince: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.10 Ex Certified Equipment Complaince: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- C10A GMRHPB Foundations Coating InspectionDocument1 pageC10A GMRHPB Foundations Coating InspectionANIL PLAMOOTTILNo ratings yet

- C07A Ymkmdc Foundations: Jithraj Anil.P.K. Ganesh ArunachalamDocument1 pageC07A Ymkmdc Foundations: Jithraj Anil.P.K. Ganesh ArunachalamANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- 6.2.2 Inspection, Measuring and Testing Equipment: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.2.2 Inspection, Measuring and Testing Equipment: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Rev A1: Oman Tank Terminal Company (Ottco)Document2 pagesRev A1: Oman Tank Terminal Company (Ottco)ANIL PLAMOOTTILNo ratings yet

- 6.3.6 Independent Testing Agency: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.6 Independent Testing Agency: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.3.2 Material Receiving Inspection: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.2 Material Receiving Inspection: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.3.4 Final Inspection and Test: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.3.4 Final Inspection and Test: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Reference Documents: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageReference Documents: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- 5.4 QC Inspectors: Ras Markaz Crude Oil Park Project (Phase1)Document1 page5.4 QC Inspectors: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 9686 6120 PR Po0101Document1 page9686 6120 PR Po0101ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureDocument1 pageRas Markaz Crude Oil Park Project (Phase1) : Site Inspection and Testing ProcedureANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document1 pageRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document1 pageRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 6.2.7 Anchor / Thrust Blocks: Ras Markaz Crude Oil Park Project (Phase1)Document1 page6.2.7 Anchor / Thrust Blocks: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- Never Drop The Pipe Into The TrenchDocument1 pageNever Drop The Pipe Into The TrenchANIL PLAMOOTTILNo ratings yet

- Abbreviations:: Ras Markaz Crude Oil Park Project (Phase1)Document1 pageAbbreviations:: Ras Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 9686 6130 FQ 000 0003Document2 pages9686 6130 FQ 000 0003ANIL PLAMOOTTILNo ratings yet

- 焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0Document1 page焊接工艺指导书 Welding Procedure Specification 文件号 Doc. No.: PWPS-A333 GR6-BW-01 Rev.0ANIL PLAMOOTTILNo ratings yet

- Pqr 实验计划/Pqr Test Plan: Project InformationDocument1 pagePqr 实验计划/Pqr Test Plan: Project InformationANIL PLAMOOTTILNo ratings yet

- Journal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFDocument6 pagesJournal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFmasgrahaNo ratings yet

- MGT-300 EVO - GBDocument2 pagesMGT-300 EVO - GBDago SaenzNo ratings yet

- 100 Pitanja Za Engleski Jezik 2Document14 pages100 Pitanja Za Engleski Jezik 2xujianchentkNo ratings yet

- Mapping Personality Traits of Doctors With Big 5 Personality DimensionsDocument5 pagesMapping Personality Traits of Doctors With Big 5 Personality DimensionsUGCJOURNAL PUBLICATIONNo ratings yet

- Training EvaluationDocument11 pagesTraining EvaluationcupidshruNo ratings yet

- 2008JCECapillary PDFDocument4 pages2008JCECapillary PDFshaileshNo ratings yet

- SeminarDocument2 pagesSeminarAerone SebastianNo ratings yet

- Chemistry Everyday LifeDocument52 pagesChemistry Everyday LifeSunilDuttB100% (1)

- FINS 3635 Short Computer Assignment-2017-2Document1 pageFINS 3635 Short Computer Assignment-2017-2joannamanngoNo ratings yet

- Palliative Care Practice and Associated Factors Among Nurses Working in Jimma University Medical Center South-West Ethiopia, 2017Document8 pagesPalliative Care Practice and Associated Factors Among Nurses Working in Jimma University Medical Center South-West Ethiopia, 2017Diani Rista SariNo ratings yet

- CV Nurul Rachma PutriDocument2 pagesCV Nurul Rachma PutrispongeraputNo ratings yet

- Cartridge Pneumatic StarterDocument15 pagesCartridge Pneumatic StarterKleberNo ratings yet

- Math Worksheet - 3Document4 pagesMath Worksheet - 3Abinaya ParthasarathyNo ratings yet

- IBM Integration Bus: MQ Flexible Topologies: Configuring MQ Nodes Using MQ Connection PropertiesDocument53 pagesIBM Integration Bus: MQ Flexible Topologies: Configuring MQ Nodes Using MQ Connection PropertiesdivaNo ratings yet

- Computer Fundamentals (ALL in ONE)Document818 pagesComputer Fundamentals (ALL in ONE)Arya BhattNo ratings yet

- Resume Jigar JayswalDocument2 pagesResume Jigar JayswaljigarjayswalNo ratings yet

- Process LayoutDocument32 pagesProcess LayoutMaryem Hassani100% (3)

- ReadmeDocument16 pagesReadmeroniellialvesNo ratings yet

- What Do You Know About JobsDocument2 pagesWhat Do You Know About JobsMónicaNo ratings yet

- 5 - Defining Your MessageDocument8 pages5 - Defining Your MessageLe SamirNo ratings yet

- Understanding Psychological Test ScoresDocument2 pagesUnderstanding Psychological Test ScoresJohn F. LeporeNo ratings yet

- People Pleasing Patterns Are Learned When Needs Are Not Met PDFDocument10 pagesPeople Pleasing Patterns Are Learned When Needs Are Not Met PDFPamela RodriguezNo ratings yet

- Heat Engine & IC EnginesDocument26 pagesHeat Engine & IC EnginesVeeresh Kumar G BNo ratings yet

- Riding 2002Document69 pagesRiding 2002Elmira RomanovaNo ratings yet

- Eltek Flatpack 1 How To GuideDocument18 pagesEltek Flatpack 1 How To GuidePankaj Jaswal100% (1)

- Model-View-Controller (MVC) Design PatternDocument17 pagesModel-View-Controller (MVC) Design PatternTamiltamil TamilNo ratings yet

- Anava Hoyt (Lama)Document7 pagesAnava Hoyt (Lama)Diana Putri AriniNo ratings yet

- Freedom Notes Class 11Document2 pagesFreedom Notes Class 11vsurendar159No ratings yet