Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

166 viewsCentrifugal Pump Data Sheet

Centrifugal Pump Data Sheet

Uploaded by

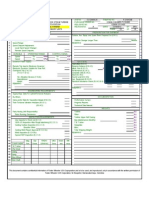

Athiphap SrisupareerathThis document provides specifications for a centrifugal pump, including:

1) The pump is an API type BB3 with multiple volute casing mounted in-line.

2) Nozzle connections include a 6" suction and 3" discharge with RTJ flanges rated for 900 psi.

3) The pump will be driven by a coupling and mounted on a full top deck baseplate with drainage and leveling screws.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- 2010 Ford F150 Diagramas de TransmisionDocument15 pages2010 Ford F150 Diagramas de TransmisionRuben100% (3)

- Spare Parts List: Hydraulic BreakersDocument12 pagesSpare Parts List: Hydraulic BreakersADELALHTBANINo ratings yet

- Manitowoc 4500 - 4665 - Parts ManualDocument280 pagesManitowoc 4500 - 4665 - Parts ManualalbertoNo ratings yet

- Volvo s60 2008 Wiring DiagramDocument20 pagesVolvo s60 2008 Wiring DiagramKellye100% (61)

- Woodward Governor Ug 8 L Manual: Read/DownloadDocument2 pagesWoodward Governor Ug 8 L Manual: Read/DownloadIwan Purwanto80% (5)

- Ge08ti 950106-01166 PBDocument384 pagesGe08ti 950106-01166 PBKeron TrotzNo ratings yet

- Branch Reinforcement - ASME 31.1Document8 pagesBranch Reinforcement - ASME 31.1zakir84md3639No ratings yet

- API Standard 619 - Rotary-Type Displacement Compressors For Petroleum, Chemical, and Gas Industry ServicesDocument2 pagesAPI Standard 619 - Rotary-Type Displacement Compressors For Petroleum, Chemical, and Gas Industry ServicesmishraenggNo ratings yet

- Jharkhand Sor 2016 (2) R.A PDFDocument419 pagesJharkhand Sor 2016 (2) R.A PDFDebasish Misra100% (12)

- Schematic 12m3 Hydraulic SystemDocument2 pagesSchematic 12m3 Hydraulic SystemalcidesNo ratings yet

- Submersible Sump Pumps 83-TMSS-01, Rev 0Document12 pagesSubmersible Sump Pumps 83-TMSS-01, Rev 0Pageduesca RouelNo ratings yet

- Miter Drawing Details For Anchor BlocksDocument1 pageMiter Drawing Details For Anchor BlocksUHPB TeamNo ratings yet

- ITP For EDGDocument6 pagesITP For EDGmuraliNo ratings yet

- Air Eliminator DatasheetDocument2 pagesAir Eliminator DatasheetbecpavanNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Cost Bunchpress & Shredder Sunli by BJM 2019 Mei EditDocument1 pageCost Bunchpress & Shredder Sunli by BJM 2019 Mei EditHeryy TanujayaNo ratings yet

- QM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During RegistrationDocument8 pagesQM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During Registrationsanjayde100% (1)

- Asme BPVC Section VIII Division 1: Key Changes 2019 EditionDocument69 pagesAsme BPVC Section VIII Division 1: Key Changes 2019 Editionhiman_chongiNo ratings yet

- Piping Material Spec C19032-PP-GEN-SPE-101 - 0 - AFCDocument96 pagesPiping Material Spec C19032-PP-GEN-SPE-101 - 0 - AFCZed WangNo ratings yet

- NPD1 Training - PTPL - Cooling Tower - PCX-Series - Apr 2020Document38 pagesNPD1 Training - PTPL - Cooling Tower - PCX-Series - Apr 2020Shyam J VyasNo ratings yet

- HIC & SSC Test ProcedureDocument32 pagesHIC & SSC Test ProcedureMohamed FarisNo ratings yet

- Minimum Distance Between Pipes With FlanchesDocument12 pagesMinimum Distance Between Pipes With FlanchesJMVNo ratings yet

- ACI 318-11 Appedix DDocument2 pagesACI 318-11 Appedix DJonathan SchauderNo ratings yet

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocument209 pagesComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999No ratings yet

- Drainage Pump 50HzDocument20 pagesDrainage Pump 50HzashishkkrNo ratings yet

- Mil C 16173Document28 pagesMil C 16173Lokesh Narasimhaiah100% (1)

- 41.water Cum Foam Monitor-Trailer MountedDocument2 pages41.water Cum Foam Monitor-Trailer MountedSimbu ArasanNo ratings yet

- Data Sheet: Document NoDocument3 pagesData Sheet: Document Nobagus handokoNo ratings yet

- Spring Datasheeet PauDocument4 pagesSpring Datasheeet PauFeri KaruanaNo ratings yet

- At N.p.c.i.l., RawatbhataDocument30 pagesAt N.p.c.i.l., RawatbhataDevendra SharmaNo ratings yet

- Mroy Pump Catalogue PDFDocument6 pagesMroy Pump Catalogue PDFTitus FelixNo ratings yet

- Failure of Gearbox Cooling Tower Fan in Cement Mill 1607659041Document15 pagesFailure of Gearbox Cooling Tower Fan in Cement Mill 1607659041Muhtiar Darja100% (1)

- Specs - Belt Conveyor 1 ProjectDocument7 pagesSpecs - Belt Conveyor 1 ProjectEdson Valter VillalunaNo ratings yet

- Sor 2010Document411 pagesSor 2010Neeraj AgrawalNo ratings yet

- ASTM B619 B619M 17aDocument6 pagesASTM B619 B619M 17aAbdülHak ÖZkaraNo ratings yet

- Beacon Planetary Drive CatalogueDocument8 pagesBeacon Planetary Drive CatalogueMaheshNo ratings yet

- RFQ For Site Fabricated TanksDocument10 pagesRFQ For Site Fabricated TanksNil BorichaNo ratings yet

- Provision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field DevelopmentDocument7 pagesProvision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field Developmentriandi100% (1)

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoqueNo ratings yet

- Muff Coupling & Split Muff CouplingDocument19 pagesMuff Coupling & Split Muff CouplingRamanathan DuraiNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- Centrifugal Force Calculation Description Result Unit 125: Graphical IllustrationDocument6 pagesCentrifugal Force Calculation Description Result Unit 125: Graphical IllustrationvenkateswaranNo ratings yet

- Spare Part Turbin PLTA Bengkok PDFDocument1 pageSpare Part Turbin PLTA Bengkok PDFAditya PrajasNo ratings yet

- Joint Inspection Stringging (NEW)Document2 pagesJoint Inspection Stringging (NEW)ari cahyonoNo ratings yet

- 3 Stack 00001Document1 page3 Stack 00001karioke mohaNo ratings yet

- Form Comisionig&Performance Conveyor TestDocument2 pagesForm Comisionig&Performance Conveyor Testariyanagung29No ratings yet

- Konveyor RantaiDocument91 pagesKonveyor Rantaiabdulloh_99No ratings yet

- Supplier Deliverable RegisterDocument4 pagesSupplier Deliverable RegisterTadaya KasaharaNo ratings yet

- Pump Assessment PDFDocument20 pagesPump Assessment PDFJonas ArifinNo ratings yet

- Area Handover FormDocument1 pageArea Handover FormsivagaaneshNo ratings yet

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Document9 pagesStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002mohan babuNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Document31 pagesSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12No ratings yet

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- Datasheet PompaDocument8 pagesDatasheet PompaagusnnnNo ratings yet

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 pageApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilNo ratings yet

- Dinflo DFCSDocument2 pagesDinflo DFCSvictorharijantoNo ratings yet

- Bharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)Document5 pagesBharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)bmanojkumar16No ratings yet

- Approved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XDocument2 pagesApproved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XP Sandana NaraNo ratings yet

- Fire Monitor Data Sheet - 3-3Document1 pageFire Monitor Data Sheet - 3-3Bagus PrambudiNo ratings yet

- PIG Handling TrollyDocument1 pagePIG Handling TrollyAnas Badar100% (1)

- NM6-110E Data SheetDocument3 pagesNM6-110E Data SheetDedi WahyudiNo ratings yet

- Api 15HR Erta 2-2008Document1 pageApi 15HR Erta 2-2008Ali KhalilNo ratings yet

- Counter Weight Drawing MCT85Document14 pagesCounter Weight Drawing MCT85Nirmalya SenNo ratings yet

- Pressure Balanced Expansion ElbowsDocument1 pagePressure Balanced Expansion ElbowsJoshua HobsonNo ratings yet

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Document1 pageCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- ระเบียบสำนักงานฯ ว่าด้วยการขึ้นทะเบียบสมาชิกของ สสว พ ศ 2559Document6 pagesระเบียบสำนักงานฯ ว่าด้วยการขึ้นทะเบียบสมาชิกของ สสว พ ศ 2559Athiphap SrisupareerathNo ratings yet

- Pump Mechanical Run TestDocument2 pagesPump Mechanical Run TestAthiphap SrisupareerathNo ratings yet

- A Basic Guide To Borescopic Inspection For Gas Engines: Energy Lives HereDocument2 pagesA Basic Guide To Borescopic Inspection For Gas Engines: Energy Lives HereAthiphap SrisupareerathNo ratings yet

- MCM Oil Tools: Cameron Style H2' Choke PartsDocument1 pageMCM Oil Tools: Cameron Style H2' Choke PartsAthiphap SrisupareerathNo ratings yet

- PrecautionDocument1 pagePrecautionAthiphap SrisupareerathNo ratings yet

- An Massflow E 11153Document4 pagesAn Massflow E 11153Athiphap SrisupareerathNo ratings yet

- FULLTEXT02Document97 pagesFULLTEXT02Athiphap SrisupareerathNo ratings yet

- Blowout Preventer System: PT Pertamina Drilling Services Indonesia Area JawaDocument23 pagesBlowout Preventer System: PT Pertamina Drilling Services Indonesia Area JawaAthiphap SrisupareerathNo ratings yet

- Facts 821 Metric Units ENDocument15 pagesFacts 821 Metric Units ENAthiphap SrisupareerathNo ratings yet

- Instructions EN 2018Document23 pagesInstructions EN 2018Athiphap SrisupareerathNo ratings yet

- Summit Pump: Installation, Operation, and Maintenance ManualDocument53 pagesSummit Pump: Installation, Operation, and Maintenance ManualAthiphap SrisupareerathNo ratings yet

- Pressure Safety Valve Sizing Calculation Rev 01Document3 pagesPressure Safety Valve Sizing Calculation Rev 01Athiphap SrisupareerathNo ratings yet

- Cepsa Group Supplier Code of Ethics and ConductDocument20 pagesCepsa Group Supplier Code of Ethics and ConductAthiphap SrisupareerathNo ratings yet

- Final Report Mech c2 - Batch 6Document41 pagesFinal Report Mech c2 - Batch 6Godwin SamuelNo ratings yet

- Ecm 7Document1 pageEcm 7Misa GamezNo ratings yet

- CUE-099-A - SubmittalDocument3 pagesCUE-099-A - SubmittalElmer Ramón Murillo MejiaNo ratings yet

- 0340 Peinersmagde-21022003-P-Peiner-Greifer-OperatingDocument94 pages0340 Peinersmagde-21022003-P-Peiner-Greifer-OperatingHui ChenNo ratings yet

- GM Install and Key Relearn Instructions FinalDocument6 pagesGM Install and Key Relearn Instructions FinalDaniel oberNo ratings yet

- John Deere 4024TF281 Replacement Part GuideDocument2 pagesJohn Deere 4024TF281 Replacement Part GuideRamon Pujol PerramonNo ratings yet

- Combinorm: Instruction ManualDocument193 pagesCombinorm: Instruction ManualHabib A. IslamNo ratings yet

- Return To Service Checklist ADocument12 pagesReturn To Service Checklist AAntonio Cesar de Sa LeitaoNo ratings yet

- ALPHARD (Model Outline) IndDocument43 pagesALPHARD (Model Outline) IndFuad AnwarNo ratings yet

- Parts Catalog: 2010/10 (Oct.) PublishedDocument29 pagesParts Catalog: 2010/10 (Oct.) PublishedВладиславМасарскийNo ratings yet

- Brochure EliteDocument2 pagesBrochure EliteSuwirman SuwirmanNo ratings yet

- Fast Moving Volvo PartsDocument2 pagesFast Moving Volvo Partsali4299No ratings yet

- Surveying 1: Awais Ahmed MirzaDocument32 pagesSurveying 1: Awais Ahmed MirzaSakthivelNo ratings yet

- WRT - Maintenance InstructionDocument63 pagesWRT - Maintenance InstructionSon DDarrellNo ratings yet

- AVIATION ENGLISH 1 - 2019/2020: TH THDocument2 pagesAVIATION ENGLISH 1 - 2019/2020: TH THDarjan SušaNo ratings yet

- Model B, C, CHD Tubing Spider Cut SheetDocument2 pagesModel B, C, CHD Tubing Spider Cut SheetEdgar Moreira Fernandez100% (1)

- TM80/TM120 Product Manual For Units With Allen Bradley PLC: Serial Number: Document ID: 16-005 V 2.0Document182 pagesTM80/TM120 Product Manual For Units With Allen Bradley PLC: Serial Number: Document ID: 16-005 V 2.0Juan Morbelli100% (1)

- Plate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)Document2 pagesPlate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)joaojitoNo ratings yet

- Multiport Fuel Injection (Mfi) : Group 13ADocument322 pagesMultiport Fuel Injection (Mfi) : Group 13AJBNo ratings yet

- Flow 2 Stairlift Brochure PDFDocument8 pagesFlow 2 Stairlift Brochure PDFJustin ThomasNo ratings yet

- Spur Gear - : Spur Gears or Straight-Cut Gears Are The Simplest TypeDocument5 pagesSpur Gear - : Spur Gears or Straight-Cut Gears Are The Simplest TyperaviNo ratings yet

- API Pump Type DefinationDocument30 pagesAPI Pump Type DefinationYadav ShwetaNo ratings yet

- Chrysler AS Town Country Caravan Voyager 1994 Service Manual Wheels and TiresDocument8 pagesChrysler AS Town Country Caravan Voyager 1994 Service Manual Wheels and Tiressimple383No ratings yet

Centrifugal Pump Data Sheet

Centrifugal Pump Data Sheet

Uploaded by

Athiphap Srisupareerath0 ratings0% found this document useful (0 votes)

166 views1 pageThis document provides specifications for a centrifugal pump, including:

1) The pump is an API type BB3 with multiple volute casing mounted in-line.

2) Nozzle connections include a 6" suction and 3" discharge with RTJ flanges rated for 900 psi.

3) The pump will be driven by a coupling and mounted on a full top deck baseplate with drainage and leveling screws.

Original Description:

Pump data

Original Title

3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for a centrifugal pump, including:

1) The pump is an API type BB3 with multiple volute casing mounted in-line.

2) Nozzle connections include a 6" suction and 3" discharge with RTJ flanges rated for 900 psi.

3) The pump will be driven by a coupling and mounted on a full top deck baseplate with drainage and leveling screws.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

166 views1 pageCentrifugal Pump Data Sheet

Centrifugal Pump Data Sheet

Uploaded by

Athiphap SrisupareerathThis document provides specifications for a centrifugal pump, including:

1) The pump is an API type BB3 with multiple volute casing mounted in-line.

2) Nozzle connections include a 6" suction and 3" discharge with RTJ flanges rated for 900 psi.

3) The pump will be driven by a coupling and mounted on a full top deck baseplate with drainage and leveling screws.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

CENTRIFUGAL PUMP DATA SHEET

1 Note CONSTRUCTION Rev

2 API PUMP TYPE: BB3 [Based on API 610 definitions] CASING MOUNTING: IN-LINE

3 CASING TYPE: (6.3.10) MULTIPLE VOLUTE

4 NOZZLE CONNECTIONS: (6.5.5) OH3 BACKPULLOUT LIFTING DEVICE REQD. (9.1.2.6) NO

5 Size Facing Rating Position CASE PRESSURE RATING:

6 SUCTION 6 RTJ 900 SIDE MAWP : (6.3.6) 1480.00 psig @ 250.00 °F

7 DISCHARGE 3 RTJ 900 SIDE HYDROTEST : 1920 psig @ 250.00 °F

8 PRESSURE CASING AUX. CONNECTIONS: (6.4.3.2)

9 No. Size Type Facing Rating Posn. HYDROTEST OH PUMP AS ASSEMBLY YES

10 BALANCE/LEAK OFF SUCT'N PRESS. REGIONS DESIGNED FOR MAWP YES

11 DRAIN ROTATION: (VIEWED FROM COUPLING END) CW

12 VENT • IMPELLERS INDIVIDUALLY SECURED :

13 PRESSURE GAGE • BOLT OH 3/4/5 PUMP TO PAD / FOUNDATION : NO

14 TEMP GAGE • PROVIDE SOLEPLATE FOR OH 3/4/5 PUMPS NO

15 WARM-UP LINE ROTOR:

16 SHAFT FLEXIBILITY INDEX (SFI) (9.1.1.3)

17 Drain Valve Supplied By SUPPLIER First Critical Speed Wet (Multi stage pumps only) N/A

18 DRAINS MANIFOLDED NO COMPONENT BALANCE TO ISO 1940 G1.0 N/A

19 VENT Valve Supplied By SUPPLIER SHRINK FIT -LIMITED MOVEMENT IMPELLERS (9.2.2.3) N/A

20 VENTS MANIFOLDED

21 THREADED CONS FOR PIPELINE SERVICE & < 50°C (6.4.3.2) COUPLING:(7.2.3) (7.2.13.f)

22 SPECIAL FITTINGS FOR TRANSITIONING (6.4.3.3) MANUFACTURER

23 CYLINDRICAL THREADS REQUIRED (6.4.3.8) MODEL

24 GUSSET SUPPORT REQUIRED RATING (POWER/100 RPM)

25 MACHINED AND STUDDED CONNECTIONS (6.4.3.12) YES SPACER LENGTH in.

26 VS 6 DRAIN SERVICE FACTOR

27 DRAIN TO SKID EDGE RIGID YES

28 COUPLING WITH HYDRAULIC FIT (7.2.10)

29 MATERIAL (6.12.1.1) COUPLING BALANCED TO ISO 1940-1 G6.3 (7.2.3)

30 APPENDIX H CLASS S-6 COUPLING WITH PROPRIETARY CLAMPING DEVICE (7.2.11)

31 MIN DESIGN METAL TEMP (6.12.4.1) °F YES

32 REDUCED-HARDNESS MATERIALS REQ'D (6.12.1.12.1) COUPLING IN COMPLIANCE WITH (7.2.4) mfr std

33 Applicable Hardness Standard (6.12.1.12.3) COUPLING GUARD STANDARD PER (7.2.13.a) ANSI B15.1

34 BARREL : Window on Coupling Guard YES

35 CASE : Carbon Steel

36 DIFFUSERS BASEPLATE

37 IMPELLER : Bronze C93200 API BASEPLATE NUMBER : N/A

38 IMPELLER WEAR RING : GR CA40 BASEPLATE CONSTRUCTION (7.3.14) FULL TOP DECKING

39 CASE WEAR RING : BASEPLATE DRAINAGE (7.3.1) Partial Drain Pan

40 SHAFT: MONEL MOUNTING :

41 Bowl (if VS-type) NON-GROUT CONSTRUCTION : (7.3.13)

42 Inspection Class VERTICAL LEVELING SCREWS :

43 BEARINGS AND LUBRICATION (6.10.1.1) LONGITUDINAL DRIVER POSITIONING SCREWS :

44 BEARING (TYPE / NUMBER): (6.11.4) SUPPLIED WITH : l GROUT AND VENT HOLES

45 RADIAL BALL / l DRAIN CONNECTION

46 THRUST BALL / MOUNTING PADS SIZED FOR BASEPLATE LEVELING (7.3.5) YES

47 REVIEW AND APPROVE THRUST BEARING SIZE : (9.2.5.2.4) MOUNTING PADS TO BE MACHINED (7.3.6) YES

48 PROVIDE SPACER PLATE UNDER ALL EQUIPMENT FEET NO

49 LUBRICATION : (6.10.2.2) (6.11.3) (9.6.1) RING OIL OTHER

50 PRESSURE LUBE SYSTEM TO ISO 10438- (9.2.6.5) Production Solution Standard Base plate

50 ISO 10438 DATA SHEETS ATTACHED

51 Pressurized Lube Oil System mtd on pump baseplate REMARKS :

52 Location of Pressurized Lube Oil System mounted on baseplate : Production Solution Standard Base plate

53

54 INTERCONNECTING PIPING PROVIDED BY Supplier

55

56 OIL VISC. ISO GRADE VG 68

57 CONSTANT LEVEL OILER :

A

DATA SHEET No. Rev: B SHEET 3 of 10

You might also like

- 2010 Ford F150 Diagramas de TransmisionDocument15 pages2010 Ford F150 Diagramas de TransmisionRuben100% (3)

- Spare Parts List: Hydraulic BreakersDocument12 pagesSpare Parts List: Hydraulic BreakersADELALHTBANINo ratings yet

- Manitowoc 4500 - 4665 - Parts ManualDocument280 pagesManitowoc 4500 - 4665 - Parts ManualalbertoNo ratings yet

- Volvo s60 2008 Wiring DiagramDocument20 pagesVolvo s60 2008 Wiring DiagramKellye100% (61)

- Woodward Governor Ug 8 L Manual: Read/DownloadDocument2 pagesWoodward Governor Ug 8 L Manual: Read/DownloadIwan Purwanto80% (5)

- Ge08ti 950106-01166 PBDocument384 pagesGe08ti 950106-01166 PBKeron TrotzNo ratings yet

- Branch Reinforcement - ASME 31.1Document8 pagesBranch Reinforcement - ASME 31.1zakir84md3639No ratings yet

- API Standard 619 - Rotary-Type Displacement Compressors For Petroleum, Chemical, and Gas Industry ServicesDocument2 pagesAPI Standard 619 - Rotary-Type Displacement Compressors For Petroleum, Chemical, and Gas Industry ServicesmishraenggNo ratings yet

- Jharkhand Sor 2016 (2) R.A PDFDocument419 pagesJharkhand Sor 2016 (2) R.A PDFDebasish Misra100% (12)

- Schematic 12m3 Hydraulic SystemDocument2 pagesSchematic 12m3 Hydraulic SystemalcidesNo ratings yet

- Submersible Sump Pumps 83-TMSS-01, Rev 0Document12 pagesSubmersible Sump Pumps 83-TMSS-01, Rev 0Pageduesca RouelNo ratings yet

- Miter Drawing Details For Anchor BlocksDocument1 pageMiter Drawing Details For Anchor BlocksUHPB TeamNo ratings yet

- ITP For EDGDocument6 pagesITP For EDGmuraliNo ratings yet

- Air Eliminator DatasheetDocument2 pagesAir Eliminator DatasheetbecpavanNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Cost Bunchpress & Shredder Sunli by BJM 2019 Mei EditDocument1 pageCost Bunchpress & Shredder Sunli by BJM 2019 Mei EditHeryy TanujayaNo ratings yet

- QM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During RegistrationDocument8 pagesQM-RF-7.1-3 Ver.2.0 - Guidelines For Preparing QAP During Registrationsanjayde100% (1)

- Asme BPVC Section VIII Division 1: Key Changes 2019 EditionDocument69 pagesAsme BPVC Section VIII Division 1: Key Changes 2019 Editionhiman_chongiNo ratings yet

- Piping Material Spec C19032-PP-GEN-SPE-101 - 0 - AFCDocument96 pagesPiping Material Spec C19032-PP-GEN-SPE-101 - 0 - AFCZed WangNo ratings yet

- NPD1 Training - PTPL - Cooling Tower - PCX-Series - Apr 2020Document38 pagesNPD1 Training - PTPL - Cooling Tower - PCX-Series - Apr 2020Shyam J VyasNo ratings yet

- HIC & SSC Test ProcedureDocument32 pagesHIC & SSC Test ProcedureMohamed FarisNo ratings yet

- Minimum Distance Between Pipes With FlanchesDocument12 pagesMinimum Distance Between Pipes With FlanchesJMVNo ratings yet

- ACI 318-11 Appedix DDocument2 pagesACI 318-11 Appedix DJonathan SchauderNo ratings yet

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocument209 pagesComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999No ratings yet

- Drainage Pump 50HzDocument20 pagesDrainage Pump 50HzashishkkrNo ratings yet

- Mil C 16173Document28 pagesMil C 16173Lokesh Narasimhaiah100% (1)

- 41.water Cum Foam Monitor-Trailer MountedDocument2 pages41.water Cum Foam Monitor-Trailer MountedSimbu ArasanNo ratings yet

- Data Sheet: Document NoDocument3 pagesData Sheet: Document Nobagus handokoNo ratings yet

- Spring Datasheeet PauDocument4 pagesSpring Datasheeet PauFeri KaruanaNo ratings yet

- At N.p.c.i.l., RawatbhataDocument30 pagesAt N.p.c.i.l., RawatbhataDevendra SharmaNo ratings yet

- Mroy Pump Catalogue PDFDocument6 pagesMroy Pump Catalogue PDFTitus FelixNo ratings yet

- Failure of Gearbox Cooling Tower Fan in Cement Mill 1607659041Document15 pagesFailure of Gearbox Cooling Tower Fan in Cement Mill 1607659041Muhtiar Darja100% (1)

- Specs - Belt Conveyor 1 ProjectDocument7 pagesSpecs - Belt Conveyor 1 ProjectEdson Valter VillalunaNo ratings yet

- Sor 2010Document411 pagesSor 2010Neeraj AgrawalNo ratings yet

- ASTM B619 B619M 17aDocument6 pagesASTM B619 B619M 17aAbdülHak ÖZkaraNo ratings yet

- Beacon Planetary Drive CatalogueDocument8 pagesBeacon Planetary Drive CatalogueMaheshNo ratings yet

- RFQ For Site Fabricated TanksDocument10 pagesRFQ For Site Fabricated TanksNil BorichaNo ratings yet

- Provision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field DevelopmentDocument7 pagesProvision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field Developmentriandi100% (1)

- Pulsating Heat Pipe ReportDocument65 pagesPulsating Heat Pipe ReportIdul Azharul HoqueNo ratings yet

- Muff Coupling & Split Muff CouplingDocument19 pagesMuff Coupling & Split Muff CouplingRamanathan DuraiNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- Centrifugal Force Calculation Description Result Unit 125: Graphical IllustrationDocument6 pagesCentrifugal Force Calculation Description Result Unit 125: Graphical IllustrationvenkateswaranNo ratings yet

- Spare Part Turbin PLTA Bengkok PDFDocument1 pageSpare Part Turbin PLTA Bengkok PDFAditya PrajasNo ratings yet

- Joint Inspection Stringging (NEW)Document2 pagesJoint Inspection Stringging (NEW)ari cahyonoNo ratings yet

- 3 Stack 00001Document1 page3 Stack 00001karioke mohaNo ratings yet

- Form Comisionig&Performance Conveyor TestDocument2 pagesForm Comisionig&Performance Conveyor Testariyanagung29No ratings yet

- Konveyor RantaiDocument91 pagesKonveyor Rantaiabdulloh_99No ratings yet

- Supplier Deliverable RegisterDocument4 pagesSupplier Deliverable RegisterTadaya KasaharaNo ratings yet

- Pump Assessment PDFDocument20 pagesPump Assessment PDFJonas ArifinNo ratings yet

- Area Handover FormDocument1 pageArea Handover FormsivagaaneshNo ratings yet

- Strength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002Document9 pagesStrength Calculation As Per Ibr Boiler Maker'S No.: Atpl-Rb002mohan babuNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- SKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1Document31 pagesSKH3-DS-20-007A-A4 Data Sheet Overhead Crane REV 0.1kebarongan12No ratings yet

- Cable Route MarkerDocument2 pagesCable Route Markersundareee96No ratings yet

- Datasheet PompaDocument8 pagesDatasheet PompaagusnnnNo ratings yet

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 pageApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilNo ratings yet

- Dinflo DFCSDocument2 pagesDinflo DFCSvictorharijantoNo ratings yet

- Bharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)Document5 pagesBharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)bmanojkumar16No ratings yet

- Approved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XDocument2 pagesApproved SMDL Copy of Worksheetin4500541788-40-Smdlrev00 - 20130911043508.141 - XP Sandana NaraNo ratings yet

- Fire Monitor Data Sheet - 3-3Document1 pageFire Monitor Data Sheet - 3-3Bagus PrambudiNo ratings yet

- PIG Handling TrollyDocument1 pagePIG Handling TrollyAnas Badar100% (1)

- NM6-110E Data SheetDocument3 pagesNM6-110E Data SheetDedi WahyudiNo ratings yet

- Api 15HR Erta 2-2008Document1 pageApi 15HR Erta 2-2008Ali KhalilNo ratings yet

- Counter Weight Drawing MCT85Document14 pagesCounter Weight Drawing MCT85Nirmalya SenNo ratings yet

- Pressure Balanced Expansion ElbowsDocument1 pagePressure Balanced Expansion ElbowsJoshua HobsonNo ratings yet

- Cp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Document1 pageCp12 Pps 3274c Me Ds 001 Data Sheet Hvac Sunyaragi Rev.0Triana Rosma Fikriyati DinaNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- ระเบียบสำนักงานฯ ว่าด้วยการขึ้นทะเบียบสมาชิกของ สสว พ ศ 2559Document6 pagesระเบียบสำนักงานฯ ว่าด้วยการขึ้นทะเบียบสมาชิกของ สสว พ ศ 2559Athiphap SrisupareerathNo ratings yet

- Pump Mechanical Run TestDocument2 pagesPump Mechanical Run TestAthiphap SrisupareerathNo ratings yet

- A Basic Guide To Borescopic Inspection For Gas Engines: Energy Lives HereDocument2 pagesA Basic Guide To Borescopic Inspection For Gas Engines: Energy Lives HereAthiphap SrisupareerathNo ratings yet

- MCM Oil Tools: Cameron Style H2' Choke PartsDocument1 pageMCM Oil Tools: Cameron Style H2' Choke PartsAthiphap SrisupareerathNo ratings yet

- PrecautionDocument1 pagePrecautionAthiphap SrisupareerathNo ratings yet

- An Massflow E 11153Document4 pagesAn Massflow E 11153Athiphap SrisupareerathNo ratings yet

- FULLTEXT02Document97 pagesFULLTEXT02Athiphap SrisupareerathNo ratings yet

- Blowout Preventer System: PT Pertamina Drilling Services Indonesia Area JawaDocument23 pagesBlowout Preventer System: PT Pertamina Drilling Services Indonesia Area JawaAthiphap SrisupareerathNo ratings yet

- Facts 821 Metric Units ENDocument15 pagesFacts 821 Metric Units ENAthiphap SrisupareerathNo ratings yet

- Instructions EN 2018Document23 pagesInstructions EN 2018Athiphap SrisupareerathNo ratings yet

- Summit Pump: Installation, Operation, and Maintenance ManualDocument53 pagesSummit Pump: Installation, Operation, and Maintenance ManualAthiphap SrisupareerathNo ratings yet

- Pressure Safety Valve Sizing Calculation Rev 01Document3 pagesPressure Safety Valve Sizing Calculation Rev 01Athiphap SrisupareerathNo ratings yet

- Cepsa Group Supplier Code of Ethics and ConductDocument20 pagesCepsa Group Supplier Code of Ethics and ConductAthiphap SrisupareerathNo ratings yet

- Final Report Mech c2 - Batch 6Document41 pagesFinal Report Mech c2 - Batch 6Godwin SamuelNo ratings yet

- Ecm 7Document1 pageEcm 7Misa GamezNo ratings yet

- CUE-099-A - SubmittalDocument3 pagesCUE-099-A - SubmittalElmer Ramón Murillo MejiaNo ratings yet

- 0340 Peinersmagde-21022003-P-Peiner-Greifer-OperatingDocument94 pages0340 Peinersmagde-21022003-P-Peiner-Greifer-OperatingHui ChenNo ratings yet

- GM Install and Key Relearn Instructions FinalDocument6 pagesGM Install and Key Relearn Instructions FinalDaniel oberNo ratings yet

- John Deere 4024TF281 Replacement Part GuideDocument2 pagesJohn Deere 4024TF281 Replacement Part GuideRamon Pujol PerramonNo ratings yet

- Combinorm: Instruction ManualDocument193 pagesCombinorm: Instruction ManualHabib A. IslamNo ratings yet

- Return To Service Checklist ADocument12 pagesReturn To Service Checklist AAntonio Cesar de Sa LeitaoNo ratings yet

- ALPHARD (Model Outline) IndDocument43 pagesALPHARD (Model Outline) IndFuad AnwarNo ratings yet

- Parts Catalog: 2010/10 (Oct.) PublishedDocument29 pagesParts Catalog: 2010/10 (Oct.) PublishedВладиславМасарскийNo ratings yet

- Brochure EliteDocument2 pagesBrochure EliteSuwirman SuwirmanNo ratings yet

- Fast Moving Volvo PartsDocument2 pagesFast Moving Volvo Partsali4299No ratings yet

- Surveying 1: Awais Ahmed MirzaDocument32 pagesSurveying 1: Awais Ahmed MirzaSakthivelNo ratings yet

- WRT - Maintenance InstructionDocument63 pagesWRT - Maintenance InstructionSon DDarrellNo ratings yet

- AVIATION ENGLISH 1 - 2019/2020: TH THDocument2 pagesAVIATION ENGLISH 1 - 2019/2020: TH THDarjan SušaNo ratings yet

- Model B, C, CHD Tubing Spider Cut SheetDocument2 pagesModel B, C, CHD Tubing Spider Cut SheetEdgar Moreira Fernandez100% (1)

- TM80/TM120 Product Manual For Units With Allen Bradley PLC: Serial Number: Document ID: 16-005 V 2.0Document182 pagesTM80/TM120 Product Manual For Units With Allen Bradley PLC: Serial Number: Document ID: 16-005 V 2.0Juan Morbelli100% (1)

- Plate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)Document2 pagesPlate Wear and Starting Gear On GR801 and GR/GRS900 (Series 3 and 4)joaojitoNo ratings yet

- Multiport Fuel Injection (Mfi) : Group 13ADocument322 pagesMultiport Fuel Injection (Mfi) : Group 13AJBNo ratings yet

- Flow 2 Stairlift Brochure PDFDocument8 pagesFlow 2 Stairlift Brochure PDFJustin ThomasNo ratings yet

- Spur Gear - : Spur Gears or Straight-Cut Gears Are The Simplest TypeDocument5 pagesSpur Gear - : Spur Gears or Straight-Cut Gears Are The Simplest TyperaviNo ratings yet

- API Pump Type DefinationDocument30 pagesAPI Pump Type DefinationYadav ShwetaNo ratings yet

- Chrysler AS Town Country Caravan Voyager 1994 Service Manual Wheels and TiresDocument8 pagesChrysler AS Town Country Caravan Voyager 1994 Service Manual Wheels and Tiressimple383No ratings yet