Professional Documents

Culture Documents

D.P. Test For All Parts

D.P. Test For All Parts

Uploaded by

S DasCopyright:

Available Formats

You might also like

- Slurry Transport Using Centrifugal Pumps (4th Edition) 2023Document494 pagesSlurry Transport Using Centrifugal Pumps (4th Edition) 2023khaledianmehdi648No ratings yet

- Standard Norsok Standard R 001 For Mechanical EqptDocument152 pagesStandard Norsok Standard R 001 For Mechanical Eqptaravindhcam100% (3)

- Method Statement For Installation of Firefighting Pump SetDocument13 pagesMethod Statement For Installation of Firefighting Pump SetRaj Kamal75% (4)

- SAT - Centrifugal Pump For TDUDocument4 pagesSAT - Centrifugal Pump For TDUNIKHIL JOHRI100% (5)

- Method Statement of Sump PumpDocument3 pagesMethod Statement of Sump Pumpjames jatt Bond100% (2)

- Cooling Tower Construction ChecklistDocument6 pagesCooling Tower Construction ChecklistGopinath GopiNo ratings yet

- Testing & Commissioning of Chilled Water PumpsDocument3 pagesTesting & Commissioning of Chilled Water Pumpsamg00750% (4)

- Fans Testing & Commissioning Format-R0Document13 pagesFans Testing & Commissioning Format-R0Hari Sankar100% (1)

- Kewaunee LV Fume Hood SpecsDocument14 pagesKewaunee LV Fume Hood SpecsprabhudNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Classification of Tests:: Testing Procedures of A PumpDocument8 pagesClassification of Tests:: Testing Procedures of A PumpMohamad Izwan HussienNo ratings yet

- 3 s2.0 B9780884156864500508 MainDocument4 pages3 s2.0 B9780884156864500508 MainAmal KaNo ratings yet

- Factory Performance Testing of Vertical Turbine PumpsDocument3 pagesFactory Performance Testing of Vertical Turbine PumpsSrećko BlaževićNo ratings yet

- ITP For Centrifugal Pump4Document1 pageITP For Centrifugal Pump4Adades Safede EfdNo ratings yet

- Specification For Fire Water PumpsDocument7 pagesSpecification For Fire Water PumpsSANDEEP KUMAR RAHEJA100% (1)

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Sudhakar KarnanNo ratings yet

- 1-Check List CF PumpDocument2 pages1-Check List CF PumpStarla HillNo ratings yet

- VCR Multi FuelDocument5 pagesVCR Multi FuelAshish VermaNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- Method Statement For Installation of Firefighting Pump Set PDFDocument13 pagesMethod Statement For Installation of Firefighting Pump Set PDFAhmed Issa100% (1)

- Tech Spec For Centrifugal PumpDocument5 pagesTech Spec For Centrifugal PumpRoby Mirza100% (1)

- Drainage & Sump Pumps Specs PDFDocument25 pagesDrainage & Sump Pumps Specs PDFWalid El Ghonamy100% (1)

- Pumps: SECTION 15/1/5Document10 pagesPumps: SECTION 15/1/5farshan296015No ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Fire Pump SpecificationDocument5 pagesFire Pump SpecificationThiru AnanthNo ratings yet

- Centrifugal Pump InspectionDocument33 pagesCentrifugal Pump InspectionAbhi Nandana100% (1)

- 60 - 15540 - HVAC Pumps and SpecialtiesDocument4 pages60 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- Annexure 3486Document8 pagesAnnexure 3486Kamal RajuNo ratings yet

- Specification For Internal Gear Pumps: 1.0 General DescriptionDocument7 pagesSpecification For Internal Gear Pumps: 1.0 General DescriptionHassan ShafiqueNo ratings yet

- Section 263235 - Standby Generator Testing and Commissioning.1Document5 pagesSection 263235 - Standby Generator Testing and Commissioning.1yaniahmad_82No ratings yet

- Clarifications and Exceptions of Api 675, Third EditionDocument3 pagesClarifications and Exceptions of Api 675, Third EditionFathan KarimanNo ratings yet

- T&CDocument13 pagesT&CAbdurRahmanFNo ratings yet

- NFPA Fire PumpDocument12 pagesNFPA Fire PumpSyed Faizan AliNo ratings yet

- 6 - Testing-Inspections-Req - 07-23-22Document56 pages6 - Testing-Inspections-Req - 07-23-22Larry Wayne Sumpter, JrNo ratings yet

- Appendix 11F: Operational ChecklistsDocument15 pagesAppendix 11F: Operational Checklists许爱文No ratings yet

- Recip. Compressor TestingDocument10 pagesRecip. Compressor TestingS DasNo ratings yet

- 3413514Document14 pages3413514vineethvskkdNo ratings yet

- Mechanical Equipment TestingDocument12 pagesMechanical Equipment TestingChemi YeNo ratings yet

- NETA Acceptance Testing Specifications - 2009 ExcerptDocument4 pagesNETA Acceptance Testing Specifications - 2009 ExcerptkpNo ratings yet

- Part 1 - General: SpecificationsDocument6 pagesPart 1 - General: SpecificationsDiego Plata VasquezNo ratings yet

- 12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865Document5 pages12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865tristan guarinoNo ratings yet

- Sprinkler System - General InformationDocument5 pagesSprinkler System - General InformationshahidenterNo ratings yet

- Fire Fighting Pumping SystemDocument23 pagesFire Fighting Pumping Systemvirtech100% (1)

- How To Conduct A Boiler Performance TestDocument4 pagesHow To Conduct A Boiler Performance Testsabill arasyidNo ratings yet

- Fire Pump Pre-Inspection QuestionnaireDocument3 pagesFire Pump Pre-Inspection QuestionnaireateeqNo ratings yet

- Commissioning of Fire PumpsDocument3 pagesCommissioning of Fire Pumpskamranarif4161No ratings yet

- Testing Commissioning Checklist For Fuel PumpDocument1 pageTesting Commissioning Checklist For Fuel PumpMoh'd SameerNo ratings yet

- Pump Start Up ChecklistDocument1 pagePump Start Up ChecklistSharif Mohammad AdwanNo ratings yet

- Testing & Commissioning Method Statement For Fire Fighting PumpsDocument4 pagesTesting & Commissioning Method Statement For Fire Fighting Pumpsvin ssNo ratings yet

- Centrifugal Compressor TestingDocument9 pagesCentrifugal Compressor TestingEnergy 2GreenNo ratings yet

- Interconnection Design Gas PipelinesDocument96 pagesInterconnection Design Gas PipelinesBeatriz Adams Garcia100% (2)

- My NotesDocument15 pagesMy NotesThe Servant of Allah SWTNo ratings yet

- 213113P - Fire Pumps and Controllers 09 09 2022Document11 pages213113P - Fire Pumps and Controllers 09 09 2022albfaragNo ratings yet

- 1510 - 15540 - HVAC Pumps and SpecialtiesDocument5 pages1510 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- 80 - 15540 - HVAC Pumps and SpecialtiesDocument5 pages80 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- Last Page PG TestDocument31 pagesLast Page PG Testarmanshaikh.engNo ratings yet

- Inspection and Test ProceduresDocument33 pagesInspection and Test Proceduresmrnoboby0407No ratings yet

- FAT PumpsDocument15 pagesFAT Pumpsaqhammam100% (1)

- Enquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item DescriptionDocument5 pagesEnquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item Descriptionpramodyad5810No ratings yet

- Genset Load TestDocument10 pagesGenset Load Testjavad100% (2)

- 90 - 15540 - HVAC Pumps and SpecialtiesDocument4 pages90 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Features (Engineered Solutions) : Smart FlowDocument1 pageFeatures (Engineered Solutions) : Smart FlowS DasNo ratings yet

- Oil With Particulate Oil With WaterDocument1 pageOil With Particulate Oil With WaterS DasNo ratings yet

- Ab 2Document1 pageAb 2S DasNo ratings yet

- Bearing Housing Put Through Rigorous TestingDocument1 pageBearing Housing Put Through Rigorous TestingS DasNo ratings yet

- Rheinhütte Rvku Chemical Centrifugal Pump in Plastic Rheinhütte Rkuv Chemical Centrifugal Pump in PlasticDocument1 pageRheinhütte Rvku Chemical Centrifugal Pump in Plastic Rheinhütte Rkuv Chemical Centrifugal Pump in PlasticS DasNo ratings yet

- Goulds 3171 Vertical Sump and Process Goulds NM3171 FRP Vertical Sump and ProcessDocument1 pageGoulds 3171 Vertical Sump and Process Goulds NM3171 FRP Vertical Sump and ProcessS DasNo ratings yet

- Humidification Loads Will Exceed 90% RH in Duct at Temperature Indicated. Booster Humidification Is RecommendedDocument1 pageHumidification Loads Will Exceed 90% RH in Duct at Temperature Indicated. Booster Humidification Is RecommendedS DasNo ratings yet

- Goulds 3175 Paper Stock / ProcessDocument1 pageGoulds 3175 Paper Stock / ProcessS DasNo ratings yet

- Goulds 3196 i-FRAME ANSI Process Goulds HT 3196 i-FRAME ANSI High Temperature Process PumpDocument1 pageGoulds 3196 i-FRAME ANSI Process Goulds HT 3196 i-FRAME ANSI High Temperature Process PumpS DasNo ratings yet

- Rheinhütte GVSO Vertical Chemical Centrifugal Pump in Metal Rheinhütte GVRN Acid Vertical Chemical Centrifugal PumpDocument1 pageRheinhütte GVSO Vertical Chemical Centrifugal Pump in Metal Rheinhütte GVRN Acid Vertical Chemical Centrifugal PumpS DasNo ratings yet

- External Space Loads: Load Estimating, Level 1: FundmentalsDocument1 pageExternal Space Loads: Load Estimating, Level 1: FundmentalsS DasNo ratings yet

- t3 PDFDocument1 paget3 PDFS DasNo ratings yet

- O 3Document1 pageO 3S DasNo ratings yet

- Load Estimating, Level 1: FundamentalsDocument1 pageLoad Estimating, Level 1: FundamentalsS DasNo ratings yet

- Basic HVAC Flow Diagrams: Configuration-1: Conventional Primary LoopDocument1 pageBasic HVAC Flow Diagrams: Configuration-1: Conventional Primary LoopS DasNo ratings yet

- Load Estimating, Level 1: Fundamentals: Solar Heat GainDocument1 pageLoad Estimating, Level 1: Fundamentals: Solar Heat GainS DasNo ratings yet

- Basic HVAC Flow Diagrams: Configuration-3: Primary Loop With Dual ReturnsDocument1 pageBasic HVAC Flow Diagrams: Configuration-3: Primary Loop With Dual ReturnsS DasNo ratings yet

- DG Brochure July, 2013Document6 pagesDG Brochure July, 2013S DasNo ratings yet

- Control Airflows Between Rooms: PressurizationDocument1 pageControl Airflows Between Rooms: PressurizationS DasNo ratings yet

- TEC Services, Inc.: Thermal Aerosol Generator, Model Compact (Inert Gas)Document1 pageTEC Services, Inc.: Thermal Aerosol Generator, Model Compact (Inert Gas)S DasNo ratings yet

- Example Fan Filter Units Arrangement: Air LockDocument1 pageExample Fan Filter Units Arrangement: Air LockS DasNo ratings yet

- ParticleDocument1 pageParticleS DasNo ratings yet

- Airborne Particle Physical Controls: Typical Ceiling Filter CoverageDocument1 pageAirborne Particle Physical Controls: Typical Ceiling Filter CoverageS DasNo ratings yet

- UAE B2b Email Database SampleDocument32 pagesUAE B2b Email Database Sampleirfan aminNo ratings yet

- Crude Oil ProjectDocument19 pagesCrude Oil ProjectYousef JawarnehNo ratings yet

- Catalogos EBARADocument15 pagesCatalogos EBARAJorge Alejandro Verde VereauNo ratings yet

- Pump MathsDocument10 pagesPump MathsSakib RafeeNo ratings yet

- .Pumps NotesDocument19 pages.Pumps NotesSean Esponge100% (1)

- Pulsation Dampener ProductsDocument16 pagesPulsation Dampener Productsgekinter100% (1)

- Product Bulletin 21Document2 pagesProduct Bulletin 21RANAIVOARIMANANANo ratings yet

- MdsDocument34 pagesMdsbalajiNo ratings yet

- Datasheet 175SR20S66-0863Document1 pageDatasheet 175SR20S66-0863Frank RodriguezNo ratings yet

- Houttuin TT BrochureDocument8 pagesHouttuin TT BrochureAswin Lorenso Gultom NamoralotungNo ratings yet

- HL200M Pump Curve - 5Document1 pageHL200M Pump Curve - 5Ayu FijriNo ratings yet

- CV Ahsan Sajjad-Hydromechanical Engr.Document9 pagesCV Ahsan Sajjad-Hydromechanical Engr.Ahsan SajjadNo ratings yet

- Gear Pump Standard Operating Manual and Instructions PDFDocument35 pagesGear Pump Standard Operating Manual and Instructions PDFdalbaasNo ratings yet

- FIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVDocument8 pagesFIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVCrysthian AspilcuetaNo ratings yet

- Ansihi 9.6.3-2012Document23 pagesAnsihi 9.6.3-2012mawirNo ratings yet

- Qty. Description SP 17-25: Company Name: Created By: Phone: DateDocument4 pagesQty. Description SP 17-25: Company Name: Created By: Phone: DatehirararaNo ratings yet

- Grundfos - CR 10 5 A FJ A E HQQEDocument11 pagesGrundfos - CR 10 5 A FJ A E HQQErosneyNo ratings yet

- Niso - CNP PumpDocument8 pagesNiso - CNP Pumpdebasish.guptaNo ratings yet

- Line SizingDocument17 pagesLine SizingAllyssa Jane ErcillaNo ratings yet

- 100 HP Sihi PumpsDocument28 pages100 HP Sihi Pumpsnapster386No ratings yet

- Flowserve Educational Services Course CatalogDocument24 pagesFlowserve Educational Services Course CatalogTrevor KanodeNo ratings yet

- Pump NPSH - Accounting For Dissolved GasesDocument13 pagesPump NPSH - Accounting For Dissolved GasesSarelys ZavalaNo ratings yet

- Ensc End Suction PumpsDocument348 pagesEnsc End Suction PumpsRheoserve Industrial SolutionsNo ratings yet

- M100-10 (M-MA Meters) - V3 - 2.11.19 - 1Document28 pagesM100-10 (M-MA Meters) - V3 - 2.11.19 - 1ronald mudimuNo ratings yet

- Potable Water PumpsDocument17 pagesPotable Water PumpsNijasNo ratings yet

- VEY Molten Salt Pump For Concentrated Solar PowerDocument6 pagesVEY Molten Salt Pump For Concentrated Solar PowerSublim ArtNo ratings yet

- Basic Theory PumpDocument37 pagesBasic Theory PumpkunkzNo ratings yet

- NPSH - Net Positive Suction HeadDocument15 pagesNPSH - Net Positive Suction HeadAhmedHamadaNo ratings yet

D.P. Test For All Parts

D.P. Test For All Parts

Uploaded by

S DasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D.P. Test For All Parts

D.P. Test For All Parts

Uploaded by

S DasCopyright:

Available Formats

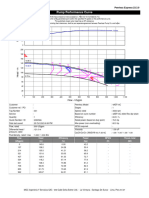

Standard running test:

The pumps shall be tested as per IS: 5120, at rated speed in manufacturer’s works to

measure capacity, total head, efficiency and power. The negative tolerance on efficiency

shall be limited to 2 ½ % (not 5% as indicated in IS: 5120). These tests will form the basis for

acceptance of pumps except for vibration and noise. The pumps shall be tested over the

range covering from shut off head to the maximum flow. The duration of the test shall be

minimum one hour or till the stabilization of bearing/mechanical seal temperature rise.

Minimum five readings approximately equidistant shall be taken for plotting the performance

curves.

The positive tolerance on power input to the pump set at duty point shall be limited to the

value, if indicated in Data Sheet. Otherwise the tolerance is governed by the tolerances on

pump capacity and efficiency of the pump set.

NPSH tests:

NPSH tests shall be conducted with water as the medium to demonstrate the ability of the

pump to draw the water the designed suction lift.

In addition to static balancing, impeller and balancing drum shall be balanced dynamically as

per ISO-1940 Gr. 6.3 near to the operating speed.

Non-destructive testing of the pump components shall be offered as specified in Data Sheet.

These tests shall be conducted in accordance with relevant standards. Prior to testing, the

test procedure and repair procedure shall be submitted for the purchaser’s approval. All

components which are tested successfully shall be used for the manufacture of final product.

All test results shall be submitted by the vendor for the purchaser’s approval.

Pumps shall be offered for visual inspection (if specified in Data Sheet) by the purchaser

before shipment. The components of the pumps shall not be painted before inspection.

:

Materials of the various pump components shall be tested in accordance with the relevant

standards. Test certificates for these shall be furnished when specified in Data Sheet and

shall be duly correlated w.r.t components/parts.

:

After installation, the pumps will be subjected to testing at field by the purchaser. If the field

performance is found not to meet the requirements regarding vibration and noise as

specified, then the equipment shall be rectified or replaced by the vendor, at no extra cost to

the purchaser.

D.P. Test for all parts : To be Witnessed

Vibration test : To be Witnessed

Noise level measurement : To be Witnessed

Strip test : To be Witnessed

You might also like

- Slurry Transport Using Centrifugal Pumps (4th Edition) 2023Document494 pagesSlurry Transport Using Centrifugal Pumps (4th Edition) 2023khaledianmehdi648No ratings yet

- Standard Norsok Standard R 001 For Mechanical EqptDocument152 pagesStandard Norsok Standard R 001 For Mechanical Eqptaravindhcam100% (3)

- Method Statement For Installation of Firefighting Pump SetDocument13 pagesMethod Statement For Installation of Firefighting Pump SetRaj Kamal75% (4)

- SAT - Centrifugal Pump For TDUDocument4 pagesSAT - Centrifugal Pump For TDUNIKHIL JOHRI100% (5)

- Method Statement of Sump PumpDocument3 pagesMethod Statement of Sump Pumpjames jatt Bond100% (2)

- Cooling Tower Construction ChecklistDocument6 pagesCooling Tower Construction ChecklistGopinath GopiNo ratings yet

- Testing & Commissioning of Chilled Water PumpsDocument3 pagesTesting & Commissioning of Chilled Water Pumpsamg00750% (4)

- Fans Testing & Commissioning Format-R0Document13 pagesFans Testing & Commissioning Format-R0Hari Sankar100% (1)

- Kewaunee LV Fume Hood SpecsDocument14 pagesKewaunee LV Fume Hood SpecsprabhudNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Classification of Tests:: Testing Procedures of A PumpDocument8 pagesClassification of Tests:: Testing Procedures of A PumpMohamad Izwan HussienNo ratings yet

- 3 s2.0 B9780884156864500508 MainDocument4 pages3 s2.0 B9780884156864500508 MainAmal KaNo ratings yet

- Factory Performance Testing of Vertical Turbine PumpsDocument3 pagesFactory Performance Testing of Vertical Turbine PumpsSrećko BlaževićNo ratings yet

- ITP For Centrifugal Pump4Document1 pageITP For Centrifugal Pump4Adades Safede EfdNo ratings yet

- Specification For Fire Water PumpsDocument7 pagesSpecification For Fire Water PumpsSANDEEP KUMAR RAHEJA100% (1)

- Enq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Document1 pageEnq - Spec - DS, FF & Other Water, Ewage System - Bpcl-Kochi - Part-1 9Sudhakar KarnanNo ratings yet

- 1-Check List CF PumpDocument2 pages1-Check List CF PumpStarla HillNo ratings yet

- VCR Multi FuelDocument5 pagesVCR Multi FuelAshish VermaNo ratings yet

- WI-INSP-07 R2 Work Instruction-Inspection of PumpsDocument5 pagesWI-INSP-07 R2 Work Instruction-Inspection of PumpsRakesh MishraNo ratings yet

- Method Statement For Installation of Firefighting Pump Set PDFDocument13 pagesMethod Statement For Installation of Firefighting Pump Set PDFAhmed Issa100% (1)

- Tech Spec For Centrifugal PumpDocument5 pagesTech Spec For Centrifugal PumpRoby Mirza100% (1)

- Drainage & Sump Pumps Specs PDFDocument25 pagesDrainage & Sump Pumps Specs PDFWalid El Ghonamy100% (1)

- Pumps: SECTION 15/1/5Document10 pagesPumps: SECTION 15/1/5farshan296015No ratings yet

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Fire Pump SpecificationDocument5 pagesFire Pump SpecificationThiru AnanthNo ratings yet

- Centrifugal Pump InspectionDocument33 pagesCentrifugal Pump InspectionAbhi Nandana100% (1)

- 60 - 15540 - HVAC Pumps and SpecialtiesDocument4 pages60 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- Annexure 3486Document8 pagesAnnexure 3486Kamal RajuNo ratings yet

- Specification For Internal Gear Pumps: 1.0 General DescriptionDocument7 pagesSpecification For Internal Gear Pumps: 1.0 General DescriptionHassan ShafiqueNo ratings yet

- Section 263235 - Standby Generator Testing and Commissioning.1Document5 pagesSection 263235 - Standby Generator Testing and Commissioning.1yaniahmad_82No ratings yet

- Clarifications and Exceptions of Api 675, Third EditionDocument3 pagesClarifications and Exceptions of Api 675, Third EditionFathan KarimanNo ratings yet

- T&CDocument13 pagesT&CAbdurRahmanFNo ratings yet

- NFPA Fire PumpDocument12 pagesNFPA Fire PumpSyed Faizan AliNo ratings yet

- 6 - Testing-Inspections-Req - 07-23-22Document56 pages6 - Testing-Inspections-Req - 07-23-22Larry Wayne Sumpter, JrNo ratings yet

- Appendix 11F: Operational ChecklistsDocument15 pagesAppendix 11F: Operational Checklists许爱文No ratings yet

- Recip. Compressor TestingDocument10 pagesRecip. Compressor TestingS DasNo ratings yet

- 3413514Document14 pages3413514vineethvskkdNo ratings yet

- Mechanical Equipment TestingDocument12 pagesMechanical Equipment TestingChemi YeNo ratings yet

- NETA Acceptance Testing Specifications - 2009 ExcerptDocument4 pagesNETA Acceptance Testing Specifications - 2009 ExcerptkpNo ratings yet

- Part 1 - General: SpecificationsDocument6 pagesPart 1 - General: SpecificationsDiego Plata VasquezNo ratings yet

- 12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865Document5 pages12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865tristan guarinoNo ratings yet

- Sprinkler System - General InformationDocument5 pagesSprinkler System - General InformationshahidenterNo ratings yet

- Fire Fighting Pumping SystemDocument23 pagesFire Fighting Pumping Systemvirtech100% (1)

- How To Conduct A Boiler Performance TestDocument4 pagesHow To Conduct A Boiler Performance Testsabill arasyidNo ratings yet

- Fire Pump Pre-Inspection QuestionnaireDocument3 pagesFire Pump Pre-Inspection QuestionnaireateeqNo ratings yet

- Commissioning of Fire PumpsDocument3 pagesCommissioning of Fire Pumpskamranarif4161No ratings yet

- Testing Commissioning Checklist For Fuel PumpDocument1 pageTesting Commissioning Checklist For Fuel PumpMoh'd SameerNo ratings yet

- Pump Start Up ChecklistDocument1 pagePump Start Up ChecklistSharif Mohammad AdwanNo ratings yet

- Testing & Commissioning Method Statement For Fire Fighting PumpsDocument4 pagesTesting & Commissioning Method Statement For Fire Fighting Pumpsvin ssNo ratings yet

- Centrifugal Compressor TestingDocument9 pagesCentrifugal Compressor TestingEnergy 2GreenNo ratings yet

- Interconnection Design Gas PipelinesDocument96 pagesInterconnection Design Gas PipelinesBeatriz Adams Garcia100% (2)

- My NotesDocument15 pagesMy NotesThe Servant of Allah SWTNo ratings yet

- 213113P - Fire Pumps and Controllers 09 09 2022Document11 pages213113P - Fire Pumps and Controllers 09 09 2022albfaragNo ratings yet

- 1510 - 15540 - HVAC Pumps and SpecialtiesDocument5 pages1510 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- 80 - 15540 - HVAC Pumps and SpecialtiesDocument5 pages80 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- Last Page PG TestDocument31 pagesLast Page PG Testarmanshaikh.engNo ratings yet

- Inspection and Test ProceduresDocument33 pagesInspection and Test Proceduresmrnoboby0407No ratings yet

- FAT PumpsDocument15 pagesFAT Pumpsaqhammam100% (1)

- Enquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item DescriptionDocument5 pagesEnquiry Cum Scope of Supply & Technical Specifications of Tender ITEM NO:-10 QUANTITY: - 1 EA (Each) Item Descriptionpramodyad5810No ratings yet

- Genset Load TestDocument10 pagesGenset Load Testjavad100% (2)

- 90 - 15540 - HVAC Pumps and SpecialtiesDocument4 pages90 - 15540 - HVAC Pumps and Specialtiesnestor159357No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Features (Engineered Solutions) : Smart FlowDocument1 pageFeatures (Engineered Solutions) : Smart FlowS DasNo ratings yet

- Oil With Particulate Oil With WaterDocument1 pageOil With Particulate Oil With WaterS DasNo ratings yet

- Ab 2Document1 pageAb 2S DasNo ratings yet

- Bearing Housing Put Through Rigorous TestingDocument1 pageBearing Housing Put Through Rigorous TestingS DasNo ratings yet

- Rheinhütte Rvku Chemical Centrifugal Pump in Plastic Rheinhütte Rkuv Chemical Centrifugal Pump in PlasticDocument1 pageRheinhütte Rvku Chemical Centrifugal Pump in Plastic Rheinhütte Rkuv Chemical Centrifugal Pump in PlasticS DasNo ratings yet

- Goulds 3171 Vertical Sump and Process Goulds NM3171 FRP Vertical Sump and ProcessDocument1 pageGoulds 3171 Vertical Sump and Process Goulds NM3171 FRP Vertical Sump and ProcessS DasNo ratings yet

- Humidification Loads Will Exceed 90% RH in Duct at Temperature Indicated. Booster Humidification Is RecommendedDocument1 pageHumidification Loads Will Exceed 90% RH in Duct at Temperature Indicated. Booster Humidification Is RecommendedS DasNo ratings yet

- Goulds 3175 Paper Stock / ProcessDocument1 pageGoulds 3175 Paper Stock / ProcessS DasNo ratings yet

- Goulds 3196 i-FRAME ANSI Process Goulds HT 3196 i-FRAME ANSI High Temperature Process PumpDocument1 pageGoulds 3196 i-FRAME ANSI Process Goulds HT 3196 i-FRAME ANSI High Temperature Process PumpS DasNo ratings yet

- Rheinhütte GVSO Vertical Chemical Centrifugal Pump in Metal Rheinhütte GVRN Acid Vertical Chemical Centrifugal PumpDocument1 pageRheinhütte GVSO Vertical Chemical Centrifugal Pump in Metal Rheinhütte GVRN Acid Vertical Chemical Centrifugal PumpS DasNo ratings yet

- External Space Loads: Load Estimating, Level 1: FundmentalsDocument1 pageExternal Space Loads: Load Estimating, Level 1: FundmentalsS DasNo ratings yet

- t3 PDFDocument1 paget3 PDFS DasNo ratings yet

- O 3Document1 pageO 3S DasNo ratings yet

- Load Estimating, Level 1: FundamentalsDocument1 pageLoad Estimating, Level 1: FundamentalsS DasNo ratings yet

- Basic HVAC Flow Diagrams: Configuration-1: Conventional Primary LoopDocument1 pageBasic HVAC Flow Diagrams: Configuration-1: Conventional Primary LoopS DasNo ratings yet

- Load Estimating, Level 1: Fundamentals: Solar Heat GainDocument1 pageLoad Estimating, Level 1: Fundamentals: Solar Heat GainS DasNo ratings yet

- Basic HVAC Flow Diagrams: Configuration-3: Primary Loop With Dual ReturnsDocument1 pageBasic HVAC Flow Diagrams: Configuration-3: Primary Loop With Dual ReturnsS DasNo ratings yet

- DG Brochure July, 2013Document6 pagesDG Brochure July, 2013S DasNo ratings yet

- Control Airflows Between Rooms: PressurizationDocument1 pageControl Airflows Between Rooms: PressurizationS DasNo ratings yet

- TEC Services, Inc.: Thermal Aerosol Generator, Model Compact (Inert Gas)Document1 pageTEC Services, Inc.: Thermal Aerosol Generator, Model Compact (Inert Gas)S DasNo ratings yet

- Example Fan Filter Units Arrangement: Air LockDocument1 pageExample Fan Filter Units Arrangement: Air LockS DasNo ratings yet

- ParticleDocument1 pageParticleS DasNo ratings yet

- Airborne Particle Physical Controls: Typical Ceiling Filter CoverageDocument1 pageAirborne Particle Physical Controls: Typical Ceiling Filter CoverageS DasNo ratings yet

- UAE B2b Email Database SampleDocument32 pagesUAE B2b Email Database Sampleirfan aminNo ratings yet

- Crude Oil ProjectDocument19 pagesCrude Oil ProjectYousef JawarnehNo ratings yet

- Catalogos EBARADocument15 pagesCatalogos EBARAJorge Alejandro Verde VereauNo ratings yet

- Pump MathsDocument10 pagesPump MathsSakib RafeeNo ratings yet

- .Pumps NotesDocument19 pages.Pumps NotesSean Esponge100% (1)

- Pulsation Dampener ProductsDocument16 pagesPulsation Dampener Productsgekinter100% (1)

- Product Bulletin 21Document2 pagesProduct Bulletin 21RANAIVOARIMANANANo ratings yet

- MdsDocument34 pagesMdsbalajiNo ratings yet

- Datasheet 175SR20S66-0863Document1 pageDatasheet 175SR20S66-0863Frank RodriguezNo ratings yet

- Houttuin TT BrochureDocument8 pagesHouttuin TT BrochureAswin Lorenso Gultom NamoralotungNo ratings yet

- HL200M Pump Curve - 5Document1 pageHL200M Pump Curve - 5Ayu FijriNo ratings yet

- CV Ahsan Sajjad-Hydromechanical Engr.Document9 pagesCV Ahsan Sajjad-Hydromechanical Engr.Ahsan SajjadNo ratings yet

- Gear Pump Standard Operating Manual and Instructions PDFDocument35 pagesGear Pump Standard Operating Manual and Instructions PDFdalbaasNo ratings yet

- FIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVDocument8 pagesFIREPUMP PEERLESS-ELECT POT-75HP-3x380V (Q-500GPM@121m.c.a) REVCrysthian AspilcuetaNo ratings yet

- Ansihi 9.6.3-2012Document23 pagesAnsihi 9.6.3-2012mawirNo ratings yet

- Qty. Description SP 17-25: Company Name: Created By: Phone: DateDocument4 pagesQty. Description SP 17-25: Company Name: Created By: Phone: DatehirararaNo ratings yet

- Grundfos - CR 10 5 A FJ A E HQQEDocument11 pagesGrundfos - CR 10 5 A FJ A E HQQErosneyNo ratings yet

- Niso - CNP PumpDocument8 pagesNiso - CNP Pumpdebasish.guptaNo ratings yet

- Line SizingDocument17 pagesLine SizingAllyssa Jane ErcillaNo ratings yet

- 100 HP Sihi PumpsDocument28 pages100 HP Sihi Pumpsnapster386No ratings yet

- Flowserve Educational Services Course CatalogDocument24 pagesFlowserve Educational Services Course CatalogTrevor KanodeNo ratings yet

- Pump NPSH - Accounting For Dissolved GasesDocument13 pagesPump NPSH - Accounting For Dissolved GasesSarelys ZavalaNo ratings yet

- Ensc End Suction PumpsDocument348 pagesEnsc End Suction PumpsRheoserve Industrial SolutionsNo ratings yet

- M100-10 (M-MA Meters) - V3 - 2.11.19 - 1Document28 pagesM100-10 (M-MA Meters) - V3 - 2.11.19 - 1ronald mudimuNo ratings yet

- Potable Water PumpsDocument17 pagesPotable Water PumpsNijasNo ratings yet

- VEY Molten Salt Pump For Concentrated Solar PowerDocument6 pagesVEY Molten Salt Pump For Concentrated Solar PowerSublim ArtNo ratings yet

- Basic Theory PumpDocument37 pagesBasic Theory PumpkunkzNo ratings yet

- NPSH - Net Positive Suction HeadDocument15 pagesNPSH - Net Positive Suction HeadAhmedHamadaNo ratings yet