Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

18 viewsShaft 03D-H24 R0 UH-1095

Shaft 03D-H24 R0 UH-1095

Uploaded by

Ayush NarangCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E E E E: Chamfer 0.3 X 45° Any Dimond Knurling Knurling Dia 7.2 Section E-EDocument1 pageE E E E: Chamfer 0.3 X 45° Any Dimond Knurling Knurling Dia 7.2 Section E-EAyush NarangNo ratings yet

- FINETURN Feasibility FormatDocument1 pageFINETURN Feasibility FormatAyush NarangNo ratings yet

- (Audit Result) Environment Management SystemDocument7 pages(Audit Result) Environment Management SystemAyush NarangNo ratings yet

- If Any Doubt Kindly Ask.: RemarksDocument1 pageIf Any Doubt Kindly Ask.: RemarksAyush NarangNo ratings yet

- Non Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLDocument1 pageNon Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLAyush Narang100% (1)

- Material SpecDocument456 pagesMaterial SpecAyush Narang70% (10)

- SKK Folder EngDocument10 pagesSKK Folder EngAyush NarangNo ratings yet

- UncontrolledDocument1 pageUncontrolledAyush NarangNo ratings yet

- 5 CopqDocument20 pages5 CopqAyush NarangNo ratings yet

- Productivity Improvement On A CNC Lathe by Automatic Loading and Unloading of Throttle Valve ComponentDocument20 pagesProductivity Improvement On A CNC Lathe by Automatic Loading and Unloading of Throttle Valve ComponentAyush NarangNo ratings yet

Shaft 03D-H24 R0 UH-1095

Shaft 03D-H24 R0 UH-1095

Uploaded by

Ayush Narang0 ratings0% found this document useful (0 votes)

18 views1 pageOriginal Title

Shaft_03D-H24_R0_UH-1095 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

18 views1 pageShaft 03D-H24 R0 UH-1095

Shaft 03D-H24 R0 UH-1095

Uploaded by

Ayush NarangCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

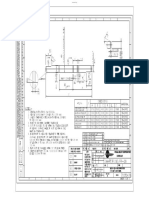

—- z

ze Oe eS ee eee coeur

cEneRa Vetere ob pent ae?

® | Process

‘© [ENOINEERING

© | custoner

®

REGULATORY

sonore

2075805 143.0201

250810

21509

240. enosi0

125 aaa

15 aa

LE SIDE OLE SID)

‘BOTH SIDE,

ere/a4

016.98/16.96

‘BOTH SIDE

oIS651555

SEE NOTE #4

NOTES:

1. puree sen. i i i

2. "RUN OUT AT SHAT TIP WRT BRG. SEATS SHOULD BE WIM IN O.1MW MAX

3. UNSPECIFIED TOLERANCES AS PER 1S:2102 MDIUM “GR”

4. SHAT MUST BE Zn. PHOSPHATED EXCEPT DM. P = 18 TO 20mm.

BEFORE PHOSPHATED DIA = #16.096/617.008

arter Prospantea DA = st7.000/017.010

PHOSPHATING SHOULD WMH STAND 72 HOURS IN SALT SPRAY CHAMBER. crop SipearoReS ra

STD. CHAMFER 1.545 PERMITED ON BOTH SIDES. [nmO Sees ane

© COMPONENT MUST BE FREE FROM BURR AND RUST el

7. COMPONENT MUST BE SUPPLED IN PROTECTNE. MATERIAL |

DULY TREATED ANTI RUST Ol. AS’ PER SPECFIED SY PCL. ‘SHAFT

18 DURING KMURLING PROCESS USE SINGLE LENGTH DIE OMLY. 7 (UH-1095)

5. COMPONENT SHOULD BE IDEXTFED WH VENDOR IDEWTINCATON MRK. FEpcu No] DESCRIPTION OF GuaNGe [DATE [ono [ apo} Sok j

ALL DMENSIONS ARE IN VM UNLESS OTHERWSE SPECIFED. PSN OH S/F Tl

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- E E E E: Chamfer 0.3 X 45° Any Dimond Knurling Knurling Dia 7.2 Section E-EDocument1 pageE E E E: Chamfer 0.3 X 45° Any Dimond Knurling Knurling Dia 7.2 Section E-EAyush NarangNo ratings yet

- FINETURN Feasibility FormatDocument1 pageFINETURN Feasibility FormatAyush NarangNo ratings yet

- (Audit Result) Environment Management SystemDocument7 pages(Audit Result) Environment Management SystemAyush NarangNo ratings yet

- If Any Doubt Kindly Ask.: RemarksDocument1 pageIf Any Doubt Kindly Ask.: RemarksAyush NarangNo ratings yet

- Non Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLDocument1 pageNon Conformity Report: Part Name:-Clamp Bolt Model: M4 Clamp Bolt Supplier:-Paradise Indus. Customer: PICLAyush Narang100% (1)

- Material SpecDocument456 pagesMaterial SpecAyush Narang70% (10)

- SKK Folder EngDocument10 pagesSKK Folder EngAyush NarangNo ratings yet

- UncontrolledDocument1 pageUncontrolledAyush NarangNo ratings yet

- 5 CopqDocument20 pages5 CopqAyush NarangNo ratings yet

- Productivity Improvement On A CNC Lathe by Automatic Loading and Unloading of Throttle Valve ComponentDocument20 pagesProductivity Improvement On A CNC Lathe by Automatic Loading and Unloading of Throttle Valve ComponentAyush NarangNo ratings yet