Professional Documents

Culture Documents

Batching Plant Apparatus Needed For Trial Mixes

Batching Plant Apparatus Needed For Trial Mixes

Uploaded by

Sarah Jane CacayorinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Batching Plant Apparatus Needed For Trial Mixes

Batching Plant Apparatus Needed For Trial Mixes

Uploaded by

Sarah Jane CacayorinCopyright:

Available Formats

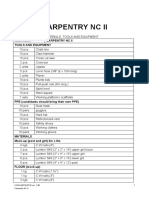

LIST OF NEEDED APPARATUS AND MATERIALS FOR TRIAL MIX AND BATCHING PLANT SET UP

(ii) CONCRETE TESTING EQUIPMENT

Description

1 each 3” x 8” diameter Brass Sieve

1 each 2” x 8” diameter Brass Sieve

1 each 1-1/2” x 8” diameter Brass Sieve

1 each 1” x 8” diameter Brass Sieve

1 each ¾” x 8” diameter Brass Sieve

1 each ½” x 8” diameter Brass Sieve

1 each 3/8” x 8” diameter Brass Sieve

1 each #4 x 8” diameter Brass Sieve

1 each #10 x 8” diameter Brass Sieve

1 each #40 x 8” diameter Brass Sieve

1 each #200 x 8” diameter Brass Sieve

1 each Brass Pan, 8” x 2” diameter

1 each Brass Cover with Ring

1 each Steel Pan, 24” x24” x3”

1 each Hand Operated Sieve Shaker

1 each Triple Beam Balance, 2610gms.

36 each Cylinder Mold, 6” x 12”

1 set Slump Cone & Base with Graduated Tamping Rod

1 each Mixing Pan, 24” x 24” x 3”

2 each Cement Trowel

1 set Pycnometer Top and Jar

1 set Density basket, 2.366 mm mesh

1 each Yield Bucket, ½ cu.ft.

1 set Air meter Device

1 set Weighing Scale 150 kg heavy duty

2 each Shovel Heavy Duty

2 each Concrete Cement Scope

6 Steel Beam Mold 6”x6”x21”

1 unit one bagger mixer heavy duty

1 each Thermometer heavy duty Ranges from -10 to +250 degree Celsius

1 unit Heavy Duty Compression Machine 200KN capacity with complete set

Materials Needed,

¾ Aggregates 3 cubic meters

G-1 Aggregates 3 cubic meters

Vibro Sand 3 cubic meters

STANDARD METHOD TEST FOR:

T-22 = Compressive Strength of Cylindrical Concrete Specimens T-23 Making and Curing Compressive and Flexural Test Specimen in the Field T-

24 Concrete Core Sampling T-26 Quality of Water to be used in Concrete T-97 Flexural Strength of Concrete T-119 Slump of Portland

Cement Concrete T-123 Capping Cylindrical Concrete Specimens

T-126 = Making and Curing Concrete Compression and Flexure Test Specimens in the Laboratory.

Prepared by : Jojo/Eugene

You might also like

- Construction Materials Price ListDocument12 pagesConstruction Materials Price ListChristian Gudino0% (1)

- Checklist of Tools and Equipment MasonryDocument4 pagesChecklist of Tools and Equipment MasonryRommel SelgaNo ratings yet

- Bill of MaterialsDocument27 pagesBill of MaterialsAngel GrospeNo ratings yet

- Forney OnlineDocument12 pagesForney OnlineHumberto MorenoNo ratings yet

- Alice BaiDocument24 pagesAlice BaiDATABASE SERVERNo ratings yet

- Bill of Quantites Per UnitDocument4 pagesBill of Quantites Per Unitcarlito camangianNo ratings yet

- Quo Yayasan Perguruan Tinggi Aggregat NTT KupangDocument7 pagesQuo Yayasan Perguruan Tinggi Aggregat NTT KupangAnita Kurniati Al-Achmad LamduNo ratings yet

- Standard Units and Commercial SizesDocument8 pagesStandard Units and Commercial SizesJhon Walter Ortega CondeNo ratings yet

- Canvas FormDocument3 pagesCanvas FormKyla Marie SasotNo ratings yet

- Admin BLDG BenguetDocument1 pageAdmin BLDG BenguetMervin Garcia BaniquedNo ratings yet

- CCC-Tool List-001Document7 pagesCCC-Tool List-001nikerNo ratings yet

- Material CanvasDocument2 pagesMaterial CanvasJoshua Ian AbanNo ratings yet

- Laboratory EquipmentDocument10 pagesLaboratory EquipmentSulpi CasilNo ratings yet

- SSH 2024Document1,390 pagesSSH 2024Firman Ahmad FauziNo ratings yet

- Estimating GuideDocument42 pagesEstimating Guidegerome aribanNo ratings yet

- Lab Eqipment ListDocument2 pagesLab Eqipment ListrvnlpunemetroNo ratings yet

- Lab Equipment ListDocument3 pagesLab Equipment ListHimagiri Rao KunaNo ratings yet

- Cons. of Library and Computer Bldg. Request For Approved MaterialsDocument4 pagesCons. of Library and Computer Bldg. Request For Approved MaterialsReden H. ArgawanonNo ratings yet

- MTO 330'x100'x22FT DECK LOAD10Document1 pageMTO 330'x100'x22FT DECK LOAD10Komar ElectricNo ratings yet

- Bill of Material Sample For ResidentialDocument4 pagesBill of Material Sample For ResidentialMyra Fe MercadoNo ratings yet

- Canvass of MaterialsDocument13 pagesCanvass of MaterialsAndrei SobrepeñaNo ratings yet

- Building Technology Lecture - 07 Concrete - 1192021Document46 pagesBuilding Technology Lecture - 07 Concrete - 1192021KC GlaizaNo ratings yet

- RDG RatesDocument30 pagesRDG RatesHazel AgravanteNo ratings yet

- Cement: Initial Setting Time and Final Setting TimeDocument7 pagesCement: Initial Setting Time and Final Setting TimeRenuka ConsultantsNo ratings yet

- Siri Lak Umaga BOQDocument3 pagesSiri Lak Umaga BOQAsiri Rukmal AtukoralaNo ratings yet

- Benguet LumberDocument5 pagesBenguet LumberKimBab100% (2)

- BSRDocument569 pagesBSRUpali Karunarathne100% (8)

- Maintenance of Pgas Government Building (Electrical System & Air Conditioning) Phase IiDocument6 pagesMaintenance of Pgas Government Building (Electrical System & Air Conditioning) Phase IiLiamNo ratings yet

- Rab BP Wet 2000 - 3000: No Items List Dimension Unit JML Sat Harsat Total KeteranganDocument5 pagesRab BP Wet 2000 - 3000: No Items List Dimension Unit JML Sat Harsat Total KeteranganyoyokNo ratings yet

- Complete ManualDocument70 pagesComplete ManualAli RazaNo ratings yet

- Maintenance of PGAS Gov't. Buildings (Rehabilitation of BAC Office Phase II)Document4 pagesMaintenance of PGAS Gov't. Buildings (Rehabilitation of BAC Office Phase II)LiamNo ratings yet

- Scope of WorkDocument4 pagesScope of Workcameron toolseeNo ratings yet

- Soil and Concrete Lab EquipmentDocument3 pagesSoil and Concrete Lab EquipmentYasir Ali DharejoNo ratings yet

- ACTIVITY-1.3 SamientoDocument3 pagesACTIVITY-1.3 SamientotagalicudlykaNo ratings yet

- Bill of Materials: Description of Materials Quantity Unit Unit Cost Total CostDocument22 pagesBill of Materials: Description of Materials Quantity Unit Unit Cost Total CostellaNo ratings yet

- Construction of Academic 6 Classroom Rrequest For Approved MaterialsDocument4 pagesConstruction of Academic 6 Classroom Rrequest For Approved MaterialsReden H. ArgawanonNo ratings yet

- Cement, Sand & Gravel: Hollow BlockDocument8 pagesCement, Sand & Gravel: Hollow BlockAnonymous xmSG3eHSNo ratings yet

- EstimatesDocument5 pagesEstimatesRamil S. ArtatesNo ratings yet

- Tracking Sheet For Material and Labour Rate Date:: Data CollectorDocument6 pagesTracking Sheet For Material and Labour Rate Date:: Data CollectorSaciid LaafaNo ratings yet

- Price ListDocument109 pagesPrice ListjcNo ratings yet

- Mr. Nasir Material ContractDocument3 pagesMr. Nasir Material ContractNasir KhanNo ratings yet

- Data BoilerDocument33 pagesData Boilerslamet supriyadiNo ratings yet

- ComputationsDocument2 pagesComputationsNikulast KidsNo ratings yet

- EIM MODEL (List of Materials)Document1 pageEIM MODEL (List of Materials)Renato C. LorillaNo ratings yet

- Comp. of Library and Computer Bldg. Request Approval of MaterialsDocument4 pagesComp. of Library and Computer Bldg. Request Approval of MaterialsReden H. ArgawanonNo ratings yet

- Excel PDFDocument47 pagesExcel PDFFranzer BalbinNo ratings yet

- Pricelist Const. MaterialsDocument4 pagesPricelist Const. Materialsjbdoromal.constructionNo ratings yet

- Bill of Quantity: Qty Satuan Harga Harga Satuan TotalDocument2 pagesBill of Quantity: Qty Satuan Harga Harga Satuan TotalGunawan WibowoNo ratings yet

- Soil Test QuationDocument4 pagesSoil Test QuationHemant GaikwadNo ratings yet

- Bill of Materials: Item Description Unit QTY Unit Cost TotalDocument1 pageBill of Materials: Item Description Unit QTY Unit Cost TotalZntotNo ratings yet

- EstimatesDocument39 pagesEstimatesGage Floyd Bitayo75% (4)

- Concrete: CementDocument10 pagesConcrete: CementHumberto MorenoNo ratings yet

- Recommended List of Equipments For FQA Civil LabDocument3 pagesRecommended List of Equipments For FQA Civil LabPRASAD THOMBARENo ratings yet

- I Forms & Scaffoldings: Item Description Qty. UnitDocument9 pagesI Forms & Scaffoldings: Item Description Qty. UnitGerome R.No ratings yet

- CARP List of Tools Materials AGDocument2 pagesCARP List of Tools Materials AGPierre PakilitNo ratings yet

- Price Master ListDocument7 pagesPrice Master ListAS LlesisNo ratings yet

- Product CatalogDocument16 pagesProduct Catalogkushar_geoNo ratings yet

- List of Carpentry & Plumbing Items of Supply: S.No Description of Item Qty. Rate Unit Amount C IDocument5 pagesList of Carpentry & Plumbing Items of Supply: S.No Description of Item Qty. Rate Unit Amount C IS.G BUSINESSNo ratings yet

- Sao-Atan Proper Materilas ListDocument10 pagesSao-Atan Proper Materilas ListJun MichaelNo ratings yet

- Numerical Questions Chapter 3Document5 pagesNumerical Questions Chapter 3DARMESHNo ratings yet

- Engineering Chemistry LabDocument116 pagesEngineering Chemistry LabLawrence YorongNo ratings yet

- Grade 9 Integrated Science (Chemistry) NotesDocument14 pagesGrade 9 Integrated Science (Chemistry) NotesKara NewmanNo ratings yet

- JCR Top 10% Journal Publications: Tan C.P Tan C.PDocument1 pageJCR Top 10% Journal Publications: Tan C.P Tan C.Pstephenlim7986No ratings yet

- Systematic Review On Chemistry Knowledge in High School StudentsDocument8 pagesSystematic Review On Chemistry Knowledge in High School StudentsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Chemistry: Pearson Edexcel GCEDocument20 pagesChemistry: Pearson Edexcel GCEMohammad Shahidullah ChowdhuryNo ratings yet

- Organic AcidsDocument206 pagesOrganic AcidsBukhariNo ratings yet

- Student Exploration: Polarity and Intermolecular ForcesDocument9 pagesStudent Exploration: Polarity and Intermolecular ForcesDaniel CastroNo ratings yet

- Ultracrete PC730Document3 pagesUltracrete PC730uchennaNo ratings yet

- Near Infrared Moisture Measurement Tea Process: "Images Kindly Supplied by Teacraft ©2010"Document3 pagesNear Infrared Moisture Measurement Tea Process: "Images Kindly Supplied by Teacraft ©2010"gaurav saikiaNo ratings yet

- TexCare SRN - SRA - LATAMDocument16 pagesTexCare SRN - SRA - LATAMCARMEN LINARESNo ratings yet

- Chemical and Physical Changes of MatterDocument4 pagesChemical and Physical Changes of MatterYhena ChanNo ratings yet

- General Organic Chemistry - Iii: Section (A) : Solvents, Reagents and Leaving GroupsDocument20 pagesGeneral Organic Chemistry - Iii: Section (A) : Solvents, Reagents and Leaving GroupsGOURISH AGRAWALNo ratings yet

- Top 10 MCQ - Chemical Equilibrium #2Document49 pagesTop 10 MCQ - Chemical Equilibrium #2Muhammad Anas BilalNo ratings yet

- Module 2Document130 pagesModule 2Jen Mae Rue TamundongNo ratings yet

- English 8 - Q2 M1 - Interpreting Non Verbal MaterialsDocument16 pagesEnglish 8 - Q2 M1 - Interpreting Non Verbal MaterialsCynthia SagunNo ratings yet

- Gen Chem 2 q3 Module 1b Properties of LiquidsDocument27 pagesGen Chem 2 q3 Module 1b Properties of LiquidsJordan DingayanNo ratings yet

- S1 TITAN 600-800 Alloy Calibration NewDocument2 pagesS1 TITAN 600-800 Alloy Calibration NewfrankieNo ratings yet

- Astm A313 2003Document7 pagesAstm A313 2003ArefkhanNo ratings yet

- CoulometryDocument19 pagesCoulometrykusumNo ratings yet

- Cost PPBDocument95 pagesCost PPBmohamad awaludinNo ratings yet

- Chemistry Project:: Analysis of HoneyDocument16 pagesChemistry Project:: Analysis of HoneyDARKRAI GAMINGNo ratings yet

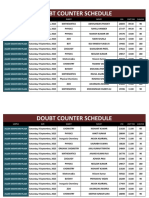

- Signature Plaza - 09th Sept - Doubt Counter - XLSX - Google SheetsDocument4 pagesSignature Plaza - 09th Sept - Doubt Counter - XLSX - Google SheetsPrabhu Krupa BiswalNo ratings yet

- LAMPIRAN Larutan KonsentrasiDocument2 pagesLAMPIRAN Larutan KonsentrasiAisya SabrinaNo ratings yet

- Bk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersDocument8 pagesBk91 1310 CPF Ved 016 Qac h13 0001 - B - Positive Material Identification Procedure For Basket FiltersPanneer SelvamNo ratings yet

- Some Basic Concepts of Chemistry PDFDocument30 pagesSome Basic Concepts of Chemistry PDFDivyaNo ratings yet

- Presentation On Bubble Column Reactor: Presented byDocument19 pagesPresentation On Bubble Column Reactor: Presented byShanmugapriyaNo ratings yet

- Revision Assignment # 07: Chemistry SECTION-I: (Ii) One or More Options Correct Type 4 (-1) 1Document7 pagesRevision Assignment # 07: Chemistry SECTION-I: (Ii) One or More Options Correct Type 4 (-1) 1KusNo ratings yet

- Aci SP-151 - 1994Document294 pagesAci SP-151 - 1994ananthNo ratings yet

- Fosroc Conbextra EPGP: Constructive SolutionsDocument2 pagesFosroc Conbextra EPGP: Constructive SolutionsVincent JavateNo ratings yet