Professional Documents

Culture Documents

83%(6)83% found this document useful (6 votes)

3K viewsJAPL-F-TE-004-Bending Machine Checklists

JAPL-F-TE-004-Bending Machine Checklists

Uploaded by

Ali HassanThe document is a weekly checklist for inspecting a bending machine. It contains items to check such as fluid levels, guards, lubrication, and equipment condition. Operators are instructed to lock the transmission when leaving the machine unattended and wear protective equipment. Supervisor and safety officer signatures are required to verify inspection.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Compactor Daily Inspection ChecklistDocument1 pageCompactor Daily Inspection ChecklistThandabantu Magengelele33% (3)

- Gas Cutting Cylinders Set Inspection ChecklistDocument1 pageGas Cutting Cylinders Set Inspection ChecklistCh Uday100% (3)

- Check List For Asphalt CutterDocument1 pageCheck List For Asphalt Cutterchassas100% (2)

- 238 Preventive Check Sheet of Press Brake MachineDocument4 pages238 Preventive Check Sheet of Press Brake MachineAjay100% (2)

- Air Blower Checklist PDFDocument1 pageAir Blower Checklist PDFBidya Bhusan Maji50% (4)

- Air Compressor Daily ChecklistDocument4 pagesAir Compressor Daily ChecklistEric54% (13)

- Telehandler Forklift Pre-Use Inspection ChecklistDocument1 pageTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- 08 - Groove - Cutting - Machine ChecklistDocument1 page08 - Groove - Cutting - Machine ChecklistKARTHIK NAIKAR83% (6)

- Check List For Cutting MachineDocument1 pageCheck List For Cutting MachineGita Iyer75% (4)

- Form 092 Excavator Safety Checklist 1Document2 pagesForm 092 Excavator Safety Checklist 1TANWIR AHEMADNo ratings yet

- Inspection Checklist For HydraDocument1 pageInspection Checklist For HydraParthiban Venkatesan75% (4)

- Checklist Pencil GrinderDocument1 pageChecklist Pencil Grinderrexivy100% (1)

- Welding Machine Safety ChecklistDocument1 pageWelding Machine Safety ChecklistImad Chaudhary100% (7)

- Arc Welding Equipment Monthly ChecklistDocument1 pageArc Welding Equipment Monthly ChecklistAnonymous VNu3ODGav40% (5)

- Abrasive BlastingDocument1 pageAbrasive BlastingRísês Ãfröz75% (4)

- Hilti Machine ChecklistDocument1 pageHilti Machine Checklistpartha67% (3)

- JAPL-F-TE-001-Dewatering Pump Inspection ChecklistDocument1 pageJAPL-F-TE-001-Dewatering Pump Inspection ChecklistAli Hassan100% (4)

- KRPL Shahjahanpur Check List For Arc Welding MachineDocument1 pageKRPL Shahjahanpur Check List For Arc Welding MachineA S YadavNo ratings yet

- L6.17 Mobile Welding Machine Inspection ChecklistDocument2 pagesL6.17 Mobile Welding Machine Inspection Checklistom prakash100% (5)

- JAPL-F-HE-002-Weekly Excavator Inspection ChecklistDocument2 pagesJAPL-F-HE-002-Weekly Excavator Inspection ChecklistAli Hassan100% (2)

- Grating Handrails Ladders Stairways Quality Control and Inspection Report FormDocument1 pageGrating Handrails Ladders Stairways Quality Control and Inspection Report Formhasan_676489616100% (1)

- HSE-036. Pre-Entry Grinding MachineDocument1 pageHSE-036. Pre-Entry Grinding MachineMithlesh Singh100% (1)

- Sop - Bar BendingDocument1 pageSop - Bar BendingHARSHAD50% (2)

- Check List For Argon GasDocument1 pageCheck List For Argon GasAnonymous jefUrqfio0% (1)

- JAPL-F-TE-003-Generator Daily Inspection ChecklistDocument1 pageJAPL-F-TE-003-Generator Daily Inspection ChecklistAli Hassan100% (1)

- JAPL-F-HE-002-Weekly Excavator Inspection ChecklistDocument2 pagesJAPL-F-HE-002-Weekly Excavator Inspection ChecklistAli Hassan100% (2)

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli Hassan100% (1)

- JAPL-F-HE-023-Heavy Equipment Onboarding ChecklistDocument1 pageJAPL-F-HE-023-Heavy Equipment Onboarding ChecklistAli HassanNo ratings yet

- Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked byDocument1 pageInspection Checklist of Drill Machine: Project Name: Date: Time: Checked byRaza Muhammad Soomro0% (1)

- Checklist For Equipment Inspection Bench Cutting MachineDocument2 pagesChecklist For Equipment Inspection Bench Cutting MachineHung Hoang100% (1)

- 13 Checklist For Hammering Drill MachineDocument1 page13 Checklist For Hammering Drill Machinexiangjintao88% (8)

- Angle Grinder Check ListDocument2 pagesAngle Grinder Check ListEdhz Bilog100% (11)

- HSE-026.Pre-entry Hydra CraneDocument2 pagesHSE-026.Pre-entry Hydra CraneMithlesh Singh80% (5)

- Eot Crane Checklist: Description DetailsDocument1 pageEot Crane Checklist: Description DetailsRaja DuraiNo ratings yet

- 01 - Gas Cutting Set Inspection ChecklistDocument1 page01 - Gas Cutting Set Inspection Checklistsanjeev kumar100% (1)

- Check List (Pre Entry) For Portable Grinding MachineDocument4 pagesCheck List (Pre Entry) For Portable Grinding Machinealvhyan anandolaki100% (1)

- Lifting-Lashing Gear Inspection ChecklistDocument1 pageLifting-Lashing Gear Inspection Checklistdnmule100% (1)

- Grinder Checklist2Document3 pagesGrinder Checklist2jovyNo ratings yet

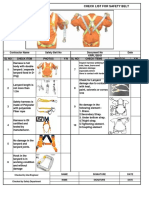

- 022 - HSSE - Full Body Harness Inspection ChecklistDocument1 page022 - HSSE - Full Body Harness Inspection ChecklistShashwat PandeyNo ratings yet

- First Aid Register FormatDocument1 pageFirst Aid Register Formatrameese muhammed50% (2)

- Side Boom ChecklistDocument6 pagesSide Boom Checklistsaqib100% (1)

- Asphalt Cutter ChecklistDocument1 pageAsphalt Cutter ChecklistDhanu Nikku100% (5)

- 03 - Hydra Crane ChecklistDocument1 page03 - Hydra Crane ChecklistAfzal Akhtar100% (5)

- Daily Machine Check List - Radial DrillDocument6 pagesDaily Machine Check List - Radial Drillshailendra5508110100% (2)

- 06 Portable Grinding MachineDocument1 page06 Portable Grinding MachineGyanendra Narayan NayakNo ratings yet

- Mobile Crane Monthly ChecklistDocument3 pagesMobile Crane Monthly ChecklistDAOUMY YOUNESSNo ratings yet

- Checklist For Equipment Inspection BOOM PLACERDocument2 pagesChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Bar Cutting Machine Inspection ChecklistDocument1 pageBar Cutting Machine Inspection ChecklistRicardo Dalisay100% (5)

- Crane Carry - in InspectionDocument3 pagesCrane Carry - in InspectionAdhy Darmawan100% (1)

- 05 Check List For Gas Cutting Set-1-1Document1 page05 Check List For Gas Cutting Set-1-1Gyanendra Narayan Nayak100% (1)

- 02 Crawler Checklist Monthly ChecklistDocument1 page02 Crawler Checklist Monthly Checklistjohn rajNo ratings yet

- Weekly Machine Check List - Lathe MachineDocument6 pagesWeekly Machine Check List - Lathe Machineshailendra550811067% (3)

- Steel Wire Rope Sling Safety ChecklistDocument1 pageSteel Wire Rope Sling Safety ChecklistImad ChaudharyNo ratings yet

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- Safety Checklist of Safety BeltDocument1 pageSafety Checklist of Safety BeltA S Yadav0% (1)

- 127 - Hse Inspection Checklist-Compressed Gas CylinderDocument1 page127 - Hse Inspection Checklist-Compressed Gas CylinderEr Ajenk80% (10)

- Mis Report Mar2017Document8 pagesMis Report Mar2017parthaNo ratings yet

- Welding Machine1Document1 pageWelding Machine1Projects DepartmentNo ratings yet

- Inspection Checklist For BACKHOE LOADER (JCB)Document1 pageInspection Checklist For BACKHOE LOADER (JCB)Idada Ezekiel100% (1)

- Form 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcDocument1 pageForm 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcHEMANT RAMJI100% (1)

- Mechanized Rock Breaker Checklist: M/S Kapoor Enterprises Vendor Code: K635Document2 pagesMechanized Rock Breaker Checklist: M/S Kapoor Enterprises Vendor Code: K635projit basu75% (4)

- FC 4.1.6 - Synthetic Sling Inspection Checklist FormDocument2 pagesFC 4.1.6 - Synthetic Sling Inspection Checklist FormJosef Demner Tiu Paspe100% (1)

- Daily Check Sheet of All MachinesDocument4 pagesDaily Check Sheet of All Machinesrahul_2005100% (2)

- Drill Machine - ChecklistDocument1 pageDrill Machine - ChecklistarkonamtfplNo ratings yet

- Guidelines For InspectionDocument12 pagesGuidelines For Inspectionjunel manuodNo ratings yet

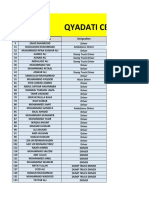

- Qyadati Certification DetailsDocument6 pagesQyadati Certification DetailsAli HassanNo ratings yet

- SA007-00-0906-SI-034-01 - Monthly HSE Training Report April 2021Document70 pagesSA007-00-0906-SI-034-01 - Monthly HSE Training Report April 2021Ali HassanNo ratings yet

- Fire Extinguisher TagDocument1 pageFire Extinguisher TagAli HassanNo ratings yet

- Jazan - Abha Refined Products Pipeline Project: Sicim Hse TeamDocument2 pagesJazan - Abha Refined Products Pipeline Project: Sicim Hse TeamAli HassanNo ratings yet

- Rules of LivingDocument1 pageRules of LivingAli HassanNo ratings yet

- JAPL-F-TE-002-Air Compressor ChecklistDocument1 pageJAPL-F-TE-002-Air Compressor ChecklistAli HassanNo ratings yet

- JAPL-F-HE-007-Concrete Pump ChecklistDocument1 pageJAPL-F-HE-007-Concrete Pump ChecklistAli HassanNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- JAPL-F-HE-006-Paywelder ChecklistDocument1 pageJAPL-F-HE-006-Paywelder ChecklistAli HassanNo ratings yet

- JAPL-F-HE-006-Paywelder ChecklistDocument1 pageJAPL-F-HE-006-Paywelder ChecklistAli HassanNo ratings yet

- Training Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetDocument2 pagesTraining Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetAli HassanNo ratings yet

- JAPL-F-HE-004-Weekly Water Tanker Inspection LogDocument1 pageJAPL-F-HE-004-Weekly Water Tanker Inspection LogAli Hassan100% (1)

- Work Permit Receiver's ListDocument6 pagesWork Permit Receiver's ListAli HassanNo ratings yet

- Serial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001Document3 pagesSerial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001Ali HassanNo ratings yet

- Telehandler Daily Inspection Sheet Jazan Abha Refined Products Pipeline ProjectDocument1 pageTelehandler Daily Inspection Sheet Jazan Abha Refined Products Pipeline ProjectAli HassanNo ratings yet

- 0918-SI-138-00 - Toolbox Talks Attendance Sheet - enDocument2 pages0918-SI-138-00 - Toolbox Talks Attendance Sheet - enAli HassanNo ratings yet

- Training Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetDocument1 pageTraining Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetAli HassanNo ratings yet

JAPL-F-TE-004-Bending Machine Checklists

JAPL-F-TE-004-Bending Machine Checklists

Uploaded by

Ali Hassan83%(6)83% found this document useful (6 votes)

3K views1 pageThe document is a weekly checklist for inspecting a bending machine. It contains items to check such as fluid levels, guards, lubrication, and equipment condition. Operators are instructed to lock the transmission when leaving the machine unattended and wear protective equipment. Supervisor and safety officer signatures are required to verify inspection.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a weekly checklist for inspecting a bending machine. It contains items to check such as fluid levels, guards, lubrication, and equipment condition. Operators are instructed to lock the transmission when leaving the machine unattended and wear protective equipment. Supervisor and safety officer signatures are required to verify inspection.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

83%(6)83% found this document useful (6 votes)

3K views1 pageJAPL-F-TE-004-Bending Machine Checklists

JAPL-F-TE-004-Bending Machine Checklists

Uploaded by

Ali HassanThe document is a weekly checklist for inspecting a bending machine. It contains items to check such as fluid levels, guards, lubrication, and equipment condition. Operators are instructed to lock the transmission when leaving the machine unattended and wear protective equipment. Supervisor and safety officer signatures are required to verify inspection.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

Relocate Jazan-Abha Refined Products Pipeline

BI# 10-00875 Contract# 6600045122

WEEKLY BENDING MACHINE INSPECTION CHECKLIST

Operator’s Name: Badge Number:

Machine No: Date Start:

Location:

CONDITION

Sr.

Item to be Checked SA SU MO TU WE

# THU F

T N N E D

1 Fluid Level

2 Check for Hydraulic Leakage

3 Ensure all guards are fitted, secure and functional

Working parts should be well lubricated and the rolls free of

4 rust and dirt

Check the oil in oil tank to make sure there is enough oil to

5 operate pipe bender

6 The marker in a designated spot and not loose on the die

7 Emergency Switch available and functional

8 Tires/Tracks

9 Wire rope slings are made properly and have no damage.

10 Fire Extinguisher

11 3rd party equipment inspection

12 CPP Sticker

SAFETY PRECAUTIONS FOR BENDING OPERATION

If you leave your machine un-attendant, push the safety lever down which locks the transmission on the

1 transmission shifter tower

2 Keep your finger away from the die /pipe interface.

3 Rings and jeweler must not be worn, Close fitting/protective clothing must be worn

4 Safety glasses must be worn at all times in work areas

5 Don’t get between pipe and tractor or pipe and bending machine

6 Don’t ride on the bending machine when it is being moved.

Operator Signature

Supervisor / Foreman Signature

Safety Officer Signature

- Ok X - Not Ok N/A- Not Applicable s

JAPL-F-TE-004

You might also like

- Compactor Daily Inspection ChecklistDocument1 pageCompactor Daily Inspection ChecklistThandabantu Magengelele33% (3)

- Gas Cutting Cylinders Set Inspection ChecklistDocument1 pageGas Cutting Cylinders Set Inspection ChecklistCh Uday100% (3)

- Check List For Asphalt CutterDocument1 pageCheck List For Asphalt Cutterchassas100% (2)

- 238 Preventive Check Sheet of Press Brake MachineDocument4 pages238 Preventive Check Sheet of Press Brake MachineAjay100% (2)

- Air Blower Checklist PDFDocument1 pageAir Blower Checklist PDFBidya Bhusan Maji50% (4)

- Air Compressor Daily ChecklistDocument4 pagesAir Compressor Daily ChecklistEric54% (13)

- Telehandler Forklift Pre-Use Inspection ChecklistDocument1 pageTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- 08 - Groove - Cutting - Machine ChecklistDocument1 page08 - Groove - Cutting - Machine ChecklistKARTHIK NAIKAR83% (6)

- Check List For Cutting MachineDocument1 pageCheck List For Cutting MachineGita Iyer75% (4)

- Form 092 Excavator Safety Checklist 1Document2 pagesForm 092 Excavator Safety Checklist 1TANWIR AHEMADNo ratings yet

- Inspection Checklist For HydraDocument1 pageInspection Checklist For HydraParthiban Venkatesan75% (4)

- Checklist Pencil GrinderDocument1 pageChecklist Pencil Grinderrexivy100% (1)

- Welding Machine Safety ChecklistDocument1 pageWelding Machine Safety ChecklistImad Chaudhary100% (7)

- Arc Welding Equipment Monthly ChecklistDocument1 pageArc Welding Equipment Monthly ChecklistAnonymous VNu3ODGav40% (5)

- Abrasive BlastingDocument1 pageAbrasive BlastingRísês Ãfröz75% (4)

- Hilti Machine ChecklistDocument1 pageHilti Machine Checklistpartha67% (3)

- JAPL-F-TE-001-Dewatering Pump Inspection ChecklistDocument1 pageJAPL-F-TE-001-Dewatering Pump Inspection ChecklistAli Hassan100% (4)

- KRPL Shahjahanpur Check List For Arc Welding MachineDocument1 pageKRPL Shahjahanpur Check List For Arc Welding MachineA S YadavNo ratings yet

- L6.17 Mobile Welding Machine Inspection ChecklistDocument2 pagesL6.17 Mobile Welding Machine Inspection Checklistom prakash100% (5)

- JAPL-F-HE-002-Weekly Excavator Inspection ChecklistDocument2 pagesJAPL-F-HE-002-Weekly Excavator Inspection ChecklistAli Hassan100% (2)

- Grating Handrails Ladders Stairways Quality Control and Inspection Report FormDocument1 pageGrating Handrails Ladders Stairways Quality Control and Inspection Report Formhasan_676489616100% (1)

- HSE-036. Pre-Entry Grinding MachineDocument1 pageHSE-036. Pre-Entry Grinding MachineMithlesh Singh100% (1)

- Sop - Bar BendingDocument1 pageSop - Bar BendingHARSHAD50% (2)

- Check List For Argon GasDocument1 pageCheck List For Argon GasAnonymous jefUrqfio0% (1)

- JAPL-F-TE-003-Generator Daily Inspection ChecklistDocument1 pageJAPL-F-TE-003-Generator Daily Inspection ChecklistAli Hassan100% (1)

- JAPL-F-HE-002-Weekly Excavator Inspection ChecklistDocument2 pagesJAPL-F-HE-002-Weekly Excavator Inspection ChecklistAli Hassan100% (2)

- JAPL-F-HE-001-Weekly Grader Inspection ChecklistDocument2 pagesJAPL-F-HE-001-Weekly Grader Inspection ChecklistAli Hassan100% (1)

- JAPL-F-HE-023-Heavy Equipment Onboarding ChecklistDocument1 pageJAPL-F-HE-023-Heavy Equipment Onboarding ChecklistAli HassanNo ratings yet

- Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked byDocument1 pageInspection Checklist of Drill Machine: Project Name: Date: Time: Checked byRaza Muhammad Soomro0% (1)

- Checklist For Equipment Inspection Bench Cutting MachineDocument2 pagesChecklist For Equipment Inspection Bench Cutting MachineHung Hoang100% (1)

- 13 Checklist For Hammering Drill MachineDocument1 page13 Checklist For Hammering Drill Machinexiangjintao88% (8)

- Angle Grinder Check ListDocument2 pagesAngle Grinder Check ListEdhz Bilog100% (11)

- HSE-026.Pre-entry Hydra CraneDocument2 pagesHSE-026.Pre-entry Hydra CraneMithlesh Singh80% (5)

- Eot Crane Checklist: Description DetailsDocument1 pageEot Crane Checklist: Description DetailsRaja DuraiNo ratings yet

- 01 - Gas Cutting Set Inspection ChecklistDocument1 page01 - Gas Cutting Set Inspection Checklistsanjeev kumar100% (1)

- Check List (Pre Entry) For Portable Grinding MachineDocument4 pagesCheck List (Pre Entry) For Portable Grinding Machinealvhyan anandolaki100% (1)

- Lifting-Lashing Gear Inspection ChecklistDocument1 pageLifting-Lashing Gear Inspection Checklistdnmule100% (1)

- Grinder Checklist2Document3 pagesGrinder Checklist2jovyNo ratings yet

- 022 - HSSE - Full Body Harness Inspection ChecklistDocument1 page022 - HSSE - Full Body Harness Inspection ChecklistShashwat PandeyNo ratings yet

- First Aid Register FormatDocument1 pageFirst Aid Register Formatrameese muhammed50% (2)

- Side Boom ChecklistDocument6 pagesSide Boom Checklistsaqib100% (1)

- Asphalt Cutter ChecklistDocument1 pageAsphalt Cutter ChecklistDhanu Nikku100% (5)

- 03 - Hydra Crane ChecklistDocument1 page03 - Hydra Crane ChecklistAfzal Akhtar100% (5)

- Daily Machine Check List - Radial DrillDocument6 pagesDaily Machine Check List - Radial Drillshailendra5508110100% (2)

- 06 Portable Grinding MachineDocument1 page06 Portable Grinding MachineGyanendra Narayan NayakNo ratings yet

- Mobile Crane Monthly ChecklistDocument3 pagesMobile Crane Monthly ChecklistDAOUMY YOUNESSNo ratings yet

- Checklist For Equipment Inspection BOOM PLACERDocument2 pagesChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Bar Cutting Machine Inspection ChecklistDocument1 pageBar Cutting Machine Inspection ChecklistRicardo Dalisay100% (5)

- Crane Carry - in InspectionDocument3 pagesCrane Carry - in InspectionAdhy Darmawan100% (1)

- 05 Check List For Gas Cutting Set-1-1Document1 page05 Check List For Gas Cutting Set-1-1Gyanendra Narayan Nayak100% (1)

- 02 Crawler Checklist Monthly ChecklistDocument1 page02 Crawler Checklist Monthly Checklistjohn rajNo ratings yet

- Weekly Machine Check List - Lathe MachineDocument6 pagesWeekly Machine Check List - Lathe Machineshailendra550811067% (3)

- Steel Wire Rope Sling Safety ChecklistDocument1 pageSteel Wire Rope Sling Safety ChecklistImad ChaudharyNo ratings yet

- DRL - Project Check List For Metal Cutting Machine: .RPM .RPMDocument1 pageDRL - Project Check List For Metal Cutting Machine: .RPM .RPMSachin Hse Rohtak100% (1)

- Safety Checklist of Safety BeltDocument1 pageSafety Checklist of Safety BeltA S Yadav0% (1)

- 127 - Hse Inspection Checklist-Compressed Gas CylinderDocument1 page127 - Hse Inspection Checklist-Compressed Gas CylinderEr Ajenk80% (10)

- Mis Report Mar2017Document8 pagesMis Report Mar2017parthaNo ratings yet

- Welding Machine1Document1 pageWelding Machine1Projects DepartmentNo ratings yet

- Inspection Checklist For BACKHOE LOADER (JCB)Document1 pageInspection Checklist For BACKHOE LOADER (JCB)Idada Ezekiel100% (1)

- Form 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcDocument1 pageForm 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcHEMANT RAMJI100% (1)

- Mechanized Rock Breaker Checklist: M/S Kapoor Enterprises Vendor Code: K635Document2 pagesMechanized Rock Breaker Checklist: M/S Kapoor Enterprises Vendor Code: K635projit basu75% (4)

- FC 4.1.6 - Synthetic Sling Inspection Checklist FormDocument2 pagesFC 4.1.6 - Synthetic Sling Inspection Checklist FormJosef Demner Tiu Paspe100% (1)

- Daily Check Sheet of All MachinesDocument4 pagesDaily Check Sheet of All Machinesrahul_2005100% (2)

- Drill Machine - ChecklistDocument1 pageDrill Machine - ChecklistarkonamtfplNo ratings yet

- Guidelines For InspectionDocument12 pagesGuidelines For Inspectionjunel manuodNo ratings yet

- Qyadati Certification DetailsDocument6 pagesQyadati Certification DetailsAli HassanNo ratings yet

- SA007-00-0906-SI-034-01 - Monthly HSE Training Report April 2021Document70 pagesSA007-00-0906-SI-034-01 - Monthly HSE Training Report April 2021Ali HassanNo ratings yet

- Fire Extinguisher TagDocument1 pageFire Extinguisher TagAli HassanNo ratings yet

- Jazan - Abha Refined Products Pipeline Project: Sicim Hse TeamDocument2 pagesJazan - Abha Refined Products Pipeline Project: Sicim Hse TeamAli HassanNo ratings yet

- Rules of LivingDocument1 pageRules of LivingAli HassanNo ratings yet

- JAPL-F-TE-002-Air Compressor ChecklistDocument1 pageJAPL-F-TE-002-Air Compressor ChecklistAli HassanNo ratings yet

- JAPL-F-HE-007-Concrete Pump ChecklistDocument1 pageJAPL-F-HE-007-Concrete Pump ChecklistAli HassanNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- JAPL-F-HE-006-Paywelder ChecklistDocument1 pageJAPL-F-HE-006-Paywelder ChecklistAli HassanNo ratings yet

- JAPL-F-HE-006-Paywelder ChecklistDocument1 pageJAPL-F-HE-006-Paywelder ChecklistAli HassanNo ratings yet

- Training Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetDocument2 pagesTraining Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetAli HassanNo ratings yet

- JAPL-F-HE-004-Weekly Water Tanker Inspection LogDocument1 pageJAPL-F-HE-004-Weekly Water Tanker Inspection LogAli Hassan100% (1)

- Work Permit Receiver's ListDocument6 pagesWork Permit Receiver's ListAli HassanNo ratings yet

- Serial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001Document3 pagesSerial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001 Serial Number: FE-001Ali HassanNo ratings yet

- Telehandler Daily Inspection Sheet Jazan Abha Refined Products Pipeline ProjectDocument1 pageTelehandler Daily Inspection Sheet Jazan Abha Refined Products Pipeline ProjectAli HassanNo ratings yet

- 0918-SI-138-00 - Toolbox Talks Attendance Sheet - enDocument2 pages0918-SI-138-00 - Toolbox Talks Attendance Sheet - enAli HassanNo ratings yet

- Training Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetDocument1 pageTraining Course Title: Training Code:: Modulo Registrazione Formazione - Training Attendance SheetAli HassanNo ratings yet