Professional Documents

Culture Documents

Hydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test Pump

Hydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test Pump

Uploaded by

pablo bazaesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test Pump

Hydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test Pump

Uploaded by

pablo bazaesCopyright:

Available Formats

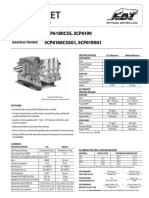

Calibration technology

Hydraulic test pumps

Models CPP1000-M, CPP1000-L, hand spindle pump

Models CPP1000-X, CPP1600-X, CPP7000-X, comparison test pump

WIKA data sheet CT 91.05

Applications

■■ Simple test pressure generation on site, in the laboratory

or in the workshop

■■ For the testing, adjustment and calibration of all types of

pressure measuring instruments

■■ Hydraulic pressure generation up to 7,000 bar

(100,000 psi)

Special features

■■ Ergonomic handling through the smooth-running, Hand spindle pump, model CPP1000-M

internally operating, precision spindle

■■ Integrated oil reservoir

■■ Removable star handle

■■ Freely rotating test connections (i.e. measuring

instruments can be aligned)

■■ Proven technology of the model CPB5800 pressure

balance

Description

Comparison test pump, model CPP1000-X

Application areas

Test pumps serve as pressure generators for the testing,

adjustment and calibration of mechanical and electronic

pressure measuring instruments through comparative

measurements. These pressure tests can take place in the

laboratory or workshop, or on site at the measuring point.

Easy operation

If one connects the test item and a sufficiently accurate

reference measuring instrument to the test pump, on

actuating the pump, the same pressure will act on both

instruments. By comparison of the two measured values at

any given pressure value, a check of the accuracy and/or

adjustment of the pressure measuring instrument under test

can be carried out.

Comparison test pump, model CPP7000-X

WIKA data sheet CT 91.05 ∙ 03/2016 Page 1 of 10

Data sheets showing similar instruments:

Test pump, pneumatic; model CPP30; see data sheet CT 91.06

Test pump, hydraulic; CPP700-H and CPP1000-H; see data sheet CT 91.07

Hand-held pressure indicator; CPH6300; see data sheet CT 12.01

ProcessCalibrator; CPH6000; see data sheet CT 15.01

Calibration software; WIKA-CAL; see data sheet CT 95.10

CPP-X series offers exceptional ease-of-use

For a precise approach to the measuring points, the test With the integrated priming pump, large test volumes can be

pumps are fitted with a spindle for fine control. In particular, easily filled and primed for the models CPP-X.

the smooth running of the hand spindle enables this, even at Due to the design of the base, the CPP-X models have a high

very high pressures. Furthermore, the spindles for this model durability and offer the highest ease-of-use with the proven

range only run within the pump body. technology of the model CPB5800 pressure balance.

This eliminates any harmful bending moment from an

externally running spindle and, especially for field operation,

there is the advantage that dimensions of these pumps do

not alter during operation through the rotation of the spindle.

Specifications

Hand spindle pump

CPP1000-M CPP1000-L

Pressure range 0 ... 1,000 bar

(0 ... 14,500 psi)

Pressure transmission medium Hydraulic fluid based on mineral oil or single distilled water 1)

(water-based hydraulic fluids are not suitable)

Reservoir 110 cm³ 55 cm³

Pressure connections

Test connection 2 x G ½ female thread, freely rotating, with O-ring

Distance between test connections 200 mm (7.9 in) 115 mm (4.5 in)

Piston of spindle pump

Piston diameter 8 mm (0.3 in)

Swept volume per revolution approx. 0.1 cm³

Overall swept volume approx. 3.9 cm³

Fine pressure adjustment optional, see accessories Fine adjustment valve on the side

Required force at

250 bar (3,600 psi) 2.0 Nm

500 bar (7,200 psi) 4.0 Nm

1,000 bar (14,500 psi) 8.0 Nm

Material

Cylinder Brass

Piston Stainless steel

Rear flange Aluminium

Sealings FKM, NBR (standard), optional EPDM 2)

Stationary mounting 2 x Ø 6.4 mm (0.25 in) through-bores in the front flange

Instrument base

Dimensions (L x W x H) 420 x 280 x 103 mm 420 x 240 x 103 mm

(16.5 x 11.0 x 4.1 in) (16.5 x 9.5 x 4.1 in)

Weight 6.3 kg (13.89 lbs.) 5.6 kg (12.35 lbs.)

1) Other pressure transmission media on request.

2) Using the EPDM variant (for aggressive media), Skydrol® or brake fluid is permissible as pressure transmission medium.

Page 2 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

Comparison test pump

CPP1000-X CPP1600-X CPP7000-X

Pressure range 0 ... 1,000 bar 0 ... 1,600 bar 0 ... 7,000 bar

(0 ... 14,500 psi) (0 ... 23,200 psi) (0 ... 100,000 psi)

Pressure transmission medium Hydraulic fluid based on mineral oil / clean water, free of Sebacate oil

calcium-carbonate 1)

Reservoir 250 cm³ 250 cm³

Pressure connections

Test connection 2 x G ½ female threaded quick-connectors, freely rotating, 2 x M16 x 1.5 male thread, freely

exchangeable, with O-ring rotating, exchangeable, with

sealing cone

Distance between test connections 300 mm (11.8 in) 346 mm (13.6 in)

Piston of the comparison test pump

Piston diameter 8 mm (0.3 in) 7.5 mm (0.3 in)

Swept volume per revolution approx. 0.1 cm³ approx. 0.08 cm³

Overall swept volume approx. 3.9 cm³ approx. 2.5 cm³

Required force at

250 bar (3,600 psi) 2.0 Nm 1.5 Nm

500 bar (7,200 psi) 4.0 Nm 3.0 Nm

1,000 bar (14,500 psi) 8.0 Nm 6.0 Nm

3,000 bar (43,500 psi) -- 18 Nm

5,000 bar (72,500 psi) -- 30 Nm

7,000 bar (100,000 psi) -- 42 Nm

Material

Cylinder Brass Stainless steel

Piston Stainless steel hardened stainless steel

Piping 1.4404 stainless steel, 6 x 2 mm (0.2 x 0.1 in) 1.4404 stainless steel, 6 x 2 mm

(0.2 x 0.1 in)

Rear flange Aluminium --

Sealings FKM, NBR (standard), optional EPDM 2) NBR

Stationary mounting Stable base Stable base

Instrument base

Dimensions (L x W x H) 400 x 375 x 265 mm 460 x 445 x 265 mm

(15.8 x 14.8 x 10.4 in) (18.1 x 17.5 x 10.4 in)

Weight 20 kg (44.1 lbs.) 32,5 kg (71.7 lbs.)

1) Other pressure transmission media on request.

2) Using the EPDM variant (for aggressive media), Skydrol® or brake fluid is permissible as pressure transmission medium.

Approvals

Logo Description Country

EC declaration of conformity for model CPP1600-X European Community

Pressure equipment directive

(PS > 1,000 bar; module A, pressure accessory

EAC Eurasian Economic Community

■■ Pressure equipment directive

■■ Machinery directive

Approvals and certificates, see website

WIKA data sheet CT 91.05 ∙ 03/2016 Page 3 of 10

Hand spindle pump model CPP1000 version M and L, up to 1,000 bar (14,500 psi),

hydraulic

The model CPP1000-M and CPP1000-L hand spindle The CPP1000-L is the case version with a narrow rear flange,

pumps, with their compact size and low weight, are the basic sealed reservoir and a fine adjustment valve built-in as

versions in the CPP series of test pumps. standard.

They have been designed primarily for the test and For the CPP1000-M, the fine adjustment valve is available as

calibration of pressure measuring instruments with small an accessory and can be fitted as an option. When using the

volumes. Test items and reference instruments with larger fine adjustment valve, only one shut-off valve can be fitted for

volumes should either be pre-filled offline from the test pump one test connection.

or also simply and conveniently filled directly from the hand The test connections are G ½ female. Corresponding thread

spindle pump, using the shut-off valves available as an adapters are available for the calibration of instruments with

accessory for the test connections. different connection threads.

Dimensions in mm (in)

Side view (right) Front view

)

94

3.

(1

4

35

Ø

418 (16.46)

306 (12.05)

~ 108 (~ 4.25)

73 (2.87)

71 (2.80)

(1.32)

33.5

Top view

1 2 3

223 (8.78)

280 (11.02)

200 (7.87)

115 (4.53)

195 (7.38)

(3.07)

78

64 (2.52)

(1.77)

2 x Ø 6.4 (0.3 in)

45

8 7 6 3 5 4

CPP1000-L CPP1000-M

1 Front flange with 2 fixing bores, Ø 6.4 mm (0,3 in) 5 Fine adjustment valve (at CPP1000-M as an option)

2 Medium reservoir 6 Shut-off valve for reservoir (optional)

3 Test connection, G ½ female thread, freely rotating, 7 Cylinder with spindle and piston

with O-ring 8 Star handle with spring-loaded thrust pad

4 Rear flange

Page 4 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

Comparison test pumps models CPP1000-X and CPP1600-X, up to 1,000 bar (14,500 psi)

or 1,600 bar (23,200 psi), hydraulic

The model CPP1000-X and CPP1600-X comparison test Both test connections on both pump models are fitted

pumps have been designed around a solid base and, with with quick-release connectors with knurled nuts and

the proven technology of the CPB5800 pressure balance, exchangeable threaded inserts (as standard G ½ female

offer exceptional ease-of-use. With the integrated priming thread). Corresponding threaded inserts are available for the

pump and the 250 ml tank, large test volumes can also be calibration of instruments with different connection threads.

easily filled and primed.

Dimensions in mm (in)

Front view Side view (left)

5

2.

43 3)

262 (10.31)

Ø 7.0

(1

129 (5.08)

375 (14.76)

441 (17.36)

Top view

1 2 1

400 (15.75)

7

300 (11.81) 50 (1.97)

(5.91)

Detailed section view model

150

CPP1600-X

- with high-pressure shut-off valve

310 (12.20)

- without pressure gauge

Dimensions are identical.

8

6 5 4 3

1 Test connections (quick-release connector with G ½ 5 Test pressure gauge

female thread, exchangeable, freely rotating, with 6 Shut-off valve 1,000 bar (14,500 psi)

O-ring)

7 Rotatable feet

2 Plug screw for medium reservoir

8 High-pressure shut-off valve 1,600 bar (23,200 psi)

3 Spindle pump with star handle

4 Priming pump

WIKA data sheet CT 91.05 ∙ 03/2016 Page 5 of 10

Comparison test pump model CPP7000-X, up to 7,000 bar (100,000 psi), hydraulic

The model CPP7000-X comparison test pump has been Both test connections are fitted with knurled nuts and

designed around a solid base and, with the proven exchangeable thread adapters with sealing cones (as

technology of the CPB5000HP high-pressure pressure standard M16 x 1.5 male threads). Corresponding thread

balance, offers exceptional ease-of-use. With the integrated adapters are available as accessories for the calibration of

priming pump and the 250 ml tank, large test volumes can instruments with other connection threads.

also be easily filled and primed.

Dimensions in mm (in)

Front view Side view (left)

587 (23.11)

Ø

55

8

(2

1.

97

)

268 (10.55)

161.5 (6.36)

445 (17.52)

Top view

2 3 2

460 (18.11)

345.5 (13.60) 44.5 (1.75)

(4.55)

115.5

280 (14.96)

7 6 5 4

1 Rotatable feet 5 Low-pressure shut-off valve (LP)

2 Test connections (knurled nut with M16 x 1.5 male 6 Priming pump

thread adapter, exchangeable, freely rotating, with 7 Spindle pump with star handle

sealing cone)

3 Plug screw for medium reservoir

4 High-pressure shut-off valve (HP)

Page 6 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

Recommended reference pressure measuring instruments:

Precision digital pressure gauge model CPG1000

Measuring ranges: up to 700 bar (10.000 psi)

Accuracy: 0.05 % of span

For further specifications see data sheet CT 10.01

Hand-held pressure indicator model CPH6300

Measuring ranges: up to 1,000 bar (14,500 psi)

Accuracy: 0.2 % of span

For further specifications see data sheet CT 12.01

Precision hand-held pressure indicator model CPH6400

Measuring ranges: up to 6,000 bar (85,000 psi)

Accuracy: up to 0.025 % of span

For further specifications see data sheet CT 14.01

ProcessCalibrator model CPH6000

Measuring ranges: up to 8,000 bar (115,000 psi)

Accuracy: up to 0.025 % of span

For further specifications see data sheet CT 15.01

Calibration software

WIKA-CAL calibration software for creating calibration

certificates or logger protocols

For specifications see data sheet CT 95.10

WIKA data sheet CT 91.05 ∙ 03/2016 Page 7 of 10

Complete test and service cases with pressure generation

Calibration case with model CPH6000

ProcessCalibrator and model CPP1000-L hand spindle

pump for pressures up to 1,000 bar (14.500 psi)

consisting of:

■■ Transport case with model CPH6000 ProcessCalibrator

■■ Hydraulic hand spindle pump model CPP1000-L up to

1,000 bar (14.500 psi)

■■ Sensor cable for external operation of sensor

■■ Test cable set with connection terminals

■■ Charger

■■ Interface cable

■■ Sealing set

■■ Spaces for several CPT6000 reference pressure sensors

Basic version incl. hydraulic pressure generation For further specifications see data sheet CT 15.01.

Calibration case with model CPG1000 precision digital

pressure gauge and model CPP700-H hand test pump,

for pressures 0 ... 700 bar (0 ... 10.000 psi), consisting

of:

■■ Plastic service case with foam insert

■■ Precision digital pressure gauge model CPG1000

■■ Hydraulic hand test pump model CPP700-H; 0 … 700 bar

(0 ... 10.000 psi)

For further specifications see data sheet CT 10.01 or

Basic version incl. hydraulic pressure generation CT 91.07

Calibration case with model CPH6400 precision

hand-held pressure indicator and model CPP30

hand test pump for pressures of -0.95 ... +35 bar

(-13,8 ... +500 psi), consisting of:

■■ Service case with foam insert

■■ Precision hand-held pressure indicator model CPH6400

■■ Pneumatic hand test pump model CPP30,

-0.95 ... +35 bar (-13,8 ... +500 psi)

■■ Sensor cable for external operation of sensor

■■ Charger

■■ Spaces for several CPT6400 reference pressure sensors

For further specifications see data sheet CT 91.06 or

Basic version incl. pneumatic pressure generation CT 14.01

Page 8 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

Hand spindle pumps models CPP1000-M and CPP1000-L

Scope of delivery reference instruments with a large volumes, two shut-off

valves are recommended.

■■ Spindle pump for filling, pressure generation and fine - Shut-off valve (recommended for connected volumes

pressure adjustment > 4 cm³), standard version

■■ Star handle - Shut-off valve (recommended for connected volumes

■■ Two test connections with G ½ female thread, loose union > 4 cm³), EPDM version

connection, with O-ring ■■ Fine adjustment valve for retrofitting to the CPP1000-M;

■■ Fine adjustment valve and/or shut-off valve for model enables precise approach to the measuring points

CPP1000-M as an option - Fine adjustment valve, standard version

■■ Shut-off valve for model CPP1000-L as an option (fine - Fine adjustment valve, EPDM version

adjustment valve is a standard)

■■ Operating instructions Pressure transmission medium

■■ Hydraulic fluid based on VG22 mineral oil in plastic bottle,

content 1 litre

Accessories

Adapters Other

■■ Set of O-rings, consisting of 10 seals for the test

■■ Connection adapter, G ½ male to G ⅛ female,

max. 250 bar (3,600 psi), mat.: brass connections, mat.: FKM/FPM, standard version

■■ Set of O-rings, consisting of 10 seals for the test

■■ Connection adapter, G ½ male to G ⅜ female,

max. 600 bar (8,700 psi), mat.: brass connections, mat.: EPDM

■■ 90° angle connection for test items with back mounting

■■ Connection adapter, G ½ male to G ¼ female,

max. 1,000 bar (14,500 psi), mat.: 1.4571 connection, standard version

■■ 90° angle connection, for test items with back mounting

■■ Connection adapter, G ½ male to M20 x 1.5 female,

max. 1,000 bar (14,500 psi), mat.: 1.4571 connection, NBR sealing

■■ Replacement tank cover incl. shut-off valve, standard

■■ Connection adapter, G ½ male to ¼ NPT female,

max. 1,000 bar (14,500 psi), mat.: 1.4571 version

■■ Replacement tank cover incl. shut-off valve, EPDM version

■■ Connection adapter, G ½ male to ½ NPT female,

■■ Replacement seal for tank cover

max. 1,000 bar (14,500 psi), mat.: 1.4571

■■ Blind plug, G ½ male, mat.: brass

Tools

■■ Maintenance set for hydraulic hand spindle pumps,

Valves

■■ Shut-off valve for test connection, enabling the easy filling

standard version

■■ Maintenance set for hydraulic hand spindle pumps, EPDM

of instruments with large volumes with filling medium,

directly from the hand spindle pump. Max. permissible version

pressure: 1,000 bar (14,500 psi). For test items and

Comparison test pump of model CPP1000-X and CPP1600-X

Scope of delivery Other

■■ Set of O-rings, consisting of 10 replacement seals (8 x 2)

■■ Priming pump for filling, spindle pump for pressure for the test connections, mat.: NBR

generation and fine pressure adjustment ■■ Set of O-rings, consisting of 10 replacement seals (8 x 2)

■■ Two test connections with G ½ female thread, loose union for the test connections, mat.: EPDM

connection, with O-ring ■■ 90° angle connection for test items with back mounting

■■ Operating instructions connection, standard version

■■ 90° angle connection, for test items with back mounting

Accessories connection, NBR sealing

■■ Replacement seal set for needle valve, standard version

Adapters ■■ Replacement seal set for needle valve, EPDM version

■■ Adapter set for quick-release connector in case with G ¼,

G ⅜, ½ NPT, ¼ NPT and M20 x 1.5 female, mat.: stainless Tools

steel ■■ Maintenance set for hydraulic volume adjuster, standard

■■ “NPT” adapter set for quick-release connector in case with version

⅛ NPT, ¼ NPT, ⅜ NPT und ½ NPT female, mat.: stainless ■■ Maintenance set for hydraulic volume adjuster, EPDM

steel version

■■ Adapter for connection column, G ½ male to M16 x 1.5 ■■ Sealing and maintenance set for instrument base (without

male with sealing cone, mat.: stainless steel volume adjuster), standard version

■■ Sealing and maintenance set for instrument base (without

Pressure transmission medium volume adjuster), EPDM version

■■ Hydraulic fluid based on VG22 mineral oil in plastic bottle,

content 1 litre

WIKA data sheet CT 91.05 ∙ 03/2016 Page 9 of 10

Comparison test pump model CPP7000-X

Scope of delivery

■■ Priming pump for filling, spindle pump for pressure

generation and fine pressure adjustment

■■ Two test connections with M16 x 1.5 male thread, loose

union connection, with sealing cone

■■ Operating instructions

Accessories

Adapters

■■ Adapter for connection column, M16 x 1.5 male with

sealing cone, mat.: hardened stainless steel

■■ Adapter for connection column, M20 x 1.5 male with

sealing cone, mat.: hardened stainless steel

■■ Adapter for connection column, 9/16-18 UNF male with

sealing cone, mat.: hardened stainless steel

■■ Adapter for connection column, G ½ female with O-ring,

max. 1,600 bar (23,200 psi), mat.: 1.4571

Pressure transmission medium

■■ Sebacate oil in plastic bottle, content 0.5 litre

Ordering information

CPP1000-M / Package / Version / Operating fluid / Left valve / Right valve / Valve mounting / Accessories / Additional ordering

information

CPP1000-L / Package / Operating fluid / Left valve / Valve mounting / Accessories / Additional ordering information

CPP1000-X / Package / Medium / Adapter set / Angle connection / Accessories / Additional ordering information

CPP1600-X / Package / Medium / Adapter set / Angle connection / Accessories / Additional ordering information

CPP7000-X / Package / Additional adapter / Accessories / Additional ordering information

© 2006 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

Page 10 of 10 WIKA data sheet CT 91.05 ∙ 03/2016

03/2016 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Freaky Friday Audition SidesDocument3 pagesFreaky Friday Audition SidesJessicaNo ratings yet

- UC Catalog PDFDocument2 pagesUC Catalog PDFKali Dass KMNo ratings yet

- Ficha Tecnica Alpha 30Document7 pagesFicha Tecnica Alpha 30jonathan francisco allende escobarNo ratings yet

- Hydraulic Comparison Test Pump Model CPP1200-X: ApplicationsDocument5 pagesHydraulic Comparison Test Pump Model CPP1200-X: ApplicationsToy HeartNo ratings yet

- Hydraulic Hand Test PumpModels CPP700-HDocument5 pagesHydraulic Hand Test PumpModels CPP700-Hcaptain essamNo ratings yet

- Data Sheet-FIREMIKS-10000-3-PP-F (Ver. G83) - 2024-01Document4 pagesData Sheet-FIREMIKS-10000-3-PP-F (Ver. G83) - 2024-01양승호No ratings yet

- Chapter 1Document6 pagesChapter 1Edgar Allende ChavezNo ratings yet

- DS CT9107 GB 10172Document4 pagesDS CT9107 GB 10172Sameer UsmaniNo ratings yet

- dynexPF2000 10 SpecsDocument5 pagesdynexPF2000 10 SpecsOILSERVICES COQUIMBONo ratings yet

- Data sheet-FIREMIKS-1000-0,5-1-3-PP-M - 2023-10Document4 pagesData sheet-FIREMIKS-1000-0,5-1-3-PP-M - 2023-10Alexis TaiNo ratings yet

- Brochure OLF 15-60Document4 pagesBrochure OLF 15-60hangmann169No ratings yet

- UNIVERSAL TESTING MACHINE 3000kNDocument1 pageUNIVERSAL TESTING MACHINE 3000kNEZIO AUDITORENo ratings yet

- Testplan 3242920Document1 pageTestplan 3242920Fx_205No ratings yet

- Cat Pump 5CP6180CSS - DDocument4 pagesCat Pump 5CP6180CSS - DMaximiliano ProiaNo ratings yet

- Snubber PDFDocument2 pagesSnubber PDFKenon FlemingsNo ratings yet

- Pump by BoseDocument26 pagesPump by BoseSonu SinghNo ratings yet

- TP - Second YearDocument12 pagesTP - Second YearOmkar KoreNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Test Plan: 8923A050: Pump SpecificationDocument2 pagesTest Plan: 8923A050: Pump Specificationveshat100% (1)

- C+ Data SheetDocument2 pagesC+ Data SheetNermeen AhmedNo ratings yet

- Fluid Mechanics & Hydrology: FM 675 Educational Compact Subsonic Wind TunnelDocument3 pagesFluid Mechanics & Hydrology: FM 675 Educational Compact Subsonic Wind Tunnelzivko13No ratings yet

- 2-PX NPCU Manifold Data Sheet 20150318Document2 pages2-PX NPCU Manifold Data Sheet 20150318Joel FloresNo ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- PRDC Sun ValveDocument3 pagesPRDC Sun ValvekhairulanuarjunNo ratings yet

- Ap LucDocument12 pagesAp LuchNo ratings yet

- Actuadores Dia P50 P110Document9 pagesActuadores Dia P50 P110Bryan NavarreteNo ratings yet

- CCCALBN en Us LetterDocument1 pageCCCALBN en Us Letterisaiahsamsonm_948069No ratings yet

- Gorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsDocument8 pagesGorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsVic Van PeborghNo ratings yet

- Hydraulic Pump (8J6730) (Part of 8J6731 Pump Group) : SpecificationsDocument7 pagesHydraulic Pump (8J6730) (Part of 8J6731 Pump Group) : SpecificationsJohn Fredy Palacio G.No ratings yet

- Cbcalin ValveDocument2 pagesCbcalin ValveArun51092No ratings yet

- Transfer Pump BrochureDocument12 pagesTransfer Pump BrochureRafert RamNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- Cat Pump Part List 67dx39g1iDocument4 pagesCat Pump Part List 67dx39g1iJorge M M100% (1)

- 01intro Baxter 1550Document12 pages01intro Baxter 1550Victor ManuelNo ratings yet

- DX225LCA: Crawler ExcavatorDocument10 pagesDX225LCA: Crawler ExcavatorSajad PkNo ratings yet

- Victus ManifoldDocument2 pagesVictus ManifoldMahendran KuppusamyNo ratings yet

- Ge Dresser HPC Meter Spec SheetDocument4 pagesGe Dresser HPC Meter Spec SheetfharishputraNo ratings yet

- Page 1271Document1 pagePage 1271EmilyTheDwarfNo ratings yet

- PF1000 Series Checkball Piston Pumps: Pressures To 10 000 PsiDocument7 pagesPF1000 Series Checkball Piston Pumps: Pressures To 10 000 PsiRodo RequenaNo ratings yet

- Hydraulic PumpsDocument54 pagesHydraulic PumpsPraveen Bavana100% (1)

- Pumps: Select The Optimum Model Between Two Different Types of PumpDocument2 pagesPumps: Select The Optimum Model Between Two Different Types of PumpLinh LeeNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- Low Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureDocument1 pageLow Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureSiéJustinDembeleNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- RSBC Full en Us A4Document2 pagesRSBC Full en Us A4Mykola TitovNo ratings yet

- UTM CatalogDocument6 pagesUTM CatalogAsmita AcharyaNo ratings yet

- Winch, Racking Board (EUAB) Product Information ManualDocument12 pagesWinch, Racking Board (EUAB) Product Information ManualTonyNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet: Double Seat ValvesDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet: Double Seat Valvesمیلاد قاسمیNo ratings yet

- Limitadora de Presion Rvga-Lan Sun HydraulicsDocument1 pageLimitadora de Presion Rvga-Lan Sun HydraulicsCarlosNo ratings yet

- Additel 918 BombaDocument1 pageAdditel 918 BombaVentas UcalibrationNo ratings yet

- LPV Hydraulic Pump Catalog PDFDocument20 pagesLPV Hydraulic Pump Catalog PDFJAGDEV PANESARNo ratings yet

- BOECO Vaccum Pumps 2016Document2 pagesBOECO Vaccum Pumps 2016Joe SamraNo ratings yet

- Avery Hardoll CM Series BulkmeterDocument8 pagesAvery Hardoll CM Series Bulkmeterhendro saputroNo ratings yet

- IPD AutoclaveEngineers Subsea Ball Valves CatalogDocument28 pagesIPD AutoclaveEngineers Subsea Ball Valves CatalogGabriel Jamariqueli BueresNo ratings yet

- Divider Block Accessory LTR HowdenDocument4 pagesDivider Block Accessory LTR HowdenjasonNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- PDFDocument111 pagesPDFmohanNo ratings yet

- Intraplast N 200 100816Document2 pagesIntraplast N 200 100816Brijendra Mani PandeyNo ratings yet

- Adce Parameter of 2gDocument4 pagesAdce Parameter of 2gAmit DevNo ratings yet

- Change Your Water Change Your Life!Document72 pagesChange Your Water Change Your Life!Jack MekwanNo ratings yet

- Canadian Importers Lists - Coconut OilDocument4 pagesCanadian Importers Lists - Coconut OilIndo Coconut PremiumNo ratings yet

- ID Strategi Pengembangan Usahatani Ubi Kayu Manihot Utilissima Di Kecamatan MenggalDocument9 pagesID Strategi Pengembangan Usahatani Ubi Kayu Manihot Utilissima Di Kecamatan MenggalBukhori Thomas EdvanNo ratings yet

- Technology Can Help Your Business Grow From A SmallDocument12 pagesTechnology Can Help Your Business Grow From A SmallPraveen KumarNo ratings yet

- Phase-Type Approximation of The Gerber-Shiu Function: Kansai UniversityDocument16 pagesPhase-Type Approximation of The Gerber-Shiu Function: Kansai UniversityAlEx HernandezNo ratings yet

- ch1 - Part 2Document13 pagesch1 - Part 2Vivvian Grace M MolahidNo ratings yet

- 150 T Crane1-36-37Document2 pages150 T Crane1-36-37laureljhonwilsonNo ratings yet

- Quantum FoamDocument47 pagesQuantum FoamATP_101No ratings yet

- Code BatmanDocument43 pagesCode BatmanLi Jie TeoNo ratings yet

- How To Pretest and Pilot A Survey Questionnaire PDFDocument7 pagesHow To Pretest and Pilot A Survey Questionnaire PDFsaimaNo ratings yet

- De 1Document6 pagesDe 1Thắng Phạm ĐứcNo ratings yet

- Open GLDocument161 pagesOpen GLRavi ParkheNo ratings yet

- COA RulesDocument22 pagesCOA RulesNoraiza Mae Keith TalbinNo ratings yet

- Poem Alam SekitarDocument1 pagePoem Alam SekitarSITI SYAHIRAH BINTI A MALEKNo ratings yet

- Fifth Year Quiz 2021 EndoDocument6 pagesFifth Year Quiz 2021 Endohoho2019kuNo ratings yet

- All in Alfloc2Document12 pagesAll in Alfloc2Choice OrganoNo ratings yet

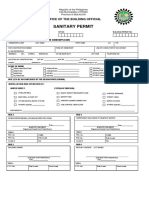

- Sanitary Permit (Front)Document1 pageSanitary Permit (Front)Darwin CustodioNo ratings yet

- JR - English Practice - Qps.apDocument20 pagesJR - English Practice - Qps.apnsmviiif08chakravarthyygsNo ratings yet

- High Lateral Tension AbdominoplastyDocument14 pagesHigh Lateral Tension AbdominoplastyAhmad Arbi AninditoNo ratings yet

- Lecture 3: Solving Linear Systems: Elif TanDocument20 pagesLecture 3: Solving Linear Systems: Elif Tansercan egilmezkolNo ratings yet

- RefDocument11 pagesRefKailash KumarNo ratings yet

- Communicationskillunit1 - LSRWDocument187 pagesCommunicationskillunit1 - LSRWjasjisha4No ratings yet

- F-QMO-017Data Use and Protection Agreement Annex-5Document3 pagesF-QMO-017Data Use and Protection Agreement Annex-5Cyan Vincent CanlasNo ratings yet

- Coke - Ethical Issues: The RecallDocument7 pagesCoke - Ethical Issues: The RecallPriya JainNo ratings yet

- Wired Drill Pipe-Fosse - Martin PDFDocument62 pagesWired Drill Pipe-Fosse - Martin PDFMohamed Anis Boumaza100% (1)

- 10 Question Related To InheritanceDocument4 pages10 Question Related To InheritancePrashant kumarNo ratings yet