Professional Documents

Culture Documents

A18L

A18L

Uploaded by

Alejandro Arroyave0 ratings0% found this document useful (0 votes)

6 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views2 pagesA18L

A18L

Uploaded by

Alejandro ArroyaveCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

ON

Reriatance

By Keith Switzer

HE goal of any grounding system is to pro-

vide a low-impedance path for fault cur-

rents until they reach the earth.

Bur the effectiveness of any

such system depends largely on whether

the soil surrounding it can absorb and dis

sipate large electrical currents. In other

words, the soil must have low resistivity to

properly support the grounding system.

The conductivity of the earth, or the

ease with which it conducts electrons,

varies with different soils and can be

influenced by moisture content and tem-

perature. Moisture content is important

because it helps the soil around ground

rods disperse the electrical current. When

‘moisture content is below 10 percent, it

can increase earth resistivity significantly

Temperatures below freezing also inerease

resistivity. When moisture turns 0 i

resistivity increases sharply. In areas sub-

ject to freecing winters, driving the

ground rod below the frost line is standard

for maintaining low resistivity.

‘When considering the grounding con-

ditions at any site its essential totes soil

resistivity. Test results must be examined carefly

since resistivity levels can vary widely, even in appar

ently similar soils. In general, lack dirt, or soils with

hich onganic content, are usually very good conduc-

tors because they tend to retain more moisture, leat

ing to low resistivity: Sandy soils, which drain faster,

tend to be less moist and are therefore higher in tesis-

tivity. Solid rock and volcanic ash, like the soils in

Hawaii, have virtually no moisture, and have such.

hhigh resistivity as to be practically useless as a

grounding material

Reducing Resistivity

If soil tests show high resistivity, grounding system

designers can choose from several options.

Depending on the soil, increasing moisture may

lower resistivity. In topsoil, resistivity may be reduced

£80,000 ohms-cm by increasing moisture from 5 t0 10

percent. An additional, though much smaller, redue-

tion in resistivity can be obtained by increasing mois-

RESISTIVITY ohm-cm

ree aan

Cee ee

ture from 10 to 20 percent. Then resistivity essen-

Tally stabilizes. In many places, ensuring low resis

ity is as simple as driving a ground rod into a subsur

face soil layer that has a relatively permanent and

conductive moisture content.

Tn the absence of such favorable conditions, there

are other options for improving conductivity. These

include filling the ground rod hole with bentonite,

treating the soil with a salt (copper ma

fate or rock salt), or using Ground Enhancement

Material (GEM™} from ERICO, Inc.

Reprinted from The Military Engineer, Vol 87, No. $71, June-July 199

Bentonite isa clay substance used in

rounding. systems in soils with high

resistivity. However, conduction in ben

tonite only occurs when ions move. Janie

conductivity can only occur in a solu-

tion, which means that bentonite must

be wet t0 provide low-resistivity level

When it loses moisture, its resitv

increases and it contracts, losing contact

‘with the surrounding soil

‘Another way to lower earth resistivity

is to treat the soil with a salt. Combined

with moisture, salts leach inte che soil

and reduce resistivity. However, this

same process can also cause problems. As

the salts are depleted, the sil reverts to

its untreated condition and the system

has to be recharged periodically. Also,

the leachate may contaminate (oun

water; local environmental regulations

then, may rule out this alternative imm

diately.

Using GEM

‘The third altemative, GEM, is a low-

resistance, noncotrosive, powdered

material that offers a resistivity of 12

cohins-em or lower when set, compared to

250 ohms-cm for bentonite. GEM

{improves grounding effectiveness regard-

less of soil conditions and is ideal for

areas with high resistance, such as rocky

sround, mountain tops, and sandy soil

GEM provides excellent and perma-

rent conductivity in even the most diffi

cult conditions. For instance, the

Oglethorpe Power Corp. had to ground a

utility building at its new Rocky

‘Mountain pumped-storage hydroelectric

pant. The plant was to be built on solid

rock, where conductivity needed for

sround rods is virtually nonexistent, Site

conditions made it imperative that the

designers ofthe grounding system look at

all options available to lower resistivity.

The original specifications called for

copper ground plates to be placed in

holes dug out of the rock and surrounded

with coke powder as the conductive

‘material. However, because groundwater

«can wash coke powder away, and ground-

ing should be permanent, it was decided

to use GEM

GEM can be installed wet or dry. It

absorbs moisture from the surrounding

soil and then hardens, retaining moisture

in its structure. When used dry, no mix:

ing is required and the material will

reach its maximum efficiency in days. To

accelerate curing time, water can be

added after the material is installed, or it

ccan be premixed with water to form a

slurry

Advantages of GEM

GEM has many advantages over ben-

tonite and rock salt. Unlike rock salt, it

ddoes not require periosic charging treat-

ments or replacement. And, because it is

chemically stable and! very low in sulfate

and chloride, it protects ground conduc-

tors from corrosion instead of attacking

them like salts do. The material sets up

hhard like cement, and fills voids hetween

the cable and the earth. Once set, it

maintains high conductivity in wet or

dry conditions. GEM meets all EPA

requirements for landfill.

‘Where ground rods ear’ be driven, or

where limited land area makes adequate

sqrounding difficult with conventional

methods, GEM may be used. Although it

eats re intially than standard fill

materials such as bentonite, only a small

amount is needed, 50 the size of the

‘grounding array can be reduced dramati-

cally.

‘At the Oglethorpe Power Rocky

Mountain plant, che process began by

using a trencher with bullet teeth to cut

narrow slots in the rock for laying the

conductor cable, and holes were drilled

for 30 ground rods. All connections were

rade with exorhermically welded con-

nections to ensure the highest possible

electrical continuity in a permanent con-

nection.

‘After the cables and rods were placed,

the slots and holes were filled with the

‘material, which was worked under and

around the cables. The amount used for

the cables varied with their length: as an

‘example of the amounts needed for such

work, however, each rod took two 25-

pound bags. Mixed with water and

poured in the rod holes in a slury, i was

firm to the touch within 48 hours and

completely set co a cementlike hardness

in seven days.

By reducing resistivity levels at the

power plant, an electrical. grounding

system was made possible in solid rock,

However, sandy soil was the challenge

for contractors who had to ground a new

Toro Irrigation Control System at a 36-

hole golf course. The system is like a

computerariven mini-weather station.

With its central weather sensor, it daily

measures temperature, wind velocity,

relative humidity, and rainfall, Then, it

analyzes these data and computes the

fevapotranspiration rate (the amount of

water that has evaporated due to tem-

perature, wind velocity, relative humid-

ity, and rainfall) for that day and auto-

matically adjusts the run time for each

sprinkler station to give individual areas

C0, ne, ttn Seon os Son Ono 4, Pon: AB NELD, FAN ECQWEDATIT NL,

of the golf course just the moisture

needed.

The main computer signals the irti-

gation controllers (88 in this case) that

activate the course's 2400 sprinklers.

‘When the computer determines that

the ground is too dry, it sends that

information to the controllers. They, in

‘tur, signal the sprinklers to begin their

irrigation cycle. The controllers have

surge arresters on each wire coming in

from and going out to the sprinklers,

and permanent, low-resistivity ground:

ing for each controller is mandatory.

Given this, a low-tesistance ground is

necessary (designers specified resistivity

‘of 10 ohms or less). However, the sol is

hhighly resistant. Act first, foot copper-

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nfpa EseDocument3 pagesNfpa EseAlejandro ArroyaveNo ratings yet

- A Statistical Analysis of Strike Data From Real Installations Which Demonstrates Effective Protection of Structures Against LightningDocument6 pagesA Statistical Analysis of Strike Data From Real Installations Which Demonstrates Effective Protection of Structures Against LightningAlejandro ArroyaveNo ratings yet

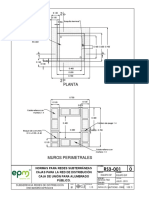

- RS3-001 - Normas para Redes Subterraneas Cajas para La Red de Distribucion y Caja de Union para Alumbrado PublicoDocument5 pagesRS3-001 - Normas para Redes Subterraneas Cajas para La Red de Distribucion y Caja de Union para Alumbrado PublicoAlejandro ArroyaveNo ratings yet

- Seleccion de La Proteccion para Una Bomba RciDocument3 pagesSeleccion de La Proteccion para Una Bomba RciAlejandro ArroyaveNo ratings yet

- Calculo de Alimentadores para MotoresDocument12 pagesCalculo de Alimentadores para MotoresAlejandro ArroyaveNo ratings yet

- Zonas de Servidumbre Ancho de Franja en Lineas de TransmisionDocument1 pageZonas de Servidumbre Ancho de Franja en Lineas de TransmisionAlejandro Arroyave100% (1)

- Regulador VS DPS SuprexorDocument2 pagesRegulador VS DPS SuprexorAlejandro ArroyaveNo ratings yet

- NEGRP Paper PDFDocument8 pagesNEGRP Paper PDFAlejandro ArroyaveNo ratings yet

- Foto RA8-001 Fusibles Trafos EpmDocument1 pageFoto RA8-001 Fusibles Trafos EpmAlejandro ArroyaveNo ratings yet

- Experimental Arrangements To Study Lightning Attachment Characteristics in Northern AustraliaDocument4 pagesExperimental Arrangements To Study Lightning Attachment Characteristics in Northern AustraliaAlejandro ArroyaveNo ratings yet

- Sustentación DPS Vs Estabilizador de VoltajeDocument2 pagesSustentación DPS Vs Estabilizador de VoltajeAlejandro ArroyaveNo ratings yet

- Moore Et Al 2003 PDFDocument10 pagesMoore Et Al 2003 PDFAlejandro ArroyaveNo ratings yet

- Reticertificamos S.A PDFDocument1 pageReticertificamos S.A PDFAlejandro ArroyaveNo ratings yet

- Iclp3 Paper PDFDocument5 pagesIclp3 Paper PDFAlejandro ArroyaveNo ratings yet

- LPS Positioning - PaperDocument6 pagesLPS Positioning - PaperAlejandro ArroyaveNo ratings yet

- Insulated downcond-DHENDocument6 pagesInsulated downcond-DHENAlejandro ArroyaveNo ratings yet

- LP EFM FinalDocument38 pagesLP EFM FinalAlejandro ArroyaveNo ratings yet

- A Review of The Lightning Attachment Process and Requirements To Achieve Improved ModellingDocument5 pagesA Review of The Lightning Attachment Process and Requirements To Achieve Improved ModellingAlejandro ArroyaveNo ratings yet

- IEEE837 Paper PDFDocument7 pagesIEEE837 Paper PDFAlejandro ArroyaveNo ratings yet

- Laboratory Studies of Corona Current Emissions From Blunt, Sharp and Multipointed Air TerminalsDocument7 pagesLaboratory Studies of Corona Current Emissions From Blunt, Sharp and Multipointed Air TerminalsAlejandro ArroyaveNo ratings yet

- EQuebecDocument6 pagesEQuebecAlejandro ArroyaveNo ratings yet

- New Techniques For Designing SPD'S Exhibiting High Mcov While Maintaining Low Residual VoltageDocument5 pagesNew Techniques For Designing SPD'S Exhibiting High Mcov While Maintaining Low Residual VoltageAlejandro ArroyaveNo ratings yet

- Safe Coordination Between Power and Communication Surge ProtectionDocument7 pagesSafe Coordination Between Power and Communication Surge ProtectionAlejandro ArroyaveNo ratings yet

- Assessment of Protection System Positioning and Models Using Observations of Lightning Strikes To StructuresDocument23 pagesAssessment of Protection System Positioning and Models Using Observations of Lightning Strikes To StructuresAlejandro ArroyaveNo ratings yet

- E5ADocument6 pagesE5AAlejandro ArroyaveNo ratings yet