Professional Documents

Culture Documents

Ieeepes12tht&d PDF

Ieeepes12tht&d PDF

Uploaded by

Alejandro Arroyave0 ratings0% found this document useful (0 votes)

17 views6 pagesOriginal Title

IEEEPES12THT&D.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

17 views6 pagesIeeepes12tht&d PDF

Ieeepes12tht&d PDF

Uploaded by

Alejandro ArroyaveCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

12TH IEEE/PES TRANSMISSION & DISTRIBUTION

CONFERENCE AND EXPOSITION

HOW GOOD IS YOUR SUBSTATION GROUND SYSTEM

WEDNESDAY SEPTEMBER 25,1991

ROOM #W108, PANEL # 37

DETERMINING CONDITION OF GROUND SYSTEM COMPONENTS

BY ANDREW C. COCKERHAM, P.E.

VIRGINIA POWER

P.O. BOX 26666

RICHMOND, VA. 23261

VIRGINIA POWER

12TH IEEE/PES TRANSMISSION & DISTRIBUTION

CONFERENCE AND EXPOSITION

HOW GooD IS YOUR SUBSTATION GROUND SYSTEM

WEDNESDAY SEPTEMBER 25,1991

ROOM W108, PANEL # 37

DETERMINING CONDTTTON OF GROUND SYSTEM COMPONENTS

BY A. C. COCKERHAM

VIRGINIA POWER

I_APPRECTATR THE OPPORTUNITY TO SHARE WITH YOU TODAY

SOME OF THE THINGS THAT MY COMPANY IS DOING TO VERIFY THE

CONDITION OF OUR SUBSTATION GROUND GRTN.

VIRGINIA POWER IS ONE OF SEVERAL SUBSTDTARTRS OF

DOMINION RESOURCES, INC. OUR SERVICE AREA COVERS

APPROXIMATELY TWO THIRDS OF VIRGINIA AND OUR STSTRR COMPANY,

NORTH CAROLINA POWER SERVES THE NORTH EAST PORTION OF NORTH

CAROLINA. TOTAL SYSTEM CAPABILITY IS AROUT 15,000 MFGAWATTS

WITH RECENT PEAK DEMAND OF ALMOST 13,000 MEGAWATTS. OUR

ENERGY SOURCES ARE 38% NUCLEAR, 40% COAL, 18% PURCHASED AND

INTERCHANGED, AND 4 % OTHER. WE HAVE APPROXIMATELY

1,780,000 CUSTOMERS. OUR MAJOR TRANSMISSION SYSTEM VOT/TAGES

ARE 500KV AND 230KV. OUR PRIMARY DISTRIBUTION VOLTAGE IS

34.5KV GROUNDED WYE.

A. DESIGN STANDARD

BRIEFLY, WE FOLLOW THE TREE GNTNE ao FOR OUR

SUBSTATION GROUND GRID DESIGN AND USE THE EPRI SUBSTATION

GROUNDING ANALYSTS COMPUTER - SGSYS PROGRAM FOR

DETERMINATION OF GRID SPACING, GROUND ROD LOCATIONS, ETC.

YEARS AGO WE USED MOSTLY THE EXOTHERMIC TYPE WELDED

CONNECTIONS. DURING THE LAST 10 YEARS WE HAVE TRIED ALMOST

EVERY TYPE OF CONNECTOR. TODAY WE ARE IN THE PROCESS OF

GOING BACK TO THE EXOTHERMIC TYPE OF WELDED CONNECTIONS AT

EACH CROSS POINT OF THE GRID AND ALSO TO THE ROD. BOLTED

CONNECTIONS CONTINUE TO BE MADE TO EACH ITEM OF EQUIPMENT

IN AT LEAST TWO LOCATIONS AND TO EACH STEEL STRUCTURE.

RECENTLY, WE CHANGED FROM 7 STRAND HARD DRAWN #4/0 COPPER

TO 19 STRAND SOFT DRAWN # 4/0 COPPER CONDUCTOR. THIS CHANGE

WAS MADE SOLELY BECAUSE IT IS MUCH EASIER TO INSTALL. THERE

WAS SOME CONCERN ABOUT CORROSION ON THE 19 STRAND CONDUCTOR,

HOWEVER WE BELIEVE THIS WILL NOT BE A PROBLEM FOR OUR SOIL

CONDITIONS.

SEVERAL YEARS AGO WE BECAME CONCERNED ABOUT THE

INTEGRITY OF OUR GROUND CONNECTIONS. THERE ARE TWO MAJOR

AREAS OF CONCERN; (1) PERSONNEL SAFETY, AND (2) PROTECTION

OF THE EQUIPMENT AGAINST VOLTAGE TRANSIENTS AND NEUTRAL

SHIFT CONDITIONS DURING FAULTS ON THE SYSTEM. OUR COMPANY

IS NOTED FOR BEING A LEADER IN THE INDUSTRY FOR "Low

EQUIPMENT BIL LEVELS." THIS ALSO INCREASES THE IMPORTANCE

OF GOOD GROUNDS. MOST IF NOT ALL THE PROBLEMS SEEM TO BE

WITH LOOSE OR DEFECTIVE CONNECTIONS, NOT THE CONDUCTORS OR

THE RODS. WE HAVE ALSO DISCOVERED SEVERAL CASES WERE THE

CONDUCTORS HAVE BEEN CUT DUE TO CONSTRUCTION IN THE AREA.

B. HIGH CURRENT TEST PROCEDURE

FOR THESE REASONS WE ADOPTED A "HICH CURRENT TEST"

PROCEDURE TO VERIFY THE CONDITION OF OUR GROUND

CONNECTIONS. THIS TEST IS PERFORMED ON ALL NEW STATIONS

BEFORE ENERGIZING AND EVERY EIGHT YEARS THEREAFTER.

I, THE FOLLOWING EQUIPMENT IS NECESSARY.

1. A. C. HIGH CURRENT SOURCE; CAPABLE OF

PRODUCING 300 AMPERES CONTINUOUSLY, WITH

7 METERS, VARIAC, ETC. SIMILAR TO MODEL GTS-300

MANUFACTURED BY EIL INSTRUMENTS., INC.

SPARKS, MD, 21152

2. CLASS TWO RUBBER CLOVES FOR OPERATORS.

3. CLIP ON AMMETER

4. CABLES

5. PERMANENT MARKERS TO IDENTIFY GROUND RISERS.

II. SAFETY CONSIDERATIONS

1. CLASS TWO RUBBER GLOVES SHALL BE WORN BY ALL

EMPLOYEES OPERATING THE HIGH CURRENT TEST SET

AND /OR CONNECTING AND DISCONNECTING THE HIGH

CURRENT TEST LEADS.

2. BEFORE DISCONNECTING ANY GROUND, BE SURE TO

PARALLEL IT WITH AN APPROVED # 2/0 TEMPORARY

GROUND. KEEP IN MIND TO NEVER " OPEN ~

CIRCUIT" THE GROUND CURRENT PATH FROM THE

TRANSFORMER NEUTRAL OR ANY OTHER EQUIPMENY

WHICH MAY HAVE CURRENT FLOW INTO THE GROUND

GRID.

HAZARDOUS VOLTAGE AND CURRENT MAY EXIST IN

SUBSTATION GROUNDING SYSTEMS AT ANY TIME. IF

A GROUND RISER OR GROUND GRID CONNECTION IS

FOUND TO BE LOOSE OR DEFECTIVE, THEN A SHUNT

GROUND MUST BE PLACED IN PARALLEL WITH THE

DEFECTIVES CONNECTION BEFORE REPAIRS ARE

STARTED. THE SHUNT GROUND SHALL BE PLACED

WITH APPROVED LIVE LINE TOOLS OR CLASS TWO, OR

EQUIVALENT, RUBBER GLOVES.

III, TEST PROCEDURES

L

FIRST CONNECT THE TWO HIGH CURRENT TESY LEADS

TOGETHER AND PASS THREE HUNDRED AMPS THROUGH

THE LEADS. RECORD THE VOLTAGE DROP FOR

REFERENCE.

USE THE TRANSFORMER NEUTRAL AS A REFERENCE

GROUND WHEN AVAILABLE.

CONNECT ONE HIGH CURRENT LEAD To THE REFERENCE

GROUND ABOVE GRADE BUT BELOW ANY BONDING

CONNECTION OR CLAMP.

CONNECT THE OTHER HIGH CURRENT LEAD TO THE

GROUND RISER TO BE TESTED.

INCREASE THE VOLTAGE ON THE TEST SET UNTIL

THREE HUNDRED AMPS PLOW THROUGH THE TEST LEADS

AND RECORD THE VOLTAGE DROP ON THE TEST SET.

THE VOLTAGE DROP WILL RISE APPROXIMATELY ONE

VOLT MORE THAN THE REFERENCE "LEAD VOLTAGE

DROP" RECORDED ABOVE FOR EACH FIFTY FEET oF

STRAIGHT LINE DISTANCE FROM THE REFERENCE

POINT To THE TEST POINT.

USING A CLIP ON AMMETER MEASURE THE AMOUNT OF

CURRENT FLOWING IN THE GROUND RISER BELOW THE

TEST LEAD TO THE GROUND GRID AND THE AMOUNT OF

CURRENT FLOWING IN THE GROUND RISER ABOVE THE

TEST LEAD TO THE CONNECTED EQUIPMENT OR

STRUCTURE. RECORD THE READINGS ON THE TEST

SHEET. ON EQUIPMENT WITH SINGLE GROUNDS, AT

LEAST 200 AMPS SHOULD FLOW DOWN TO THE GROUND

GRID. ON SOME GROUNDS OF THIS TYPE, 100 AMPS

WILL FLOW BACK TO THE GRID THROUGH FOUNDATION

BOLTS, CONDUITS, ETC.

IF THE CURRENT FLOWS AND OR VOLIAGE DROP IS

NOT IN ACCORDANCE WITH THE ABOVE THEN THE

GROUND RISER SHOULD BE EXCAVATED, THE CAUSE OF

THE HIGH RESISTANCE DETERMINED AND CORRECTED.

IN LARGE STATIONS IT MAY BECOME NECESSARY TO

ADD EXTENSION LEADS TO THE HIGH CURRENT TEST

LEADS OR RELOCATE THE TEST SET. IN WHICH CASE

A PREVIOUSLY TESTED GROUND RISER MAY BE USED

AS A NEW REFERENCE GROUND.

ON EQUIPMENT WITH MULTI GROUNDS, AT LEAST HALF OR 150

AMPS OF THE TEST CURRENT SHOULD FLOW TO TIIE GRID. IF THE

CURRENT TO THE GRID IS LESS THAN 150 AMPS, DISCONNECT THE

GROUND FROM THE EQUIPMENT ( SBE CAUTION ADOVE ) AND AGAIN

PASS 300 AMPS THROUGH IT. IF THE GROUND PASSES 300 AMPS AND

THE VOLTAGE DROP DOES NOT INCREASE MORE THAN .5 VOLTS OVER

THE PREVIOUS LEVEL, CONSIDER THE GROUND SATISFACTORY.

OBSERVATIONS

WE ARE AWARE THAT THE ABOVE PROCEDURE DOES NOT WORK

WELL TO FIND ALL QUESTIONABLE CONNECTIONS DUE TO OTHER

NORMAL A. C. CURRENTS PRESENT IN THE GROUND CONDUCTORS WIEN

THE STATION IS IN SERVICE. WE ARE WORKING ON A NEW TEST

SET USING D. C. RATHER THAN AN A. C, VOLTAGE SOURCE. THIS

METHOD WOULD ALLOW US TO CALCULATE AND OR MEASURE THE ACTUAL

CIRCUIT RESISTANCE AND THUS FIND HIGH RESISTANCE

CONNECTIONS.

OUR NORTHERN DIVISION HAS 365 SUBSTATIONS TRANSFORMERS.

RECENT TEST FOUND 67 TRANSFORMER LOCATIONS WHERE THE CURRENT

PASSING THROUGH THE NEUTRAL GROUND WAS LESS THAN THE TOTAL

CURRENT PASSING THROUGH THE TANK GROUNDS. THIS

IS MOST LIKELY DUE TO THE FACT THAT THE NEUTRAL IS BONDED TO

THE TANK WITH MULTIPLE TANK GROUNDS. OUR STANDARD

DISTRIBUTION IS SOLID GROUNDED WYE CONNECTIONS WITH ALL

NEUTRALS; FROM THE CIRCUITS AND THE TRANSFORMERS CONNECTED

DIRECTLY TO THE GROUND GRID. WE DO NOT USE A NEUTRAL BUS,

AS SUCH, EXCEPT IN THE CASE OF SINGLE PHASE TRANSFORMERS.

IN AT LEAST TWO OF THESE STATIONS WE ARE IN THE PROCESS

OF REPLACING THE EXISTING GRID DUE TO THE DETERIORATED

CONDITIONS OF THE CONNECTORS DISCOVERED BY THIS TEST

PROCEDURE. FROM THIS PROJECT IN ADDITION TO THE OTHER

CHANCES TO OUR STANDARDS WE HOPE TO BE ABLE TO IMPROVE OUR

SUBSTATION GROUNDING SYSTEM.

WE HAVE SEVERAL STATIONS WITH TERRACED GROUND

ELEVATIONS AND OR STATIONS WHERE MAJOR ADDITIONS HAVE

TAKEN PLACE. WE HAVE DISCOVERED, IN MANY OF THESE

LOCATIONS, A LACK OF BONDING OF THE GROUNDS BETWEEN THE TWO

AREAS. THIS WAS DISCOVERED WHEN TEMPORARY PERSONAL

PROTECTIVE BONDING CONDUCTORS WERE USED TO BOND BETWEEN

THESE SEPARATE AREAS.

WHERE NEW ADDITIONS ARE ADDED OFTEN THE EXISTING

GROUND GRID IS CUT TO ALLOW NEW FOUNDATIONS, CONDUIT RUNS,

ETC. WE HAVE FOUND CASES WHERE THE NEW STRUCTURE GROUNDS

WERE NOT ADEQUATELY CONNECTED TO THE EXISTING GROUND GRID.

THERE HAVE BEEN CASES WHERE CONTROL CIRCUIT GROUNDS

ATTEMPTED TO PASS HIGH GROUND CURRENTS AND ACTED AS FUSIBLE

LINKS, BURNING IN TWO.

OVER THE YEARS, SEVERAL TYPES OF GROUNDING HARDWARE

HAVE BEEN USED ON OUR SYSTEM, RANGING FROM MECHANICAL, TO

COMPRESSION, TO EXOTHERMIC TYPE CONNECTIONS. DIFFERENT

TYPES REQUIRE DIFFERENT TOOLS, DIES, ETC FOR PROPER

INSTALLATION. OFTEN, BECAUSE OF OUR TOOL STANDARDS WE DID *

NOT HAVE AVAILABLE, THE PROPER TOOL TO INSTALL A CERTAIN

TYPE COMPRESSION CONNECTOR. THIS, PERHAPS HAS CONTRIBUTED

TO THE CAUSE OF SOME OF THE POOR CONNECTIONS WE HAVE FOUND.

CROSS REFERENCE TABLES ARE AVAILABLE, HOWEVER I BELIEVE AT

LEAST PART OF OUR PROBLEM WAS THE SEVEN STRAND HARD DRAWN

COPPER CONDUCTOR MENTIONED EARLIER.

OTHRR PROBLEMS ARE IN CLEANING THE MUD, WATER

DROPLETS, ETC PRIOR TO MAKING AN EXOTHERMIC TYPE CONNECTION.

THERE IS ALSO A CONCERN FOR THE THREADED CONNECTIONS

BETWEEN SECTIONAT, COPPER CI.AD GROUND RONS. OTHER TYPE

CONNECTIONS INCLUDING EXOTHERMIC ARE BEING EVALUATED.

FIELD TEST ARE ALSO PRESENTLY UNDERWAY ON DIFFERENT TYPES oF

GROUND RODS. DIFFERENT DIAMETER RODS, DIFFERENT MATERIALS AS

WELL AS DIFFERENT TYPE SPLICES ARF BEING RVALUATED.

D. GROUND GRTD GENERAT, REQUTREMENTS

1. RIGHTREN INCHES DEEP AND EXTEND THREE FEET OUTSIDE

STATION FENCE LINE. #4/0 19 STRAND SOFT DRAWN

COPPER

2. MAXIMUM GRID SPACING SHOULD BE 50 FEET, MINIMUM WILL

NORMALLY BE 5 FEET.

3. OPTIMUM ROD SPACING FOR LOWERING THE GROUND

RESISTANCE IS 2 TIMES THE LENGTH OF THE RODS.

4. A MINIMUM OF TWO 6 FOOT RODS SHOULD BE USED AT EACH

ROD LOCATION.

5. GRAVEL SHOULD BE AT LEAST 3 INCHES DEEP.

6. GROUND GRID RESISTANCE FOR LARGE DISTRIBUTION

AND TRANSMISSION STATIONS SHOULD BE 1 OHM OR LESS.

SMALLER STATIONS SHOULD BE LESS THAN 5 OHMS.

REFERENCE :HIGH-CURRENT METHOD OF TESTING GROUND GRID

INTEGRITY, BY A. S. GILL,P.E. "NETA WORLD." MR.

GILL IS A SENIOR ENGINEER WITH THE NUCLEAR

REGULATORY COMMISSION.

VIRGINIA POWER SUBSTATION OPERATING GUIDELINES AND

WORK PROCEDURES, ELECTRIC OPERATIONS DEPARTMENT.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nfpa EseDocument3 pagesNfpa EseAlejandro ArroyaveNo ratings yet

- A Statistical Analysis of Strike Data From Real Installations Which Demonstrates Effective Protection of Structures Against LightningDocument6 pagesA Statistical Analysis of Strike Data From Real Installations Which Demonstrates Effective Protection of Structures Against LightningAlejandro ArroyaveNo ratings yet

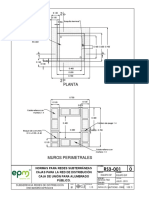

- RS3-001 - Normas para Redes Subterraneas Cajas para La Red de Distribucion y Caja de Union para Alumbrado PublicoDocument5 pagesRS3-001 - Normas para Redes Subterraneas Cajas para La Red de Distribucion y Caja de Union para Alumbrado PublicoAlejandro ArroyaveNo ratings yet

- Seleccion de La Proteccion para Una Bomba RciDocument3 pagesSeleccion de La Proteccion para Una Bomba RciAlejandro ArroyaveNo ratings yet

- Calculo de Alimentadores para MotoresDocument12 pagesCalculo de Alimentadores para MotoresAlejandro ArroyaveNo ratings yet

- Zonas de Servidumbre Ancho de Franja en Lineas de TransmisionDocument1 pageZonas de Servidumbre Ancho de Franja en Lineas de TransmisionAlejandro Arroyave100% (1)

- Regulador VS DPS SuprexorDocument2 pagesRegulador VS DPS SuprexorAlejandro ArroyaveNo ratings yet

- NEGRP Paper PDFDocument8 pagesNEGRP Paper PDFAlejandro ArroyaveNo ratings yet

- Foto RA8-001 Fusibles Trafos EpmDocument1 pageFoto RA8-001 Fusibles Trafos EpmAlejandro ArroyaveNo ratings yet

- Experimental Arrangements To Study Lightning Attachment Characteristics in Northern AustraliaDocument4 pagesExperimental Arrangements To Study Lightning Attachment Characteristics in Northern AustraliaAlejandro ArroyaveNo ratings yet

- Sustentación DPS Vs Estabilizador de VoltajeDocument2 pagesSustentación DPS Vs Estabilizador de VoltajeAlejandro ArroyaveNo ratings yet

- Moore Et Al 2003 PDFDocument10 pagesMoore Et Al 2003 PDFAlejandro ArroyaveNo ratings yet

- Reticertificamos S.A PDFDocument1 pageReticertificamos S.A PDFAlejandro ArroyaveNo ratings yet

- Iclp3 Paper PDFDocument5 pagesIclp3 Paper PDFAlejandro ArroyaveNo ratings yet

- LPS Positioning - PaperDocument6 pagesLPS Positioning - PaperAlejandro ArroyaveNo ratings yet

- Insulated downcond-DHENDocument6 pagesInsulated downcond-DHENAlejandro ArroyaveNo ratings yet

- LP EFM FinalDocument38 pagesLP EFM FinalAlejandro ArroyaveNo ratings yet

- A Review of The Lightning Attachment Process and Requirements To Achieve Improved ModellingDocument5 pagesA Review of The Lightning Attachment Process and Requirements To Achieve Improved ModellingAlejandro ArroyaveNo ratings yet

- IEEE837 Paper PDFDocument7 pagesIEEE837 Paper PDFAlejandro ArroyaveNo ratings yet

- Laboratory Studies of Corona Current Emissions From Blunt, Sharp and Multipointed Air TerminalsDocument7 pagesLaboratory Studies of Corona Current Emissions From Blunt, Sharp and Multipointed Air TerminalsAlejandro ArroyaveNo ratings yet

- EQuebecDocument6 pagesEQuebecAlejandro ArroyaveNo ratings yet

- New Techniques For Designing SPD'S Exhibiting High Mcov While Maintaining Low Residual VoltageDocument5 pagesNew Techniques For Designing SPD'S Exhibiting High Mcov While Maintaining Low Residual VoltageAlejandro ArroyaveNo ratings yet

- Safe Coordination Between Power and Communication Surge ProtectionDocument7 pagesSafe Coordination Between Power and Communication Surge ProtectionAlejandro ArroyaveNo ratings yet

- Assessment of Protection System Positioning and Models Using Observations of Lightning Strikes To StructuresDocument23 pagesAssessment of Protection System Positioning and Models Using Observations of Lightning Strikes To StructuresAlejandro ArroyaveNo ratings yet

- E5ADocument6 pagesE5AAlejandro ArroyaveNo ratings yet