Professional Documents

Culture Documents

Leeds Metro Univ-Portlad Gate

Leeds Metro Univ-Portlad Gate

Uploaded by

stefanCopyright:

Available Formats

You might also like

- Arup CampusDocument3 pagesArup Campusnono04050% (1)

- Diagrid, Prada Boutique AoyamaDocument4 pagesDiagrid, Prada Boutique AoyamastefanNo ratings yet

- Graduate Architecture PortfolioDocument40 pagesGraduate Architecture Portfoliochad_bunnell0% (2)

- 2524 8 Chifley Sustainable Structural and Fire EngineeringDocument8 pages2524 8 Chifley Sustainable Structural and Fire EngineeringJulio MzpNo ratings yet

- Roof DetailsDocument37 pagesRoof DetailsAhmedBIowar0% (1)

- Parametric Study of Double Layer Steel Dome With Reference To Span To Height RatioDocument9 pagesParametric Study of Double Layer Steel Dome With Reference To Span To Height RatioIjsrnet EditorialNo ratings yet

- Fts 3Document6 pagesFts 33PD20EE002 ABID SHAFINo ratings yet

- Swot Analysis: Polytechnic University of The Philippines Lopez, Quezon Bs Architecture ProgramDocument8 pagesSwot Analysis: Polytechnic University of The Philippines Lopez, Quezon Bs Architecture ProgramMa. Gliceria May A. MoldeNo ratings yet

- "Hybrid" Light Steel Panel and Modular Systems PDFDocument11 pages"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozNo ratings yet

- The Rational Optimization and Evolution of The Structural Diagonal Aesthetic in Supertall TowersDocument15 pagesThe Rational Optimization and Evolution of The Structural Diagonal Aesthetic in Supertall TowersAdeniran OmobolanleNo ratings yet

- The Emergence of The Diagrid Structures PDFDocument12 pagesThe Emergence of The Diagrid Structures PDFistructeNo ratings yet

- Engineering Structures: Fabio Rizzo, Piero D'Asdia, Massimiliano Lazzari, Lorenzo ProcinoDocument17 pagesEngineering Structures: Fabio Rizzo, Piero D'Asdia, Massimiliano Lazzari, Lorenzo ProcinoMarco CamposNo ratings yet

- Cairo Expo City - A Free-Form Spatial RoofDocument7 pagesCairo Expo City - A Free-Form Spatial RoofShane Lu100% (1)

- 1 s2.0 S0022460X12005135 MainDocument16 pages1 s2.0 S0022460X12005135 MainLexin LINo ratings yet

- Wa0000.Document3 pagesWa0000.Abdullah NadeemNo ratings yet

- Freddie Jeffries - Fang You - Hajie Shan - Linghao Chen - Mischa Patel - Hywel BeasdaleDocument39 pagesFreddie Jeffries - Fang You - Hajie Shan - Linghao Chen - Mischa Patel - Hywel BeasdaleMarvin ItolondoNo ratings yet

- IABSE SEI 1 2007 Stress Ribbon Roof StructuresDocument6 pagesIABSE SEI 1 2007 Stress Ribbon Roof StructuresAarti ChandrasekharNo ratings yet

- Site - Structure - Architecture - Projects That Create ChangeDocument12 pagesSite - Structure - Architecture - Projects That Create ChangeLAPANZEBRA ferinaNo ratings yet

- Engineering Structures: SciencedirectDocument17 pagesEngineering Structures: SciencedirectAndy GarciaNo ratings yet

- Structural Assessment of Masonry Arch Bridges by CombinationDocument18 pagesStructural Assessment of Masonry Arch Bridges by CombinationAreaya mahetemNo ratings yet

- IAP House CompetitionDocument5 pagesIAP House CompetitionSyedAhsanKamalNo ratings yet

- Arc3983 - Final Report Format-1Document10 pagesArc3983 - Final Report Format-1YASER ALADIBNo ratings yet

- Tree-Structure Canopy A Case Study in deDocument18 pagesTree-Structure Canopy A Case Study in deDrGanesh KameNo ratings yet

- The Savill Garden Gridshell Design and ConstructionDocument7 pagesThe Savill Garden Gridshell Design and ConstructionAlex RastyNo ratings yet

- Structural Steel Design Awards 2014Document20 pagesStructural Steel Design Awards 2014bachNo ratings yet

- Lopezlopez 2014 Iass Prototype Ultra Thin Concrete Vaulted Floor System - 1410359100Document8 pagesLopezlopez 2014 Iass Prototype Ultra Thin Concrete Vaulted Floor System - 1410359100mina saadatNo ratings yet

- Seismic Performance of Flat Slab With Drop and Conventional Structure IJERTV5IS100240Document13 pagesSeismic Performance of Flat Slab With Drop and Conventional Structure IJERTV5IS100240Vishnu Vardhan MekalaNo ratings yet

- EARW Assignment 1Document2 pagesEARW Assignment 1Abdul AzeemNo ratings yet

- Lucky No 8 Chifley PDFDocument6 pagesLucky No 8 Chifley PDFErnest OdhiamboNo ratings yet

- Urban Design GlossaryDocument8 pagesUrban Design GlossaryashimaNo ratings yet

- LASSANCE - The Sensitive TowerDocument8 pagesLASSANCE - The Sensitive TowerPatricia TakamatsuNo ratings yet

- 11 12 2010 MuseumConditionSummaryDocument4 pages11 12 2010 MuseumConditionSummaryECI HyerNo ratings yet

- Archi Case Study On Eden Project UK Design Sol PDFDocument12 pagesArchi Case Study On Eden Project UK Design Sol PDFQalbun TriwaniNo ratings yet

- Engineering Structures: Xinzheng Lu, Linlin Xie, Cheng Yu, Xiao LuDocument11 pagesEngineering Structures: Xinzheng Lu, Linlin Xie, Cheng Yu, Xiao Luم.احمدخليلNo ratings yet

- Sustainability Design For Raft & Piled-Raft Foundations - Green Initiative!Document8 pagesSustainability Design For Raft & Piled-Raft Foundations - Green Initiative!정주호No ratings yet

- Laboratories For The 21st Century: Case Studies: N R e L, S T F, G, CDocument10 pagesLaboratories For The 21st Century: Case Studies: N R e L, S T F, G, Cmukesh.dmanNo ratings yet

- Thesis On Bridge EngineeringDocument8 pagesThesis On Bridge Engineeringsusancoxarlington100% (2)

- 1.Ph.D. Candidate, 2.professor, Department of Civil Engineering, National Cheng Kung University, Tainan, TaiwanDocument6 pages1.Ph.D. Candidate, 2.professor, Department of Civil Engineering, National Cheng Kung University, Tainan, TaiwanandysupaNo ratings yet

- Advance Building Construction II Questionnaire Final Exam ANSWEREDDocument12 pagesAdvance Building Construction II Questionnaire Final Exam ANSWERED123No ratings yet

- DD Draft1 AbhsihekDocument30 pagesDD Draft1 AbhsihekRUTWIK JOSHINo ratings yet

- IRJET Design and Analysis of A MonolithiDocument5 pagesIRJET Design and Analysis of A MonolithiISLAVATH SANDHYANo ratings yet

- Literature Review On Flat SlabDocument7 pagesLiterature Review On Flat Slabc5haeg0n100% (1)

- Structure Oct20 SergDocument21 pagesStructure Oct20 SergmarvinNo ratings yet

- An Integral Approach To Structure and ArchitectureDocument10 pagesAn Integral Approach To Structure and Architecturehda_paris100% (1)

- Case Study5 RedhillDocument4 pagesCase Study5 RedhillreshmiNo ratings yet

- A Matrix-Based Method For The Structural Analysis of Diagrid SystemsDocument13 pagesA Matrix-Based Method For The Structural Analysis of Diagrid SystemsIda MøllerNo ratings yet

- National Convention CentreDocument1 pageNational Convention CentreMahmood RashwanNo ratings yet

- DD Draft1 Abhsihek-CompressedDocument34 pagesDD Draft1 Abhsihek-CompressedRUTWIK JOSHINo ratings yet

- Integrated Design and Construction of Tall Buildings (Moon 2010)Document8 pagesIntegrated Design and Construction of Tall Buildings (Moon 2010)Jose Antoni LasdNo ratings yet

- Analysis of A Four-Story Single-Family Building in The Pasto City According To The Stipulated Heights by The POTDocument15 pagesAnalysis of A Four-Story Single-Family Building in The Pasto City According To The Stipulated Heights by The POTJhon Freddy Perez GuerreroNo ratings yet

- Tal 477Document11 pagesTal 477Peter UkwuejiNo ratings yet

- Large Span Structures - Arjun and JahanDocument51 pagesLarge Span Structures - Arjun and JahanJacob K Thomas100% (1)

- Structural Steel Sets The Framework For Massive Airport RedevelopmentDocument4 pagesStructural Steel Sets The Framework For Massive Airport Redevelopmentclam2014No ratings yet

- Ferry TerminalDocument133 pagesFerry TerminalshishirkrNo ratings yet

- Portfolio - Shravan VaidyanathDocument6 pagesPortfolio - Shravan VaidyanathCatrina JordanNo ratings yet

- ANWER - REPORT - IV - YEAR - PG - No 1 To 50 26.11.2023 - 11Document49 pagesANWER - REPORT - IV - YEAR - PG - No 1 To 50 26.11.2023 - 113001 ANWER RIHAAN HNo ratings yet

- Cost AnalysisDocument13 pagesCost AnalysisReaditReaditNo ratings yet

- Technical Challenges of Large Movable Scaffolding SystemsDocument6 pagesTechnical Challenges of Large Movable Scaffolding SystemsArmus MarsNo ratings yet

- Exploring The Application Domain of Adaptive StructuresDocument22 pagesExploring The Application Domain of Adaptive StructuresAhmed SuwaedNo ratings yet

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Centru cultural-ONASSIS HOUSDocument4 pagesCentru cultural-ONASSIS HOUSstefanNo ratings yet

- Sala Concerte DanemarcaDocument7 pagesSala Concerte DanemarcastefanNo ratings yet

- Opera Outstanding Structure: House, CopenhagenDocument3 pagesOpera Outstanding Structure: House, CopenhagenstefanNo ratings yet

- Diagrid HEARST TOWER PDFDocument4 pagesDiagrid HEARST TOWER PDFstefanNo ratings yet

- FCI Godown SpecificationsDocument2 pagesFCI Godown SpecificationsKunal SharmaNo ratings yet

- Task Force Bangon Marawi UpdatesDocument37 pagesTask Force Bangon Marawi UpdatesKaj Hojilla EstradaNo ratings yet

- Advanced Building Construction: Tubular Truss (Scale 1:20) ElevationDocument1 pageAdvanced Building Construction: Tubular Truss (Scale 1:20) ElevationPankaj DhakedNo ratings yet

- Ancient Roman ArchitectureDocument79 pagesAncient Roman ArchitectureSuleimanNo ratings yet

- Design 7 Midterm Esquisse Part 1Document5 pagesDesign 7 Midterm Esquisse Part 1Eva Margarita H BuenaobraNo ratings yet

- Concrete FormsDocument11 pagesConcrete FormsmurdicksNo ratings yet

- Measures To Prevent Damages in Black Cotton Soil AreasDocument6 pagesMeasures To Prevent Damages in Black Cotton Soil AreasSabyasachi Naik (Zico)100% (1)

- Hanging Gardens of BabylonDocument6 pagesHanging Gardens of BabylonMohammed Al-azem100% (1)

- Written by Razib Shahriar RubenceDocument4 pagesWritten by Razib Shahriar RubenceAnoopNo ratings yet

- Pipe SupportsDocument87 pagesPipe SupportsVeeramanikandanNo ratings yet

- Flexural Design of Singly Section (CIVE209) (CIVE304)Document6 pagesFlexural Design of Singly Section (CIVE209) (CIVE304)Mohammed FattalNo ratings yet

- AZ 300T01A ENU TrainerPrepGuide PDFDocument14 pagesAZ 300T01A ENU TrainerPrepGuide PDFNikul GoyalNo ratings yet

- SWPMDocument560 pagesSWPMFernando Angel Ortiz Rodriguez67% (3)

- ObserveIT Release Notes v5 - 7 - 2Document2 pagesObserveIT Release Notes v5 - 7 - 2gabytgvNo ratings yet

- 3438 19045 1 PBDocument6 pages3438 19045 1 PBFrod 22No ratings yet

- Astm D1785 (2012) PDFDocument11 pagesAstm D1785 (2012) PDFchairul anwarNo ratings yet

- High Rise Building DesignDocument4 pagesHigh Rise Building DesignGel SanchezNo ratings yet

- Microcode Update GuidanceDocument14 pagesMicrocode Update Guidanceproxymo1No ratings yet

- Transport SystemDocument12 pagesTransport SystemLaasyaSweetNo ratings yet

- CGCEL LED PRICELIST 2019-20 Wef 1st Nov 2019 PDFDocument72 pagesCGCEL LED PRICELIST 2019-20 Wef 1st Nov 2019 PDFRavish RamNo ratings yet

- Reviewer !Document18 pagesReviewer !kristine jewelleNo ratings yet

- Pensabene Villa CasaleDocument9 pagesPensabene Villa CasaleJosé Ignacio Villanueva LanzaNo ratings yet

- Stone Dust & RubberDocument64 pagesStone Dust & RubberSyed Mohd Mehdi100% (1)

- Synology Drive WPDocument18 pagesSynology Drive WPMark Brown100% (1)

- Installing Windows Server 2008 DHCP Server: Dynamic Host Configuration Protocol (DHCP)Document13 pagesInstalling Windows Server 2008 DHCP Server: Dynamic Host Configuration Protocol (DHCP)sambradshaw945No ratings yet

- Denah Rumah MinimalisDocument2 pagesDenah Rumah MinimalisIrham SyarifNo ratings yet

- Soil Nailing in GermanyDocument56 pagesSoil Nailing in GermanyJose Martinez100% (1)

- Msbjournal 28 FebruaryDocument33 pagesMsbjournal 28 Februaryalex mvp100% (2)

- Koha Xubuntu: /etc/apt/sources - List.d/koha - List Apt Get UpdateDocument4 pagesKoha Xubuntu: /etc/apt/sources - List.d/koha - List Apt Get Updatepksunil_77No ratings yet

- PHP and MySQL Project Report On Online Blogging System DownloadDocument3 pagesPHP and MySQL Project Report On Online Blogging System Downloadbalwant100% (1)

Leeds Metro Univ-Portlad Gate

Leeds Metro Univ-Portlad Gate

Uploaded by

stefanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leeds Metro Univ-Portlad Gate

Leeds Metro Univ-Portlad Gate

Uploaded by

stefanCopyright:

Available Formats

Leeds Metropolitan University Portland Gate-Engineering

the Rosebowl, UK

Derek Roberts, MEng., CEng., MIStructE, MICE, Senior Struct. Eng.. Ove Arup and Partners Ltd. Sheffield, UK

and Neil Hooton, MEng., CEng., MIStructE, Associate, Ove Arup and Partners Ltd, Leeds, UK.

Contact: Derek. Roberts@aruP.com

DOI: 10.27 49/1 0168661 1X1 2910257 102118

Abstract

The Portland Gate development is a

new facility housing the School of Busi-

ness and Law at Leeds Metropolitan

University. A key feature of the build-

ing is the landmark steel-framed "Rose-

bowl". This freestanding structure lies

partially within the main atrium space

and houses seven lecture theatres.

The 25 m tall Rosebowl is supported

on bespoke double storey Y-columns,

each weighing between 3 and 5 t.These

triangular tapered profile sections pro-

vide horizontal stability and vertical

support to the diagrid structure above.

This paper follows this unique struc-

ture through the design, fabrication

and erection process. This includes a

review of the global buckling assess-

ment of the Rosebowl and the detailing

and fabrication of the architecturally Fig. 1:Photograph of Rosebowl as viewedfrom the ])u.ii, tottrr|ttrd (Photocredit: Giles

Rocholl)

exposed sway elements.

Keywords: conceptual design; sway The University had high aspira- the ba:e uhich supports the diagrid

frame; diagrid; buckling analysis;

tions when setting the sustainability struciure above.

fabrication.

agenda on Leeds Met Portland Gate. A series ol walkways cross a Public

Introduction The team met these goals through a atriunr. u hich allows daylight to penetrate

number of strategic level design deci- to the centre of the building, and links

Leeds Metropolitan University (the sions-including the incorporation of the lecture theatres to the four-storey

University/Leeds Met) has procured a a combined heat and power system, perinrci, r accommodation housing

new faculty building for the School of rainwater harvesting and recycling of

oHicc: .inJ tcaching spaces. The treat-

Business and Law through a two stage demolition waste. The development ment of the elevation and the scale of the

RIBA stage D tendered design and as a whole focused on the appropri-

neu school respond to the architectural

build process. (The Royal Institute of ate use of sustainable materials and rhr thnr oi the Civic Hall, opposite.

British Architects Stage D is described achieved 25ok recycled content overall.

ss Scheme Design/Detailed Propos- In addition, the development achieved The eir-r'ations to the main faculty

als and is approximately equivalent to its target BREEAM Excellent rating buildins ate clad in stone, transparent

(Environmental Assessment Method qlass ;ind pressed metal spandrel pan-

Detailed Design (DD) proposals under

American designations ). for buildings around the world). els.The central Rosebowl is clad in 795

semi-translucent triangulated cladding

The Portland Gate development pro- The building takes its name from the elements uith fritting in front of the

vides l2 0U0 m2 of floor area compris- dramatic form of the tapering central niirlt,rcd back. Thi: lreatment soft-

ing offices, general teaching, lecture pod, the Rosebowl (Fig. l), at the heart

eried the overall surface of the geomet-

theatres. restaurants and break-out of the complex. The Rosebowl is recto- ric lacetted oanel setout which curved

spaces. In addition, car parking is pro- circular on plan (a flattened ellipse in line u'ith ihe form of the structure.

vided within the three-level basement. with semicircular ends) and stands

The Portland Gate project responds 24 m wide by 28 m long and 23.5 m

to the University's aspirations that the tall. This structure houses the main 150 Concept Design

new development should help inte- seat lecture theatre as well as trio 1J0

grate the University within the wider seat and four 60 seat lecture theatres. The Rosebowl pod was conceived as

context of its location, and further link A perimeter ring of 7.5 m tall Y-shaped the central feature of the development.

the campus with the Leeds city centre. tree columns form a swav frame at The main faculty building plan of the

26 Technical Report Structural Engineering International U20Il

Portland Gate development mirrors Internally, two spine beams allowed a Restraint is applied at varying levels

that of the adjacent Civic Hall horse- reduced structural depth to be formed around the perimeter of the Rosebowl.

shoe building, and creates an urban between them in the central 2,4 m of the Typically, this occurs either at mid-height

courtyard. The majority of this space is Rosebowl.This formed the main mechan- or full height of the Y-columns, but in a

for public access, but the introduction ical horizontal sewice distribution with few cases occurs at level 3. This is 3,9 m

of the covered atrium area within the branches being taken off through perfo- above the top of the columns, and is the

Portland Gate development defines a rations in the 10 t spine beams. first level of continuous floor diaphragm.

semi-public circulation and congrega-

The stiffness of the restraints is there-

tion area within the school building. Detailed Analysis/Design fore not infinite and is difficult to quatify.

The Rosebowl is situated on the A complete global buckling analysis of

interface between these two spaces, Interaction with the Bqsement

the structure was therefore undertaken.

Transfer Structure

creating a public face to the develop-

ment whilst housing lecture theatres The Rosebowl is supported over the

A buckling model was produced in

used for a range of public and private three-storey basement car park. The

a Finite Element software and this

events. The Rosebowl is susoended modelled the whole diagraid struc-

rectilinear column grid within the

above the ground level to prouide an ture and sway stability legs. The focus

car park and the recto-circular plan

open-plan information/IT hub within arrangement of columns for the Rose-

of the analysis was on the support-

the atrium area. As such, the Rosebowl

ing sway structure and accompanying

bowl are reconciled through a system

and atrium spaces are positioned cen-

diagrid.

of reinforced concrete transfer beams.

trally and provide the majority of the

These elements are relatively shallow

The in-house-developed analysis

shared facilities. whilst the individual method modified the geometric stiff-

at 700 to 800 mm depth. The 15 m tall

faculty teaching and research accom- ness of the structure based on the axial

diagrid structure above the Y-columns

modation wraps around this area. loads in a given ultimate limit state, and

is therefore an order of magnitude then carried out a modal analysis on

The diagrid concept was chosen so stiffer and redistributes the loadings

that the structural form followed the this revised geometrical matrix. Each

from the basement capping slab and

complex cladding outline. The diagrid buckled mode shape was assessed to

the Rosebowl structure towards the

increased the available internal area derive a buckled effective length of

stiffer.points of support.

by removing any need for internal the system and a probable magnitude

bracing and minimised the cost of the Ths amount of redistribution that of the Euler imperfection. The results

expensive bespoke glazing by provid- can occur is dependent on the con- were then amolified to account for

ing a constant connection interface struction and loading sequence. A these effects and combined with the

between the primary structure and the reasonable proportion of the loading p- A analysis results to arrive at the

cladding bracketry, without the need is applied prior to the diagrid system local forces within the members.

for a secondary support system. gaining enough stiffness to provide

The comparative result of this analysis

truss action. and therefore these forces

The diagrid structure was originally concluded that the effective length of

are locked into the reinforced con-

designed to be supported by V-shaped the sway columns was approximately

crete transfer structure as construction

columns, providing a braced ring to 2,4 times the trunk height and the sys-

progresses.

ground around the perimeter of the tem had a minimum l" critical of 4,9.

structure. Architecturally, there were To account for this, the support con- When compared to the Annex E assess-

concerns that this visually interrupted ditions were modelled both at upper ment, the effect of assessing the stiff-

the free-flowing open-plan space and bound, as fixed pins, and at lower ness of the restraint provided a modest

gave an aesthetic reminiscent of a bound where the transfer was mod- increase in section forces, confirming

cooling tower. The design was devel- elled explicitly with appropriately the architect's desired section sizes.

oped with input from the City Archi- reduced cracked section stiffnesses.

I{owever, as part of the value engineer-

tect to arrive at the final form. The This provided an envelope of analysis

ing proposals put forward, the size of

V-detail was lifted to the first level, results for which the Rosebowl steel

the bespoke triangular sections were

and vertical elements introduced structure and concrete transfer were

marginally increased to reduce section

below to free up ground level space, designed.

wall thickness, weld size requirements

creating the final tree profile of the and tonnage. The benefit was partially

Globul Buckling Analysis

Y-shaped columns. derived from the step changes in the

The centre line of the Y-columns is The Rosebowl diagrid structure is lat- allowable yield stress of steel associ-

splayed to provide the columns with erally restrained by the sway legs in ated with different plate thicknesses in

a flat back face'. a decision made pri- the north to south direction. Initial siz- B55950, but more importantly with the

marily to simplify fabrication and ing of these sway elements was deter- additional geometrical stiffness resis-

transportation. This also prescribed a mined using the "relative stiffness tance that the size change provided

smooth profile to the virtual internal effective length" assessment contained against buckling.

space defined by the columns. within Annex E of BS5950r-deliver-

ing an effective length of 2,2 times the Y-Column Weld and Node Design

The Y-columns and diagrid above are

length of the trunk of the Y-columns.

set out to two radial grids with a hori- The main analysis models define

zontal node spacing of approximately Annex E makes the assumption that the the Y-columns as a stepped profile

4 m, varying to suit the taper of the stiffness of the lateral restraint of the of one-dimensional (1D) finite ele-

Rosebowl profile. By maintaining the system is effectively infinite. In reality, ments. The sections were offset to

angular setout, the number of different each individual Y-column is restrained account for the increasing eccentricity

node types was minimised. bv the frames in the other direction. towards the node point. generated by

Structural Engineering International U20ll Technical Report 27

the requirement to keep the back face to prove the process. Prepped plates required accurate positioning of these

flush. The force data sets were then were produced and aligned in a jig 3 to 5 t elements at the far reach of the

compared directly with the local ele- with a track-mounted submerged arc allocated tower cranes.

ment capacities in the regular manner welder positioned over Lhe loneitudi-

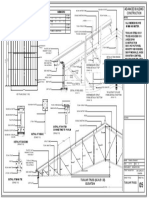

and plate thicknesses were optimised. nal weld lines.This allowed rhe sisniii- The level 1 and 2 floor systems make

cant partial penetration butt welds for up the support for the main split level

To define the weld capacity require- lecture theatre and provide lateral

ments between the individual plates and plates up to 55 mm to be carried out in

either a single or a double pass. restraint to separate halves of the Rose-

the central node location. a comolete Y- bowl floor plate (see Flg. 3).This makes

column was generaled as a two-dimen- The welds were ground flush, and the it difficult to stabilise the Y-columns

sional (2D) element shell. Stiffenine steel was passed through the blasting in the temporary stage until the struc-

plates were designed in the node posi process for a second time, makins the ture reaches level 3 and all Y-columns

tion by an iterative process between weld locations indistinguishable Trom are tied into a solid floor olate. In

the fabricator and the consultant engi- the parent material apart from some ljne with the engineers' duties under

neer. This deliverecl a practical plate heat-induced discolouration. the CDM2 Regulations, a detailed

affangement and direct loadpath for

Each branch and trunk element of the constructron sequence was drawn up

this intersection, where three directional

tree columns was then positioned in a between the consultant and the con-

moments and shears had to be resolved.

further rotatable jig so fhar all welding tractor. The four central non-sway

The process included the mock-up of a columns were braced in all directions

full node to test the fabricarion process could be carried out downhand (i.e.

below the operator). The internal piat- during the temporary condition to pro-

and aesthetic qualities of the section. vide a solid stable core. The surround-

ing arrangement derived by the con-

Weld sizes were approximated by hand sultant was maintained and develooed ing structure was then tied back to this

calculation for each of the Y-columns. through lhe test node, enabling the core until sufficient permanent work

The final 2D element shell includins fabricator to modify the plate t"qu.n.- traming was in place for the structure

stiifening plates was then inserted into ing to ease fabrication and improve the to be self-stable. The east-west bracing

the buckling analysis model and used final aesthetic. was maintained as part of the perma-

to confirm these weld sizes at each nent solution at one level as a means of

plate interface (see Fig 2). maintaining lateral restraint.

Erection

Fabrication The Portland Gate development was

primaiily erected using two tower Cladding Interfaces

The Y-columns were fabricated in Ire- cranes. Crawler cranes were utilised to The outrvard taper to the Rosebowl

land, with a test node beins carried out install the perimeter Y-columns which and its complex geometry required

(a) (b) (c)

i

I

@)

Fig' 2: (a) Buckling analysis model o,f Rosebowt; (b) primary buckled modeshape of Rosebowl

structure; (c) close up of 2D plate y-

column node in model; (d) fabricator's 3D visualisation of node plate aruangement; (e) node

mock-up in fabrication

28 Technical Report Structural Engineering International 1l20ll

with its landmark feature cladding and

Y-shaped tree column support.

The design, fabrication and erection of

the structure provided many engineer-

ing challenges, both in technical terms

and in the detailed coordination with

the complex cladding interfaces and

mechanical distribution.

Through rationalisation of detailing

and use of advanced analysis tech-

niques, the required complex architec-

Fig. 3: Rosebowl erection photographs showing the Y-columns and stepped diaphragm tural form was achieved with a high

olanes quality of finish on a relatively modest

steelwork was derived to move the budget.

atrium glazing movement interface The building provides a flexible and

away from the facetted face of the functional internal space which the

Rosebowl. Relative movements were end client, Leeds Metropolitan Uni-

then taken up by a combination of versity, has adopted as a centrepiece to

conventional joints and articulated the city centre campus.

rotating piers at the roof level.

The Rosebowl Y-column setout was Acknowledgements

aligned with the atrium vertical glaztng The authors are pleased to acknowledge the

interface to allow the glazing to fly past efforts of the whole team in delivering the

the mid-bay alignment of the structure, integrated multidisciplinary design and con-

avoiding a difficult and expensive clad- struction of the Rosebowl. In particular we

Fig. 4:Y-column to diagrid connection

ding interface with the triangular steel would like to thank Arup Fellow Pat Dallard

includin g claddin g b r ac ketry)

sections (Figs. 4 and 5). and also the fabricator. Fisher, for their input

into the design process.

careful consideration and control of

A detailed study and report into the

progressive movement of the structure References

the movements and tolerances of the

structure, to enable both its own erec-

during construction, combined with

careful detailing and precise fabrication, [1] British National Standard 855950-1:2000

tion and the attachment and detailing Structural use of Steelwork in Building Part l:

allowed the structure and cladding to

of the cladding. Code of Practice for Design-Rolled andWelded

be installed without additional require- Sections-Annex E-Effective Lengths of

The Rosebowl is a standalone struc- ments for packing or remedial work. Compression Members in Continuous Sttuctures'

ture positioned partially within the British Standards Institute: London, UK.

atrium space, and the relative move- Conclusion [2] UK Statutory Instruments 2007 No. 320.

ments of the Rosebowl and adjacent Health and Safety: The Construction (Design

faculty building required to be articu- The Rosebowl lecture theatre Pod and Management) Regulations 2007 Crown

lated in the cladding system. A sup- makes a strong architectural contribu- Copyright.

porting frame of hot-rolled secondary tion to the fabric of Leeds city centre

SEI Data Block

Owner:

Leeds Metropolitan UniversitY

Structural engineer:

Ove Arup and Partners, Yorkshire

Services engineer:

Ove Arup and Partners, Yorkshire

Architect:

Sheppard Robson, Manchester

Main contractor:

BAM Northern (UK)-Leeds

Steel fabricator:

Fisher Engineering-Northern Ireland

Cladding contractor:

Seele GmbH & Co. KG

Approximate const ruct ion

value (EUR million): 31

Fig.5: Multidisciplinary engineering Building Information Model (BIM) rendering Service date: May 2009

showing the structure behind the triangulated cladding

Structural Engineering International U2011 Technical Report 29

You might also like

- Arup CampusDocument3 pagesArup Campusnono04050% (1)

- Diagrid, Prada Boutique AoyamaDocument4 pagesDiagrid, Prada Boutique AoyamastefanNo ratings yet

- Graduate Architecture PortfolioDocument40 pagesGraduate Architecture Portfoliochad_bunnell0% (2)

- 2524 8 Chifley Sustainable Structural and Fire EngineeringDocument8 pages2524 8 Chifley Sustainable Structural and Fire EngineeringJulio MzpNo ratings yet

- Roof DetailsDocument37 pagesRoof DetailsAhmedBIowar0% (1)

- Parametric Study of Double Layer Steel Dome With Reference To Span To Height RatioDocument9 pagesParametric Study of Double Layer Steel Dome With Reference To Span To Height RatioIjsrnet EditorialNo ratings yet

- Fts 3Document6 pagesFts 33PD20EE002 ABID SHAFINo ratings yet

- Swot Analysis: Polytechnic University of The Philippines Lopez, Quezon Bs Architecture ProgramDocument8 pagesSwot Analysis: Polytechnic University of The Philippines Lopez, Quezon Bs Architecture ProgramMa. Gliceria May A. MoldeNo ratings yet

- "Hybrid" Light Steel Panel and Modular Systems PDFDocument11 pages"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozNo ratings yet

- The Rational Optimization and Evolution of The Structural Diagonal Aesthetic in Supertall TowersDocument15 pagesThe Rational Optimization and Evolution of The Structural Diagonal Aesthetic in Supertall TowersAdeniran OmobolanleNo ratings yet

- The Emergence of The Diagrid Structures PDFDocument12 pagesThe Emergence of The Diagrid Structures PDFistructeNo ratings yet

- Engineering Structures: Fabio Rizzo, Piero D'Asdia, Massimiliano Lazzari, Lorenzo ProcinoDocument17 pagesEngineering Structures: Fabio Rizzo, Piero D'Asdia, Massimiliano Lazzari, Lorenzo ProcinoMarco CamposNo ratings yet

- Cairo Expo City - A Free-Form Spatial RoofDocument7 pagesCairo Expo City - A Free-Form Spatial RoofShane Lu100% (1)

- 1 s2.0 S0022460X12005135 MainDocument16 pages1 s2.0 S0022460X12005135 MainLexin LINo ratings yet

- Wa0000.Document3 pagesWa0000.Abdullah NadeemNo ratings yet

- Freddie Jeffries - Fang You - Hajie Shan - Linghao Chen - Mischa Patel - Hywel BeasdaleDocument39 pagesFreddie Jeffries - Fang You - Hajie Shan - Linghao Chen - Mischa Patel - Hywel BeasdaleMarvin ItolondoNo ratings yet

- IABSE SEI 1 2007 Stress Ribbon Roof StructuresDocument6 pagesIABSE SEI 1 2007 Stress Ribbon Roof StructuresAarti ChandrasekharNo ratings yet

- Site - Structure - Architecture - Projects That Create ChangeDocument12 pagesSite - Structure - Architecture - Projects That Create ChangeLAPANZEBRA ferinaNo ratings yet

- Engineering Structures: SciencedirectDocument17 pagesEngineering Structures: SciencedirectAndy GarciaNo ratings yet

- Structural Assessment of Masonry Arch Bridges by CombinationDocument18 pagesStructural Assessment of Masonry Arch Bridges by CombinationAreaya mahetemNo ratings yet

- IAP House CompetitionDocument5 pagesIAP House CompetitionSyedAhsanKamalNo ratings yet

- Arc3983 - Final Report Format-1Document10 pagesArc3983 - Final Report Format-1YASER ALADIBNo ratings yet

- Tree-Structure Canopy A Case Study in deDocument18 pagesTree-Structure Canopy A Case Study in deDrGanesh KameNo ratings yet

- The Savill Garden Gridshell Design and ConstructionDocument7 pagesThe Savill Garden Gridshell Design and ConstructionAlex RastyNo ratings yet

- Structural Steel Design Awards 2014Document20 pagesStructural Steel Design Awards 2014bachNo ratings yet

- Lopezlopez 2014 Iass Prototype Ultra Thin Concrete Vaulted Floor System - 1410359100Document8 pagesLopezlopez 2014 Iass Prototype Ultra Thin Concrete Vaulted Floor System - 1410359100mina saadatNo ratings yet

- Seismic Performance of Flat Slab With Drop and Conventional Structure IJERTV5IS100240Document13 pagesSeismic Performance of Flat Slab With Drop and Conventional Structure IJERTV5IS100240Vishnu Vardhan MekalaNo ratings yet

- EARW Assignment 1Document2 pagesEARW Assignment 1Abdul AzeemNo ratings yet

- Lucky No 8 Chifley PDFDocument6 pagesLucky No 8 Chifley PDFErnest OdhiamboNo ratings yet

- Urban Design GlossaryDocument8 pagesUrban Design GlossaryashimaNo ratings yet

- LASSANCE - The Sensitive TowerDocument8 pagesLASSANCE - The Sensitive TowerPatricia TakamatsuNo ratings yet

- 11 12 2010 MuseumConditionSummaryDocument4 pages11 12 2010 MuseumConditionSummaryECI HyerNo ratings yet

- Archi Case Study On Eden Project UK Design Sol PDFDocument12 pagesArchi Case Study On Eden Project UK Design Sol PDFQalbun TriwaniNo ratings yet

- Engineering Structures: Xinzheng Lu, Linlin Xie, Cheng Yu, Xiao LuDocument11 pagesEngineering Structures: Xinzheng Lu, Linlin Xie, Cheng Yu, Xiao Luم.احمدخليلNo ratings yet

- Sustainability Design For Raft & Piled-Raft Foundations - Green Initiative!Document8 pagesSustainability Design For Raft & Piled-Raft Foundations - Green Initiative!정주호No ratings yet

- Laboratories For The 21st Century: Case Studies: N R e L, S T F, G, CDocument10 pagesLaboratories For The 21st Century: Case Studies: N R e L, S T F, G, Cmukesh.dmanNo ratings yet

- Thesis On Bridge EngineeringDocument8 pagesThesis On Bridge Engineeringsusancoxarlington100% (2)

- 1.Ph.D. Candidate, 2.professor, Department of Civil Engineering, National Cheng Kung University, Tainan, TaiwanDocument6 pages1.Ph.D. Candidate, 2.professor, Department of Civil Engineering, National Cheng Kung University, Tainan, TaiwanandysupaNo ratings yet

- Advance Building Construction II Questionnaire Final Exam ANSWEREDDocument12 pagesAdvance Building Construction II Questionnaire Final Exam ANSWERED123No ratings yet

- DD Draft1 AbhsihekDocument30 pagesDD Draft1 AbhsihekRUTWIK JOSHINo ratings yet

- IRJET Design and Analysis of A MonolithiDocument5 pagesIRJET Design and Analysis of A MonolithiISLAVATH SANDHYANo ratings yet

- Literature Review On Flat SlabDocument7 pagesLiterature Review On Flat Slabc5haeg0n100% (1)

- Structure Oct20 SergDocument21 pagesStructure Oct20 SergmarvinNo ratings yet

- An Integral Approach To Structure and ArchitectureDocument10 pagesAn Integral Approach To Structure and Architecturehda_paris100% (1)

- Case Study5 RedhillDocument4 pagesCase Study5 RedhillreshmiNo ratings yet

- A Matrix-Based Method For The Structural Analysis of Diagrid SystemsDocument13 pagesA Matrix-Based Method For The Structural Analysis of Diagrid SystemsIda MøllerNo ratings yet

- National Convention CentreDocument1 pageNational Convention CentreMahmood RashwanNo ratings yet

- DD Draft1 Abhsihek-CompressedDocument34 pagesDD Draft1 Abhsihek-CompressedRUTWIK JOSHINo ratings yet

- Integrated Design and Construction of Tall Buildings (Moon 2010)Document8 pagesIntegrated Design and Construction of Tall Buildings (Moon 2010)Jose Antoni LasdNo ratings yet

- Analysis of A Four-Story Single-Family Building in The Pasto City According To The Stipulated Heights by The POTDocument15 pagesAnalysis of A Four-Story Single-Family Building in The Pasto City According To The Stipulated Heights by The POTJhon Freddy Perez GuerreroNo ratings yet

- Tal 477Document11 pagesTal 477Peter UkwuejiNo ratings yet

- Large Span Structures - Arjun and JahanDocument51 pagesLarge Span Structures - Arjun and JahanJacob K Thomas100% (1)

- Structural Steel Sets The Framework For Massive Airport RedevelopmentDocument4 pagesStructural Steel Sets The Framework For Massive Airport Redevelopmentclam2014No ratings yet

- Ferry TerminalDocument133 pagesFerry TerminalshishirkrNo ratings yet

- Portfolio - Shravan VaidyanathDocument6 pagesPortfolio - Shravan VaidyanathCatrina JordanNo ratings yet

- ANWER - REPORT - IV - YEAR - PG - No 1 To 50 26.11.2023 - 11Document49 pagesANWER - REPORT - IV - YEAR - PG - No 1 To 50 26.11.2023 - 113001 ANWER RIHAAN HNo ratings yet

- Cost AnalysisDocument13 pagesCost AnalysisReaditReaditNo ratings yet

- Technical Challenges of Large Movable Scaffolding SystemsDocument6 pagesTechnical Challenges of Large Movable Scaffolding SystemsArmus MarsNo ratings yet

- Exploring The Application Domain of Adaptive StructuresDocument22 pagesExploring The Application Domain of Adaptive StructuresAhmed SuwaedNo ratings yet

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureFrom EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureRating: 4.5 out of 5 stars4.5/5 (11)

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Centru cultural-ONASSIS HOUSDocument4 pagesCentru cultural-ONASSIS HOUSstefanNo ratings yet

- Sala Concerte DanemarcaDocument7 pagesSala Concerte DanemarcastefanNo ratings yet

- Opera Outstanding Structure: House, CopenhagenDocument3 pagesOpera Outstanding Structure: House, CopenhagenstefanNo ratings yet

- Diagrid HEARST TOWER PDFDocument4 pagesDiagrid HEARST TOWER PDFstefanNo ratings yet

- FCI Godown SpecificationsDocument2 pagesFCI Godown SpecificationsKunal SharmaNo ratings yet

- Task Force Bangon Marawi UpdatesDocument37 pagesTask Force Bangon Marawi UpdatesKaj Hojilla EstradaNo ratings yet

- Advanced Building Construction: Tubular Truss (Scale 1:20) ElevationDocument1 pageAdvanced Building Construction: Tubular Truss (Scale 1:20) ElevationPankaj DhakedNo ratings yet

- Ancient Roman ArchitectureDocument79 pagesAncient Roman ArchitectureSuleimanNo ratings yet

- Design 7 Midterm Esquisse Part 1Document5 pagesDesign 7 Midterm Esquisse Part 1Eva Margarita H BuenaobraNo ratings yet

- Concrete FormsDocument11 pagesConcrete FormsmurdicksNo ratings yet

- Measures To Prevent Damages in Black Cotton Soil AreasDocument6 pagesMeasures To Prevent Damages in Black Cotton Soil AreasSabyasachi Naik (Zico)100% (1)

- Hanging Gardens of BabylonDocument6 pagesHanging Gardens of BabylonMohammed Al-azem100% (1)

- Written by Razib Shahriar RubenceDocument4 pagesWritten by Razib Shahriar RubenceAnoopNo ratings yet

- Pipe SupportsDocument87 pagesPipe SupportsVeeramanikandanNo ratings yet

- Flexural Design of Singly Section (CIVE209) (CIVE304)Document6 pagesFlexural Design of Singly Section (CIVE209) (CIVE304)Mohammed FattalNo ratings yet

- AZ 300T01A ENU TrainerPrepGuide PDFDocument14 pagesAZ 300T01A ENU TrainerPrepGuide PDFNikul GoyalNo ratings yet

- SWPMDocument560 pagesSWPMFernando Angel Ortiz Rodriguez67% (3)

- ObserveIT Release Notes v5 - 7 - 2Document2 pagesObserveIT Release Notes v5 - 7 - 2gabytgvNo ratings yet

- 3438 19045 1 PBDocument6 pages3438 19045 1 PBFrod 22No ratings yet

- Astm D1785 (2012) PDFDocument11 pagesAstm D1785 (2012) PDFchairul anwarNo ratings yet

- High Rise Building DesignDocument4 pagesHigh Rise Building DesignGel SanchezNo ratings yet

- Microcode Update GuidanceDocument14 pagesMicrocode Update Guidanceproxymo1No ratings yet

- Transport SystemDocument12 pagesTransport SystemLaasyaSweetNo ratings yet

- CGCEL LED PRICELIST 2019-20 Wef 1st Nov 2019 PDFDocument72 pagesCGCEL LED PRICELIST 2019-20 Wef 1st Nov 2019 PDFRavish RamNo ratings yet

- Reviewer !Document18 pagesReviewer !kristine jewelleNo ratings yet

- Pensabene Villa CasaleDocument9 pagesPensabene Villa CasaleJosé Ignacio Villanueva LanzaNo ratings yet

- Stone Dust & RubberDocument64 pagesStone Dust & RubberSyed Mohd Mehdi100% (1)

- Synology Drive WPDocument18 pagesSynology Drive WPMark Brown100% (1)

- Installing Windows Server 2008 DHCP Server: Dynamic Host Configuration Protocol (DHCP)Document13 pagesInstalling Windows Server 2008 DHCP Server: Dynamic Host Configuration Protocol (DHCP)sambradshaw945No ratings yet

- Denah Rumah MinimalisDocument2 pagesDenah Rumah MinimalisIrham SyarifNo ratings yet

- Soil Nailing in GermanyDocument56 pagesSoil Nailing in GermanyJose Martinez100% (1)

- Msbjournal 28 FebruaryDocument33 pagesMsbjournal 28 Februaryalex mvp100% (2)

- Koha Xubuntu: /etc/apt/sources - List.d/koha - List Apt Get UpdateDocument4 pagesKoha Xubuntu: /etc/apt/sources - List.d/koha - List Apt Get Updatepksunil_77No ratings yet

- PHP and MySQL Project Report On Online Blogging System DownloadDocument3 pagesPHP and MySQL Project Report On Online Blogging System Downloadbalwant100% (1)