Professional Documents

Culture Documents

Sala Concerte Danemarca

Sala Concerte Danemarca

Uploaded by

stefanCopyright:

Available Formats

You might also like

- New Method For Construction of DwallDocument9 pagesNew Method For Construction of DwallthirisuNo ratings yet

- Long Span Structures Case Study-Shivani KothawadeDocument25 pagesLong Span Structures Case Study-Shivani KothawadeShivani Kothawade0% (2)

- Diagrid, Prada Boutique AoyamaDocument4 pagesDiagrid, Prada Boutique AoyamastefanNo ratings yet

- Multi-Level Basement Construction - A Dossier of The Londoner HotelDocument11 pagesMulti-Level Basement Construction - A Dossier of The Londoner HotelVictor OmotoriogunNo ratings yet

- Assignment 2Document21 pagesAssignment 2anthonyunisaNo ratings yet

- The Dispersed Tectonics of A Built Diagram: The Engineering of Sanaa'S Kunstlinie in AlmereDocument4 pagesThe Dispersed Tectonics of A Built Diagram: The Engineering of Sanaa'S Kunstlinie in AlmereRRNo ratings yet

- Casa Da MusicaDocument3 pagesCasa Da Musica1219440No ratings yet

- The Messeturm in Rostock - A Tensegrity Tower by SchlaichDocument7 pagesThe Messeturm in Rostock - A Tensegrity Tower by SchlaichTensegrity Wiki0% (1)

- Stress Ribbon and Cable-Supported Pedestrian Bridges CAP 1Document12 pagesStress Ribbon and Cable-Supported Pedestrian Bridges CAP 1Anonymous VkzquW39No ratings yet

- Structural Design of The Arch and Roof of Wembley StadiumDocument6 pagesStructural Design of The Arch and Roof of Wembley StadiumCristi Andone50% (2)

- Butterfly RoofDocument3 pagesButterfly Roofpierre_oosthuizen0% (1)

- Space FrameDocument12 pagesSpace FrameSanika KadamNo ratings yet

- Geographic Location & Climate: Italian Romanesque ArchitectureDocument2 pagesGeographic Location & Climate: Italian Romanesque ArchitectureClintAbellaNo ratings yet

- Case Study 1Document7 pagesCase Study 1harishma hsNo ratings yet

- The "EXPO-roof" in Hanover - A New Dimension For Ripped Shells in TimberDocument8 pagesThe "EXPO-roof" in Hanover - A New Dimension For Ripped Shells in TimberMariana RobuNo ratings yet

- Manchester City Stadium - Structural Case StudyDocument20 pagesManchester City Stadium - Structural Case StudyYuvan SethNo ratings yet

- Twin TowerDocument21 pagesTwin TowerPETA DEVENDRANo ratings yet

- New York TimesDocument20 pagesNew York TimesShreeya SNo ratings yet

- ReliantDocument4 pagesReliantΘΕΟΦΑΝΗΣ ΣΤΑΘΗΣNo ratings yet

- Heydar Aliyev Cultural Centre: StructureDocument3 pagesHeydar Aliyev Cultural Centre: Structurenusha rakheNo ratings yet

- Gehry Steel DetailsDocument3 pagesGehry Steel DetailsKarl FarrugiaNo ratings yet

- Long Span Structures1Document69 pagesLong Span Structures1mani arora100% (1)

- Tensinet 1Document10 pagesTensinet 1suhailzubair1231No ratings yet

- Concrete Construction Article PDF - National Gallery Exhibits The Cutting Edge of Contemporary Architectural ConcreteDocument4 pagesConcrete Construction Article PDF - National Gallery Exhibits The Cutting Edge of Contemporary Architectural ConcreteDhruvi KananiNo ratings yet

- Wellington Central Police Station Base Isolation Maintenance C. R. SmartDocument16 pagesWellington Central Police Station Base Isolation Maintenance C. R. SmartAnkush BhartiNo ratings yet

- Kauffman CenterDocument29 pagesKauffman CenterK.SRI CHAANTHANANo ratings yet

- The Role of Cables in Large Span Spatial Structures - IDocument10 pagesThe Role of Cables in Large Span Spatial Structures - INESTOR CARVAJALNo ratings yet

- Torres Colon PDFDocument1 pageTorres Colon PDFGonzalo de la CruzNo ratings yet

- I 5 New Dehli V Sahc 2006Document10 pagesI 5 New Dehli V Sahc 2006api-250294171No ratings yet

- Mediatheque Çok Iyi KaynakDocument45 pagesMediatheque Çok Iyi KaynakMehmet Akif CiritNo ratings yet

- IiBT - Part 03Document9 pagesIiBT - Part 03bamiesoepNo ratings yet

- Shanghai ArtículoDocument5 pagesShanghai ArtículoIng Martín Castillo FloresNo ratings yet

- AD 415 - Vertical Tying of Columns and Column Splices, February 2018Document1 pageAD 415 - Vertical Tying of Columns and Column Splices, February 2018symon ellimacNo ratings yet

- An Integral Approach To Structure and ArchitectureDocument10 pagesAn Integral Approach To Structure and Architecturehda_paris100% (1)

- T6 - Part B - TowersDocument16 pagesT6 - Part B - Towerschinyik.528No ratings yet

- Steel Lattice Telecommunication MastsDocument7 pagesSteel Lattice Telecommunication MastsjojogarciaNo ratings yet

- Tube-Structures PREDocument31 pagesTube-Structures PREMorshed Bin Alam FervvezNo ratings yet

- The Crystal CathedralDocument12 pagesThe Crystal CathedralClaudia Kristell Mattos RivasNo ratings yet

- Arch206 - Lecture2 - Işık Ülkün PDFDocument71 pagesArch206 - Lecture2 - Işık Ülkün PDFRAJ AGRAWALNo ratings yet

- Le Calcul de Structure Du Minaret de La Mosqu e D Alger 1683793174Document13 pagesLe Calcul de Structure Du Minaret de La Mosqu e D Alger 1683793174Yahfdou CherifNo ratings yet

- Structural Design of The New Football Stadium of Panathinaikos in VotanikosDocument8 pagesStructural Design of The New Football Stadium of Panathinaikos in VotanikosiskeletorsNo ratings yet

- The Envelopes of The Arts Centre in SingaporeDocument13 pagesThe Envelopes of The Arts Centre in Singaporekarina tsurutaNo ratings yet

- Vanke CenterDocument30 pagesVanke CenterSahil KaradNo ratings yet

- 2002 12 TaipeiDocument4 pages2002 12 TaipeiElvis GrayNo ratings yet

- Resumen PuentesDocument6 pagesResumen PuentesJohan OrdoñezNo ratings yet

- Centru cultural-ONASSIS HOUSDocument4 pagesCentru cultural-ONASSIS HOUSstefanNo ratings yet

- Tube Structures: Presented by AglaiaDocument31 pagesTube Structures: Presented by AglaiaMorshed Bin Alam FervvezNo ratings yet

- The Santa Fe II Tower: A Central Core, Tall, Slender Building in MexicoDocument4 pagesThe Santa Fe II Tower: A Central Core, Tall, Slender Building in MexicoPierre SalasNo ratings yet

- The Savill Garden Gridshell Design and ConstructionDocument7 pagesThe Savill Garden Gridshell Design and ConstructionAlex RastyNo ratings yet

- Millennium Tour Brochure Lores PDFDocument9 pagesMillennium Tour Brochure Lores PDFindraNo ratings yet

- Long Span StructuresDocument25 pagesLong Span StructureslithikaNo ratings yet

- 25 Arpana RoyDocument6 pages25 Arpana Royarpanaroy1No ratings yet

- Thesis Proposal: Sean Felton - StructuralDocument14 pagesThesis Proposal: Sean Felton - StructuralmudraNo ratings yet

- March11 Houstonballet WebDocument4 pagesMarch11 Houstonballet WebNaken FittaNo ratings yet

- Grandstands: in Precast ConcreteDocument4 pagesGrandstands: in Precast Concretereza ebadiNo ratings yet

- 18 - Sarthak Patel - ABCMreport01Document15 pages18 - Sarthak Patel - ABCMreport01sarthak patelNo ratings yet

- Use of Steel in The Seismic Retrofit of Historic Oakland City HallDocument12 pagesUse of Steel in The Seismic Retrofit of Historic Oakland City HallRigobertoGuerraNo ratings yet

- Unit 8 Roof Trusses: StructureDocument24 pagesUnit 8 Roof Trusses: StructureanbugobiNo ratings yet

- Design of Roof TrussesDocument24 pagesDesign of Roof TrussesAlam Mohammad Parvez Saifi69% (16)

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- Centru cultural-ONASSIS HOUSDocument4 pagesCentru cultural-ONASSIS HOUSstefanNo ratings yet

- Opera Outstanding Structure: House, CopenhagenDocument3 pagesOpera Outstanding Structure: House, CopenhagenstefanNo ratings yet

- Leeds Metro Univ-Portlad GateDocument4 pagesLeeds Metro Univ-Portlad GatestefanNo ratings yet

- Diagrid HEARST TOWER PDFDocument4 pagesDiagrid HEARST TOWER PDFstefanNo ratings yet

- WBDDocument4 pagesWBDPiyush BhandariNo ratings yet

- ST Laurentius Interior Nomination FINALDocument56 pagesST Laurentius Interior Nomination FINALhal2archangelNo ratings yet

- Boqcomparativechart - 2023-05-27T095500.235Document17 pagesBoqcomparativechart - 2023-05-27T095500.235Abode ArtisanNo ratings yet

- Archaeological Survey of India Delhi Agra Vol IVDocument325 pagesArchaeological Survey of India Delhi Agra Vol IVsudipto917100% (1)

- Document B: Specific Guidance For Hostels and Shared Houses in Multiple Occupation (Hmo)Document9 pagesDocument B: Specific Guidance For Hostels and Shared Houses in Multiple Occupation (Hmo)Ngonidzashe MhukaNo ratings yet

- Finalkuchhtour 160504150108Document10 pagesFinalkuchhtour 160504150108Ar Ayoushika AbrolNo ratings yet

- Bridge TerminologyDocument11 pagesBridge TerminologyAndrea TokarovaNo ratings yet

- Antonio Sant'Elia - Manifesto of Futurist ArchitectureDocument5 pagesAntonio Sant'Elia - Manifesto of Futurist ArchitecturedijaforaNo ratings yet

- Riddhi Patel Margesh Patel Twinkle Rojiwadia Harshil NairDocument20 pagesRiddhi Patel Margesh Patel Twinkle Rojiwadia Harshil NairPola TharwatNo ratings yet

- Traducido Steel and WoodDocument7 pagesTraducido Steel and WoodRoberto RoseroNo ratings yet

- 1construction of Supersture - RimnaDocument27 pages1construction of Supersture - RimnaShiva Raj AdhikariNo ratings yet

- Glass Fiber Reinforced Gypsum Panel Use in Building ConstructionDocument5 pagesGlass Fiber Reinforced Gypsum Panel Use in Building ConstructionGRD JournalsNo ratings yet

- TB-Catalogue PHI 4.0 Short-VersionDocument28 pagesTB-Catalogue PHI 4.0 Short-Versionafshin abdiNo ratings yet

- Waterstop RX Installation Instructions 1693276Document8 pagesWaterstop RX Installation Instructions 1693276pouyaNo ratings yet

- Retaining Wall L4 Design Drawings DetailsDocument7 pagesRetaining Wall L4 Design Drawings DetailsAbdullahiNo ratings yet

- FastTread FormworkDocument9 pagesFastTread FormworkAndrew WeiNo ratings yet

- Balance Point: FindingDocument10 pagesBalance Point: FindingRyan De Vera PagalNo ratings yet

- Cell / Model Name Description DateDocument9 pagesCell / Model Name Description DateSami AjNo ratings yet

- 1.1.1.A HistoryCivilEngineeringArchitecureDocument3 pages1.1.1.A HistoryCivilEngineeringArchitecureAnonymous XQeqSWNo ratings yet

- Building Construction TechnologyDocument21 pagesBuilding Construction TechnologyBCAS HND QS Assignment100% (1)

- Guidelines For The Construction of Compliant Rural Houses: Group MembersDocument6 pagesGuidelines For The Construction of Compliant Rural Houses: Group MembersjinnaNo ratings yet

- (Additional) QT1-CC1-Notification of Inspection List 20240404Document2 pages(Additional) QT1-CC1-Notification of Inspection List 20240404ĐỨC ĐOÀN NGỌCNo ratings yet

- 11 ValluzziDocument73 pages11 ValluzziROHIT SHRIVASTAVANo ratings yet

- Coefficients Slab For ACI Code 318Document14 pagesCoefficients Slab For ACI Code 318relu59No ratings yet

- Standard Barchart RetailDocument6 pagesStandard Barchart RetailRemi de MeyerNo ratings yet

- TSFDC Kothagudem WorkDocument42 pagesTSFDC Kothagudem WorkS UDAY KUMARNo ratings yet

- The Renaissance ArchitectureDocument18 pagesThe Renaissance ArchitectureRazvan BataiosuNo ratings yet

- Gates of BhopalDocument6 pagesGates of BhopalAman GuptaNo ratings yet

Sala Concerte Danemarca

Sala Concerte Danemarca

Uploaded by

stefanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sala Concerte Danemarca

Sala Concerte Danemarca

Uploaded by

stefanCopyright:

Available Formats

Design of a Concert Hall, Denmark

Max Baagoe Rasmussen, MSc, Civ. Eng., NIRAS, Copenhagen, Denmark; Mikkel Bramsen, MSc, Civ. Eng., NIRAS,Aarhus,

Denmark; Henrik Schiichter Andersen, MSc, Civ. Eng., NIRAS, Copenhagen, Denmark. Contact: mib@niras.dk

DOI I0.27 49/10168661 1X12910257 1027 58

Abstract

This paper describes the process of

designing a concert complex: from

the architectural visions of a flying

concrete meteor to the static calcula-

tions that made it happen. Because

of differential settlements from the

non-uniform underground conditions,

hydraulic jacks have been introduced

so that upward and downward adjust-

ments are possible for the concert

hall. Furthermore, the whole building

is covered by a complex two-sYstem

cable facade, where each cable sYs-

tem affects the other. Finally, dynamic

investigations have been conducted

for the huge balcony structures.

Keywords: concert hall; cable facade;

hydraulic jacks; post tensioning; con-

crete structure. Fig. l: Concert hall

Introduction

In 2009, the new Danish Concert Hall

won the IABSE Denmark's Struc-

ture's Award 2009,the European Steel

Design Award (ECCS) and many

other awards. From the beginning of

the project, it was questioned whether

it was possible to construct a flying

concert hall supported by slender col-

umns. Over the course of the project,

the architectural and acoustic solutions

have been uncompromising and have

challenged engineering calculations.

The building is situated in Copenha-

gen and is in fact an unPrecedented

spectacular building (Fig. 1)'

Fig. 2: DR Town

Architectural Visions

The concert hall is one of four seg- and function. The whole town is char- author Peter H@egh's "Smillas's Sense

ments, called DRTown (Danish Radio) acterised by transparency, light and of Snow", where a meteor has landed

(Fig.2) All segments were designed as openness. The purpose was to create a in glacial ice in Greenland, inspired the

an overall plan, but separate architec- climate where media production of the architect to cover the whole building

tural competitions were held for each future and creativity are united in an in a semi-transparent blue projection

segment. The four segments are con- inspiring environment. screen. Behind this screen the "flying

nected by an inner street. The idea meteor" is partially visible.

The architectural idea with the concert

for the project arose from the Middle hall is that, in an area where the sur-

E,astern Kasbah, which is a mix of roundings are very neutral and where

covered squares, markets, streets and

Description

a neighbouring environment has not

shops, where each neighbourhood has yet been created, the highest value that The meteor is the main concert hall

its own special character. can be created is the opposite-some- in the whole concert complex. It can

In much the same way, the buildings thing spectacular. This, together with accommodate an audience of uP to

in DR Town have their own identitY inspiration from the Danish national 1800 people (Fig.3).The meteor looks

Structural Engineering International U20LI Technical Report l0'7

Fig. 4: The meteor covereti with the shell cladding'View from the

Fig. 3: Inside the concert hall

foyer

of the staircase section in terrain. The curve height of 1,5 m, and also enable

like it is flying 30 m above the ground, tension forces to be transferred from

mainly resting on three slender stair- bottom of the concert hall is designed

as a large post-tensioned concrete slab, the leaning staircase 1 to the stiffer

cases. The main concert hall itself is and verticil staircase 3. Staircase 1

designed with a verY comPlex geom- which ipart from functioning as the

floor of the concert hall also ensures would not be stable without this sup-

etrv based on acoustic requirements' oort. In addition to this, the bottom

ThL load-bearing structure is like a the horizontal stability of the staircases

(Fig 6). olare ol the caisson slab structure is

walnut shell surrounding the hall and

bost-tensioned by horizontal cables

defining its acoustics and architec- The post-tensioned concrete slab is a 2 (tensioned to 2,5 MN), on average Per

ture. The structure consists of a steel m high caisson slab supporting the stage every 800 mm, to obtain the neces-

struclure covered by concrete. work- and inner seating areas. It spans 34 m sary strength and stiffness of the slab'

ing as a composite structure, but also across the foyer connecting staircase 1 The stiffness of the staircases does not

r"iu"s as the acoustic barrier against to staircase 3. The slab is constructed influence the cable forces.

the surroundings. To make this con- as a caisson slab to reduce weight. The

crele sphere look like a meteor' the structure consists of 300 mm thick top The remaining Part of the bottom of

surfaces are covered with a thin and bottom plates, and interior walls of the concert hall is made of large geo-

glass-fibre-reinforced concrete shell 300 to 500 mm thickness everY 5 m' metrically challenging steel structures'

cladding. The large open foyer area

Main oost-tension cables are inte- which are suPPorted bY the concert

is located right under the PrimarY hall shell structure. The concrete plat-

concert hall (Frg. 4). In the basement srated lnto the entire 48 m through

both staircases and the slab struc- form is spray-moulded on trapezoidal

there are three smaller concert halls/

ture. Two cables are located in each sheets thit are supported by the steel,

studios. Everything is covered by the

wall (each tensioned to 3,4 MN). The after which the structures function as a

blue screen, which is supported by an

almost invisible vierendeel steel frame cables partly suPPort the slab bY a composite structure.

structure.

Concert Hall

The concert hall itself is conslructed

as a concrete shell, "the meteor"' This

huse concrete shell measures 65 x 68 m

utrd is 34 m high. Its perimeter consists

of lining walls that are up to 18 m high

and 20b mm thick. Below the lining

walls a perimeter ring duct is located-

which, bisides working as torsion-stiff

supporting structure for the lining

wilis, also works as a ventilation duct'

The concert hall almost floats in the air

and is only supported by three stair-

cases and six imall columns (Fig' 5)'

As an example of the uncompromising

architecture, one of the staircase tow-

ers is designed to be tilted, such that

the reaction from the concert hall is

located far from the centre of gravity Fig. 5: Plan view

Structural Engineering International U2017

108 Technical RePort

a static load on 1,5o/" of gravity in any

horizontal direction. Due to the high

mass of the raised concert hall. seismic

loads are considered. which are the

design load for some supporting struc-

tures and directions.

The roof is concrete cast as shotcrete

on corrugated steel plates, which are

placed between the purlins.

This huge concert hall is not self-sup-

porting before the roof is cast, and

works as a shell construction (Fig.9):

hence temporary supports are placed

below the perimeter ring duct in the

construction phase.

Below the concert hall are located

studios 2, 3 and 4, to accommodate

540,7'70 and 240 persons, respectively

(Fig.10).T\ese studios are designed as

Fig. 6; Cross section a "box-in-box" solution, which means

that a steel box has been built in a

room limited by concrete walls. This

solution was chosen because of the

acoustics.

Balcony s Hat-sectron

Hydraulic Jacks

Apart from the three staircases below

the floating concert hall, there are six

Perimeter ring duct column supports to the north. These

columns are again supported by post-

Fig.8: Framework tensioned high concrete beams that

Fig.7: Balconies and lining walls

lead the forces past the 24 m wide

studio 2.

The top of the concert hall is covered a "hat-section" that fulfils the require-

This highly statically indeterminate

with a concrete slab, which is suP- ments. Because of varying heights and

structure is sensitive to creep, shrink-

ported by 12 individual steel trusses varying loads, the dimension of the hat-

age and differential settlements of the

with a maximum length of 47 m and a section also varies (Fig. B)

foundation. The non-uniform under-

height of 3,2 m to match. The girders ground conditions cause differential

Wind load is the dominating horizon-

are supported along the walls on steel settlements and with this a possibly

tal load. Seismic loads in Denmark are

columns. Steel was chosen to minimise

very low due to weak and rare seismic critical redistribution of the load, par-

the weight of the whole roof structure

activity in the area, and is calculated as ticularly regarding the columns.

and as a frame on which the concrete

roof and walls could be cast. The steel

truss structure also allows free pas-

sage in the large technical area that

is located between the ceiling and the

roof.

Between the columns, pre-fabricated

concrete panels are erected with

protruding bows, and the joints are

grouted (Fig. 7). Shear dowels are

welded to the steel columns, such that IiI:-

the connections to the concrete work g:

as a composite structure. !i-=:-: 3

)

The steel columns have different func-

7.1:":: 1

tions. They have to span between the ffi'.

perimeter ring duct and the roof, and

8,.

T.

resist the wind forces; work as a frame-

II

7

work for the concrete column that is cast 3.,

Kir

in the steel-section; and furthermore.

allow connection of the concrete lining

wall elements. The solution was to use Fig. 9: Horizontal stress distribution of the top of concert hall

Structural Engineering International u20ll Technical Report 109

with 88 brown fibre-reinforced con-

crete shells. All the shells are at differ-

ent angles and varying distances from

the concrete surface. The shells are sup-

ported by a secondary steel frame' This

iecondary frame is erected directly on a

variety of different primary steel frames,

of which the largest is 30 mz. The con-

nections between the primary lrames

and the concrete walls are achieved by

High bean a geometric complex support system'

_lL ___

litI Facade

lll,".li--,*i.

The facade has multiPle PurPoses.

To enable the outside viewer to see

Fig. 10: Longitudinal sectnn

the flying meteor through the facade,

the siruCture has to be as light and

transparent as possible. To cover the

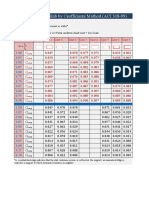

The column reactions are glven m wholi complexiit took 15 000 m2 of

Fig. 12. The intentional column reac- this semi-transparent blue screen'

tions are the dead load plus half of the At night, the blue screen.works as a

Iive load. In the operational period, it is proiection screen, and pro1ectors posl-

'tion"O

ensured that the maximal design loads on the neighbouring buildings

are not exceeded. Column C6 has the and in sPecial towers Project both

same intentional and design load.There- moving and still images onto the blue

fore this column is critical as regards s.te"tt. Itt this way, the exterior of the

overloading, and it should be ensured concert hall is able to change character

that the load value is never exceeded. according to the event inside. Besides

Aftei the temPorarY supports are this, all foyer areas are to have large

removed, an inspection of the pressure glass facades.

in the iacks is carried out. Then the jacks To l-ulfil these requirements. a steel

are locked. During the construction frame surrounds the concert hall' The

period, until the commissioning of the structure consists of an external and

Fig. 11: Hydraulic jack

ioncert hall, all the jacks gradually an internal facade with an inter-space

increased the load until the intentional of approximatelY 2 m. On the exter-

column reactions were oblained (Fig. /3). nal facade the blue screen is attached,

In order to take this unwanted extra and on the internal facade the glass is

The pressures in thejacks were checked

load into account, hydraulic jacks are attached.

every month during the first year after

olaced between columns and the con-

commission. During the next year the

fert hall in the six supports to the north

insoections were reduced to every sec-

(Fig. 11) to ensure that the columns are The Facade Steel Cage

ond month. This was continued everY

not being overloaded.

6 months, and after 6 years when there

The main structure of the facade con-

The hydraulic jacks make it possible will be no more creep in the concrete

sists of an optimised steel cage, which

to adjust the column tops by up to +75 structures, the inspection will end.

is 50 m high,100 m long and 60 m wide

mm with a caPacitY of uP to 800 t Per

The hydraulic jacks function as fixed and consists of SHS260-Profiles'

column, thereby controlling the exact

mechanical supports during the peri-

force in each column. As requested by the architect, all are

ods between adjustments.

box se-ctions, which have been welded

The permanent deformations from together, with very few exceptions' It is

creep, shrinkage and differential set- a iequirement that all facade profiles

tlements are taken into account by Shells are placed either vertically or h.ori-

adjustments of the jacks in the first zont;ily, for which reason the stability

6yearsoftheoperationalperiodofTomaketheconcerthalllooklikea

sphere is covered is handled solely by vierendeel effect

the structure. meteor, the concrete

with the stress concentration in the

column beam junctions'

It was the architect's requirement that

Column C1 C2 C3 C4 C5 C6

the steel structures were to appear

Dead load 4t26 1147 2374 3412 4217 1000 with no other finish but Paint' The

1 000

Intentional load 4450 1860 2490 3600 4350 welded seams in the welded sections

DL+0,5xLL and joints therefore seem unground

1000

Desisn load 59'76 2805 3191 4532 s609

8000 2000

with a resulting rough aPPearance,

8000

Jack capacitY 8000 8000 8000 together with the characteristic con-

crete surlaces.

Fig. 12: Column reactions

Structural Engineering International U20ll.

110 Technical RePort

5000 Dynamics

4500

^

tr 4000

All five southern balconies in the

; 3500

concert hall are large steel structures

.€ 3ooo

fi zsoo with a special geometry. Theoretical

: 2ooo dynamic modal analysis was carried

E lsoo out for the platform steel and a lowest

E

o 1000

soo eigenfrequen cy of 4,3 Hz was found for

0 the corresponding vertical oscillation.

99€rrrrrrr€

O-Of,OOCOOOO

OOCOOOOOCOO

NNNNNdNNNNN

Furthermore, an independent check

x=-=aa9.*q-: was undertaken of peak accelerations

+oo€o@r9nso and dynamic impact on the structure.

NFNFCN:ONiO

Date If a peak acceleration limit of 15%

Fig. 13: Inspection of pressure in jacks of gravity was decided upon, and a

fundamental frequency >3,4 Hz with

relative damping of 0,06 was recom-

mended, <3,0}{2 would be very critical.

The structure was analysed for rhyth-

mic crowd loading, simulating persons

jumping in a time history study, and

maximal accelerations below L5"/o of

gravity were found. It is important to

calculate the exact eigenfrequency and

damping for the structure because the

acceleration is sensitive to these val-

ues. Therefore, subsequently frequency

measurements were carried out by a

to ensure the integrity

full-scale test

Fig. 14: Internal facade with pre-tensioned Fig. 15: Glass facade and comfort of the structure under

rods rhythmic load. The test included a

huge mass that hung from the platform

steel. The mass was released and the

The columns in the facade are stabi- where the cables lean at an angle of platform started to vibrate (Fig. U).

lised with a beam every 15 m. In order 45" (Fig.15). This glass/cable structure Eigenfrequency of 5,2 Hz and relative

to give the structure lightness, stiffen- resists the wind forces on the glass as a damping of at least 0,04 were measured

ing with diagonals has not been carried membrane effect-like the strings in a in this test. This result satisfied the

out. Naturally, the result is that all beam tennis racquet. The mounting and pre- requirement of eigenfrequency >3,4

column joints are made moment-stiff tension of 150 kN of the cable system Hz. A time history analysis showed

as a welded solution. Due to the fact take place only after the mounting of that the acceleration was 13% of grav-

that columns with a length of 15 m in the horizontal pre-tensioned rods, the ity for the high eigenfrequency of 5,2

this structure are sensitive to stability result of which is that the force in the Hz and a relative damping of 0,04. It

problems, the columns are further sta- pre-tensioned rods changes. is, of course, still difficult to say exactly

bilised with pre-tensioned rods every 5 what the true eigenfrequency for the

To determine the interaction and ten-

m. Each rod is tensioned to a force of structure is, because at the time when

sion procedure for the stabilising ten-

50 to 250 kN depending on its position the full-scale test was made the struc-

sion rods and the cable grid for the

in the structve (Fig.14). ture was not completely cast together,

glazed facade, which are both supported

so the mass and stiffness were still sub-

The columns are placed with a spacing by the same steel structure, a variety of

ject to change. It is also well known

of 9,8 m in the internal facade and 4,8 complex step-by-step calculations have

been accomplished (Fig. 16).

that damping increases in a room with

m in the external facade.

people, compared with room without

Between the facade and the concert The large tension coming from the people.The true dynamic impact on the

hall, another steel structure supports cable grid at its perimeter is supported structure can therefore actually only

the glass roof above the foyer. The by the bending in the large beams. be realized by a full-scale test during

joints towards the concert hall are

designed as acoustic damped bearings

and have a natural frequencv lower

than 10 Hz.

Glass Facade

In all of the foyer areas, the internal

facade are mounted with glass pan-

els in a diagonal grid of 1,7 x 7,1 m.

Again, in order to give lightness to the

structure, the glass panels are mounted Fig. 16: Facade steel. (a) Glass roof steel. (b) Horiz.ontalpre-tensioned rods. (c) Cable net

directly onto a diagonal cable net, in foyer areas

Structural Engineering International U2011 Technical Report 111

Fig. 17: Fttll-scale dynamic test of balconies

Fig.20: Casting of walls

a concert with the true mass, stiffness tuned mass dampers (TMD). After

and damping. This has not been done, the complex dynamic interaction was

but the above investigations and analy- monitored during actual use, some of

sis showed that the eigenfrequency is the longest stairs in the foyer areas

definitely larger than 3,4 Hz and the were prepared to be installed with up

damping is at least 0,04. Hence, the to three 500 kg tuned mass dampers.

vibrations turned out to be a non-issue.

Erection

The slender walkways, stairs and esca-

Fig. 18: Perimeter ring lators are suspended in the foyer area. The sequence for the concert hall

In order to meet the architect's high started by erecting the three stair-

requirements for slenderness of the up cases and columns. Then the perimeter

to 2J m long spans, these steel struc- ring duct was cast all the way around

tures were prepared with openings for (Fig. 18) simultaneously with the large

Fig. 19: Erecting sequence Fig.21: Construction of lacade

I12 Technicai Report Structural Engineering International U20L1,

concrete slab between the staircases. and high strength concrete, steel and

Steel columns and roof trusses were cables were mainly used everywhere. SEI Data Block

erected on top of the perimeter ring

and the concert hall was cast (Figs. 19 The very slender facade construction Owner:

and 20). At the same time, the steel was designed to handle large deforma- Danish Broadcasting Corporation (DR)

for the platform structures had to be tions. and the interaction between the

different facade systems made it neces- Architectttral des ign:

hoisted into the hall and hung on the Ateliers Jean Nouvel

perimeter ring.Then the walls sary to solve complex non-linear stabil-

ind rool'

were cast, and after completing most ity effects in many different load cases. Structural design:

of the roof and the structure was found The interaction in the facade is in fact NIRAS A/S

stable, all the temporary supports were exceptional. From the very beginning,

Acoustical design:

removed. Construction of the facades the main target for all structures in the Nagata Acoustics

then commenced (Fig. 21). concert hall was to meet the require-

ments of the architectural design and Main contractor:

Conclusion

the acouslics. These requiremenls M.T. H@jgaard

made it necessary to arrive at complex Cable facade contractor:

It was indeed a challenge to design the

concrete and steel solutions and chal_ Waagner Biro

concert hall. Use of finite element pro- lenged the static, dynamic and fabrica-

tion tasks. Steel (t): 3500

grams and computers in general were

Concrete (m3): 18 000

a crucial factor. The planning of how Overall, it was a pioneer project that Post tension cables (m): 2200

all structures would work together in increased the expectations for what is Reinforcement steel (t): 3600

this huge concert complex was a com- possible to build in future and heloed

Total cost (EUR million): 220

plicated job. Every single corner of this to place Copenhagen on the archiiec-

building was considered and discussed. tural and structural world map. Service date: January 2009

Being a Member of TABSH brings you together...

Companies,

increase their access to visibility within the worldwide structu ra I engi neeri ng

community, and to new i nform ation, new pers pectives and new contacts.

..tell you r colleague.

www.iabse.org

Structural Engineering International 1lZ0lI

Technical Report 113

You might also like

- New Method For Construction of DwallDocument9 pagesNew Method For Construction of DwallthirisuNo ratings yet

- Long Span Structures Case Study-Shivani KothawadeDocument25 pagesLong Span Structures Case Study-Shivani KothawadeShivani Kothawade0% (2)

- Diagrid, Prada Boutique AoyamaDocument4 pagesDiagrid, Prada Boutique AoyamastefanNo ratings yet

- Multi-Level Basement Construction - A Dossier of The Londoner HotelDocument11 pagesMulti-Level Basement Construction - A Dossier of The Londoner HotelVictor OmotoriogunNo ratings yet

- Assignment 2Document21 pagesAssignment 2anthonyunisaNo ratings yet

- The Dispersed Tectonics of A Built Diagram: The Engineering of Sanaa'S Kunstlinie in AlmereDocument4 pagesThe Dispersed Tectonics of A Built Diagram: The Engineering of Sanaa'S Kunstlinie in AlmereRRNo ratings yet

- Casa Da MusicaDocument3 pagesCasa Da Musica1219440No ratings yet

- The Messeturm in Rostock - A Tensegrity Tower by SchlaichDocument7 pagesThe Messeturm in Rostock - A Tensegrity Tower by SchlaichTensegrity Wiki0% (1)

- Stress Ribbon and Cable-Supported Pedestrian Bridges CAP 1Document12 pagesStress Ribbon and Cable-Supported Pedestrian Bridges CAP 1Anonymous VkzquW39No ratings yet

- Structural Design of The Arch and Roof of Wembley StadiumDocument6 pagesStructural Design of The Arch and Roof of Wembley StadiumCristi Andone50% (2)

- Butterfly RoofDocument3 pagesButterfly Roofpierre_oosthuizen0% (1)

- Space FrameDocument12 pagesSpace FrameSanika KadamNo ratings yet

- Geographic Location & Climate: Italian Romanesque ArchitectureDocument2 pagesGeographic Location & Climate: Italian Romanesque ArchitectureClintAbellaNo ratings yet

- Case Study 1Document7 pagesCase Study 1harishma hsNo ratings yet

- The "EXPO-roof" in Hanover - A New Dimension For Ripped Shells in TimberDocument8 pagesThe "EXPO-roof" in Hanover - A New Dimension For Ripped Shells in TimberMariana RobuNo ratings yet

- Manchester City Stadium - Structural Case StudyDocument20 pagesManchester City Stadium - Structural Case StudyYuvan SethNo ratings yet

- Twin TowerDocument21 pagesTwin TowerPETA DEVENDRANo ratings yet

- New York TimesDocument20 pagesNew York TimesShreeya SNo ratings yet

- ReliantDocument4 pagesReliantΘΕΟΦΑΝΗΣ ΣΤΑΘΗΣNo ratings yet

- Heydar Aliyev Cultural Centre: StructureDocument3 pagesHeydar Aliyev Cultural Centre: Structurenusha rakheNo ratings yet

- Gehry Steel DetailsDocument3 pagesGehry Steel DetailsKarl FarrugiaNo ratings yet

- Long Span Structures1Document69 pagesLong Span Structures1mani arora100% (1)

- Tensinet 1Document10 pagesTensinet 1suhailzubair1231No ratings yet

- Concrete Construction Article PDF - National Gallery Exhibits The Cutting Edge of Contemporary Architectural ConcreteDocument4 pagesConcrete Construction Article PDF - National Gallery Exhibits The Cutting Edge of Contemporary Architectural ConcreteDhruvi KananiNo ratings yet

- Wellington Central Police Station Base Isolation Maintenance C. R. SmartDocument16 pagesWellington Central Police Station Base Isolation Maintenance C. R. SmartAnkush BhartiNo ratings yet

- Kauffman CenterDocument29 pagesKauffman CenterK.SRI CHAANTHANANo ratings yet

- The Role of Cables in Large Span Spatial Structures - IDocument10 pagesThe Role of Cables in Large Span Spatial Structures - INESTOR CARVAJALNo ratings yet

- Torres Colon PDFDocument1 pageTorres Colon PDFGonzalo de la CruzNo ratings yet

- I 5 New Dehli V Sahc 2006Document10 pagesI 5 New Dehli V Sahc 2006api-250294171No ratings yet

- Mediatheque Çok Iyi KaynakDocument45 pagesMediatheque Çok Iyi KaynakMehmet Akif CiritNo ratings yet

- IiBT - Part 03Document9 pagesIiBT - Part 03bamiesoepNo ratings yet

- Shanghai ArtículoDocument5 pagesShanghai ArtículoIng Martín Castillo FloresNo ratings yet

- AD 415 - Vertical Tying of Columns and Column Splices, February 2018Document1 pageAD 415 - Vertical Tying of Columns and Column Splices, February 2018symon ellimacNo ratings yet

- An Integral Approach To Structure and ArchitectureDocument10 pagesAn Integral Approach To Structure and Architecturehda_paris100% (1)

- T6 - Part B - TowersDocument16 pagesT6 - Part B - Towerschinyik.528No ratings yet

- Steel Lattice Telecommunication MastsDocument7 pagesSteel Lattice Telecommunication MastsjojogarciaNo ratings yet

- Tube-Structures PREDocument31 pagesTube-Structures PREMorshed Bin Alam FervvezNo ratings yet

- The Crystal CathedralDocument12 pagesThe Crystal CathedralClaudia Kristell Mattos RivasNo ratings yet

- Arch206 - Lecture2 - Işık Ülkün PDFDocument71 pagesArch206 - Lecture2 - Işık Ülkün PDFRAJ AGRAWALNo ratings yet

- Le Calcul de Structure Du Minaret de La Mosqu e D Alger 1683793174Document13 pagesLe Calcul de Structure Du Minaret de La Mosqu e D Alger 1683793174Yahfdou CherifNo ratings yet

- Structural Design of The New Football Stadium of Panathinaikos in VotanikosDocument8 pagesStructural Design of The New Football Stadium of Panathinaikos in VotanikosiskeletorsNo ratings yet

- The Envelopes of The Arts Centre in SingaporeDocument13 pagesThe Envelopes of The Arts Centre in Singaporekarina tsurutaNo ratings yet

- Vanke CenterDocument30 pagesVanke CenterSahil KaradNo ratings yet

- 2002 12 TaipeiDocument4 pages2002 12 TaipeiElvis GrayNo ratings yet

- Resumen PuentesDocument6 pagesResumen PuentesJohan OrdoñezNo ratings yet

- Centru cultural-ONASSIS HOUSDocument4 pagesCentru cultural-ONASSIS HOUSstefanNo ratings yet

- Tube Structures: Presented by AglaiaDocument31 pagesTube Structures: Presented by AglaiaMorshed Bin Alam FervvezNo ratings yet

- The Santa Fe II Tower: A Central Core, Tall, Slender Building in MexicoDocument4 pagesThe Santa Fe II Tower: A Central Core, Tall, Slender Building in MexicoPierre SalasNo ratings yet

- The Savill Garden Gridshell Design and ConstructionDocument7 pagesThe Savill Garden Gridshell Design and ConstructionAlex RastyNo ratings yet

- Millennium Tour Brochure Lores PDFDocument9 pagesMillennium Tour Brochure Lores PDFindraNo ratings yet

- Long Span StructuresDocument25 pagesLong Span StructureslithikaNo ratings yet

- 25 Arpana RoyDocument6 pages25 Arpana Royarpanaroy1No ratings yet

- Thesis Proposal: Sean Felton - StructuralDocument14 pagesThesis Proposal: Sean Felton - StructuralmudraNo ratings yet

- March11 Houstonballet WebDocument4 pagesMarch11 Houstonballet WebNaken FittaNo ratings yet

- Grandstands: in Precast ConcreteDocument4 pagesGrandstands: in Precast Concretereza ebadiNo ratings yet

- 18 - Sarthak Patel - ABCMreport01Document15 pages18 - Sarthak Patel - ABCMreport01sarthak patelNo ratings yet

- Use of Steel in The Seismic Retrofit of Historic Oakland City HallDocument12 pagesUse of Steel in The Seismic Retrofit of Historic Oakland City HallRigobertoGuerraNo ratings yet

- Unit 8 Roof Trusses: StructureDocument24 pagesUnit 8 Roof Trusses: StructureanbugobiNo ratings yet

- Design of Roof TrussesDocument24 pagesDesign of Roof TrussesAlam Mohammad Parvez Saifi69% (16)

- A Guide to Some of the Equations used in Constructing a Suspension BridgeFrom EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- Centru cultural-ONASSIS HOUSDocument4 pagesCentru cultural-ONASSIS HOUSstefanNo ratings yet

- Opera Outstanding Structure: House, CopenhagenDocument3 pagesOpera Outstanding Structure: House, CopenhagenstefanNo ratings yet

- Leeds Metro Univ-Portlad GateDocument4 pagesLeeds Metro Univ-Portlad GatestefanNo ratings yet

- Diagrid HEARST TOWER PDFDocument4 pagesDiagrid HEARST TOWER PDFstefanNo ratings yet

- WBDDocument4 pagesWBDPiyush BhandariNo ratings yet

- ST Laurentius Interior Nomination FINALDocument56 pagesST Laurentius Interior Nomination FINALhal2archangelNo ratings yet

- Boqcomparativechart - 2023-05-27T095500.235Document17 pagesBoqcomparativechart - 2023-05-27T095500.235Abode ArtisanNo ratings yet

- Archaeological Survey of India Delhi Agra Vol IVDocument325 pagesArchaeological Survey of India Delhi Agra Vol IVsudipto917100% (1)

- Document B: Specific Guidance For Hostels and Shared Houses in Multiple Occupation (Hmo)Document9 pagesDocument B: Specific Guidance For Hostels and Shared Houses in Multiple Occupation (Hmo)Ngonidzashe MhukaNo ratings yet

- Finalkuchhtour 160504150108Document10 pagesFinalkuchhtour 160504150108Ar Ayoushika AbrolNo ratings yet

- Bridge TerminologyDocument11 pagesBridge TerminologyAndrea TokarovaNo ratings yet

- Antonio Sant'Elia - Manifesto of Futurist ArchitectureDocument5 pagesAntonio Sant'Elia - Manifesto of Futurist ArchitecturedijaforaNo ratings yet

- Riddhi Patel Margesh Patel Twinkle Rojiwadia Harshil NairDocument20 pagesRiddhi Patel Margesh Patel Twinkle Rojiwadia Harshil NairPola TharwatNo ratings yet

- Traducido Steel and WoodDocument7 pagesTraducido Steel and WoodRoberto RoseroNo ratings yet

- 1construction of Supersture - RimnaDocument27 pages1construction of Supersture - RimnaShiva Raj AdhikariNo ratings yet

- Glass Fiber Reinforced Gypsum Panel Use in Building ConstructionDocument5 pagesGlass Fiber Reinforced Gypsum Panel Use in Building ConstructionGRD JournalsNo ratings yet

- TB-Catalogue PHI 4.0 Short-VersionDocument28 pagesTB-Catalogue PHI 4.0 Short-Versionafshin abdiNo ratings yet

- Waterstop RX Installation Instructions 1693276Document8 pagesWaterstop RX Installation Instructions 1693276pouyaNo ratings yet

- Retaining Wall L4 Design Drawings DetailsDocument7 pagesRetaining Wall L4 Design Drawings DetailsAbdullahiNo ratings yet

- FastTread FormworkDocument9 pagesFastTread FormworkAndrew WeiNo ratings yet

- Balance Point: FindingDocument10 pagesBalance Point: FindingRyan De Vera PagalNo ratings yet

- Cell / Model Name Description DateDocument9 pagesCell / Model Name Description DateSami AjNo ratings yet

- 1.1.1.A HistoryCivilEngineeringArchitecureDocument3 pages1.1.1.A HistoryCivilEngineeringArchitecureAnonymous XQeqSWNo ratings yet

- Building Construction TechnologyDocument21 pagesBuilding Construction TechnologyBCAS HND QS Assignment100% (1)

- Guidelines For The Construction of Compliant Rural Houses: Group MembersDocument6 pagesGuidelines For The Construction of Compliant Rural Houses: Group MembersjinnaNo ratings yet

- (Additional) QT1-CC1-Notification of Inspection List 20240404Document2 pages(Additional) QT1-CC1-Notification of Inspection List 20240404ĐỨC ĐOÀN NGỌCNo ratings yet

- 11 ValluzziDocument73 pages11 ValluzziROHIT SHRIVASTAVANo ratings yet

- Coefficients Slab For ACI Code 318Document14 pagesCoefficients Slab For ACI Code 318relu59No ratings yet

- Standard Barchart RetailDocument6 pagesStandard Barchart RetailRemi de MeyerNo ratings yet

- TSFDC Kothagudem WorkDocument42 pagesTSFDC Kothagudem WorkS UDAY KUMARNo ratings yet

- The Renaissance ArchitectureDocument18 pagesThe Renaissance ArchitectureRazvan BataiosuNo ratings yet

- Gates of BhopalDocument6 pagesGates of BhopalAman GuptaNo ratings yet