Professional Documents

Culture Documents

Alloy 4047 Weld Data Sheet: Typical Applications

Alloy 4047 Weld Data Sheet: Typical Applications

Uploaded by

MarcoAntonioCopyright:

Available Formats

You might also like

- Astm B545Document8 pagesAstm B545MarcoAntonio100% (1)

- 60 Minutes-60 Questions: Mathematics TestDocument14 pages60 Minutes-60 Questions: Mathematics TestJihyun YeonNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- Din 6799Document1 pageDin 6799MarcoAntonioNo ratings yet

- The Case of The Port of Antwerp PDFDocument11 pagesThe Case of The Port of Antwerp PDFCastilla CarlosNo ratings yet

- A 2319 TdsDocument2 pagesA 2319 TdsSyam NathNo ratings yet

- USA 110S-1 Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 110S-1 Welding Wire and Rod: Cert # 05-R0925javadmohammadiNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- 4340 Wire For Low Alloy SteelsDocument1 page4340 Wire For Low Alloy SteelsPankaj KumbhareNo ratings yet

- Code of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Document11 pagesCode of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Sarbendu PaulNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- Busbar Selection ChartDocument4 pagesBusbar Selection ChartRahul Chougule100% (1)

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Welding CableDocument7 pagesWelding CableRafeek AliNo ratings yet

- BOHLER Union S EM12K + UV C 401 - R6 - 231218 - 131726Document2 pagesBOHLER Union S EM12K + UV C 401 - R6 - 231218 - 131726hars wisNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Enerji Katalog enDocument406 pagesEnerji Katalog enllruNo ratings yet

- WeldingDocument1 pageWeldingNNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Select 90c d2Document1 pageSelect 90c d2nateNo ratings yet

- Er70s 6Document1 pageEr70s 6sdsdsdnNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- DC Voltage Drop CalcDocument12 pagesDC Voltage Drop CalcJonathan Brylle CardinalNo ratings yet

- WeldingCable JAINSON ITEM#1Document4 pagesWeldingCable JAINSON ITEM#1Rafeek AliNo ratings yet

- 02112015000000B - Boehler FOX EAS 2-A - CeDocument1 page02112015000000B - Boehler FOX EAS 2-A - CeAHRAKNo ratings yet

- 70ksi Grade MIG Solid Wire: Code DataDocument2 pages70ksi Grade MIG Solid Wire: Code Datarahman2007No ratings yet

- Voltage Drop - ARD - TameplateDocument6 pagesVoltage Drop - ARD - TameplateJian RoganNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- PD 314179Document14 pagesPD 314179Bhavesh KeraliaNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Impedance & Reactance Data-: Circuit Breakers and ConductorsDocument1 pageImpedance & Reactance Data-: Circuit Breakers and ConductorsEdgar MirandaNo ratings yet

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Document1 pagePOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- Seleccionar PTCDocument5 pagesSeleccionar PTCAldimir AcopaNo ratings yet

- 1.4466 (310L Ug)Document4 pages1.4466 (310L Ug)ramramjeyNo ratings yet

- Ok 83.28Document1 pageOk 83.28joe_frangiehNo ratings yet

- 4 - Stainless Steels - Wrought and CastDocument24 pages4 - Stainless Steels - Wrought and CastdennykvgNo ratings yet

- RATNA 7016: A Hydrogen Controlled Basic Coated Electrode For Welding High and Medium Tensile SteelsDocument1 pageRATNA 7016: A Hydrogen Controlled Basic Coated Electrode For Welding High and Medium Tensile SteelsiabdillahNo ratings yet

- Aws Er70sDocument4 pagesAws Er70smanofNo ratings yet

- Welding Duplex Stainless SteelDocument44 pagesWelding Duplex Stainless SteelInoCastilloNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Dasco HvacDocument35 pagesDasco HvacrafaelNo ratings yet

- E7018 PDFDocument3 pagesE7018 PDFPrakash RajNo ratings yet

- 2 5271474990313636959 PDFDocument292 pages2 5271474990313636959 PDFحسن علي جاسمNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Iron Special Iron Material Spec Finecast Foundry 28.8.20Document4 pagesIron Special Iron Material Spec Finecast Foundry 28.8.20Lê ChiếnNo ratings yet

- 5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332Document2 pages5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332LXCNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, KilledDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, Killedamit kumar sarkarNo ratings yet

- 03112015000000B - Boehler FOX SUM - CeDocument1 page03112015000000B - Boehler FOX SUM - Cekapster KannourNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Datasheet Sandvik 2re69 enDocument9 pagesDatasheet Sandvik 2re69 enMuzammilNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- CastMaterials E00510Document6 pagesCastMaterials E00510samir basuniNo ratings yet

- TS-347 TientaiDocument1 pageTS-347 TientaiOscar JimenezNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- G9SP Instructions Reference ManualDocument108 pagesG9SP Instructions Reference ManualMarcoAntonioNo ratings yet

- Chemical Composition: ASTM B103Document1 pageChemical Composition: ASTM B103MarcoAntonioNo ratings yet

- A20 High Strength Low Alloy SteelsDocument7 pagesA20 High Strength Low Alloy SteelsMarcoAntonioNo ratings yet

- Hardened Flat Washer, Astm F436: Size O.D. I.D. Thickness Size O.D. I.D. ThicknessDocument1 pageHardened Flat Washer, Astm F436: Size O.D. I.D. Thickness Size O.D. I.D. ThicknessMarcoAntonioNo ratings yet

- A10 Steels For Cold Forming and Deep Drawing ApplicationsDocument5 pagesA10 Steels For Cold Forming and Deep Drawing ApplicationsMarcoAntonioNo ratings yet

- ' MV ' MV: 0hwdo Ujlfd$JdwkrqDocument1 page' MV ' MV: 0hwdo Ujlfd$JdwkrqMarcoAntonioNo ratings yet

- Electrical Plate-5 Ports PMIDocument1 pageElectrical Plate-5 Ports PMIMarcoAntonioNo ratings yet

- G9SP Operation ManualDocument210 pagesG9SP Operation ManualMarcoAntonioNo ratings yet

- PlusDocument2 pagesPlusMarcoAntonioNo ratings yet

- Astm A229Document3 pagesAstm A229Ratnakar PatilNo ratings yet

- Infinity Users GuideDocument172 pagesInfinity Users GuideSridhar DasariNo ratings yet

- MR July-Aug 2020Document161 pagesMR July-Aug 2020minthuhtunNo ratings yet

- White Resonant MirrorDocument7 pagesWhite Resonant Mirrorlucia.marneanuNo ratings yet

- HR Policies Procedures Version 3Document50 pagesHR Policies Procedures Version 3Program ManagerNo ratings yet

- Hastage Magazine's Latest DECEMBER Issue!Document66 pagesHastage Magazine's Latest DECEMBER Issue!HastagmagazineNo ratings yet

- Kangen Enagic Water Brochure OCT 2021Document12 pagesKangen Enagic Water Brochure OCT 2021Karan RawatNo ratings yet

- 8 Features of The Caste SystemDocument2 pages8 Features of The Caste SystemSaurabh TiwariNo ratings yet

- Closed Loop Fed DC DriveDocument103 pagesClosed Loop Fed DC DriveDhivagar NamakkalNo ratings yet

- How To Do A Resume On WordDocument5 pagesHow To Do A Resume On Wordafjwfealtsielb100% (2)

- Risk Management Practices Followed by The Commercial Banks in PakistanDocument15 pagesRisk Management Practices Followed by The Commercial Banks in PakistanMaria YasinNo ratings yet

- Factor Effecting RecruitmentDocument4 pagesFactor Effecting RecruitmentsogatNo ratings yet

- Sikkim PrintDocument3 pagesSikkim Printdinesh1407No ratings yet

- Full Download Test Bank For Essential Cell Biology 4th Edition Bruce Alberts PDF Full ChapterDocument36 pagesFull Download Test Bank For Essential Cell Biology 4th Edition Bruce Alberts PDF Full Chaptermilreis.cunettew2ncs100% (19)

- 31Document5 pages31iskricaman7No ratings yet

- LPI - Company Profile - 2022Document4 pagesLPI - Company Profile - 2022Chrisneil DelosreyesNo ratings yet

- Philosophies and Theories of EducationDocument26 pagesPhilosophies and Theories of Educationcynthiaaa sNo ratings yet

- Assesment of Ammoniacal Ammonium Sulphate Leachins As A Pretreatment Process For Copper Bearing Gold OresDocument7 pagesAssesment of Ammoniacal Ammonium Sulphate Leachins As A Pretreatment Process For Copper Bearing Gold OresZeryan GuerraNo ratings yet

- Syllabus 8 SemDocument9 pagesSyllabus 8 SemRahulNo ratings yet

- Social Contract A Brief IntroductionDocument6 pagesSocial Contract A Brief IntroductionAriel David Calvopiña QuezadaNo ratings yet

- Poverty 2Document9 pagesPoverty 2Camid AlanissahNo ratings yet

- Tornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartDocument1 pageTornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartGabriel Cabezas NaranjoNo ratings yet

- BLM Physics II Um 2021Document78 pagesBLM Physics II Um 2021Tanmayi KartikNo ratings yet

- C3g - 2 People v. NardoDocument2 pagesC3g - 2 People v. NardoAaron AristonNo ratings yet

- Adiabatic Saturation Temperature of AirDocument2 pagesAdiabatic Saturation Temperature of AirRahul ChandrawarNo ratings yet

- Accessories Verins ShefferDocument20 pagesAccessories Verins ShefferAristideNo ratings yet

- List of Approved Vendors QAM 25.04.2017 FinalDocument59 pagesList of Approved Vendors QAM 25.04.2017 FinalMayank Singhania100% (1)

- Creative Clothing TLPDocument11 pagesCreative Clothing TLPapi-245252207No ratings yet

- 3rd Quarterly ExamDocument8 pages3rd Quarterly ExamLeanmarx TejanoNo ratings yet

Alloy 4047 Weld Data Sheet: Typical Applications

Alloy 4047 Weld Data Sheet: Typical Applications

Uploaded by

MarcoAntonioOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alloy 4047 Weld Data Sheet: Typical Applications

Alloy 4047 Weld Data Sheet: Typical Applications

Uploaded by

MarcoAntonioCopyright:

Available Formats

ALLOY 4047 WELD DATA SHEET

TYPICAL APPLICATIONS

Welding Filler Wire

GENERAL INFORMATION

Trade Designations: Almigweld and Altigweld

Non-Heat treatable

Similar to AlSi12 (Germany)

ISO designation AlSi12

Principle alloying elements: Silicon

Applicable specifications: ANSI/AWS A5.10(ER & R), AMS 4185

WELDING APPROVALS

Canadian Welding Bureau

TYPICAL PROPERTIES

Melting range: 1070 - 1080oF Resistance to corrosion: B (Gen) A (SCC)

Conductivity: 41 % IACS (-O) Anodize Color: Gray-Black

Density: .096 lbs./cu. in.

CHEMISTRY

OTHERS

SILICON IRON COPPER MANGANESE MAGNESIUM CHROMIUM ZINC TITANIUM BERYLLIUM EACH TOTAL ALUM

11.0-13.0 0.8 0 .30 0.15 0.10 ----- 0.20 ---- 0.0003 0.05 0.15 REM

NOTE: SINGLE VALUES ARE MAXIMUM UNLESS OTHERWISE NOTED.

TYPICAL MECHANICAL PROPERTIES OF GTAW GROOVE JOINT WELDS*

BASE ALLOY PROPERTIES AS WELDED POSTWELD HEAT-TREATED & AGED1

BASE ALLOY UTS (KSI) UYS (KSI) ELONG (%) UTS (KSI) UYS (KSI) ELONG (%) UTS (KSI) UYS (KSI) ELONG (%)

2014-T6 70 60 13 34 28 4 50 ---- 2

2

6061-T4 35 21 22 27 18 8 35 ---- 82

6061-T6 45 40 12 27 18 8 44 40 5

6063-T4 25 22 22 20 10 12 30 ---- 13

(1) REQUIRES SUFFICIENT DILUTION OF BASE METAL INTO WELD POOL FOR HEAT TREAT AND/OR AGE RESPONSE. REFER TO

ALCOTECHNIC CONCERNING ALLOY 4643 FOR ADDITIONAL INFORMATION.

(2) POSTWELD AGED ONLY.

* ALLOYS 4043 AND 4047 ARE CONSIDERED THE SAME FOR PROPERTIES PER AWS D1.2 STRUCTURAL WELDING CODE.

AlcoTec Wire Corporation

2750 Aero Park Dr., Traverse City, MI 49686-9263 U.S.A. 1-800-228-0750 FAX: 231-941-9154

E-mail: alcotec@traverse.com Website: www.alcotec.com

ALLOY CHARACTERISTICS

ALLOY 4047 WAS ORIGINALLY DEVELOPED AS A BRAZING ALLOY (BAlSi-4) OR (718)TO TAKE ADVANTAGE OF ITS

LOW MELTING POINT AND NARROW FREEZING RANGE. IN ADDITION, IT HAS A HIGHER SILICON CONTENT THAN

4043, WHICH PROVIDES FOR INCREASED FLUIDITY AND REDUCED SHRINKAGE. THE ALLOY PRODUCES BRIGHT

AND ALMOST SMUT FREE WELDS. HOT CRACKING IS SIGNIFICANTLY REDUCED WHEN 4047 IS USED AS A FILLER

ALLOY.

THE ALLOY MAY BE USED IN APPLICATIONS OF SUSTAINED ELEVATED TEMPERATURES.

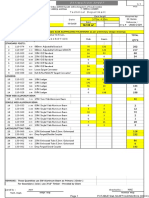

Typical Semiautomatic GMA Procedures for Fillet and Lap Welding Aluminum

3 1

DC(EP) Base DC(EP) Wire Argon Approximate

2

Wire Dia Range Thickness Suggested Feed Gas Flow Consumption

Inches Amps Volts Inches Amps Volts IPM CFH Lbs/100Ft

.030 100-130 18-22 .094 100 22 500 30 0.75

125-150 20-24 .125 120 22 600 30 1

.035 85-120 20-23 .094 110 22 480 30 0.75

125-150 20-24 .125 130 22 566 30 1

170-190 21-26 .250 170 23 740 35 4

.047 125-150 20-24 .125 150 23 360 30 1

180-210 22026 .187 180 23 410 30 2.3

170-240 24-28 .250 190 24 470 40 4

.062 190-260 21-26 .250 200 23 265 50 4

240-300 22-27 .375 230 24 300 50 9

260-310 22-27 .500 260 26 340 60 16

280-320 24-28 .750 280 27 385 65 36

290-340 26-30 1.000 300 28 420 70 64

.094 280-360 26-30 .750 320 29 170 60 36

300-400 26-32 1.000 330 30 180 80 64

1. Metal thickness of ¾” or greater for fillet welds sometimes employs a double vee bevel of 50 deg or

greater included vee with 3/32 to 1/8 inch land thickness on the abutting member.

2. Electrode consumption given for weld on one side only and based on leg length equal to plate

thickness.

3. For 5XXX series electrodes use a welding current in the high side of the range given and an arc

voltage in the lower portion of the range. 1XXX, 2XXX, and 4XXX series electrodes would use the

lower currents and higher arc voltages.

THIS INFORMATION IS BASED ON DATA DEVELOPED UNDER LABORATORY CONDITIONS AND IS DESIGNED AS A

GUIDELINE ONLY. INDIVIDUAL CONDITIONS, WELDING EQUIPMENT AND ENVIRONMENT CAN AFFECT

SUGGESTED SETTINGS.

AlcoTec Wire Corporation

2750 Aero Park Dr., Traverse City, MI 49686-9263 U.S.A. 1-800-228-0750 FAX: 231-941-9154

E-mail: alcotec@traverse.com Website: www.alcotec.com

You might also like

- Astm B545Document8 pagesAstm B545MarcoAntonio100% (1)

- 60 Minutes-60 Questions: Mathematics TestDocument14 pages60 Minutes-60 Questions: Mathematics TestJihyun YeonNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- Din 6799Document1 pageDin 6799MarcoAntonioNo ratings yet

- The Case of The Port of Antwerp PDFDocument11 pagesThe Case of The Port of Antwerp PDFCastilla CarlosNo ratings yet

- A 2319 TdsDocument2 pagesA 2319 TdsSyam NathNo ratings yet

- USA 110S-1 Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 110S-1 Welding Wire and Rod: Cert # 05-R0925javadmohammadiNo ratings yet

- USA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Document1 pageUSA 70S-B2L Welding Wire and Rod: Cert # 05-R0925Nhien ManNo ratings yet

- 4340 Wire For Low Alloy SteelsDocument1 page4340 Wire For Low Alloy SteelsPankaj KumbhareNo ratings yet

- Code of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Document11 pagesCode of Practice For Selection, Laying of Moist Fuel Gas Lines IPSS:1-06-014-17Sarbendu PaulNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- Busbar Selection ChartDocument4 pagesBusbar Selection ChartRahul Chougule100% (1)

- 230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505Document1 page230 Broadway Huntington Station, NY 11746 P: 631.547.5470 - F: 631.547.5475 100 Commerce Way Aliquippa, PA 15001 P: 724.378.6351 - F: 724.378.2505mohamed AdelNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Welding CableDocument7 pagesWelding CableRafeek AliNo ratings yet

- BOHLER Union S EM12K + UV C 401 - R6 - 231218 - 131726Document2 pagesBOHLER Union S EM12K + UV C 401 - R6 - 231218 - 131726hars wisNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Enerji Katalog enDocument406 pagesEnerji Katalog enllruNo ratings yet

- WeldingDocument1 pageWeldingNNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Select 90c d2Document1 pageSelect 90c d2nateNo ratings yet

- Er70s 6Document1 pageEr70s 6sdsdsdnNo ratings yet

- WELDING SPREADER Electrode KALMAR PDFDocument1 pageWELDING SPREADER Electrode KALMAR PDFArtin HykoNo ratings yet

- DC Voltage Drop CalcDocument12 pagesDC Voltage Drop CalcJonathan Brylle CardinalNo ratings yet

- WeldingCable JAINSON ITEM#1Document4 pagesWeldingCable JAINSON ITEM#1Rafeek AliNo ratings yet

- 02112015000000B - Boehler FOX EAS 2-A - CeDocument1 page02112015000000B - Boehler FOX EAS 2-A - CeAHRAKNo ratings yet

- 70ksi Grade MIG Solid Wire: Code DataDocument2 pages70ksi Grade MIG Solid Wire: Code Datarahman2007No ratings yet

- Voltage Drop - ARD - TameplateDocument6 pagesVoltage Drop - ARD - TameplateJian RoganNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- PD 314179Document14 pagesPD 314179Bhavesh KeraliaNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Impedance & Reactance Data-: Circuit Breakers and ConductorsDocument1 pageImpedance & Reactance Data-: Circuit Breakers and ConductorsEdgar MirandaNo ratings yet

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Document1 pagePOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelNo ratings yet

- SMAW Bohler Fox S EV 50 1 E7018 1H4RDocument1 pageSMAW Bohler Fox S EV 50 1 E7018 1H4RYoga ArdiansyahNo ratings yet

- Seleccionar PTCDocument5 pagesSeleccionar PTCAldimir AcopaNo ratings yet

- 1.4466 (310L Ug)Document4 pages1.4466 (310L Ug)ramramjeyNo ratings yet

- Ok 83.28Document1 pageOk 83.28joe_frangiehNo ratings yet

- 4 - Stainless Steels - Wrought and CastDocument24 pages4 - Stainless Steels - Wrought and CastdennykvgNo ratings yet

- RATNA 7016: A Hydrogen Controlled Basic Coated Electrode For Welding High and Medium Tensile SteelsDocument1 pageRATNA 7016: A Hydrogen Controlled Basic Coated Electrode For Welding High and Medium Tensile SteelsiabdillahNo ratings yet

- Aws Er70sDocument4 pagesAws Er70smanofNo ratings yet

- Welding Duplex Stainless SteelDocument44 pagesWelding Duplex Stainless SteelInoCastilloNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Dasco HvacDocument35 pagesDasco HvacrafaelNo ratings yet

- E7018 PDFDocument3 pagesE7018 PDFPrakash RajNo ratings yet

- 2 5271474990313636959 PDFDocument292 pages2 5271474990313636959 PDFحسن علي جاسمNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Iron Special Iron Material Spec Finecast Foundry 28.8.20Document4 pagesIron Special Iron Material Spec Finecast Foundry 28.8.20Lê ChiếnNo ratings yet

- 5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332Document2 pages5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332LXCNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, KilledDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, Killedamit kumar sarkarNo ratings yet

- 03112015000000B - Boehler FOX SUM - CeDocument1 page03112015000000B - Boehler FOX SUM - Cekapster KannourNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Datasheet Sandvik 2re69 enDocument9 pagesDatasheet Sandvik 2re69 enMuzammilNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- CastMaterials E00510Document6 pagesCastMaterials E00510samir basuniNo ratings yet

- TS-347 TientaiDocument1 pageTS-347 TientaiOscar JimenezNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- G9SP Instructions Reference ManualDocument108 pagesG9SP Instructions Reference ManualMarcoAntonioNo ratings yet

- Chemical Composition: ASTM B103Document1 pageChemical Composition: ASTM B103MarcoAntonioNo ratings yet

- A20 High Strength Low Alloy SteelsDocument7 pagesA20 High Strength Low Alloy SteelsMarcoAntonioNo ratings yet

- Hardened Flat Washer, Astm F436: Size O.D. I.D. Thickness Size O.D. I.D. ThicknessDocument1 pageHardened Flat Washer, Astm F436: Size O.D. I.D. Thickness Size O.D. I.D. ThicknessMarcoAntonioNo ratings yet

- A10 Steels For Cold Forming and Deep Drawing ApplicationsDocument5 pagesA10 Steels For Cold Forming and Deep Drawing ApplicationsMarcoAntonioNo ratings yet

- ' MV ' MV: 0hwdo Ujlfd$JdwkrqDocument1 page' MV ' MV: 0hwdo Ujlfd$JdwkrqMarcoAntonioNo ratings yet

- Electrical Plate-5 Ports PMIDocument1 pageElectrical Plate-5 Ports PMIMarcoAntonioNo ratings yet

- G9SP Operation ManualDocument210 pagesG9SP Operation ManualMarcoAntonioNo ratings yet

- PlusDocument2 pagesPlusMarcoAntonioNo ratings yet

- Astm A229Document3 pagesAstm A229Ratnakar PatilNo ratings yet

- Infinity Users GuideDocument172 pagesInfinity Users GuideSridhar DasariNo ratings yet

- MR July-Aug 2020Document161 pagesMR July-Aug 2020minthuhtunNo ratings yet

- White Resonant MirrorDocument7 pagesWhite Resonant Mirrorlucia.marneanuNo ratings yet

- HR Policies Procedures Version 3Document50 pagesHR Policies Procedures Version 3Program ManagerNo ratings yet

- Hastage Magazine's Latest DECEMBER Issue!Document66 pagesHastage Magazine's Latest DECEMBER Issue!HastagmagazineNo ratings yet

- Kangen Enagic Water Brochure OCT 2021Document12 pagesKangen Enagic Water Brochure OCT 2021Karan RawatNo ratings yet

- 8 Features of The Caste SystemDocument2 pages8 Features of The Caste SystemSaurabh TiwariNo ratings yet

- Closed Loop Fed DC DriveDocument103 pagesClosed Loop Fed DC DriveDhivagar NamakkalNo ratings yet

- How To Do A Resume On WordDocument5 pagesHow To Do A Resume On Wordafjwfealtsielb100% (2)

- Risk Management Practices Followed by The Commercial Banks in PakistanDocument15 pagesRisk Management Practices Followed by The Commercial Banks in PakistanMaria YasinNo ratings yet

- Factor Effecting RecruitmentDocument4 pagesFactor Effecting RecruitmentsogatNo ratings yet

- Sikkim PrintDocument3 pagesSikkim Printdinesh1407No ratings yet

- Full Download Test Bank For Essential Cell Biology 4th Edition Bruce Alberts PDF Full ChapterDocument36 pagesFull Download Test Bank For Essential Cell Biology 4th Edition Bruce Alberts PDF Full Chaptermilreis.cunettew2ncs100% (19)

- 31Document5 pages31iskricaman7No ratings yet

- LPI - Company Profile - 2022Document4 pagesLPI - Company Profile - 2022Chrisneil DelosreyesNo ratings yet

- Philosophies and Theories of EducationDocument26 pagesPhilosophies and Theories of Educationcynthiaaa sNo ratings yet

- Assesment of Ammoniacal Ammonium Sulphate Leachins As A Pretreatment Process For Copper Bearing Gold OresDocument7 pagesAssesment of Ammoniacal Ammonium Sulphate Leachins As A Pretreatment Process For Copper Bearing Gold OresZeryan GuerraNo ratings yet

- Syllabus 8 SemDocument9 pagesSyllabus 8 SemRahulNo ratings yet

- Social Contract A Brief IntroductionDocument6 pagesSocial Contract A Brief IntroductionAriel David Calvopiña QuezadaNo ratings yet

- Poverty 2Document9 pagesPoverty 2Camid AlanissahNo ratings yet

- Tornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartDocument1 pageTornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartGabriel Cabezas NaranjoNo ratings yet

- BLM Physics II Um 2021Document78 pagesBLM Physics II Um 2021Tanmayi KartikNo ratings yet

- C3g - 2 People v. NardoDocument2 pagesC3g - 2 People v. NardoAaron AristonNo ratings yet

- Adiabatic Saturation Temperature of AirDocument2 pagesAdiabatic Saturation Temperature of AirRahul ChandrawarNo ratings yet

- Accessories Verins ShefferDocument20 pagesAccessories Verins ShefferAristideNo ratings yet

- List of Approved Vendors QAM 25.04.2017 FinalDocument59 pagesList of Approved Vendors QAM 25.04.2017 FinalMayank Singhania100% (1)

- Creative Clothing TLPDocument11 pagesCreative Clothing TLPapi-245252207No ratings yet

- 3rd Quarterly ExamDocument8 pages3rd Quarterly ExamLeanmarx TejanoNo ratings yet