Professional Documents

Culture Documents

DRP001-OUF-SPE-C-000-002-B2 (Concrete Mix Design Criteria)

DRP001-OUF-SPE-C-000-002-B2 (Concrete Mix Design Criteria)

Uploaded by

Kannan MurugesanCopyright:

Available Formats

You might also like

- Method Statement For Septic Tank ConstructionDocument10 pagesMethod Statement For Septic Tank ConstructionCobbinah Mark100% (6)

- Method Statement For Aluminium Windows and Doors Related Glazing) (K)Document9 pagesMethod Statement For Aluminium Windows and Doors Related Glazing) (K)Akash Yadav67% (3)

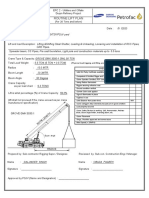

- Routine Lift Plan For All Crane-Grove GMK 50 TonDocument1 pageRoutine Lift Plan For All Crane-Grove GMK 50 TonKannan Murugesan100% (1)

- AC232 - June 2018Document92 pagesAC232 - June 2018TomNo ratings yet

- GP 04.01.01Document13 pagesGP 04.01.01Jose VasquezNo ratings yet

- Quality Management Review Agenda and MinutesDocument4 pagesQuality Management Review Agenda and MinutesKannan MurugesanNo ratings yet

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- PIP STC01018 - 2014 - Blast Resistant Building Design CriteriaDocument51 pagesPIP STC01018 - 2014 - Blast Resistant Building Design Criteriamirko huarancca100% (1)

- Method Statement For Concrete Pouring Using Steel Pipes Suspended by Cranes) (B)Document5 pagesMethod Statement For Concrete Pouring Using Steel Pipes Suspended by Cranes) (B)Akash YadavNo ratings yet

- MoW Module 02 Specification For Construction WorksDocument69 pagesMoW Module 02 Specification For Construction WorksKiran D Anvekar100% (1)

- EDGE Materials Reference Guide Version 2.1 Release A PDFDocument160 pagesEDGE Materials Reference Guide Version 2.1 Release A PDFbrigitteflorezNo ratings yet

- DRP001-OUF-SPE-W-000-017-B1 Material Certification RequirementsDocument11 pagesDRP001-OUF-SPE-W-000-017-B1 Material Certification RequirementsDaniel MartinezNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument4 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetDoan Ngoc DucNo ratings yet

- DRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Document10 pagesDRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Kannan MurugesanNo ratings yet

- BIW Ref: 00-SP-03-3000 Rev 03Document46 pagesBIW Ref: 00-SP-03-3000 Rev 03niuxiaoliangNo ratings yet

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocument25 pages26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- TEC-033000.1-MET-DoR-002 (Method Statement For The Blinding Concrete (PCC) Works)Document8 pagesTEC-033000.1-MET-DoR-002 (Method Statement For The Blinding Concrete (PCC) Works)Haymanot BaynesagnNo ratings yet

- 11-Qa - QC ProcedureDocument18 pages11-Qa - QC Procedureerwin hidayat100% (1)

- TEC-031100A-MET-DoR-002 (Method Statement For Deshuttering of RCC Elements)Document8 pagesTEC-031100A-MET-DoR-002 (Method Statement For Deshuttering of RCC Elements)Ahmet ÖzdenNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument52 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesAsif ChougleNo ratings yet

- Pavement Works (Prime Coat, Tack Coat, Base Course & Wearing Course)Document20 pagesPavement Works (Prime Coat, Tack Coat, Base Course & Wearing Course)Adarsh kumar100% (1)

- Eil Cable EntryDocument85 pagesEil Cable EntryHarshkumar PatelNo ratings yet

- COE 0350-01-15 en TechRpt 0006 Nitrogen Plant Vessel Nozzle Load Assessments - RevA0Document80 pagesCOE 0350-01-15 en TechRpt 0006 Nitrogen Plant Vessel Nozzle Load Assessments - RevA0SbuZikalalaNo ratings yet

- BP12A 074313 Aluminium Cladding and Roofing D00Document26 pagesBP12A 074313 Aluminium Cladding and Roofing D00Chrill DsilvaNo ratings yet

- DRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDocument11 pagesDRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDaniel Martinez100% (1)

- This Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionDocument10 pagesThis Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionVidyut UjalaNo ratings yet

- Specification For Hdpe (3lpe) Coating of Carbon Steel PipesDocument21 pagesSpecification For Hdpe (3lpe) Coating of Carbon Steel PipesDanish MohammedNo ratings yet

- Specifications Pakistan Review Report 23-08Document11 pagesSpecifications Pakistan Review Report 23-08Adil IftikharNo ratings yet

- Hydrant Water Tank Foundation Design Calc - Ebocha1Document39 pagesHydrant Water Tank Foundation Design Calc - Ebocha1Levi UbaNo ratings yet

- Method Statement For Erection of Scaffolding PDFDocument20 pagesMethod Statement For Erection of Scaffolding PDFChris Enyinnaya100% (1)

- R02 I16D05 JAC SPC ST 0011 (C2) 预制混凝土Document11 pagesR02 I16D05 JAC SPC ST 0011 (C2) 预制混凝土hatemmashagbeh84No ratings yet

- SECTION 03 3001 Reinforced Concrete Lanl Master SpecificationDocument50 pagesSECTION 03 3001 Reinforced Concrete Lanl Master Specification081382991318No ratings yet

- TEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Document8 pagesTEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Haymanot BaynesagnNo ratings yet

- TEC-030100.4-MET-DoR-001 (Method Statement For Bulged Concrete Repair Using BASF Emaco S88CT)Document7 pagesTEC-030100.4-MET-DoR-001 (Method Statement For Bulged Concrete Repair Using BASF Emaco S88CT)Alvin BadzNo ratings yet

- 08572-TRHT-CE-PL-18-OO-201 - Rev 0Document63 pages08572-TRHT-CE-PL-18-OO-201 - Rev 0belhaska100% (1)

- VNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecDocument29 pagesVNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecĐiệnBiênNhâm100% (1)

- UntitledDocument26 pagesUntitledjerinkv86No ratings yet

- A.01.38. PWS GuideBearingInspectionRefurbishment - 48 13 13 07 26 Rev 2Document12 pagesA.01.38. PWS GuideBearingInspectionRefurbishment - 48 13 13 07 26 Rev 2jitender.singh29No ratings yet

- 2019 Key Changes Section VIII-2Document59 pages2019 Key Changes Section VIII-2Niniza Sibusiso Prince DlaminiNo ratings yet

- MS For Waterproofing of CulvertsDocument29 pagesMS For Waterproofing of CulvertsAdrian Frantescu100% (2)

- Painting SpecificationDocument27 pagesPainting SpecificationMohamed Thasim100% (1)

- 1 SS PP 007Document44 pages1 SS PP 007SURAJ PRSADNo ratings yet

- STS02380 Application of ACI 336.1-01, Specification For The Construction of Drilled PiersDocument8 pagesSTS02380 Application of ACI 336.1-01, Specification For The Construction of Drilled PiersjppreciadomNo ratings yet

- TEC-033000 - MET-DoR-PIV-P623 (Method Statement For Cast in Situ Concrete Water Tank)Document6 pagesTEC-033000 - MET-DoR-PIV-P623 (Method Statement For Cast in Situ Concrete Water Tank)Haymanot BaynesagnNo ratings yet

- STR-ISEJ - Final - 19 - 09 - 2022Document10 pagesSTR-ISEJ - Final - 19 - 09 - 2022Preeti goswamiNo ratings yet

- TEC-030100.2-MET-DoR-002-Fosroc1 (Method Statement For Repair of Concrete With Fosrocs Rendroc Materials)Document6 pagesTEC-030100.2-MET-DoR-002-Fosroc1 (Method Statement For Repair of Concrete With Fosrocs Rendroc Materials)Alvin BadzNo ratings yet

- Indian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoDocument14 pagesIndian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoMohitrajranikashyapNo ratings yet

- Bp12a 084400 Curtain Wall and Glazed Assemblies D00Document40 pagesBp12a 084400 Curtain Wall and Glazed Assemblies D00Chrill DsilvaNo ratings yet

- Pip CVS02350-2017Document15 pagesPip CVS02350-2017d-fbuser-93320248100% (1)

- Abs Type Approval1 - TeamDocument5 pagesAbs Type Approval1 - TeamRogério FreitasNo ratings yet

- Pip CVS02010-2009Document13 pagesPip CVS02010-2009Eagle3232No ratings yet

- Specification For Field Joint of Polypropylene Corrosion Protection Coating of Concrete Weight Coated Carbon Steel Line PipeDocument18 pagesSpecification For Field Joint of Polypropylene Corrosion Protection Coating of Concrete Weight Coated Carbon Steel Line PipeHAYAZ NAUSEEFNo ratings yet

- TRHT TB PL 18 Oo 201 - 0Document21 pagesTRHT TB PL 18 Oo 201 - 0belhaskaNo ratings yet

- 277 SpecDocument86 pages277 Specmanil_5No ratings yet

- Method Statement For CulvertDocument11 pagesMethod Statement For CulvertHà VũNo ratings yet

- Shop Fabrication Welding & Painting Procedure 22-07 Rev-2Document48 pagesShop Fabrication Welding & Painting Procedure 22-07 Rev-262239a658fb23fNo ratings yet

- BGS-AU-051 Rev BDocument6 pagesBGS-AU-051 Rev BAllwyn AbrahamNo ratings yet

- Materials System SpecificationDocument17 pagesMaterials System SpecificationSyed Zain AliNo ratings yet

- Piping Stress SpecificationDocument23 pagesPiping Stress SpecificationNuno Felipe Matos Mota da FonsecaNo ratings yet

- ctsc1000 0607Document26 pagesctsc1000 0607Hakim BERDINo ratings yet

- General Specification For Material Inweth S ServiceDocument10 pagesGeneral Specification For Material Inweth S Servicetomas budrysNo ratings yet

- Section 32150 - Bonded Epoxy LiningDocument11 pagesSection 32150 - Bonded Epoxy LininghelalsolimanNo ratings yet

- A MTL Pro 000 38673 CDocument21 pagesA MTL Pro 000 38673 CHussein Adnan FneishNo ratings yet

- Qa QC Duties and ResponsibilityDocument3 pagesQa QC Duties and ResponsibilityKannan MurugesanNo ratings yet

- Sample Test report-HDPEDocument1 pageSample Test report-HDPEKannan MurugesanNo ratings yet

- 24-10-2020 Sample Quality Walk ThroughDocument3 pages24-10-2020 Sample Quality Walk ThroughKannan MurugesanNo ratings yet

- Masterflow Solutions BASF ProfileDocument8 pagesMasterflow Solutions BASF ProfileKannan MurugesanNo ratings yet

- Cub Summery NewDocument27 pagesCub Summery NewKannan MurugesanNo ratings yet

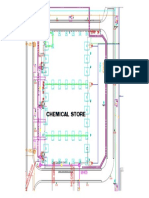

- Chemical Store: 8" Dia Pipe OwsDocument1 pageChemical Store: 8" Dia Pipe OwsKannan MurugesanNo ratings yet

- Base Plate and Anchor Rod DesignDocument2 pagesBase Plate and Anchor Rod DesignKannan MurugesanNo ratings yet

- Consumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Document27 pagesConsumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Kannan MurugesanNo ratings yet

- Curing TrackerDocument1 pageCuring TrackerKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Unit 680 Pipe Supports PS057, 062 BBSDocument6 pagesUnit 680 Pipe Supports PS057, 062 BBSKannan MurugesanNo ratings yet

- Course Appraisal Form (1 Tutor)Document3 pagesCourse Appraisal Form (1 Tutor)Kannan MurugesanNo ratings yet

- Air India Web Booking ETicket (J3ZGV) - ThangarajuDocument2 pagesAir India Web Booking ETicket (J3ZGV) - ThangarajuKannan MurugesanNo ratings yet

- Survey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Document1 pageSurvey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Kannan MurugesanNo ratings yet

- Air Ticket Kochi MaleDocument1 pageAir Ticket Kochi MaleKannan MurugesanNo ratings yet

- G.O (MS) No.221 7.5 Reservation - Amount Sanction G.ODocument10 pagesG.O (MS) No.221 7.5 Reservation - Amount Sanction G.OKannan MurugesanNo ratings yet

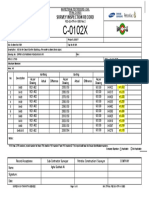

- Compressive Test Strength of ConcreteDocument1 pageCompressive Test Strength of ConcreteKannan MurugesanNo ratings yet

- Presentation: Jamuhar, Rothas Bihar Faculty of Management StudiesDocument19 pagesPresentation: Jamuhar, Rothas Bihar Faculty of Management StudieshimikatiwariNo ratings yet

- Wu and Ye 2020, Study of Carbonation Rate of Synthetic C-S-H by XRD, NMR and FTIRDocument18 pagesWu and Ye 2020, Study of Carbonation Rate of Synthetic C-S-H by XRD, NMR and FTIRLeoNo ratings yet

- JSW Steel ReportDocument45 pagesJSW Steel ReportrandomcctcNo ratings yet

- ANALYSIS of FINANCIAL STATEMENT Using Technique of Ratio Analysis by Furkan KamdarDocument72 pagesANALYSIS of FINANCIAL STATEMENT Using Technique of Ratio Analysis by Furkan Kamdarhumayunrashid84No ratings yet

- Building Materials Cement ESE-SSC-PSC Workbook 1649366671616Document48 pagesBuilding Materials Cement ESE-SSC-PSC Workbook 1649366671616Mohit kumarNo ratings yet

- Advances in Concrete TechnologyDocument10 pagesAdvances in Concrete TechnologytusshaarpatilNo ratings yet

- ASTM C1417M Standard Specification For Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe For Direct DesignDocument8 pagesASTM C1417M Standard Specification For Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe For Direct DesignLiu ZhenguoNo ratings yet

- CBGMDocument16 pagesCBGMmanil_5No ratings yet

- Astm C 76-19Document12 pagesAstm C 76-19Carlos Manuel Ampié BerriosNo ratings yet

- Characteristics of Steel Slags and Their Use in Cement and ConcreteDocument11 pagesCharacteristics of Steel Slags and Their Use in Cement and ConcreteArulvijayNo ratings yet

- Fundamentals of Civil EngineeringDocument161 pagesFundamentals of Civil EngineeringAmyNo ratings yet

- Experimental Study On Strength Properties of Concrete by Partially Replacing Fine Aggregate With Quarry Dust and Cement With GgbsDocument18 pagesExperimental Study On Strength Properties of Concrete by Partially Replacing Fine Aggregate With Quarry Dust and Cement With Ggbsvineela saiNo ratings yet

- Construction Materials and TestingDocument145 pagesConstruction Materials and TestingrajeshwaridasondhiNo ratings yet

- Flexcrete Technology - Toward 2030Document47 pagesFlexcrete Technology - Toward 2030Calvin WongNo ratings yet

- QuizDocument38 pagesQuizgtarun22guptaNo ratings yet

- Manufacturing of Brick Using Waste MaterialDocument19 pagesManufacturing of Brick Using Waste Materials yaswanth reddyNo ratings yet

- TaguchiDocument9 pagesTaguchiAhmet SevinçNo ratings yet

- Indian Standard Is 456 2000 For Print SECTIONS 1 2 3Document42 pagesIndian Standard Is 456 2000 For Print SECTIONS 1 2 3Kalasekar M SwamyNo ratings yet

- BMC TYPES OF CEMENTDocument20 pagesBMC TYPES OF CEMENTBharath SrinivasanNo ratings yet

- Durability of Concrete: Ashok KumarDocument45 pagesDurability of Concrete: Ashok KumarashoknrNo ratings yet

- Case Studies in Construction MaterialsDocument12 pagesCase Studies in Construction MaterialsSithesh RNo ratings yet

- ADMIX C-1000 NF: Description PackagingDocument4 pagesADMIX C-1000 NF: Description PackagingTariq MahmoodNo ratings yet

- García-Lodeiro, I., Maltseva, O., Palomo, A., & Fernández-Jiménez, A. (Enero de 2012)Document7 pagesGarcía-Lodeiro, I., Maltseva, O., Palomo, A., & Fernández-Jiménez, A. (Enero de 2012)Jorge GonzalezNo ratings yet

- Mix Design For PQCDocument34 pagesMix Design For PQCSAMRADDHI PRAJAPATINo ratings yet

- Day 2 (Feb 27, 2018) Schedule of PapersDocument11 pagesDay 2 (Feb 27, 2018) Schedule of Papersdigvijay singhNo ratings yet

- Quality Comparison of Tessellated Wall and Panel Wall Using RCA in Response To Natural DisastersDocument28 pagesQuality Comparison of Tessellated Wall and Panel Wall Using RCA in Response To Natural DisastersKenneth Peña JavierNo ratings yet

- Journal of Innovative Technology and Exploring EngineeringDocument678 pagesJournal of Innovative Technology and Exploring EngineeringAntonio Díaz0% (1)

- Geopolymer Concrete 2011 PDFDocument42 pagesGeopolymer Concrete 2011 PDFbasanth babu100% (1)

DRP001-OUF-SPE-C-000-002-B2 (Concrete Mix Design Criteria)

DRP001-OUF-SPE-C-000-002-B2 (Concrete Mix Design Criteria)

Uploaded by

Kannan MurugesanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DRP001-OUF-SPE-C-000-002-B2 (Concrete Mix Design Criteria)

DRP001-OUF-SPE-C-000-002-B2 (Concrete Mix Design Criteria)

Uploaded by

Kannan MurugesanCopyright:

Available Formats

Duqm Refinery Project

EPC Package 2 –

Utilities and Offsites

Contract No. CNT-1100-1000-007

CONCRETE MIX DESIGN CRITERIA

B2 11-NOV-2018 Class 1 Issued for Design H.S.N K.H.K W.W.C

B1 26-AUG-2018 Class 1 Issued for Design H.S.N K.H.K W.W.C

A1 03-AUG-2018 Class 1 Issued for Client Comments Incorporated H.S.N K.H.K W.W.C

O2 21-JUN-2018 Class 1 Issued for Client Review H.S.N K.H.K W.W.C

O1 15-May-2018 Class 1 Issued for Client Review H.S.N K.H.K W.W.C

Rev. Date Document Class Issue Purpose Author Checked Approved

Number Origin Document Number Rev.

Client’s Number DRP001-OUF-SPE-C-000-002

B2

Contractor’s Number SO0267-EA0B-PHL-SPE-C-000-002

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

Revision History

Amendment Revision Amender

Amendment

Date Number Initials

Incorporation of FEED Amendment Notes, EPC2 Design Notes

15-May-2018 O1 HSN

and Accepted VE

21-JUN-2018 O2 HSN Highlight the changes from the FEED document

03-AUG-2018 A1 HSN Client comments incorporated

26-AUG-2018 B1 HSN Client comments incorporated

11-NOV-2018 B2 HSN Client comments incorporated

Related Documents

Document Number Document Name Description of Content

Holds

Section Number Short Description of Hold

Definitions and Abbreviations

Term Comment

DRP001-OUF-SPE-C-000-002 Page 2 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

CONTENTS

1. PURPOSE ................................................................................................................................................. 4

2. SCOPE ...................................................................................................................................................... 4

3. CODES AND STANDARDS ...................................................................................................................... 4

3.1. American Association of State Highway and Transportation Officials (AASHTO): ......................... 4

3.2. American Concrete Institute (ACI): ................................................................................................ 4

3.3. American Society for Testing and Materials (ASTM) ..................................................................... 4

4. REFERENCE DOCUMENTS .................................................................................................................... 7

4.1. Project Specifications .................................................................................................................... 7

4.2. Geotechnical Reports .................................................................................................................... 7

4.3. Technical Literature ...................................................................................................................... 7

4.4. Project Standards Drawings .......................................................................................................... 7

5. DEFINITIONS of terminology................................................................................................................... 7

6. QUALITY ASSURANCE AND QUALITY CONTROL .............................................................................. 9

7. GENERAL ................................................................................................................................................. 9

8. EXISTING SOIL PROPERTIES ................................................................................................................. 9

9. CONCRETE ............................................................................................................................................. 10

9.1. Cement ....................................................................................................................................... 10

9.2. Water .......................................................................................................................................... 10

9.3. Aggregates .................................................................................................................................. 11

9.4. Admixtures .................................................................................................................................. 11

9.5. Mortar Mix ................................................................................................................................... 11

9.6. Mix Workability Requirements ..................................................................................................... 11

10. CONCRETE GRADES............................................................................................................................. 11

11. TRIAL MIXES .......................................................................................................................................... 12

DRP001-OUF-SPE-C-000-002 Page 3 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

1. PURPOSE

The purpose of this document is to define the minimum requirements for concrete mix designs for Duqm

Refinery Project.

2. SCOPE

This specification provides recommendations on the minimum requirements for concrete mix design, which

are based on the documents as cited in Section 4.2. However, EPC Contractor shall carry out further

detailed geotechnical investigation and review the results in order to compare and conclude the design

criteria. For the Geotechnical Interpretative Report, refer to the DRP001-OUF-RPT-C-000-001. EPC

Contractor shall update this document accordingly and provide to Company for review.

3. CODES AND STANDARDS

The applicable parts of the following codes and standards and references shall be considered to be an

integral part of this specification. Unless noted otherwise, the edition in effect on the date of the Contract

Award shall be used. If there is, or appears to be any conflict between this specification and referenced

documents, the matter shall be referred to Company for resolution. The most stringent requirement shall

govern until written clarification is provided by Company.

3.1. American Association of State Highway and Transportation Officials (AASHTO):

AASHTO T 260 Standard Method of Test for Sampling and Testing for Chloride Ion

in Concrete and Concrete Raw Materials

AASHTO T 199 Standard Method of Test for Air Content of Freshly Mixed Concrete

by Chace Indicator

3.2. American Concrete Institute (ACI):

ACI 301 Specifications for Structural Concrete

ACI 304R Guide for Measuring, Mixing, Transporting, and Placing Concrete

ACI 305R Guide to Hot Weather Concreting

ACI 308R Guide to Curing Concrete

ACI 318/318R Building Code Requirements for Structural Concrete and

Commentary

3.3. American Society for Testing and Materials (ASTM)

ASTM C31 Practice for Making and Curing Concrete Test Specimens in the

Field

ASTM C33 Standard Specification for Concrete Aggregates

ASTM C39 Standard Test Method for Compressive Strength of Cylindrical

Concrete Specimens

ASTM C40 Standard Test Method for Organic Impurities in Fine Aggregates for

Concrete

ASTM C78 Standard Test Method for Flexural Strength of Concrete (Using

Simple Beam with Third-Point Loading)

ASTM C87 Standard Test Method for Effect of Organic Impurities in Fine

Aggregate on Strength of Mortar

ASTM C88 Standard Test Method for Soundness of Aggregates by Use of

Sodium Sulphate or Magnesium Sulphate

ASTM C94 Standard Specification for Ready-Mixed Concrete

DRP001-OUF-SPE-C-000-002 Page 4 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

ASTM C109 Standard Test Method for Compressive Strength of Hydraulic

Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

ASTM C117 Standard Test Method for Materials Finer than 75- m (No. 200)

Sieve in Mineral Aggregates by Washing

ASTM C127 Standard Test Method for Density, Relative Density (Specific

Gravity), and Absorption of Coarse Aggregate

ASTM C128 Standard Test Method for Density, Relative Density (Specific

Gravity), and Absorption of Fine Aggregate

ASTM C131 Standard Test Method for Resistance to Degradation of Small-Size

Coarse Aggregate by Abrasion and Impact in the Los Angeles

Machine

ASTM C138 Standard Test Method for Density (Unit Weight), Yield, and Air

Content (Gravimetric) of Concrete

ASTM C142 Standard Test Method for Clay Lumps and Friable Particles in

Aggregates

ASTM C143 Standard Test Method for Slump of Hydraulic-Cement Concrete

ASTM C150 Standard Specification for Portland Cement

ASTM C172 Practice for Sampling Freshly Mixed Concrete

ASTM C173 Standard Test Method for Air Content of Freshly Mixed Concrete by

the Volumetric Method

ASTM C186 Standard Test Method for Heat of Hydration of Hydraulic Cement

ASTM C191 Standard Test Methods for Time of Setting of Hydraulic Cement by

Vicat Needle

DRP001-OUF-SPE-C-000-002 Page 5 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

ASTM C192 Standard Practice for Making and Curing Concrete Test Specimens

in the Laboratory

ASTM C227 Standard Test Method for Potential Alkali Reactivity of Cement-

Aggregate Combinations (Mortar-Bar Method)

ASTM C231 Standard Test Method for Air Content of Freshly Mixed Concrete by

the Pressure Method

ASTM C232 Standard Test Methods for Bleeding of Concrete

ASTM C260 Specification for Air-Entraining Admixtures for Concrete

ASTM C289 Standard Test Method for Potential Alkali-Silica Reactivity of

Aggregates (Chemical Method)

ASTM C330 Specification for Lightweight Aggregates for Structural Concrete

ASTM C404 Standard Specification for Aggregates for Masonry Grouts

ASTM C 457 Standard Test Method for Microscopical Determination of

Parameters of the Air-Void System in Hardened Concrete

ASTM C494 Standard Specification for Chemical Admixtures for Concrete

ASTM C496 Standard Test Method for Splitting Tensile Strength of Cylindrical

Concrete Specimens

ASTM C535 Standard Test Method for Resistance to Degradation of Large-Size

Coarse Aggregate by Abrasion and Impact in the Los Angeles

Machine

ASTM C595 Standard Specification for Blended Hydraulic Cements

ASTM C618 Standard Specification for Coal Fly Ash and Raw or Calcined

Natural Pozzolan for Use in Concrete

ASTM C642 Standard Test Method for Density, Absorption, and Voids in

Hardened Concrete

ASTM C685 Standard Specification for Concrete Made by Volumetric Batching

and Continuous Mixing

ASTM C856 Standard Practice for Petrographic Examination of Hardened

Concrete

ASTM C1017 Standard Specification for Chemical Admixtures for Use in

Producing Flowing Concrete

ASTM C1019 Standard Method of Sampling and Testing Grout

ASTM C1064 Standard Test Method for Temperature of Freshly Mixed Hydraulic-

Cement Concrete

ASTM C1078 Determining the Cement Content of Freshly Mixed Concrete

ASTM C1079 Standard Test Method for Determining the Water Content of Freshly

Mixed Concrete

ASTM C1152 Standard Test Method for Acid-Soluble Chloride in Mortar and

Concrete

ASTM C1202 Standard Test Method for Electrical Indication of Concrete’s Ability

to Resist Chloride Ion Penetration

ASTM C1218 Standard Test Method for Water-Soluble Chloride in Mortar and

Concrete

ASTM C1260 Potential Alkali Reactivity of Aggregates (Mortar-Bar Method)

ASTM C1602 Standard Specification for Mixing Water Used in the Production of

Hydraulic Cement Concrete

ASTM D75 Standard Practice for Sampling Aggregates

DRP001-OUF-SPE-C-000-002 Page 6 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

ASTM D512 Standard Test Methods for Chloride Ion in Water

ASTM D516 Standard Test Method for sulphate Ion in Water

ASTM D1293 Standard Test Methods for pH of Water

4. REFERENCE DOCUMENTS

4.1. Project Specifications

DRP001-OUF-PRO-Q-000-001 Project Quality Plan

DRP001-OUF-SPE-U-000-002 Project Design Data

DRP001-OUF-SPE-C-000-001 Civil Engineering Design Criteria

DRP001-OUF-SPE-C-000-004 Concrete Roads And Paving

DRP001-OUF-SPE-C-000-005 Specification for Concrete Works

4.2. Geotechnical Reports

DRP001-OUF-RPT-C-000-001 Geotechnical Interpretative Report

*Using the data presented in Table 2 and 6 of CS163(Guide to the Design of Concrete

Structures in the Arabian Peninsula), the sulphate and chloride concentration classes can be

assigned to the investigated site. Refer to the chapter 11 of Geotechnical Interpretative Report.

DRP001-OUF-RPT-C-000-002 Topographical Survey Report

4.3. Technical Literature

Walker, M. (Ed.). (2002). Guide to the Construction of Reinforced Concrete in the Arabian

Peninsula. London: CIRIA and The Concrete Society

The Concrete Society. (2009). Guide to the Design of Concrete Structures in the Arabian

Peninsula (CS163). Surrey: Author

4.4. Project Standards Drawings

DRP001-OUF-000010-C-TS-101-001~003 General Notes

DRP001-OUF-000010-C-TS-102-001 Abbreviation and Symbols

DRP001-OUF-000010-C-TS-003-001~003 Reinforcing Detail

DRP001-OUF-000010-C-TS-601-001 Typical Drawing for Concrete Paving

DRP001-OUF-000010-C-TS-602-001 Typical Drawing for Asphalt Road

DRP001-OUF-000010-C-TS-604-001 Typical Drawing for AOC Catch Basin

DRP001-OUF-000010-C-TS-605-001 Typical Drawing for AOC Manhole Sheet 1

DRP001-OUF-000010-C-TS-605-002 Typical Drawing for AOC Manhole Sheet 2

Typical Drawing for OWS Manhole &

DRP001-OUF-000010-C-TS-607-001

Cleanout Sheet 1

Typical Drawing for OWS Manhole &

DRP001-OUF-000010-C-TS-607-002

Cleanout Sheet 2

DRP001-OUF-SPE-C-000-002 Page 7 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

DRP001-OUF-000010-C-TS-608-001 Typical Drawing for CSS Manhole

Typical Drawing for CSS Manhole with

DRP001-OUF-000010-C-TS-606-001

Open Ditch

Typical Drawing for CSS Manhole with Pipe

DRP001-OUF-000010-C-TS-613-001

Culvert

Typical Drawing for CSS Manhole with Box

DRP001-OUF-000010-C-TS-618-001

Culvert

DRP001-OUF-000010-C-TS-609-001 Typical Drawing for Sanitary Manhole

DRP001-OUF-000010-C-TS-610-001 Typical Drawing for Closed Drain Trench

DRP001-OUF-000010-C-TS-619-001 Typical Drawing for Open Ditch Detail

DRP001-OUF-000010-C-TS-611-001 Typical Drawing for Cable Trench Sheet 1

DRP001-OUF-000010-C-TS-611-002 Typical Drawing for Cable Trench Sheet 2

DRP001-OUF-000010-C-TS-612-001 Typical Drawing for Duct Bank Sheet 1

DRP001-OUF-000010-C-TS-612-002 Typical Drawing for Duct Bank Sheet 2

DRP001-OUF-000010-C-TS-614-001 Typical Drawing for Earthing Pit

Typical Drawing for Pipe Bedding and

DRP001-OUF-000010-C-TS-615-001

Backfilling Sheet 1

Typical Drawing for Pipe Bedding and

DRP001-OUF-000010-C-TS-615-002

Backfilling Sheet 2

Typical Drawing for Barrier & Bollards

DRP001-OUF-000010-C-TS-616-001

Sheet 1

Typical Drawing for Barrier & Bollards

DRP001-OUF-000010-C-TS-616-002

Sheet 2

Typical Drawing for Gravel Surfacing for

DRP001-OUF-000010-C-TS-620-001

Sloped Areas

DRP001-OUF-SPE-C-000-002 Page 8 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

5. DEFINITIONS of terminology

EPC Contractor Joint Venture of Petrofac International and Samsung Engineering Co. Ltd.

Company Duqm Refinery & Petrochemical Industries Company (Duqm Refinery)

Works: All works and services provided by the EPC Contractor in order to

construct, install, erect, commission, test and complete the Facilities.

6. QUALITY ASSURANCE AND QUALITY CONTROL

Reference shall be made to DRP001-OUF-PRO-Q-000-001 Project Quality Plan for Quality Assurance and

Quality Control requirements.

7. GENERAL

Good concrete design and construction practices must be carefully observed in the Oman area due to the

high temperatures and aggressive ground conditions faced when working with reinforced concrete.

Following the chemical analysis and geophysical investigation carried out in DRP001-OUF-RPT-C-000-001

Geotechnical Interpretative Report, the site is classified as highly corrosive. The amounts of sulphates and

chlorides are defined in the above mentioned report, and these can be used along with the requirements

found in the CIRIA Guide to the Design of Concrete Structures in the Arabian Peninsula (CS 163) when

designing the concrete mix. The above guide provides suggestions on the cement type, minimum cement

contents, maximum water/cement ratio and nominal cover to reinforcement.

The CIRIA CS 163 Guide provides the following guidelines:

Table 1* provides the common cements used in the Arabian Peninsula.

Table 2* is used to determine the chloride & carbonation exposure class.

Table 3* provides suggested values for properties of concrete and cover to reinforcement

based on the chloride & carbonation exposure class.

Table 6* is used to determine the sulphate exposure class.

Table 7* provides suggested mix specifications for concrete based on the sulphate

exposure class.

*Table number as stated in CS163

8. EXISTING SOIL PROPERTIES

The chemical analysis carried out on soil and water samples collected at the all investigated site. Refer to the

chapter 11 of DRP001-OUF-RPT-C-000-001 Geotechnical Interpretative Report. Results of chemical

analysis of existing soil are summarize on Table 1.

In cases where concrete construction is to be executed within the fill area, a further assessment should be

undertaken as deemed necessary for the actual fill materials.

Table 1. Summary of Chemical Lab results in Soil Samples*

(Table 11. 1, DRP001-OUF-RPT-C-000-001)

Test Performed Results

Chloride “Cl”(%) 0.02~1.89(0.48)

DRP001-OUF-SPE-C-000-002 Page 9 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

Sulphate “SO3” (g/L) 0.02~2.74(1.11)

Sulphate “SO4” (g/L) 0.02~3.29(1.33)

pH 8.00~9.30(8.44)

* DRP001-OUF-RPT-C-000-001 Geotechnical Interpretative Report

Note, Chloride and sulphate tests were conducted as water soluble as well as acid soluble.

Numbers in parenthesis () represent average values.

** Traditionally sulphates contents are expressed in terms of SO3. If it is desire to get the sulphate content in SO4,

the results in terms of SO3 should multiplied by 1.2.

9. CONCRETE

9.1. Cement

Using the data provided in Table 1, and in conjunction with Table 6 of CS 163, the sulphate class can be

categorized as S-3. With regards to corrosion induced by chlorides, class description of “severe” can be

adopted as per Table 2 of CS 163.

Table 2. Suggested Concrete Specifications as per the Arabian Peninsula by Concrete

Society*

(Table 11. 2, DRP001-OUF-RPT-C-000-001)

Minimum

Maximum free cement Recommended

Minimum Equivalent

w/c or content for cement and

Class strength Cylinder

combination 20mm combination

class1 Strength

content aggregate group

size

S-1 C37 C30 0.50 340 E

S-3 C50 C40 0.40 380 E

Table 3. Recommended Cement used in the Arabian Peninsula Region

(Table 11. 3, DRP001-OUF-RPT-C-000-001)

Cement and

Cement Percentages of components

combination group

Triple blend PC/fly 55-70% PC, 35-25% PFA, 10-

E

ash/silica fume 5% MS

E Triple blend 30-45% PC, 60-50% GGBs, 10-

PC/GGBs/silica fume 5% MS

Notes:

PC – Portland Cement

PFA – Pulverised Fuel Ash

GGBS – Ground Granulated Blast Furnace Slag

MS – Micro-silica (Silica fume)

9.2. Water

Water used in mixing concrete shall conform to ASTM C1602. Water shall be obtained from a source

approved by the Company and shall be clean and free of acids, oils, vegetable and deleterious matter which

may have an effect on the strength, durability, and appearance of the hardened concrete. Recommended

DRP001-OUF-SPE-C-000-002 Page 10 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

criteria for impurities in water used in concreting operations can be found in the CIRIA Guide to the

construction of reinforced concrete in the Arabian Peninsula, Chapter 11.

9.3. Aggregates

Fine and coarse aggregate shall be free of deleterious matter and dust and conform to all the requirements

of ASTM C33.

Aggregates shall be sampled according to ASTM D75.

9.4. Admixtures

Admixtures for water reduction and setting time modification shall conform to ASTM C494.

Admixtures for use in producing flowing concrete shall conform to ASTM C1017.

Air-entraining admixtures shall conform to ASTM C260.

All admixtures to be used are to be approved by the Company.

9.5. Mortar Mix

Mortar mix requirements shall conform to the following standards:

ASTM C1019 Standard Method of Sampling and Testing Grout

ASTM C150 Standard Specification for Portland Cement

ASTM C595 Standard Specification for Blended Hydraulic Cements

ASTM C404 Standard Specification for Aggregates for Masonry Grouts

ACI 530.1/ASCE 6 Specifications for Masonry Structures

9.6. Mix Workability Requirements

For mix workability and slump requirements refer doc. DRP001-OUF-SPE-C-000-005 Specification for

Concrete Works.

10. CONCRETE GRADES

The concrete grade shall be determined from CIRIA Guide to the Design of Concrete Structures in the

Arabian Peninsula.

The recommendations for all areas on site are as follows, based on Clause 11.1.1 of Geotechnical

Interpretative Report, DRP001-OUF-RPT-C-000-001.

Table 4. Recommended concrete mix design parameters

Min. Min. Recommended Min.

sulph Max.

Equivalent Cementitious cement and Cover to

ate Strength Free W/C

Cylinder Content combination Reinf.

Class Class1 Ratio

Strength (kg/m3) group (mm)

S-1 C37 C30 0.50 340 E 60 + ∆c2

S-3 C50 C40 0.40 380 E 60 + ∆c2

Notes:

(1) All strengths classes are cube strengths.

(2) ∆c is a reinforcement fixing tolerance. It is recommended that 15mm be used for in-situ construction.

10mm may be appropriate if good quality control is maintained on site, or for precast members where

there is good control over reinforcement placing.

As per the EPC-2 FEED Package Amendment Notes(CNT-1100-1000-007) No. CSA-048, the minimum

concrete grade requirements are as follow:

DRP001-OUF-SPE-C-000-002 Page 11 of 12 Rev: B2

Duqm Refinery Project – EPC Package 2 Concrete Mix Design Criteria

Concrete Element Duqm Refinery Cylinder Strength

Foundations (all sub-structures) C40

Water Retention structure (includes manholes, C40

catchbasins, pits)

Buildings, Beams, Walls, Columns (all super-structures) C40

Slab on Grade (paving) C30

Blinding C30

Ductbanks C30

Trenches, ditches & channels C30

11. TRIAL MIXES

Mix designs for each type of concrete shall be established on the basis of laboratory trial mixtures in

accordance with ACI 301.

The Company shall be notified of the trial mixes preparation and testing program well in advance so that the

Company representative can witness the mixing and subsequent testing as required.

The proposed mix design of concrete and all supporting background data, such as statistical records,

analyses and test results of trial batches, shall be submitted in writing to the Company for approval and

authorization to proceed prior to commencement of the Works.

The data to be submitted shall also include all the test results for the individual components of the concrete

mix, such as cement, water, aggregate and admixtures.

Cylindrical concrete specimens are to be made and tested in accordance with ASTM C192. A minimum of 6

cylinders shall be tested unless otherwise agreed by the Company.

Workability shall be measured by the slump of concrete at the time of placement, in accordance with

Specification DRP001-OUF-SPE-C-000-005 Specification for Concrete Works.

DRP001-OUF-SPE-C-000-002 Page 12 of 12 Rev: B2

You might also like

- Method Statement For Septic Tank ConstructionDocument10 pagesMethod Statement For Septic Tank ConstructionCobbinah Mark100% (6)

- Method Statement For Aluminium Windows and Doors Related Glazing) (K)Document9 pagesMethod Statement For Aluminium Windows and Doors Related Glazing) (K)Akash Yadav67% (3)

- Routine Lift Plan For All Crane-Grove GMK 50 TonDocument1 pageRoutine Lift Plan For All Crane-Grove GMK 50 TonKannan Murugesan100% (1)

- AC232 - June 2018Document92 pagesAC232 - June 2018TomNo ratings yet

- GP 04.01.01Document13 pagesGP 04.01.01Jose VasquezNo ratings yet

- Quality Management Review Agenda and MinutesDocument4 pagesQuality Management Review Agenda and MinutesKannan MurugesanNo ratings yet

- Detailed Design: General Notes TABLE '1' Structural SteelworkDocument1 pageDetailed Design: General Notes TABLE '1' Structural Steelworkmsiddiq1No ratings yet

- PIP STC01018 - 2014 - Blast Resistant Building Design CriteriaDocument51 pagesPIP STC01018 - 2014 - Blast Resistant Building Design Criteriamirko huarancca100% (1)

- Method Statement For Concrete Pouring Using Steel Pipes Suspended by Cranes) (B)Document5 pagesMethod Statement For Concrete Pouring Using Steel Pipes Suspended by Cranes) (B)Akash YadavNo ratings yet

- MoW Module 02 Specification For Construction WorksDocument69 pagesMoW Module 02 Specification For Construction WorksKiran D Anvekar100% (1)

- EDGE Materials Reference Guide Version 2.1 Release A PDFDocument160 pagesEDGE Materials Reference Guide Version 2.1 Release A PDFbrigitteflorezNo ratings yet

- DRP001-OUF-SPE-W-000-017-B1 Material Certification RequirementsDocument11 pagesDRP001-OUF-SPE-W-000-017-B1 Material Certification RequirementsDaniel MartinezNo ratings yet

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument4 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetDoan Ngoc DucNo ratings yet

- DRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Document10 pagesDRP001-OUF-SPE-C-000-007-B3 (Storm Sewers & Culverts)Kannan MurugesanNo ratings yet

- BIW Ref: 00-SP-03-3000 Rev 03Document46 pagesBIW Ref: 00-SP-03-3000 Rev 03niuxiaoliangNo ratings yet

- 26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureDocument25 pages26071-100-GPP-GCX-00056-001 Concrete Repair ProcedureAsril Sang Lentera Senja100% (1)

- TEC-033000.1-MET-DoR-002 (Method Statement For The Blinding Concrete (PCC) Works)Document8 pagesTEC-033000.1-MET-DoR-002 (Method Statement For The Blinding Concrete (PCC) Works)Haymanot BaynesagnNo ratings yet

- 11-Qa - QC ProcedureDocument18 pages11-Qa - QC Procedureerwin hidayat100% (1)

- TEC-031100A-MET-DoR-002 (Method Statement For Deshuttering of RCC Elements)Document8 pagesTEC-031100A-MET-DoR-002 (Method Statement For Deshuttering of RCC Elements)Ahmet ÖzdenNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument52 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesAsif ChougleNo ratings yet

- Pavement Works (Prime Coat, Tack Coat, Base Course & Wearing Course)Document20 pagesPavement Works (Prime Coat, Tack Coat, Base Course & Wearing Course)Adarsh kumar100% (1)

- Eil Cable EntryDocument85 pagesEil Cable EntryHarshkumar PatelNo ratings yet

- COE 0350-01-15 en TechRpt 0006 Nitrogen Plant Vessel Nozzle Load Assessments - RevA0Document80 pagesCOE 0350-01-15 en TechRpt 0006 Nitrogen Plant Vessel Nozzle Load Assessments - RevA0SbuZikalalaNo ratings yet

- BP12A 074313 Aluminium Cladding and Roofing D00Document26 pagesBP12A 074313 Aluminium Cladding and Roofing D00Chrill DsilvaNo ratings yet

- DRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDocument11 pagesDRP001-OUF-SPE-Q-000-512 B1 Pipeline Weld Numbering ProcedureDaniel Martinez100% (1)

- This Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionDocument10 pagesThis Document Is The Property of CORRTECH. It Should Not Be Used, Copied or Reproduced Without Their Written PermissionVidyut UjalaNo ratings yet

- Specification For Hdpe (3lpe) Coating of Carbon Steel PipesDocument21 pagesSpecification For Hdpe (3lpe) Coating of Carbon Steel PipesDanish MohammedNo ratings yet

- Specifications Pakistan Review Report 23-08Document11 pagesSpecifications Pakistan Review Report 23-08Adil IftikharNo ratings yet

- Hydrant Water Tank Foundation Design Calc - Ebocha1Document39 pagesHydrant Water Tank Foundation Design Calc - Ebocha1Levi UbaNo ratings yet

- Method Statement For Erection of Scaffolding PDFDocument20 pagesMethod Statement For Erection of Scaffolding PDFChris Enyinnaya100% (1)

- R02 I16D05 JAC SPC ST 0011 (C2) 预制混凝土Document11 pagesR02 I16D05 JAC SPC ST 0011 (C2) 预制混凝土hatemmashagbeh84No ratings yet

- SECTION 03 3001 Reinforced Concrete Lanl Master SpecificationDocument50 pagesSECTION 03 3001 Reinforced Concrete Lanl Master Specification081382991318No ratings yet

- TEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Document8 pagesTEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Haymanot BaynesagnNo ratings yet

- TEC-030100.4-MET-DoR-001 (Method Statement For Bulged Concrete Repair Using BASF Emaco S88CT)Document7 pagesTEC-030100.4-MET-DoR-001 (Method Statement For Bulged Concrete Repair Using BASF Emaco S88CT)Alvin BadzNo ratings yet

- 08572-TRHT-CE-PL-18-OO-201 - Rev 0Document63 pages08572-TRHT-CE-PL-18-OO-201 - Rev 0belhaska100% (1)

- VNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecDocument29 pagesVNM-IPGN-PPL-SPC-EDG-0000-00019-00-G03 FBE SpecĐiệnBiênNhâm100% (1)

- UntitledDocument26 pagesUntitledjerinkv86No ratings yet

- A.01.38. PWS GuideBearingInspectionRefurbishment - 48 13 13 07 26 Rev 2Document12 pagesA.01.38. PWS GuideBearingInspectionRefurbishment - 48 13 13 07 26 Rev 2jitender.singh29No ratings yet

- 2019 Key Changes Section VIII-2Document59 pages2019 Key Changes Section VIII-2Niniza Sibusiso Prince DlaminiNo ratings yet

- MS For Waterproofing of CulvertsDocument29 pagesMS For Waterproofing of CulvertsAdrian Frantescu100% (2)

- Painting SpecificationDocument27 pagesPainting SpecificationMohamed Thasim100% (1)

- 1 SS PP 007Document44 pages1 SS PP 007SURAJ PRSADNo ratings yet

- STS02380 Application of ACI 336.1-01, Specification For The Construction of Drilled PiersDocument8 pagesSTS02380 Application of ACI 336.1-01, Specification For The Construction of Drilled PiersjppreciadomNo ratings yet

- TEC-033000 - MET-DoR-PIV-P623 (Method Statement For Cast in Situ Concrete Water Tank)Document6 pagesTEC-033000 - MET-DoR-PIV-P623 (Method Statement For Cast in Situ Concrete Water Tank)Haymanot BaynesagnNo ratings yet

- STR-ISEJ - Final - 19 - 09 - 2022Document10 pagesSTR-ISEJ - Final - 19 - 09 - 2022Preeti goswamiNo ratings yet

- TEC-030100.2-MET-DoR-002-Fosroc1 (Method Statement For Repair of Concrete With Fosrocs Rendroc Materials)Document6 pagesTEC-030100.2-MET-DoR-002-Fosroc1 (Method Statement For Repair of Concrete With Fosrocs Rendroc Materials)Alvin BadzNo ratings yet

- Indian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoDocument14 pagesIndian Railways: Ref: CG-WI-4.2.1-1 Ver.-1.0 Page 1 of 14 Date of Issue October 2018 Spec. NoMohitrajranikashyapNo ratings yet

- Bp12a 084400 Curtain Wall and Glazed Assemblies D00Document40 pagesBp12a 084400 Curtain Wall and Glazed Assemblies D00Chrill DsilvaNo ratings yet

- Pip CVS02350-2017Document15 pagesPip CVS02350-2017d-fbuser-93320248100% (1)

- Abs Type Approval1 - TeamDocument5 pagesAbs Type Approval1 - TeamRogério FreitasNo ratings yet

- Pip CVS02010-2009Document13 pagesPip CVS02010-2009Eagle3232No ratings yet

- Specification For Field Joint of Polypropylene Corrosion Protection Coating of Concrete Weight Coated Carbon Steel Line PipeDocument18 pagesSpecification For Field Joint of Polypropylene Corrosion Protection Coating of Concrete Weight Coated Carbon Steel Line PipeHAYAZ NAUSEEFNo ratings yet

- TRHT TB PL 18 Oo 201 - 0Document21 pagesTRHT TB PL 18 Oo 201 - 0belhaskaNo ratings yet

- 277 SpecDocument86 pages277 Specmanil_5No ratings yet

- Method Statement For CulvertDocument11 pagesMethod Statement For CulvertHà VũNo ratings yet

- Shop Fabrication Welding & Painting Procedure 22-07 Rev-2Document48 pagesShop Fabrication Welding & Painting Procedure 22-07 Rev-262239a658fb23fNo ratings yet

- BGS-AU-051 Rev BDocument6 pagesBGS-AU-051 Rev BAllwyn AbrahamNo ratings yet

- Materials System SpecificationDocument17 pagesMaterials System SpecificationSyed Zain AliNo ratings yet

- Piping Stress SpecificationDocument23 pagesPiping Stress SpecificationNuno Felipe Matos Mota da FonsecaNo ratings yet

- ctsc1000 0607Document26 pagesctsc1000 0607Hakim BERDINo ratings yet

- General Specification For Material Inweth S ServiceDocument10 pagesGeneral Specification For Material Inweth S Servicetomas budrysNo ratings yet

- Section 32150 - Bonded Epoxy LiningDocument11 pagesSection 32150 - Bonded Epoxy LininghelalsolimanNo ratings yet

- A MTL Pro 000 38673 CDocument21 pagesA MTL Pro 000 38673 CHussein Adnan FneishNo ratings yet

- Qa QC Duties and ResponsibilityDocument3 pagesQa QC Duties and ResponsibilityKannan MurugesanNo ratings yet

- Sample Test report-HDPEDocument1 pageSample Test report-HDPEKannan MurugesanNo ratings yet

- 24-10-2020 Sample Quality Walk ThroughDocument3 pages24-10-2020 Sample Quality Walk ThroughKannan MurugesanNo ratings yet

- Masterflow Solutions BASF ProfileDocument8 pagesMasterflow Solutions BASF ProfileKannan MurugesanNo ratings yet

- Cub Summery NewDocument27 pagesCub Summery NewKannan MurugesanNo ratings yet

- Chemical Store: 8" Dia Pipe OwsDocument1 pageChemical Store: 8" Dia Pipe OwsKannan MurugesanNo ratings yet

- Base Plate and Anchor Rod DesignDocument2 pagesBase Plate and Anchor Rod DesignKannan MurugesanNo ratings yet

- Consumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Document27 pagesConsumable Control Procedure-Slpg-S-000-0069-H22-001-001-4-0-Code-2Kannan MurugesanNo ratings yet

- Curing TrackerDocument1 pageCuring TrackerKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Unit 680 Pipe Supports PS057, 062 BBSDocument6 pagesUnit 680 Pipe Supports PS057, 062 BBSKannan MurugesanNo ratings yet

- Course Appraisal Form (1 Tutor)Document3 pagesCourse Appraisal Form (1 Tutor)Kannan MurugesanNo ratings yet

- Air India Web Booking ETicket (J3ZGV) - ThangarajuDocument2 pagesAir India Web Booking ETicket (J3ZGV) - ThangarajuKannan MurugesanNo ratings yet

- Survey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Document1 pageSurvey Inspection Record: PEC-QU-ITR-X-11083 Rev 2Kannan MurugesanNo ratings yet

- Air Ticket Kochi MaleDocument1 pageAir Ticket Kochi MaleKannan MurugesanNo ratings yet

- G.O (MS) No.221 7.5 Reservation - Amount Sanction G.ODocument10 pagesG.O (MS) No.221 7.5 Reservation - Amount Sanction G.OKannan MurugesanNo ratings yet

- Compressive Test Strength of ConcreteDocument1 pageCompressive Test Strength of ConcreteKannan MurugesanNo ratings yet

- Presentation: Jamuhar, Rothas Bihar Faculty of Management StudiesDocument19 pagesPresentation: Jamuhar, Rothas Bihar Faculty of Management StudieshimikatiwariNo ratings yet

- Wu and Ye 2020, Study of Carbonation Rate of Synthetic C-S-H by XRD, NMR and FTIRDocument18 pagesWu and Ye 2020, Study of Carbonation Rate of Synthetic C-S-H by XRD, NMR and FTIRLeoNo ratings yet

- JSW Steel ReportDocument45 pagesJSW Steel ReportrandomcctcNo ratings yet

- ANALYSIS of FINANCIAL STATEMENT Using Technique of Ratio Analysis by Furkan KamdarDocument72 pagesANALYSIS of FINANCIAL STATEMENT Using Technique of Ratio Analysis by Furkan Kamdarhumayunrashid84No ratings yet

- Building Materials Cement ESE-SSC-PSC Workbook 1649366671616Document48 pagesBuilding Materials Cement ESE-SSC-PSC Workbook 1649366671616Mohit kumarNo ratings yet

- Advances in Concrete TechnologyDocument10 pagesAdvances in Concrete TechnologytusshaarpatilNo ratings yet

- ASTM C1417M Standard Specification For Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe For Direct DesignDocument8 pagesASTM C1417M Standard Specification For Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe For Direct DesignLiu ZhenguoNo ratings yet

- CBGMDocument16 pagesCBGMmanil_5No ratings yet

- Astm C 76-19Document12 pagesAstm C 76-19Carlos Manuel Ampié BerriosNo ratings yet

- Characteristics of Steel Slags and Their Use in Cement and ConcreteDocument11 pagesCharacteristics of Steel Slags and Their Use in Cement and ConcreteArulvijayNo ratings yet

- Fundamentals of Civil EngineeringDocument161 pagesFundamentals of Civil EngineeringAmyNo ratings yet

- Experimental Study On Strength Properties of Concrete by Partially Replacing Fine Aggregate With Quarry Dust and Cement With GgbsDocument18 pagesExperimental Study On Strength Properties of Concrete by Partially Replacing Fine Aggregate With Quarry Dust and Cement With Ggbsvineela saiNo ratings yet

- Construction Materials and TestingDocument145 pagesConstruction Materials and TestingrajeshwaridasondhiNo ratings yet

- Flexcrete Technology - Toward 2030Document47 pagesFlexcrete Technology - Toward 2030Calvin WongNo ratings yet

- QuizDocument38 pagesQuizgtarun22guptaNo ratings yet

- Manufacturing of Brick Using Waste MaterialDocument19 pagesManufacturing of Brick Using Waste Materials yaswanth reddyNo ratings yet

- TaguchiDocument9 pagesTaguchiAhmet SevinçNo ratings yet

- Indian Standard Is 456 2000 For Print SECTIONS 1 2 3Document42 pagesIndian Standard Is 456 2000 For Print SECTIONS 1 2 3Kalasekar M SwamyNo ratings yet

- BMC TYPES OF CEMENTDocument20 pagesBMC TYPES OF CEMENTBharath SrinivasanNo ratings yet

- Durability of Concrete: Ashok KumarDocument45 pagesDurability of Concrete: Ashok KumarashoknrNo ratings yet

- Case Studies in Construction MaterialsDocument12 pagesCase Studies in Construction MaterialsSithesh RNo ratings yet

- ADMIX C-1000 NF: Description PackagingDocument4 pagesADMIX C-1000 NF: Description PackagingTariq MahmoodNo ratings yet

- García-Lodeiro, I., Maltseva, O., Palomo, A., & Fernández-Jiménez, A. (Enero de 2012)Document7 pagesGarcía-Lodeiro, I., Maltseva, O., Palomo, A., & Fernández-Jiménez, A. (Enero de 2012)Jorge GonzalezNo ratings yet

- Mix Design For PQCDocument34 pagesMix Design For PQCSAMRADDHI PRAJAPATINo ratings yet

- Day 2 (Feb 27, 2018) Schedule of PapersDocument11 pagesDay 2 (Feb 27, 2018) Schedule of Papersdigvijay singhNo ratings yet

- Quality Comparison of Tessellated Wall and Panel Wall Using RCA in Response To Natural DisastersDocument28 pagesQuality Comparison of Tessellated Wall and Panel Wall Using RCA in Response To Natural DisastersKenneth Peña JavierNo ratings yet

- Journal of Innovative Technology and Exploring EngineeringDocument678 pagesJournal of Innovative Technology and Exploring EngineeringAntonio Díaz0% (1)

- Geopolymer Concrete 2011 PDFDocument42 pagesGeopolymer Concrete 2011 PDFbasanth babu100% (1)