Professional Documents

Culture Documents

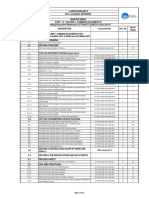

Indicative Inspection & Test Plan : Project: - Iocl Panipat

Indicative Inspection & Test Plan : Project: - Iocl Panipat

Uploaded by

Ashish Dhok0 ratings0% found this document useful (0 votes)

169 views2 pagesThis document outlines an indicative inspection and test plan for a column condenser. It lists 23 inspection points to be carried out by various parties such as the vendor, sub-vendors, a third party inspection agency, and Jacobs/the client. Some key inspection points include witnessing pre-inspection meetings, reviewing inspection plans and procedures, inspecting materials, witnessing manufacturing stages such as welding and tube insertion, and reviewing certifications and test reports before equipment release. The document notes that this is an indicative plan and the vendor must generate a detailed inspection plan meeting all specifications for approval.

Original Description:

Original Title

2.8.1. ITP for Column

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines an indicative inspection and test plan for a column condenser. It lists 23 inspection points to be carried out by various parties such as the vendor, sub-vendors, a third party inspection agency, and Jacobs/the client. Some key inspection points include witnessing pre-inspection meetings, reviewing inspection plans and procedures, inspecting materials, witnessing manufacturing stages such as welding and tube insertion, and reviewing certifications and test reports before equipment release. The document notes that this is an indicative plan and the vendor must generate a detailed inspection plan meeting all specifications for approval.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

169 views2 pagesIndicative Inspection & Test Plan : Project: - Iocl Panipat

Indicative Inspection & Test Plan : Project: - Iocl Panipat

Uploaded by

Ashish DhokThis document outlines an indicative inspection and test plan for a column condenser. It lists 23 inspection points to be carried out by various parties such as the vendor, sub-vendors, a third party inspection agency, and Jacobs/the client. Some key inspection points include witnessing pre-inspection meetings, reviewing inspection plans and procedures, inspecting materials, witnessing manufacturing stages such as welding and tube insertion, and reviewing certifications and test reports before equipment release. The document notes that this is an indicative plan and the vendor must generate a detailed inspection plan meeting all specifications for approval.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

INDICATIVE INSPECTION & TEST PLAN** ITP NO.

PROJECT : 44AC7500 – IOCL PANIPAT : DT

SHEET 1 OF 2

EQUIPMENT / ITEM DESCRIPTION : Column Condenser VENDOR :

EQUIPMENT / ITEM TAG NO. : P.O. NO. :

TEST & INSPECTION AS PER : PR/PS NO.

(CODES & SPECIFICATIONS) : DRG. NO.

A 1 Witness inspection and / or document review by JACOBS / Client

C

T 2 Witness Inspection and / or document review by Third Party Inspection Agency (TPIA

I appointed by vendor )/ Statutory Authority

V 3 Witness inspection by Sub vendor, Vendor.

I

T 4 Certificates / data to be submitted by sub vendor / vendor for approval /

Y review by TPIA (TPIA appointed by vendor) / JACOBS / Client

1 H H H X Pre-inspection meeting to be conducted after issue of PO / PR / PS.

Agenda to be prepared by JACOBS.

2 A A R X Detailed Inspection & Test Plan after issue of PO / PR / PS (including for all

bought – out items)

3 A A R X Inspection & Test procedures including NDT / PMI / Weld Repair / Hydro

Test / Pneumatic test / Tube to Tube Sheet Mock up Procedure / Acid

pickling and Passivation / Surface Preparation and Painting / N2 purging

etc. As applicable

4 R A X Packing procedure (including equipment Drying, N2 purging etc.) / shipping

drawing of completed equipment.

5 R R X Summary of all Supplementary requirements as specified in the PO / PR /

PS

6 A W X Welding procedure specifications and procedure qualification record

including weld repair.

7 A W X Welders’ qualification / welder’s performance records

8 W H X New welding procedures and welder’s qualification

9 R R X Welding consumables batch certificate

10 W W X Raw material Inspection / Identification for all Pressure parts / components,

W.R.T Manufacturers Test Certificates.

11 R W X Raw material identification for non-pressure parts / structural materials

12 R R X Sub-order verification for bought-out items viz Plates, Tube sheet, Tubes,

flanges / forgings, girth flanges fittings, Pipes, Dished ends, bellows,

Fasteners & Gaskets etc. as applicable

13 W W X Inspection of bought-out items at manufactures, works for forgings, girth

Flanges, U tubes, Packings, Pipes, Fittings, Fasteners, dished ends,

Gaskets etc.

14 W W X Identifications of all bought out items at fabrication shop

15 W W X Stages of Manufacturing,

Forming of D/ends, Cone, Shell Long seam, Circ Seam set ups, Root and

Final weld DPT, Nozzle fit ups and inspection of NDT of Root and final

welds. Fitment and welding of Column internals (Packing support ring / TSR

etc.), Tube Bundle assembly – Drilling & Reaming of Tube sheet & Baffles,

Skeleton Assly. Tube insertion, Welding & NDE of Tube to Tube sheet

welds, Helium leak test, Tube expansion.

DP /MP for welds on pressure parts. Radiography – review of Films.

Pneumatic Air test of RF Pads as per Drawing / PR document.

INDICATIVE INSPECTION & TEST PLAN** ITP NO.

PROJECT : 44AC7500 – IOCL PANIPAT : DT

SHEET 1 OF 2

EQUIPMENT / ITEM DESCRIPTION : Column Condenser VENDOR :

EQUIPMENT / ITEM TAG NO. : P.O. NO. :

TEST & INSPECTION AS PER : PR/PS NO.

(CODES & SPECIFICATIONS) : DRG. NO.

A 1 Witness inspection and / or document review by JACOBS / Client

C

T 2 Witness Inspection and / or document review by Third Party Inspection Agency (TPIA

I appointed by vendor) / Statutory Authority

V 3 Witness inspection by Sub vendor, Vendor.

I

T 4 Certificates / data to be submitted by sub vendor / vendor for approval /

Y review by TPIA (TPIA appointed by vendor) / JACOBS / Client

16 W W X PMI for alloying elements

17 W W X NDT (RT, UT, MT, PT, etc., as applicable.) Examination / NDT clearance of

weld joints before & after PWHT / Hydrotest, as applicable.

18 W W X Visual (internals & external) & Dimensional check. Resolution to CR /NCN if

any, before release for Hydro test.

19 W W X Hydro test (Shell and Tube side)

20 W W X Hot Gas Cycle Test as per Invista Spec 3.2.3.5.6 and Helium Leak test as

per specification. As applicable

21 W W X Surface preparation, painting for external surfaces / Pickling and

Passivation.

22 W W X Final documentation including certification of as-built drawings and stamping

of equipment. Verification of Spares.

23 H W X Issue the Inspection Release Note

LEGENDS : H - HOLD, W - WITNESS, R – REVIEW, A - APPROVAL, I - INFORMATION, X – SUBMIT

PO – PURCHASE ORDER, PR – PURCHASE REQUISITION, PS – PURCHASE SPECIFICATION

** NOTE : THIS IS AN INDICATIVE INSPECTION AND TEST PLAN IDENTIFYING SCOPE OF INSPECTION

/REVIEW OF DOCUMENTS AS A MINIMUM REQUIREMENT, DETAILED INSPECTION AND TEST PLAN

INDICATING ALL SPECIFIED REQUIREMENTS AFTER ISSUE OF PO / PR TO BE GENERATED BY

VENDOR AND SAME DULY APPROVED BY TPI A TO BE SUBMITTED TO JACOBS /CLIENT FOR

APPROVAL.

OWNER / PMC RESERVES RIGHT TO WITNESS INSPECTION OF ANY ITEM AT ANY STAGE WHICH SHALL BE INDICATED ON QAP /

INSPECTION & TEST PLAN AT THE TIME OF APPROVAL AND SAME TO BE COVERED AS PART OF PURCHASE ORDER CONDITION

ISSUED BY CLIENT.

You might also like

- Basic Surface Wellhead SchoolDocument47 pagesBasic Surface Wellhead SchoolIWCF IADC100% (3)

- Fan Lub CFM56-7Document89 pagesFan Lub CFM56-7ANDRA100% (1)

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- 000 L Ee 0020129Document2,433 pages000 L Ee 0020129avaisharmaNo ratings yet

- UG-39 - Flat Head ReinforcementDocument3 pagesUG-39 - Flat Head ReinforcementAshish DhokNo ratings yet

- Blakeborough Control ValvesDocument51 pagesBlakeborough Control ValvesjlpinemNo ratings yet

- Himalayan 1 PDFDocument20 pagesHimalayan 1 PDFJulian GallegoNo ratings yet

- ES 49BranchConnections PDFDocument7 pagesES 49BranchConnections PDFprabuharan89No ratings yet

- Itp For ValvesDocument2 pagesItp For ValvesSuraj ShettyNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- Compiled Vol IIDocument69 pagesCompiled Vol IIashish.mathur1No ratings yet

- 6 77 0001 Rev - 4 PDFDocument40 pages6 77 0001 Rev - 4 PDFRam Kadam0% (1)

- Test Package: Pt. TTN (Tambang Tondano Nusajaya)Document18 pagesTest Package: Pt. TTN (Tambang Tondano Nusajaya)unto gunungNo ratings yet

- Tubing Data ChartsDocument30 pagesTubing Data ChartsIvo NunesNo ratings yet

- EPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Document10 pagesEPCC-5 (MS Block - Octamax Unit) Part-III-Master Index - Volume-1Structures ProductionNo ratings yet

- Gas Pipeline SpecDocument4 pagesGas Pipeline SpecA_bener100% (2)

- Ongc 2004a Rev 7Document78 pagesOngc 2004a Rev 7dzardoniNo ratings yet

- CC ITP Sample PDFDocument4 pagesCC ITP Sample PDFMRezaNo ratings yet

- 03c EIL MR 3002 dd1059Document146 pages03c EIL MR 3002 dd1059Kalai Selvan100% (1)

- Eds L 1Document267 pagesEds L 1Sam Jose100% (1)

- 3-WPS Checklist Master PieceDocument3 pages3-WPS Checklist Master PieceTuTuy An100% (1)

- TPP-ABE-PP-1001-0001, Piping Material Take-Off - IDC - 15-Feb-2016Document10 pagesTPP-ABE-PP-1001-0001, Piping Material Take-Off - IDC - 15-Feb-2016OlusayoNo ratings yet

- MOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsDocument20 pagesMOM MUR 10 ST SP 0001-00-03 Specification For Structural MaterialsAnonymous 1ykzuaxWgYNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

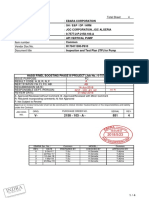

- IS, I I I: Name of ManufacturerDocument1 pageIS, I I I: Name of ManufacturercynideNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- Orifice Flange Guide - Daniel FlowDocument45 pagesOrifice Flange Guide - Daniel FlowSammyNo ratings yet

- Tech. Spec. For VesselsDocument6 pagesTech. Spec. For Vesselssanjay421No ratings yet

- BlastPainting Report R.1Document1 pageBlastPainting Report R.1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Specifications of LR BendDocument11 pagesSpecifications of LR BendPrafulla PatilNo ratings yet

- Es 01 PDFDocument10 pagesEs 01 PDFharryNo ratings yet

- Pages From ONGC-SPEC-02-MS-03Document12 pagesPages From ONGC-SPEC-02-MS-03Prathamesh OmtechNo ratings yet

- Tata Consulting Engineers Limited: Piping Material SpecificationDocument3 pagesTata Consulting Engineers Limited: Piping Material SpecificationkasvikrajNo ratings yet

- API STANDARD For PipingDocument28 pagesAPI STANDARD For PipingsahaNo ratings yet

- Responsibility Matrix For Shop & Site WorksDocument3 pagesResponsibility Matrix For Shop & Site WorksRenny DevassyNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- MR For Ball ValvesDocument12 pagesMR For Ball Valvesengr_umer_01100% (1)

- MD1-0-T-030-05-00071 ITP For Steel Structure ErectionDocument10 pagesMD1-0-T-030-05-00071 ITP For Steel Structure ErectionTran KhuynhNo ratings yet

- EPC3-BRT Pj. - Intergral Double Block & Bleed ValvesDocument6 pagesEPC3-BRT Pj. - Intergral Double Block & Bleed ValvesUsman Arif100% (1)

- Project Department Kuwait National Petroleum Company: Daily Welding Inspection ReportDocument1 pageProject Department Kuwait National Petroleum Company: Daily Welding Inspection ReportMuthazhagan SaravananNo ratings yet

- Jangkrik Complex - Mto Piping Bulk (Bidding)Document13 pagesJangkrik Complex - Mto Piping Bulk (Bidding)shoghi wisesaNo ratings yet

- General Technical Requirement For Mechanical - Piping (D 13Document18 pagesGeneral Technical Requirement For Mechanical - Piping (D 13Elias EliasNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- H2so4 SpillDocument4 pagesH2so4 SpilludayNo ratings yet

- Technical FF PRT C 20181016 1715231Document99 pagesTechnical FF PRT C 20181016 1715231AayeshaNo ratings yet

- Progress Piping CLDocument64 pagesProgress Piping CLAnggi Sepha PraditaNo ratings yet

- F5063a-K-003-00 NDT Procedure PDFDocument11 pagesF5063a-K-003-00 NDT Procedure PDFJatmika Budi SantosaNo ratings yet

- V-2158-103-A-851 - 4 ITP For PumpDocument4 pagesV-2158-103-A-851 - 4 ITP For PumpMessaoud GoutasNo ratings yet

- Ultrasonic Examination Procedure (Issue 2)Document14 pagesUltrasonic Examination Procedure (Issue 2)Li Liu100% (1)

- 6 44 0005 A2Document25 pages6 44 0005 A2S.selvakumarNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Document14 pagesExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- Bill of Material Piping: Linde EngineeringDocument2 pagesBill of Material Piping: Linde EngineeringKreshna Wisnu BrataNo ratings yet

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- Material Selection FBE Pipeline PDFDocument2 pagesMaterial Selection FBE Pipeline PDFJosua100% (2)

- BES-L007 Pig LaunchersReceiversDocument13 pagesBES-L007 Pig LaunchersReceiversRakesh PanchalNo ratings yet

- Gail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFDocument612 pagesGail Tender - Volume-Ii-Sow (A) - Pipeline - 20181208 - 122802 PDFChirag ShahNo ratings yet

- API 5L 45-th Edition: Item No SawlDocument6 pagesAPI 5L 45-th Edition: Item No SawlRob WillestoneNo ratings yet

- Weld Map of Well 32 FLDocument13 pagesWeld Map of Well 32 FLArfanAliNo ratings yet

- EIL - Specification Sheet123Document1 pageEIL - Specification Sheet123Dinesh ChouguleNo ratings yet

- ELT-01-EP-TS-0006 - Specification For Inspection and Test of Piping Material - R1Document28 pagesELT-01-EP-TS-0006 - Specification For Inspection and Test of Piping Material - R1jorgekarlosprNo ratings yet

- COPI - Welding Spec For Flowlines To API 1104-1999Document12 pagesCOPI - Welding Spec For Flowlines To API 1104-1999AdvisNo ratings yet

- Material Requisition For Flexible Hose - Rev0Document5 pagesMaterial Requisition For Flexible Hose - Rev0altipatlarNo ratings yet

- 7 2itpDocument2 pages7 2itpbalakrishnanmuruganNo ratings yet

- Annexure 4 - Indicative Inspection Test PlanDocument2 pagesAnnexure 4 - Indicative Inspection Test PlanClaudio PataniaNo ratings yet

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- INDSDV009-5 - Rev 1-Saddle-5 PDFDocument1 pageINDSDV009-5 - Rev 1-Saddle-5 PDFAshish DhokNo ratings yet

- SA 20 Table A2.15 (Impact Test Temp) PDFDocument1 pageSA 20 Table A2.15 (Impact Test Temp) PDFAshish DhokNo ratings yet

- Blind Flange With Multiplpe Opening (U Stamp) )Document12 pagesBlind Flange With Multiplpe Opening (U Stamp) )Ashish Dhok0% (1)

- Dot 192 Full StandardDocument133 pagesDot 192 Full StandardWilmer EgeaNo ratings yet

- Final Year ProjectnewDocument42 pagesFinal Year ProjectnewkowshikdhevNo ratings yet

- Screenshot 2019-11-23 at 9.02.36 PM PDFDocument64 pagesScreenshot 2019-11-23 at 9.02.36 PM PDFSrisaila VidadalaNo ratings yet

- 3/2 Directional ValveDocument9 pages3/2 Directional ValveMohan ArumugavallalNo ratings yet

- Hygienic DesignDocument18 pagesHygienic DesignSarah Perez100% (1)

- Operating and Installation Instructions: Pressure Reducing Station Ari-Presys (Type PRS)Document13 pagesOperating and Installation Instructions: Pressure Reducing Station Ari-Presys (Type PRS)behnam fallahNo ratings yet

- Catalogo Generale Marston PDFDocument40 pagesCatalogo Generale Marston PDFANo ratings yet

- Van bi inox lắp bích điều khiển khí nénDocument1 pageVan bi inox lắp bích điều khiển khí nénAutoma Viet NamNo ratings yet

- Cryogenic ValvesDocument36 pagesCryogenic ValvesZakky Ibnu FadjrieNo ratings yet

- Alfa AdapterDocument204 pagesAlfa AdapterRudi Arief St Majoindo100% (1)

- ISA-67.01.01-2002 (R2007) - Transducer and Transmitter Installation For Nuclear Safety ApplicationsDocument26 pagesISA-67.01.01-2002 (R2007) - Transducer and Transmitter Installation For Nuclear Safety Applicationslionking1No ratings yet

- Valve Range SupplierDocument8 pagesValve Range Suppliercuongnv_19No ratings yet

- Inground Pool GuideDocument59 pagesInground Pool GuidetimNo ratings yet

- STRAUB TM 072019 en LQ CPDocument128 pagesSTRAUB TM 072019 en LQ CPJoaoNo ratings yet

- Ingersoll Rand 185Document143 pagesIngersoll Rand 185guata1013100% (1)

- Issued For Construction: Pipe Class Ms-11Document4 pagesIssued For Construction: Pipe Class Ms-11Yapo Freddy50% (2)

- A1 APiping ClassDocument3 pagesA1 APiping ClassBarwin CruzNo ratings yet

- Flender - Gear MotorDocument42 pagesFlender - Gear Motorikuzma_10% (1)

- Flange Leakage WebinarDocument89 pagesFlange Leakage WebinarAdekimi Emmanuel100% (3)

- Valve MaintenanceDocument6 pagesValve Maintenancemoorthymech1979No ratings yet

- Clampco CatalogueDocument39 pagesClampco CatalogueMisaghNo ratings yet

- Eriks Quote For B011E00255-SP-VLV-000-0004 REV C Boiler Water and Steam ...Document11 pagesEriks Quote For B011E00255-SP-VLV-000-0004 REV C Boiler Water and Steam ...Pinak ProjectsNo ratings yet

- Min Spacing in Between Pipes On PiperackDocument5 pagesMin Spacing in Between Pipes On PiperackAbhishek SharmaNo ratings yet

- TIMAS-PR-PI-002 - Installation Procedure For Pipe SupportDocument14 pagesTIMAS-PR-PI-002 - Installation Procedure For Pipe SupportMechanical Static WRKNo ratings yet

- Comparison ASME KTADocument7 pagesComparison ASME KTAAndres_Pastor1987No ratings yet

- Zirconia AnalyzerDocument60 pagesZirconia AnalyzeraudithiraNo ratings yet