Professional Documents

Culture Documents

Fused Zirconia Alumina ZA25

Fused Zirconia Alumina ZA25

Uploaded by

Zai Jsc0 ratings0% found this document useful (0 votes)

13 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views1 pageFused Zirconia Alumina ZA25

Fused Zirconia Alumina ZA25

Uploaded by

Zai JscCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Fused Zirconia Alumina (ZA25)

Fused Zirconia Alumina is an electro-fused alumina-zirconia grain, produced by fusing

alumina and zirconia raw material in electric arc furnaces, and then by quenching,

crushing and sieving.

ZA25 is a hard and tough raw material, which has compact structure, high hardness and

toughness, good grinding performance.

Chemical Composition:

ZrO2 Al2O3 SiO2 Fe2O3 TiO2 CaO

23-25% 72-78% ≤1.0% ≤0.5% ≤0.80% ≤0.15%

Grits Available:

F4 to F220, 20/40mesh, 30/60mesh.

In accordance with the current GB / FEPA / JIS / ANSI sieve standards.

Application:

It is mainly used for producing high pressure grinding wheels as well as abrasive belts, and

sandblasting. Due to it can quickly soften the metal strength without letting the metal get

burned, it has very good grinding effect on steel, cast iron, nickel alloys, titanium alloys,

aluminum alloys and tungsten alloys.

For sandblasting, the most common application is in pressure blasting of very hard

surfaces...like granite.

You might also like

- Metallurgy and Machinability PDFDocument34 pagesMetallurgy and Machinability PDFromanosky11No ratings yet

- A Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesFrom EverandA Complete Guide to Watch Repair - Barrels, Fuses, Mainsprings, Balance Springs, Pivots, Depths, Train Wheels and Common Stoppages of WatchesRating: 4 out of 5 stars4/5 (1)

- 3 Engineering Materials Non Ferrous MaterialsDocument28 pages3 Engineering Materials Non Ferrous Materialsg googleNo ratings yet

- MetalsDocument3 pagesMetalsvaleidshafikNo ratings yet

- LM25 Aluminium Casting Alloy (Al - Si7Mg) : Chemical CompositionDocument3 pagesLM25 Aluminium Casting Alloy (Al - Si7Mg) : Chemical Compositiondaniel_sasikumarNo ratings yet

- 20Mn2, GB T 3077-1999 20Mn2 Steel, 20Mn2 Stainless SteelDocument2 pages20Mn2, GB T 3077-1999 20Mn2 Steel, 20Mn2 Stainless Steeltiele_barcelosNo ratings yet

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNo ratings yet

- CUMI Emd CatalogDocument6 pagesCUMI Emd CatalogKARTHIGEYAN.RNo ratings yet

- Aluminum Alloy Specification'Document12 pagesAluminum Alloy Specification'ArjunNo ratings yet

- Note 3Document9 pagesNote 3Dr. Aung Ko LattNo ratings yet

- Literature ReviewDocument5 pagesLiterature ReviewAbdul hafeez Taha mehkariNo ratings yet

- Material2016 II CeramicsDocument4 pagesMaterial2016 II CeramicsMohamed Abo ElyazeedNo ratings yet

- LM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical CompositionDocument3 pagesLM25 Aluminium Casting Alloy (Al Ð Si7Mg) : Chemical Compositionsankar4582No ratings yet

- Non Ferrous Metal MachiningDocument1 pageNon Ferrous Metal MachiningAmit KarmakarNo ratings yet

- LM29Document6 pagesLM29Thangapandian NNo ratings yet

- Cast IronDocument9 pagesCast Ironedward biwottNo ratings yet

- Copper AlloysDocument39 pagesCopper Alloys1209540046No ratings yet

- 2 Grade InformationDocument17 pages2 Grade InformationAndres Alejandro RoblesNo ratings yet

- Aluminum 5052Document2 pagesAluminum 5052Praveen ThomasNo ratings yet

- No Ferrous MetalDocument27 pagesNo Ferrous MetalDripto MaityNo ratings yet

- Engg - Materials - Effect of Alloying ElementDocument22 pagesEngg - Materials - Effect of Alloying ElementSmruthi SuvarnaNo ratings yet

- Bolts - ASTM F3125Document4 pagesBolts - ASTM F3125rahuljoagNo ratings yet

- Die Casting AlloysDocument75 pagesDie Casting AlloysYuvaraj YuvarajNo ratings yet

- Metallographic Preparation of Aluminum and Aluminum AlloysDocument6 pagesMetallographic Preparation of Aluminum and Aluminum AlloysCayqueCasaleNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Types of Cast IronDocument7 pagesTypes of Cast IronEddy VëraNo ratings yet

- 3 2020 05 18!05 54 36 PM PDFDocument9 pages3 2020 05 18!05 54 36 PM PDFtuqaNo ratings yet

- Manganese Steel: Hard, Abrasive and Unique Are Some of The Qualities Our Manganese Steel Can Be, What Do You Need?Document3 pagesManganese Steel: Hard, Abrasive and Unique Are Some of The Qualities Our Manganese Steel Can Be, What Do You Need?hhNo ratings yet

- What Are Nonferrous Metals?: AdvantagesDocument29 pagesWhat Are Nonferrous Metals?: AdvantagesHunter On HighwayNo ratings yet

- Engineering Alloys (Non Ferrous)Document52 pagesEngineering Alloys (Non Ferrous)Sukhwinder Singh GillNo ratings yet

- Corrosion of Titanium July2014Document3 pagesCorrosion of Titanium July2014marekol227No ratings yet

- Machining Titanium AlloysDocument22 pagesMachining Titanium AlloysSarswati SuryawanshiNo ratings yet

- Steel: Stones Bricks Cement ConcreteDocument46 pagesSteel: Stones Bricks Cement ConcreteKaushik RNo ratings yet

- Bonded Abrasives CataloguesDocument10 pagesBonded Abrasives CataloguesValeriia HnutovaNo ratings yet

- Ceramics NotesDocument35 pagesCeramics NotesAditya MahajanNo ratings yet

- Chapter 2 Cast IronDocument9 pagesChapter 2 Cast IronHelen AdugnaNo ratings yet

- Screenshot 2022-12-31 at 7.45.47 PM PDFDocument73 pagesScreenshot 2022-12-31 at 7.45.47 PM PDFHardi HedayatNo ratings yet

- 7 Steel and Steel AlloysDocument3 pages7 Steel and Steel AlloysKent Clark VillaNo ratings yet

- Automotive MaterialsDocument45 pagesAutomotive MaterialsVinoth MalaikaniNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- MetalsDocument18 pagesMetalsJohnNo ratings yet

- D-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldDocument42 pagesD-Met 04 Welding of Stainless Steels, CI and Dissimilar WeldTrepend Simplifying BusinessNo ratings yet

- Aluminium AnodisingDocument7 pagesAluminium AnodisingChinmay Bhuta100% (1)

- Alloy 20 (UNS N08020)Document2 pagesAlloy 20 (UNS N08020)Pravin PawarNo ratings yet

- Aluminium Titanate: Chemical FormulaDocument6 pagesAluminium Titanate: Chemical FormulaaadhanNo ratings yet

- Brwon Aluminum Oxide-AbrasiveDocument1 pageBrwon Aluminum Oxide-AbrasiveZai JscNo ratings yet

- Prepared By: Pallav Radia Asst Prof. Aits, RajkotDocument33 pagesPrepared By: Pallav Radia Asst Prof. Aits, Rajkotnaseema shaikNo ratings yet

- Home About News Contact: Bebon Steel Carbon andDocument2 pagesHome About News Contact: Bebon Steel Carbon andahmetNo ratings yet

- AAMRADocument50 pagesAAMRARona Khairol Pratama100% (1)

- Cast Iron ComposiotionDocument34 pagesCast Iron ComposiotionMubash AbdNo ratings yet

- Cast IronDocument21 pagesCast Irondellibabu509No ratings yet

- Chart of ASTM Iron Alloys Penticton FoundryDocument2 pagesChart of ASTM Iron Alloys Penticton FoundrySaeid MirNo ratings yet

- Carbon Steel SpecificationDocument4 pagesCarbon Steel SpecificationSteinol SolutionsNo ratings yet

- Sand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityDocument13 pagesSand Casting: Low Cost Tooling Largest Casting Sizes Achievable Very Low Gas Porosity General VersatilityEmba MadrasNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Unstacking PressDocument2 pagesUnstacking PressZai JscNo ratings yet

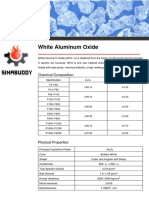

- White Aluminum Oxide-AbrasivesDocument2 pagesWhite Aluminum Oxide-AbrasivesZai JscNo ratings yet

- Brwon Aluminum Oxide-AbrasiveDocument1 pageBrwon Aluminum Oxide-AbrasiveZai JscNo ratings yet

- Black Silicon Carbide-AbrasiveDocument2 pagesBlack Silicon Carbide-AbrasiveZai JscNo ratings yet

- 2020 Inter Abrasiv Flap Disc PricesDocument1 page2020 Inter Abrasiv Flap Disc PricesZai JscNo ratings yet

- ZAI AD - Berkovitza, Bulgaria: World Class Quality Manufactured in BulgariaDocument7 pagesZAI AD - Berkovitza, Bulgaria: World Class Quality Manufactured in BulgariaZai JscNo ratings yet

- Black/death/doom Metal and Dungeon Synth/dark Ambient/similar Projects Demos, Lives & O.O.P. Items - Generally Tape Rips Hail SatanDocument1 pageBlack/death/doom Metal and Dungeon Synth/dark Ambient/similar Projects Demos, Lives & O.O.P. Items - Generally Tape Rips Hail SatanZai JscNo ratings yet