Professional Documents

Culture Documents

White Aluminum Oxide-Abrasives

White Aluminum Oxide-Abrasives

Uploaded by

Zai JscOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

White Aluminum Oxide-Abrasives

White Aluminum Oxide-Abrasives

Uploaded by

Zai JscCopyright:

Available Formats

White Aluminum Oxide

White Aluminum Oxide (WFA / A) is obtained from the fusion of high purity alumina powder

in electric arc furnaces. WFA is one raw material characterized with high hardness, yet

friable with high purity, chemical stability, a high melting point, and large crystal size.

Chemical Composition:

Specification Al2O3 Na2O

F4~F80

≥99.10 ≤0.35

P12~P80

F90~F150

≥99.10 ≤0.40

P100~P150

F180~F220

≥98.60 ≤0.50

P180~P220

F230~F800

≥98.30 ≤0.60

P240~P800

F1000~F1200

≥98.10 ≤0.70

P1000~P1200

P1500~P2500 ≥97.50 ≤0.90

Physical Properties:

Principal Crystalline Phase α-Al2O3

Color Brilliant White

Shape Cubic and Angular and Sharp

Crystal size 600μm ~1400μm

True Specific Gravity ≥3.9 g/cm³

Bulk Density 1.5~1.95 g/cm³

Knoop Hardness 2200~2300 kg/mm2

Mohs hardness ≥9.00

Refractoriness ≥1850℃ min

Grits Available:

F4~F220, F230~F1200, P12~P220, P240~P2500, JIS240~JIS4000.

In accordance with the current GB / FEPA / JIS / ANSI sieve standards.

Application:

White Aluminum Oxide is used in many applications such as Bonded abrasives (grinding

and cutting off wheels, cutting discs, mounted points), Coated abrasives (sandpaper,sand

cloth and sand belts), surface treatment, blasting media, laminate flooring, coatings,

lapping and polishing, investment casting shells, etc.

You might also like

- Airblast Abrasives: Brown Fused AluminaDocument2 pagesAirblast Abrasives: Brown Fused Aluminamekhman mekhtyNo ratings yet

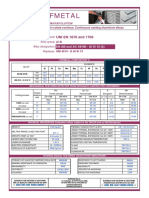

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Amandeep SinghNo ratings yet

- High Tensile Steel 4140Document2 pagesHigh Tensile Steel 4140Lazzarus Az GunawanNo ratings yet

- Tds Yieh 6082 Profile SheetDocument6 pagesTds Yieh 6082 Profile SheetRonnalyn TorresNo ratings yet

- BS en 1706 - En44100 PDFDocument2 pagesBS en 1706 - En44100 PDFDhamodaran RNo ratings yet

- En 44100Document2 pagesEn 44100hiren_mistry55No ratings yet

- TDS YIEH 6082 PlateDocument4 pagesTDS YIEH 6082 PlateSatendra ThakurNo ratings yet

- Tds Yieh 5052 Plate SheeetsDocument4 pagesTds Yieh 5052 Plate SheeetsRonnalyn TorresNo ratings yet

- Brwon Aluminum Oxide-AbrasiveDocument1 pageBrwon Aluminum Oxide-AbrasiveZai JscNo ratings yet

- Das TDS - Ma PDSDocument2 pagesDas TDS - Ma PDSIMRAN KHANNo ratings yet

- Chapter 05Document7 pagesChapter 05PARIXIT MAJHINo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- 1045-Bright-Carbon-Steel-Bar (Les Différentes Traitements Thermiques, Recuit de Normalisation)Document3 pages1045-Bright-Carbon-Steel-Bar (Les Différentes Traitements Thermiques, Recuit de Normalisation)Mouna KallelNo ratings yet

- Dental Castin ResinDocument3 pagesDental Castin ResinBernardo LopezNo ratings yet

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- 1022 Carbon Steel Bar PDFDocument3 pages1022 Carbon Steel Bar PDFjeyakumarNo ratings yet

- En1.7225 42CrMo4Document1 pageEn1.7225 42CrMo4Ahmed El-sheshtawyNo ratings yet

- Material Specification Special Alloys and CopperDocument6 pagesMaterial Specification Special Alloys and CopperOscar SchmüthNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Martin DuarteNo ratings yet

- Abrasive Grit Summary Tables (Stones and Scotchpads)Document3 pagesAbrasive Grit Summary Tables (Stones and Scotchpads)endgameNo ratings yet

- Inspection DetailsDocument11 pagesInspection DetailsBiswajeet Kumar Routh100% (1)

- EN47100Document2 pagesEN47100tsonjayaNo ratings yet

- Ceramic Fibre Boards: AvailabilityDocument2 pagesCeramic Fibre Boards: AvailabilitysmrndrdasNo ratings yet

- Filite ProductOverview - StandardRangeDocument1 pageFilite ProductOverview - StandardRangekokotampanNo ratings yet

- Oaisdokas 123123Document5 pagesOaisdokas 123123Justine Lloyd BautistaNo ratings yet

- Coa-Red Rock Garnet 30-60mesh - R1Document1 pageCoa-Red Rock Garnet 30-60mesh - R1goushbashaNo ratings yet

- Fine Ceramics PerformanceDocument1 pageFine Ceramics PerformanceArvin Jun PerezNo ratings yet

- History History History History: Production Production Production Production Process Process Process ProcessDocument19 pagesHistory History History History: Production Production Production Production Process Process Process ProcessKalyan HalderNo ratings yet

- HASLE Datasheet OverviewDocument2 pagesHASLE Datasheet OverviewkINGNo ratings yet

- Pricelist TokoDocument2 pagesPricelist Tokoadit_sandhiNo ratings yet

- 3 - High Temperature CorrosionDocument35 pages3 - High Temperature CorrosiondennykvgNo ratings yet

- General CapabilitiesDocument1 pageGeneral CapabilitiesBenito LópezNo ratings yet

- 6060 PropertiesDocument3 pages6060 Propertiesinterpon07No ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- Properties of Tungsten Carbide: 1328 Research Park Drive Dayton, Ohio 45432 USADocument1 pageProperties of Tungsten Carbide: 1328 Research Park Drive Dayton, Ohio 45432 USAArthur EmidioNo ratings yet

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFDocument2 pages304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalNo ratings yet

- 3M™ Diamond Grade™ Conspicuity Markings Series 983: Transportation Safety DivisionDocument7 pages3M™ Diamond Grade™ Conspicuity Markings Series 983: Transportation Safety DivisionNgân Hàng Ngô Mạnh TiếnNo ratings yet

- Blastrite Brown Aluminium Oxide - ALCABDocument1 pageBlastrite Brown Aluminium Oxide - ALCABYoutube For EducationNo ratings yet

- SilcoTek Coatings For High Purity ApplicationsDocument30 pagesSilcoTek Coatings For High Purity ApplicationsKommu RohithNo ratings yet

- Technical Data of Vacuum Formed Ceramic Fiber PDFDocument2 pagesTechnical Data of Vacuum Formed Ceramic Fiber PDFba ajinNo ratings yet

- Technical Data of Vacuum Formed Ceramic FiberDocument2 pagesTechnical Data of Vacuum Formed Ceramic Fiberba ajinNo ratings yet

- Technical Data of Vacuum Formed Ceramic FiberDocument2 pagesTechnical Data of Vacuum Formed Ceramic FiberAjin SNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- z3T - Dental Cobalt Chrome Alloy (EOS CC SP2)Document1 pagez3T - Dental Cobalt Chrome Alloy (EOS CC SP2)martinm3tNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Hareth MRAIDINo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document1 pageRaffmetal: UNI EN 1676 and 1706swaroop NalamNo ratings yet

- Ultrasonic Wall Thickness Gauge Measurement: All Velocities Are ApproximationsDocument6 pagesUltrasonic Wall Thickness Gauge Measurement: All Velocities Are ApproximationsAvijit DebnathNo ratings yet

- Interpon D1036 LSA Cool CoatingsDocument3 pagesInterpon D1036 LSA Cool Coatings120120120120No ratings yet

- Brief Introduction of UHMWPEDocument3 pagesBrief Introduction of UHMWPEFatima NusserNo ratings yet

- Aluminium Bronze To Bs 1400: Ab1Document1 pageAluminium Bronze To Bs 1400: Ab1Fred Duarte CaldeiraNo ratings yet

- Kronos Metal A.Ş. Beyaz Alüminyum Oksit TDSDocument3 pagesKronos Metal A.Ş. Beyaz Alüminyum Oksit TDSÖzcan YarliganNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- Sensing Fiber 1 & 2Document2 pagesSensing Fiber 1 & 2Zulfikri ShamsudinNo ratings yet

- Refractories Technical Specification For BricksDocument3 pagesRefractories Technical Specification For BricksJCSNo ratings yet

- Aluminium Bronze To Bs 1400: Ab2Document1 pageAluminium Bronze To Bs 1400: Ab2Sharad KokateNo ratings yet

- AR Plate Specification JXNG2051-2010Document2 pagesAR Plate Specification JXNG2051-2010mohammad zareiNo ratings yet

- X2CrNiN23 4 1.4362 2304 ENGDocument1 pageX2CrNiN23 4 1.4362 2304 ENGShariq KhanNo ratings yet

- Unstacking PressDocument2 pagesUnstacking PressZai JscNo ratings yet

- Fused Zirconia Alumina ZA25Document1 pageFused Zirconia Alumina ZA25Zai JscNo ratings yet

- Brwon Aluminum Oxide-AbrasiveDocument1 pageBrwon Aluminum Oxide-AbrasiveZai JscNo ratings yet

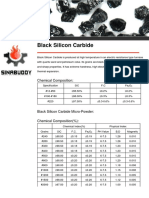

- Black Silicon Carbide-AbrasiveDocument2 pagesBlack Silicon Carbide-AbrasiveZai JscNo ratings yet

- 2020 Inter Abrasiv Flap Disc PricesDocument1 page2020 Inter Abrasiv Flap Disc PricesZai JscNo ratings yet

- ZAI AD - Berkovitza, Bulgaria: World Class Quality Manufactured in BulgariaDocument7 pagesZAI AD - Berkovitza, Bulgaria: World Class Quality Manufactured in BulgariaZai JscNo ratings yet

- Black/death/doom Metal and Dungeon Synth/dark Ambient/similar Projects Demos, Lives & O.O.P. Items - Generally Tape Rips Hail SatanDocument1 pageBlack/death/doom Metal and Dungeon Synth/dark Ambient/similar Projects Demos, Lives & O.O.P. Items - Generally Tape Rips Hail SatanZai JscNo ratings yet