Professional Documents

Culture Documents

LASIQ Ceramic Data Sheet

LASIQ Ceramic Data Sheet

Uploaded by

Christos LeptokaridisCopyright:

Available Formats

You might also like

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- LASIQ Porcelain Data SheetDocument2 pagesLASIQ Porcelain Data SheetChristos LeptokaridisNo ratings yet

- Sikaceram®-117 Qa: Product Data SheetDocument3 pagesSikaceram®-117 Qa: Product Data SheetM. KumaranNo ratings yet

- LASIQ EASY10 Data SheetDocument2 pagesLASIQ EASY10 Data SheetChristos LeptokaridisNo ratings yet

- Sikaceram - 116 StandardDocument3 pagesSikaceram - 116 StandardMash-out VivA (www.VivA.com)No ratings yet

- Sikaceram®-118: Product Data SheetDocument3 pagesSikaceram®-118: Product Data SheetdipinnediyaparambathNo ratings yet

- Premix Skim Coat: High Quality Cementitious RenderingDocument2 pagesPremix Skim Coat: High Quality Cementitious RenderingHaytham KhairyNo ratings yet

- Akenova Rocket 200 TMB enDocument3 pagesAkenova Rocket 200 TMB enalice.l.victorNo ratings yet

- sikarep.pdf#_~_text=SikaRep® is a one component, cement based, multi-purpose,and repair mortar, incorporating the use of micro-fibres.Document3 pagessikarep.pdf#_~_text=SikaRep® is a one component, cement based, multi-purpose,and repair mortar, incorporating the use of micro-fibres.Abbas ElouzeirNo ratings yet

- 14 - TDS - Concresive 2020Document2 pages14 - TDS - Concresive 2020aahtagoNo ratings yet

- Pds Sikaceram 4Document4 pagesPds Sikaceram 4mertelululalalolo23No ratings yet

- X-Tile CTADocument2 pagesX-Tile CTABernardo GarciaNo ratings yet

- RCT-ConTile BondDocument2 pagesRCT-ConTile BondfahadNo ratings yet

- Sikaceram - 88Document3 pagesSikaceram - 88sensor_versionNo ratings yet

- Sika® Concrete Crack Fix: Product Data SheetDocument3 pagesSika® Concrete Crack Fix: Product Data SheetHamidreza AraghianNo ratings yet

- TALYEES-G100 Data SheetDocument3 pagesTALYEES-G100 Data SheetChristos LeptokaridisNo ratings yet

- Hydroblocker Superelastic: Liquid MembraneDocument2 pagesHydroblocker Superelastic: Liquid MembraneSemir SpahicNo ratings yet

- TDS Weberfloor 620 PMB PlusDocument3 pagesTDS Weberfloor 620 PMB PlusBurak AkyazıNo ratings yet

- Dry 135 WR: Silane/Siloxane Water Based Surface Water RepellentDocument2 pagesDry 135 WR: Silane/Siloxane Water Based Surface Water RepellentInsafians PowerNo ratings yet

- Sikaceram - 255Document3 pagesSikaceram - 255Puneet PagariaNo ratings yet

- Ceralastic: Elastomeric Waterproof CoatingDocument2 pagesCeralastic: Elastomeric Waterproof Coatingharish GiriNo ratings yet

- Cerabond 27: High Performance Polymer Based Tile AdhesiveDocument2 pagesCerabond 27: High Performance Polymer Based Tile AdhesiveBharat KoraleNo ratings yet

- Cerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationDocument2 pagesCerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationBharat KoraleNo ratings yet

- Coarse Putty TDSDocument3 pagesCoarse Putty TDSZafarNo ratings yet

- MAJOON WRF Data SheetDocument2 pagesMAJOON WRF Data SheetChristos LeptokaridisNo ratings yet

- Rheomix 125: Binder 5Document3 pagesRheomix 125: Binder 5Raven James Angelo IgnacioNo ratings yet

- TDS - GypEX Silver PlasterDocument4 pagesTDS - GypEX Silver Plastersuyog kattelNo ratings yet

- Weber - Tec MC1Document2 pagesWeber - Tec MC1rangarajan1989No ratings yet

- Advatile Adhesive TDSDocument2 pagesAdvatile Adhesive TDSMohammed AbugharbiehNo ratings yet

- Sika PDS E SikaCeram - 191Document3 pagesSika PDS E SikaCeram - 191lwin_oo2435No ratings yet

- Sikaceram®-200 Ta Tilefix: Product Data SheetDocument3 pagesSikaceram®-200 Ta Tilefix: Product Data SheetYulis TanNo ratings yet

- Webercol MaxDocument2 pagesWebercol Maxajee doNo ratings yet

- Tds - Tile Adhesive 711v1910Document2 pagesTds - Tile Adhesive 711v1910Susana KhoNo ratings yet

- Boscolastic TDSDocument2 pagesBoscolastic TDSSasi KumarNo ratings yet

- Weberfloor Rapid TDSDocument3 pagesWeberfloor Rapid TDSIbrahim EzzatNo ratings yet

- ResiGard TAS 2022-08-18 06 - 13 - 14Document3 pagesResiGard TAS 2022-08-18 06 - 13 - 14Sridhar RajajiNo ratings yet

- Bostik Boscolastic Rev1Document2 pagesBostik Boscolastic Rev1decenabuilders2016No ratings yet

- MAJOON WRB Data SheetDocument2 pagesMAJOON WRB Data SheetChristos LeptokaridisNo ratings yet

- Full Submittal Cembond 100Document41 pagesFull Submittal Cembond 100mo khNo ratings yet

- RCT-ConTile Bond SDocument2 pagesRCT-ConTile Bond SfahadNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Recebond HD: Product Data SheetDocument2 pagesRecebond HD: Product Data SheetAmira RamleeNo ratings yet

- TDS Weberdry RoofDocument2 pagesTDS Weberdry RoofMahendra Singh BudhathokiNo ratings yet

- Maxiseal Plus: Features / BenefitsDocument3 pagesMaxiseal Plus: Features / Benefitsannayya.chandrashekar Civil EngineerNo ratings yet

- Dry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRDocument2 pagesDry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRADEE666No ratings yet

- Sikawall 100 IqskimDocument3 pagesSikawall 100 Iqskimsabamajed564No ratings yet

- Basf Masterprotect 2020Document2 pagesBasf Masterprotect 2020SHAIK ASIMUDDIN100% (1)

- Sikalatex SuperDocument3 pagesSikalatex SuperAkash ChardeNo ratings yet

- Granite Polymer c2 - TdsDocument1 pageGranite Polymer c2 - TdsryanNo ratings yet

- Vetonit PlasterMix-S PLS222Document2 pagesVetonit PlasterMix-S PLS222toni mujiyonoNo ratings yet

- Pds Sikaceram flx23Document5 pagesPds Sikaceram flx23mertelululalalolo23No ratings yet

- Rheomix 131: Page 1 of 2Document2 pagesRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- Acrylic WaterProofing Liquide TDSDocument3 pagesAcrylic WaterProofing Liquide TDSMohamed MagdiNo ratings yet

- Fairmate Waterproofing - PunjabDocument128 pagesFairmate Waterproofing - PunjabAyush GoyalNo ratings yet

- Sikagard - 62: Solvent Free Epoxy CoatingDocument5 pagesSikagard - 62: Solvent Free Epoxy CoatingLance Zhengling YinNo ratings yet

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoNo ratings yet

- Alccofast (CE)Document2 pagesAlccofast (CE)Siddhesh Kamat MhamaiNo ratings yet

- Flowcoat: Pumacoat WDDocument2 pagesFlowcoat: Pumacoat WDDan George IonescuNo ratings yet

- TALYEES-G100 Data SheetDocument3 pagesTALYEES-G100 Data SheetChristos LeptokaridisNo ratings yet

- MOONA-N Data SheetDocument2 pagesMOONA-N Data SheetChristos LeptokaridisNo ratings yet

- LASIQ EASY10 Data SheetDocument2 pagesLASIQ EASY10 Data SheetChristos LeptokaridisNo ratings yet

- LASIQ Porcelain Data SheetDocument2 pagesLASIQ Porcelain Data SheetChristos LeptokaridisNo ratings yet

- MAJOON WRF Data SheetDocument2 pagesMAJOON WRF Data SheetChristos LeptokaridisNo ratings yet

- MAJOON WRB Data SheetDocument2 pagesMAJOON WRB Data SheetChristos LeptokaridisNo ratings yet

- Viscochape DUBAI NOV 2019Document58 pagesViscochape DUBAI NOV 2019Christos LeptokaridisNo ratings yet

- Zk150he Zyklos TD eDocument2 pagesZk150he Zyklos TD eChristos LeptokaridisNo ratings yet

- Basics of Uncertainty Analysis: ActivityDocument4 pagesBasics of Uncertainty Analysis: ActivityChristos LeptokaridisNo ratings yet

- Mci 2005Document3 pagesMci 2005Christos LeptokaridisNo ratings yet

- Talyees G100Document2 pagesTalyees G100Christos LeptokaridisNo ratings yet

- Technical Data Sheet For Slag Cement (GGBFS) : ASTM C989 - 2014Document2 pagesTechnical Data Sheet For Slag Cement (GGBFS) : ASTM C989 - 2014Christos LeptokaridisNo ratings yet

- Work OrdersDocument81 pagesWork OrdersEllie CapinaNo ratings yet

- Zakon o Bankama FBiHDocument15 pagesZakon o Bankama FBiHNihad MuhamedagicNo ratings yet

- Formulation of A Hybrid Nanofertilizer For Slow and Sustainable Release of MicronutrientsDocument7 pagesFormulation of A Hybrid Nanofertilizer For Slow and Sustainable Release of MicronutrientsJuan PabloNo ratings yet

- BS 5977-1 1981Document14 pagesBS 5977-1 1981saman2580100% (1)

- Adhesive TapeDocument38 pagesAdhesive Tape김성훈No ratings yet

- Talzat ZachariaDocument8 pagesTalzat ZachariaArun KumarNo ratings yet

- Tamilnadu 12th Chemistry Lesson 11 - One Marks: Choose The Correct AnswerDocument7 pagesTamilnadu 12th Chemistry Lesson 11 - One Marks: Choose The Correct AnswerM05059 Kaushik S XI ANo ratings yet

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- iNORGANIC Salt AnalysisDocument12 pagesiNORGANIC Salt AnalysisNishant KaushikNo ratings yet

- Ravenol VST Sae 5W-40Document3 pagesRavenol VST Sae 5W-40Cătălin SavaNo ratings yet

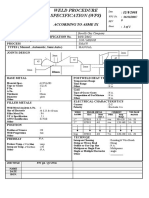

- Weld Procedure Specification (WPS) : According To Asme IxDocument1 pageWeld Procedure Specification (WPS) : According To Asme IxMina Roger Samy50% (2)

- Polimi Thesis GuideDocument15 pagesPolimi Thesis GuideMohanraj ShanmugamNo ratings yet

- Ar002 PDFDocument104 pagesAr002 PDFwaheed2286No ratings yet

- Zeolite MaterialsDocument8 pagesZeolite MaterialsDeepak MahaleNo ratings yet

- AWS90 Structural Nonlin Ch02 NonlinearDocument94 pagesAWS90 Structural Nonlin Ch02 NonlinearVictor SanchezNo ratings yet

- Specifications For Earthing & Lightning ProtectionDocument3 pagesSpecifications For Earthing & Lightning ProtectionVenu GopalNo ratings yet

- Band Theory of Solids: (Garcia Chapter 24)Document46 pagesBand Theory of Solids: (Garcia Chapter 24)hoangan_lyk12100% (1)

- LedDocument20 pagesLedYogesh YadavNo ratings yet

- Chapter 4 Environmental Risk Assessment and Emergency Response PlanDocument10 pagesChapter 4 Environmental Risk Assessment and Emergency Response Planangelo plumosNo ratings yet

- Seatwork 2Document1 pageSeatwork 2Gia Janella SemillaNo ratings yet

- Ductility of BitumenDocument4 pagesDuctility of BitumenArpita MulikNo ratings yet

- VGB PowerTech Magazine ArticleDocument7 pagesVGB PowerTech Magazine ArticlemacrespoNo ratings yet

- AHRI Standard 700-2015Document25 pagesAHRI Standard 700-2015Pete DechaNo ratings yet

- Determination of Velocity Seal AreaDocument4 pagesDetermination of Velocity Seal AreaNajem A. SakorNo ratings yet

- Chem 152 Number 3asdsdfgsfdgDocument16 pagesChem 152 Number 3asdsdfgsfdgjosh17% (18)

- Summary of Structural Calculation of 2-Barrel Box CulvertDocument51 pagesSummary of Structural Calculation of 2-Barrel Box CulvertPutri Lambok LubisNo ratings yet

- J Ijhydene 2018 09 039Document18 pagesJ Ijhydene 2018 09 039HARISHKOTHARU48No ratings yet

- Exercise No.1 Soil Sampling For Chemical and Physical AnalysesDocument22 pagesExercise No.1 Soil Sampling For Chemical and Physical AnalysesMark MatthewNo ratings yet

- Information About The Fire TriangleDocument5 pagesInformation About The Fire TriangleJey RhyNo ratings yet

- Article Faisal SalehDocument20 pagesArticle Faisal SalehMohamed BelmokaddemNo ratings yet

LASIQ Ceramic Data Sheet

LASIQ Ceramic Data Sheet

Uploaded by

Christos LeptokaridisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LASIQ Ceramic Data Sheet

LASIQ Ceramic Data Sheet

Uploaded by

Christos LeptokaridisCopyright:

Available Formats

الصق بالط مسبق الخلط

Premixed Tile Adhesive

CERAMIC Ceramic Tiles Adhesive

Product Description Technical Data1

LASIQ-CERAMIC is a preblended cement-based polymer Appearance White/ gray powder

modified tile adhesive which can be used for fixing all types

of ceramic tile, natural stone floor and wall tiles. Aggregate Size Up to 0.6 mm

LASIQ-CERAMIC is used for interior applications for the Wet Density 1.6 ± 0.1 kg/l

following purposes:

Open Time by Tensile ≥ 0.5 Mpa after 20 min

• For ceramic and natural stone floor tiles. Adhesion2

• For ceramic tiles applied on walls. Leveling minor

undulation on plastered and concrete surfaces. Pot life (at 25° C) ≥ 45 min

•Tiling on concrete surfaces, Plastered surfaces, blocks

and plasterboard. Initial Tensile Adhesion ≥ 0.7 N/mm2

• For wet and dry condition. Strength3

LASIQ-CERAMIC is composed of hydraulic binders, selected Slip Resistance4 ≤ 0.5 mm

aggregates, and high-performance additives to provide

superior workability and excellent adhesion. Flexural Strength5 ≥ 2.5 N/mm2

Features/Advantages EN 12004 Class C1T

• Pre-blended dry material that only requires the addition Approx 12 to 13 m2 per

of potable water at site. Coverage 50kg bag

• Factory-controlled ensuring high quality and assured

consistency. Packing 50kg paper bags

• Can be applied internally onto vertical and horizontal

surfaces. Shelf Life7 12 months

• Easy to apply with superior workability and extended

Application Thickness8 3 – 10 mm

open time.

• Suitable for internal ceramic and natural stone application.

• Suitable for dry conditions and wet condition (such as 1 The above technical data are generated under laboratory conditions, some

bathroom and kitchen). variations are expected due to weather, site, and application conditions

• Excellent adhesion and slip resistance. which are beyond the control of the manufacturer.

2 Open time by tensile adhesion as per EN 1346, EN 12004-2.

• In accordance with international specifications. 3 Initial Tensile Adhesion Strength at 28 days as per BS EN 1348, EN 12004-2.

4 Slip Resistance as per EN 1308, EN 12004-2.

5 Flexural Strength at 28 days (EN 1015-11).

Conformity with Standards 6 The figures of coverage mentioned above are based on 3 mm coat

thickness and are meant as a general guideline only. Actual coverage

LASIQ-CERAMIC conforms to the following standards: depends on application method, substrate type and nature, and material

wastage.

• EN 12004 • EN 105-12 •ASTM C150 • ASTM C109 7 Under dry shaded conditions and in its original unopened packing.

• ASTM C348 • ISO 13007 8 Depends on the type of the tile and the quality of the substrate.

920 000 209 info@saudireadymix.com www.saudireadymix.com © 2020 Saudi Readymix

Ceramic Tiles Adhesive |Ceramic

Application Instructions Precautions & Limitations

Surface Preparation Do not re-temper the mixed material. Do not apply LASIQ-

CERAMIC at an ambient temperature lower than 5 C.

Surfaces must be clean, sound, and free from oil, grease,

Do not mix LASIQ-CERAMIC with any other material not

curing compound or any other materials that may reduce

recommended by Saudi Readymix. Protect LASIQ-CERAMIC

the adhesion and the bonding of LASIQ-CERAMIC with

from direct sunlight, wind and rain during application. Clean

the substrate surface. Remove cement laitance, dust, and

the tools with water before product hardening. In case of

loosely adhering particles. Wet the entire surface with clean

hardening, tools should be cleaned mechanically. LASIQ-

portable water. Except for gypsum and cement boards,

CERAMIC is for internal use only.

surfaces should be in the condition of saturated surface dry

(SSD) condition prior of the application of LASIQ-CERAMIC.

Saudi Readymix has no responsibility for the defects due to

Mixing the improper or non-recommended use of the product. For

further information contact our technical department.

Add 50 kg of LASIQ-CERAMIC to 14 to 16 liters of clean

potable water (always add the material to water, not water Storage

to the material). Mix with low speed electric drill fitted with

Paper bags should be kept sealed, placed on wooden pallets

a suitable paddle until a uniform, lump-free consistency is

above ground level and covered by a waterproof tarpaulin.

achieved. Allow the material to stand for about five minutes

and remix the material again (without adding additional

water). Health & Safety

Since LASIQ-CERAMIC is a cement-based product so it is a

Application highly alkaline material. Care should be taken during the

use and storage of LASIQ-CERAMIC to avoid direct contact

Apply the mixed adhesive to the surface using a suitable

with eyes and skin. The use of protective gloves and goggles

notched trowel, use the straight edge of the trowel to spread

during application is recommended. Wash the skin with soap

the adhesive on the surface. Hold the trowel at about 45º

and water in case of contact. In case of contact with eye,

and move it several times, backward and forward until the

wash immediately with plenty amount of clean water and

adhesive bed is relatively even (do not apply the adhesive on

seek medical advice.

a larger surface than needed).

LASIQ-CERAMIC is a noncombustible material as per BS EN

Comb the tile adhesive with the notched edge of the trowel

13501-1 (Class A1).

(the trowel angled at about 45º).

Lay the tiles on the adhesive and set them into position, by

using a mallet (do not hit the tiles too hard). Ensure that at

least 75% of the tile surface has contact with the applied

material. Use spacers between the tiles, as to get consistent

joints.

Tile position can be adjusted if required within maximum 15

minutes of the application (variations are expected based on

the weather, application and substrate conditions).

Applied tiles should be remined undisturbed for at least 48

hours.

Legal Disclaimer:

The terms and conditions of Saudi Readymix legal disclaimer applies and are an integral part of this product data sheet. Please refer to the

legal disclaimer document for further information.

920 000 209 info@saudireadymix.com www.saudireadymix.com © 2020 Saudi Readymix

You might also like

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- LASIQ Porcelain Data SheetDocument2 pagesLASIQ Porcelain Data SheetChristos LeptokaridisNo ratings yet

- Sikaceram®-117 Qa: Product Data SheetDocument3 pagesSikaceram®-117 Qa: Product Data SheetM. KumaranNo ratings yet

- LASIQ EASY10 Data SheetDocument2 pagesLASIQ EASY10 Data SheetChristos LeptokaridisNo ratings yet

- Sikaceram - 116 StandardDocument3 pagesSikaceram - 116 StandardMash-out VivA (www.VivA.com)No ratings yet

- Sikaceram®-118: Product Data SheetDocument3 pagesSikaceram®-118: Product Data SheetdipinnediyaparambathNo ratings yet

- Premix Skim Coat: High Quality Cementitious RenderingDocument2 pagesPremix Skim Coat: High Quality Cementitious RenderingHaytham KhairyNo ratings yet

- Akenova Rocket 200 TMB enDocument3 pagesAkenova Rocket 200 TMB enalice.l.victorNo ratings yet

- sikarep.pdf#_~_text=SikaRep® is a one component, cement based, multi-purpose,and repair mortar, incorporating the use of micro-fibres.Document3 pagessikarep.pdf#_~_text=SikaRep® is a one component, cement based, multi-purpose,and repair mortar, incorporating the use of micro-fibres.Abbas ElouzeirNo ratings yet

- 14 - TDS - Concresive 2020Document2 pages14 - TDS - Concresive 2020aahtagoNo ratings yet

- Pds Sikaceram 4Document4 pagesPds Sikaceram 4mertelululalalolo23No ratings yet

- X-Tile CTADocument2 pagesX-Tile CTABernardo GarciaNo ratings yet

- RCT-ConTile BondDocument2 pagesRCT-ConTile BondfahadNo ratings yet

- Sikaceram - 88Document3 pagesSikaceram - 88sensor_versionNo ratings yet

- Sika® Concrete Crack Fix: Product Data SheetDocument3 pagesSika® Concrete Crack Fix: Product Data SheetHamidreza AraghianNo ratings yet

- TALYEES-G100 Data SheetDocument3 pagesTALYEES-G100 Data SheetChristos LeptokaridisNo ratings yet

- Hydroblocker Superelastic: Liquid MembraneDocument2 pagesHydroblocker Superelastic: Liquid MembraneSemir SpahicNo ratings yet

- TDS Weberfloor 620 PMB PlusDocument3 pagesTDS Weberfloor 620 PMB PlusBurak AkyazıNo ratings yet

- Dry 135 WR: Silane/Siloxane Water Based Surface Water RepellentDocument2 pagesDry 135 WR: Silane/Siloxane Water Based Surface Water RepellentInsafians PowerNo ratings yet

- Sikaceram - 255Document3 pagesSikaceram - 255Puneet PagariaNo ratings yet

- Ceralastic: Elastomeric Waterproof CoatingDocument2 pagesCeralastic: Elastomeric Waterproof Coatingharish GiriNo ratings yet

- Cerabond 27: High Performance Polymer Based Tile AdhesiveDocument2 pagesCerabond 27: High Performance Polymer Based Tile AdhesiveBharat KoraleNo ratings yet

- Cerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationDocument2 pagesCerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationBharat KoraleNo ratings yet

- Coarse Putty TDSDocument3 pagesCoarse Putty TDSZafarNo ratings yet

- MAJOON WRF Data SheetDocument2 pagesMAJOON WRF Data SheetChristos LeptokaridisNo ratings yet

- Rheomix 125: Binder 5Document3 pagesRheomix 125: Binder 5Raven James Angelo IgnacioNo ratings yet

- TDS - GypEX Silver PlasterDocument4 pagesTDS - GypEX Silver Plastersuyog kattelNo ratings yet

- Weber - Tec MC1Document2 pagesWeber - Tec MC1rangarajan1989No ratings yet

- Advatile Adhesive TDSDocument2 pagesAdvatile Adhesive TDSMohammed AbugharbiehNo ratings yet

- Sika PDS E SikaCeram - 191Document3 pagesSika PDS E SikaCeram - 191lwin_oo2435No ratings yet

- Sikaceram®-200 Ta Tilefix: Product Data SheetDocument3 pagesSikaceram®-200 Ta Tilefix: Product Data SheetYulis TanNo ratings yet

- Webercol MaxDocument2 pagesWebercol Maxajee doNo ratings yet

- Tds - Tile Adhesive 711v1910Document2 pagesTds - Tile Adhesive 711v1910Susana KhoNo ratings yet

- Boscolastic TDSDocument2 pagesBoscolastic TDSSasi KumarNo ratings yet

- Weberfloor Rapid TDSDocument3 pagesWeberfloor Rapid TDSIbrahim EzzatNo ratings yet

- ResiGard TAS 2022-08-18 06 - 13 - 14Document3 pagesResiGard TAS 2022-08-18 06 - 13 - 14Sridhar RajajiNo ratings yet

- Bostik Boscolastic Rev1Document2 pagesBostik Boscolastic Rev1decenabuilders2016No ratings yet

- MAJOON WRB Data SheetDocument2 pagesMAJOON WRB Data SheetChristos LeptokaridisNo ratings yet

- Full Submittal Cembond 100Document41 pagesFull Submittal Cembond 100mo khNo ratings yet

- RCT-ConTile Bond SDocument2 pagesRCT-ConTile Bond SfahadNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Recebond HD: Product Data SheetDocument2 pagesRecebond HD: Product Data SheetAmira RamleeNo ratings yet

- TDS Weberdry RoofDocument2 pagesTDS Weberdry RoofMahendra Singh BudhathokiNo ratings yet

- Maxiseal Plus: Features / BenefitsDocument3 pagesMaxiseal Plus: Features / Benefitsannayya.chandrashekar Civil EngineerNo ratings yet

- Dry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRDocument2 pagesDry RBV (UAE) : Rubberized Bitumen Emulsion Modified With SBRADEE666No ratings yet

- Sikawall 100 IqskimDocument3 pagesSikawall 100 Iqskimsabamajed564No ratings yet

- Basf Masterprotect 2020Document2 pagesBasf Masterprotect 2020SHAIK ASIMUDDIN100% (1)

- Sikalatex SuperDocument3 pagesSikalatex SuperAkash ChardeNo ratings yet

- Granite Polymer c2 - TdsDocument1 pageGranite Polymer c2 - TdsryanNo ratings yet

- Vetonit PlasterMix-S PLS222Document2 pagesVetonit PlasterMix-S PLS222toni mujiyonoNo ratings yet

- Pds Sikaceram flx23Document5 pagesPds Sikaceram flx23mertelululalalolo23No ratings yet

- Rheomix 131: Page 1 of 2Document2 pagesRheomix 131: Page 1 of 2Ankita Baban Gavade100% (1)

- Acrylic WaterProofing Liquide TDSDocument3 pagesAcrylic WaterProofing Liquide TDSMohamed MagdiNo ratings yet

- Fairmate Waterproofing - PunjabDocument128 pagesFairmate Waterproofing - PunjabAyush GoyalNo ratings yet

- Sikagard - 62: Solvent Free Epoxy CoatingDocument5 pagesSikagard - 62: Solvent Free Epoxy CoatingLance Zhengling YinNo ratings yet

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoNo ratings yet

- Alccofast (CE)Document2 pagesAlccofast (CE)Siddhesh Kamat MhamaiNo ratings yet

- Flowcoat: Pumacoat WDDocument2 pagesFlowcoat: Pumacoat WDDan George IonescuNo ratings yet

- TALYEES-G100 Data SheetDocument3 pagesTALYEES-G100 Data SheetChristos LeptokaridisNo ratings yet

- MOONA-N Data SheetDocument2 pagesMOONA-N Data SheetChristos LeptokaridisNo ratings yet

- LASIQ EASY10 Data SheetDocument2 pagesLASIQ EASY10 Data SheetChristos LeptokaridisNo ratings yet

- LASIQ Porcelain Data SheetDocument2 pagesLASIQ Porcelain Data SheetChristos LeptokaridisNo ratings yet

- MAJOON WRF Data SheetDocument2 pagesMAJOON WRF Data SheetChristos LeptokaridisNo ratings yet

- MAJOON WRB Data SheetDocument2 pagesMAJOON WRB Data SheetChristos LeptokaridisNo ratings yet

- Viscochape DUBAI NOV 2019Document58 pagesViscochape DUBAI NOV 2019Christos LeptokaridisNo ratings yet

- Zk150he Zyklos TD eDocument2 pagesZk150he Zyklos TD eChristos LeptokaridisNo ratings yet

- Basics of Uncertainty Analysis: ActivityDocument4 pagesBasics of Uncertainty Analysis: ActivityChristos LeptokaridisNo ratings yet

- Mci 2005Document3 pagesMci 2005Christos LeptokaridisNo ratings yet

- Talyees G100Document2 pagesTalyees G100Christos LeptokaridisNo ratings yet

- Technical Data Sheet For Slag Cement (GGBFS) : ASTM C989 - 2014Document2 pagesTechnical Data Sheet For Slag Cement (GGBFS) : ASTM C989 - 2014Christos LeptokaridisNo ratings yet

- Work OrdersDocument81 pagesWork OrdersEllie CapinaNo ratings yet

- Zakon o Bankama FBiHDocument15 pagesZakon o Bankama FBiHNihad MuhamedagicNo ratings yet

- Formulation of A Hybrid Nanofertilizer For Slow and Sustainable Release of MicronutrientsDocument7 pagesFormulation of A Hybrid Nanofertilizer For Slow and Sustainable Release of MicronutrientsJuan PabloNo ratings yet

- BS 5977-1 1981Document14 pagesBS 5977-1 1981saman2580100% (1)

- Adhesive TapeDocument38 pagesAdhesive Tape김성훈No ratings yet

- Talzat ZachariaDocument8 pagesTalzat ZachariaArun KumarNo ratings yet

- Tamilnadu 12th Chemistry Lesson 11 - One Marks: Choose The Correct AnswerDocument7 pagesTamilnadu 12th Chemistry Lesson 11 - One Marks: Choose The Correct AnswerM05059 Kaushik S XI ANo ratings yet

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- iNORGANIC Salt AnalysisDocument12 pagesiNORGANIC Salt AnalysisNishant KaushikNo ratings yet

- Ravenol VST Sae 5W-40Document3 pagesRavenol VST Sae 5W-40Cătălin SavaNo ratings yet

- Weld Procedure Specification (WPS) : According To Asme IxDocument1 pageWeld Procedure Specification (WPS) : According To Asme IxMina Roger Samy50% (2)

- Polimi Thesis GuideDocument15 pagesPolimi Thesis GuideMohanraj ShanmugamNo ratings yet

- Ar002 PDFDocument104 pagesAr002 PDFwaheed2286No ratings yet

- Zeolite MaterialsDocument8 pagesZeolite MaterialsDeepak MahaleNo ratings yet

- AWS90 Structural Nonlin Ch02 NonlinearDocument94 pagesAWS90 Structural Nonlin Ch02 NonlinearVictor SanchezNo ratings yet

- Specifications For Earthing & Lightning ProtectionDocument3 pagesSpecifications For Earthing & Lightning ProtectionVenu GopalNo ratings yet

- Band Theory of Solids: (Garcia Chapter 24)Document46 pagesBand Theory of Solids: (Garcia Chapter 24)hoangan_lyk12100% (1)

- LedDocument20 pagesLedYogesh YadavNo ratings yet

- Chapter 4 Environmental Risk Assessment and Emergency Response PlanDocument10 pagesChapter 4 Environmental Risk Assessment and Emergency Response Planangelo plumosNo ratings yet

- Seatwork 2Document1 pageSeatwork 2Gia Janella SemillaNo ratings yet

- Ductility of BitumenDocument4 pagesDuctility of BitumenArpita MulikNo ratings yet

- VGB PowerTech Magazine ArticleDocument7 pagesVGB PowerTech Magazine ArticlemacrespoNo ratings yet

- AHRI Standard 700-2015Document25 pagesAHRI Standard 700-2015Pete DechaNo ratings yet

- Determination of Velocity Seal AreaDocument4 pagesDetermination of Velocity Seal AreaNajem A. SakorNo ratings yet

- Chem 152 Number 3asdsdfgsfdgDocument16 pagesChem 152 Number 3asdsdfgsfdgjosh17% (18)

- Summary of Structural Calculation of 2-Barrel Box CulvertDocument51 pagesSummary of Structural Calculation of 2-Barrel Box CulvertPutri Lambok LubisNo ratings yet

- J Ijhydene 2018 09 039Document18 pagesJ Ijhydene 2018 09 039HARISHKOTHARU48No ratings yet

- Exercise No.1 Soil Sampling For Chemical and Physical AnalysesDocument22 pagesExercise No.1 Soil Sampling For Chemical and Physical AnalysesMark MatthewNo ratings yet

- Information About The Fire TriangleDocument5 pagesInformation About The Fire TriangleJey RhyNo ratings yet

- Article Faisal SalehDocument20 pagesArticle Faisal SalehMohamed BelmokaddemNo ratings yet