Professional Documents

Culture Documents

Sig VT

Sig VT

Uploaded by

carey stewartOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sig VT

Sig VT

Uploaded by

carey stewartCopyright:

Available Formats

SHARP IRON GROUP

Visual Welding Inspection Procedure

VT 1.0 Rev – 1, 3.4.2013

1.0 PURPOSE

The purpose of this procedure is to provide detailed instruction and requirements for the visual

inspection of welds, wrought materials, forgings, and components.

2.0 APPLICABILITY

This procedure is applicable to the visual weld inspection performed in accordance with the

American Society of Mechanical Engineers (ASME) Sections I, V, VIII, IX, B31.1, B31.3, and AWS D1.1,

but may be used with other codes, standards, and specifications if their acceptance criteria is

provided.

3.0 REFERENCES

3.1 Sharp Iron Groups “Nondestructive Testing Personnel, Training, Qualification, and Certification

Program, Written Practice.

3.2 ASME Boiler and Pressure Vessel Code, Sections I, V, VIII, IX, B31.1, and B31.3. Latest Editions

and Addenda.

3.3 AWS D1.1 Latest Edition

3.4 American Society for Nondestructive Testing, ASNT TC-1A – 2011 Edition.

3.5 American Welding Society, AWS QC1 Latest Edition, Standard and Guide for Qualification and

Certification of Welding Inspectors.

4.0 INSTRUCTIONS

4.1 Personnel Qualification

4.1.1 All Visual weld inspection personnel shall be trained, qualified, and certified in

accordance with Reference 3.1, 3.3, and/or 3.4. The Welding Inspector may be supported with

Assistant Inspectors, who may perform specific functions under the supervision of the Welding

Inspector.

Assistant Inspectors shall be qualified by training and experience to perform the specific

functions to which they are assigned. The work of the Assistant Inspector shall be regularly

monitored by the Welding Inspector, generally on a daily basis.

Page 2 of 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Lost Book Preserving Food NaturallyDocument46 pagesThe Lost Book Preserving Food Naturallycarey stewart80% (5)

- The Lost Book SuperfoodsDocument27 pagesThe Lost Book Superfoodscarey stewart89% (9)

- Updated Layered Welding Audit ChecklistDocument1 pageUpdated Layered Welding Audit Checklistcarey stewart100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Medicinal GardenDocument34 pagesMedicinal Gardencarey stewart100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Herbal DispensaryDocument47 pagesHerbal Dispensarycarey stewart100% (16)

- 2018 Welding Machine CalibrationsDocument47 pages2018 Welding Machine Calibrationscarey stewartNo ratings yet

- Welder QualificationsDocument19 pagesWelder Qualificationscarey stewartNo ratings yet

- WPS Table of ContentsDocument2 pagesWPS Table of Contentscarey stewartNo ratings yet

- Paint Inspection Report For Epiroc Tower FinalsDocument1 pagePaint Inspection Report For Epiroc Tower Finalscarey stewartNo ratings yet

- Hydrostatic Test Form For Low Pressure VesselsDocument1 pageHydrostatic Test Form For Low Pressure Vesselscarey stewartNo ratings yet

- Pressure Boundary Bolted Flange Joint AssemblyDocument1 pagePressure Boundary Bolted Flange Joint Assemblycarey stewartNo ratings yet

- Wire Feeder Certificate of CalibrationDocument1 pageWire Feeder Certificate of Calibrationcarey stewartNo ratings yet

- Quick and Easy KaizenDocument4 pagesQuick and Easy Kaizencarey stewartNo ratings yet

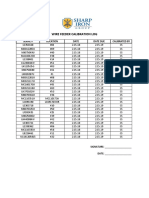

- Wire Feeder Calibration LogDocument1 pageWire Feeder Calibration Logcarey stewartNo ratings yet

- Weld LogDocument1 pageWeld Logcarey stewartNo ratings yet

- The LostDocument52 pagesThe Lostdavidmiller274No ratings yet

- Daily Paint ReportDocument2 pagesDaily Paint Reportcarey stewart100% (3)

- Wire Feeder Calibration LogDocument1 pageWire Feeder Calibration Logcarey stewartNo ratings yet

- Mini Kaizen FormDocument1 pageMini Kaizen Formcarey stewartNo ratings yet

- Weld MapDocument7 pagesWeld Mapcarey stewartNo ratings yet

- Hydrostatic Test Form For Low Pressure VesselsDocument1 pageHydrostatic Test Form For Low Pressure Vesselscarey stewartNo ratings yet