Professional Documents

Culture Documents

SEM164 Humidity & Temperature Transmitters: 2.2 Mechanical

SEM164 Humidity & Temperature Transmitters: 2.2 Mechanical

Uploaded by

Elsad HasanliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEM164 Humidity & Temperature Transmitters: 2.2 Mechanical

SEM164 Humidity & Temperature Transmitters: 2.2 Mechanical

Uploaded by

Elsad HasanliCopyright:

Available Formats

1.0 INTRODUCTION 2.

2 MECHANICAL

The SEM164 range of temperature and humidity transmitters includes

types for both wall and duct mounting as follows : Base Entry Probe

SEM164 W / 3 / HP (Wall mount 3%)

SEM164 W / 2 / HP (Wall mount 2%)

SEM164 D / 3 / HP (Duct mount 3%)

SEM164 D / 2 / HP (Duct mount 2%)

SEM164 Two wire loop powered operation provides good noise immunity and

economic site wiring. Connection of the site wiring to the transmitter is via

HUMIDITY &

screw terminals which are removable from the PCB for ease of wiring.

The sensor is fitted with a PTFE membrane filter around the

TEMPERATURE sensor guard body, to filter harmful dust and other airborne

pollutants whilst allowing the moisture vapours to enter the

sensing area of the probe. The probe MUST NOT be operated without this

TRANSMITTERS filter in place.

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL THIS TRANSMITTER.

Side Entry Probe

2.0 HANDLING

Handle the probe with care during installation, the sensing element used

to measure the humidity is of glass construction. Although mechanically

robust when permanently fixed into position, it may be damaged if the

probe is dropped or shocked in any way.

Sensor probes should not be mounted in positions in which they will be

exposed to direct moisture contact e.g. rain. Units being mounted outdoors

should be fitted into suitable protective enclosures. Sensors should not be

exposed to humidity and temperature levels outside their specified

operating ranges.

2.1 INSTALLATION

(DUCT MOUNT VERSIONS) Cut a 27mm hole in the chosen position of

Supplied by : the duct wall to allow the probe to enter the duct. Make sure the probe

does not foul the opposite wall of the duct. Position the probe shaft through

the 27mm aperture to it’s full extent and with the cable gland of the

electronics housing in the vertical downwards position, note and mark the

two fixing slots at the side of this housing. The fixing slots are moulded at

an angle to facilitate easier screwdriver access.

3.0 WIRING

(WALL MOUNT VERSIONS) Position the transmitter at the desired

Green Lane Business Park The electronic housing contains the wiring terminals which are screw

location with the sensor stem either horizontal or pointing downwards mid

Tewkesbury type clamps. A maximum core size of 2.5mm² can be accepted, with an

way between floor and ceiling. Avoid the following locations :-

Glos, GL20 8DE, UK overall cable diameter of between 4 and 8mm. Pass the cable through

the cable gland of the probe and connect to the relevant terminals

Telephone : 01684 296818 Near to entrances, exits or windows

using small loops for each core to reduce strain on the PCB mountings.

Fax : 01684 293746 In direct sunlight or near room heating devices

The connecting terminals are removable from the PCB for ease of wiring

E-mail : support@status.co.uk In direct line of air conditioning vents

(see diagram in section 3.1).

Remove the probe and drill the two marked positions to receive No.6

It is recommended that transmitters are fitted into an installation after the

x 19.1mm self-tapping screws. As a guide, in soft materials ie. aluminium,

air distribution system has been running for an initial period of at least

plastics, wood etc. a 2.5mm drill is recommended. In harder and/or

several hours. This will permit the system to clear itself of contaminants

thicker materials use a 3mm drill.

and reduce the possibility of sensor saturation.

Every effort has been taken to ensure the accuracy of this

document, however we do not accept responsibility for damage, injury, Unscrew the cover of the electronic housing and remove the plastic

loss or expense resulting from errors and omissions, and we reserve the bag containing the two self-tapping screws, replace cover. Now fix

right of amendment without notice. the probe permanently into position. On duct mount devices, the neoprene

compression ring, between the housing and the duct, will give a good

Stock code : 52-214-2074-01 Issue:01 degree of sealing when the probe is fixed as recommended.

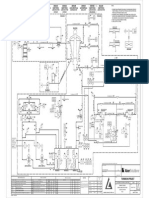

3.1 ELECTRICAL 5.0 CALIBRATION CHECK FOR HUMIDITY (%RH) Temperature

Connections are made to the four way terminal on the transmitter PCB, Output signal: 4-20mA

as shown in diagram below : The probe may be checked for correct operations if the need arises, Range: 0-50°C

calibration capsules are required. Either check capsules or NAMAS Sensor: Mo1000 thin film

Both relative humidity and temperature channels require DC supplies certified capsules for more precise calibration are available. With power Class: 'B' equivalent to IEC 751

in the range of 12 to 32 volts (nominal 24 volts). applied to the probe affix the lowest value of capsule over the sensor cage, (DIN 43760)

leave for 30 minutes then check the %RH 4-20mA output using an Accuracy: 0 °C = ±0.3°C

Ammeter. Adjust humidity ZERO pot if required. 50°C = ±0.55°C

Calibration accuracy: = ±0.1%

Note: The reading should be Capsule Value (%RH) x 16mA + 4mA Loop power supply: 24V DC nominal

Replace low value capsule for a high value capsule, leave for 30 minutes Maximum loop load: Rload(max) = (Vloop -12V)

and check the %RH output signal. Adjust the humidity SPAN pot if 20mA

required, repeat process until unit is within specification. Remove Mechanical Details

power from the probe, disconnect Ammeter, refit the probe into position. Materials of construction: ABS for main body

Polypropylene for sensor

5.1 CALIBRATION CHECK FOR TEMPERATURE °C mounting

To check the calibration of the temperature, the probe should be compared Sensor filter material: PTFE Sub-micronic

with a reference probe within a stable environment. Slight inaccuracies Filter type: Field replaceable

can be corrected by adjusting the temperature zero pot. If greater Protection: IP65 enclosure

inaccuracies have occurred the unit should be sent back for re-calibration. Connections: Removable screw terminals

Maximum core size: 2.5mm²

6.0 SPECIFICATION Recommended cable diameter: 4-8mm

Cable entry: Compression type cable

Humidity gland - to IP65

Output signal: 4-20mA linear

Electrical Connections : Sensor type: capacitive - wettable

1 Humidity - 2 Humidity + ORDER CODE

Measuring range: 0-100%RH

3 Temperature - 4 Temperature + Probe tip working temperature: -25°C to +80°C

Electronics working temperature: -25°C to +55°C

4.0 CHANGING THE FILTER

Grade 3 Grade 2

Remove protection cage from the probe stem (as shown below), by Accuracy: ±3%RH ±2%RH

applying steady upward pressure to the sensor cage. Hysteresis: <3%RH ±1%RH

Response time: 0-95%RH (90% of change): <15s

Use a high grade 12mm wide PTFE tape, lay onto a piece of paper to Linearity 5-95%RH: <2%RH

reduce the static effect, cut off a 50mm length. The PTFE tape is Loop power supply: 24V DC nom

now fitted to the PTFE membrane to cover the sensor guard holes.

Apply light pressure, to rub the tape in the direction of the tape Maximum loop load: Rload(max) = (Vloop - 12V)

end joint will effect the bonding. Refit the sensor cage after the 20mA

operation. eg. Vloop 24V DC - Rload(max) = 600 Ohms

52-214-2074-01

You might also like

- Bacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional SystemsDocument8 pagesBacnet® Fixed Function Thermostat: For Fan Coil/Heat Pump/Conventional Systemsamjadjaved033148100% (1)

- Chapter-0 Control Valves Handbook PDFDocument60 pagesChapter-0 Control Valves Handbook PDFOscarGomezMecanico100% (2)

- Operating Instructions Wind-Sensors INDUSTRY 0... 10 V (145x7)Document6 pagesOperating Instructions Wind-Sensors INDUSTRY 0... 10 V (145x7)Florencia CarrioNo ratings yet

- SEM203P Instruction ManualDocument2 pagesSEM203P Instruction ManualDaniel Adi SaputraNo ratings yet

- 18-0110 Rev. A Installation InstructionsDocument1 page18-0110 Rev. A Installation InstructionsAgusBetaNo ratings yet

- Datum Electronics: Series 460 Bolt-On Strain Gauge SensorsDocument7 pagesDatum Electronics: Series 460 Bolt-On Strain Gauge Sensorsmuhammad taufik rahmanNo ratings yet

- Tempra: A Range You Can Rely OnDocument26 pagesTempra: A Range You Can Rely OnVictor AfandiNo ratings yet

- Reverse Cycle Ducted Split Systems R32 Installation & MaintenanceDocument8 pagesReverse Cycle Ducted Split Systems R32 Installation & MaintenanceFilipNo ratings yet

- EGE Level SensorsDocument40 pagesEGE Level SensorsYing Kei ChanNo ratings yet

- E7 Vibrating Wire Soil ExtensometerDocument4 pagesE7 Vibrating Wire Soil ExtensometerJhasell MarinNo ratings yet

- Termostato Honeywell T7350Document12 pagesTermostato Honeywell T7350Jhon CatenaNo ratings yet

- E10 Rod Extensometer: Precisely MeasuredDocument4 pagesE10 Rod Extensometer: Precisely MeasuredAlberto MartinezNo ratings yet

- IRaccessoriesGB UMDocument16 pagesIRaccessoriesGB UMStephen AnoffNo ratings yet

- Termostato Bacnet TB3026BDocument12 pagesTermostato Bacnet TB3026BEfrain J Colina ANo ratings yet

- Convertidor de Temperatura pt100Document8 pagesConvertidor de Temperatura pt100pelayo polaNo ratings yet

- SEN5226 A4 EnviroSCAN ProductBrochure 4LR FINALDocument2 pagesSEN5226 A4 EnviroSCAN ProductBrochure 4LR FINALDaniel SloczynskiNo ratings yet

- Operating Instructions Wind Sensors PROFESSIONAL (1452x) : Descriptions Advantages at A GlanceDocument6 pagesOperating Instructions Wind Sensors PROFESSIONAL (1452x) : Descriptions Advantages at A GlancehoneyNo ratings yet

- Tempra: A Range You Can Rely OnDocument32 pagesTempra: A Range You Can Rely Onajinkya deshmukhNo ratings yet

- Sd119 ManualDocument2 pagesSd119 ManualVictor PatsiNo ratings yet

- Continuous Level Measurement Guided Wave Radar TransmittersDocument43 pagesContinuous Level Measurement Guided Wave Radar TransmittersAlen KušecNo ratings yet

- LKS Dust & Opacity Analyzer D10Document18 pagesLKS Dust & Opacity Analyzer D10KC WangNo ratings yet

- Vibrating Wire Push-In Pressure CellDocument4 pagesVibrating Wire Push-In Pressure Cells pradhanNo ratings yet

- Aprilaire 8051 Installation InstructionsDocument2 pagesAprilaire 8051 Installation InstructionsYonathan ArdilaNo ratings yet

- Retrievable ExtensometerDocument2 pagesRetrievable ExtensometerDeora AwangNo ratings yet

- Ramsey Microwave Point Level 8026 1114Document2 pagesRamsey Microwave Point Level 8026 1114Panner2009No ratings yet

- EDS-91 Vertical Inclinometer Cum Magnetic Settlement SystemDocument8 pagesEDS-91 Vertical Inclinometer Cum Magnetic Settlement SystemdavzuluetaNo ratings yet

- Mini Air Handling Unit - For Ducted Ventilation With Heat RecoveryDocument16 pagesMini Air Handling Unit - For Ducted Ventilation With Heat RecoverypttnpttnNo ratings yet

- Ultrasonic Sensors B1104Document32 pagesUltrasonic Sensors B1104Fady MorkusNo ratings yet

- E2 Magnetic Probe ExtensometerDocument4 pagesE2 Magnetic Probe Extensometergeo ghallabNo ratings yet

- Flexible Copper Duct Average Temperature Sensor: TSDC Series - Installation InstructionsDocument2 pagesFlexible Copper Duct Average Temperature Sensor: TSDC Series - Installation InstructionskirmaniNo ratings yet

- 6300 Inplace InclinometerDocument2 pages6300 Inplace InclinometerSalvatore LombardoNo ratings yet

- W9 Standard Vibrating Wire Piezometer: Precisely MeasuredDocument4 pagesW9 Standard Vibrating Wire Piezometer: Precisely MeasuredtqhunghnNo ratings yet

- Firebeam Xtra User GuideDocument16 pagesFirebeam Xtra User GuideSreten TodorovicNo ratings yet

- Pressure Measurement: Applying Remote Seal, Isolation Diaphragms Between Process Fluids and TransmittersDocument8 pagesPressure Measurement: Applying Remote Seal, Isolation Diaphragms Between Process Fluids and TransmittersJose JohnNo ratings yet

- LKS Dust Opacity Analyzer D10 2Document19 pagesLKS Dust Opacity Analyzer D10 2KC WangNo ratings yet

- Installation Instructions: SplitterDocument4 pagesInstallation Instructions: Splitterlos hermanos ValiNo ratings yet

- Technical Sheet EUROSTAR Lightning Protection SystemsDocument2 pagesTechnical Sheet EUROSTAR Lightning Protection SystemsnabaroonNo ratings yet

- Busa Sent1 0607Document48 pagesBusa Sent1 0607KhoilnNo ratings yet

- Manual Delta Mobrey m310 - revAB - 1108Document12 pagesManual Delta Mobrey m310 - revAB - 1108Micah KipropNo ratings yet

- Beam Ray RFX70 ManualDocument16 pagesBeam Ray RFX70 Manualwalid kawsarNo ratings yet

- Miltronics The Probe 2 wire-Manual-Spanish (FN.117) PDFDocument59 pagesMiltronics The Probe 2 wire-Manual-Spanish (FN.117) PDFJuan MontufarNo ratings yet

- Manual Del Termostato PDFDocument81 pagesManual Del Termostato PDFlechepinitoNo ratings yet

- AccuTrak Silver BulletDocument4 pagesAccuTrak Silver BulletMaximilianoNo ratings yet

- Manual Ilia EnDocument36 pagesManual Ilia EnShakee ShkNo ratings yet

- C2020 Standard: Assembly & Installation InstructionsDocument5 pagesC2020 Standard: Assembly & Installation InstructionsHidetoshi NakataNo ratings yet

- MASS 6000 - ManualDocument16 pagesMASS 6000 - ManualAlberto GonzalezNo ratings yet

- W4 Heavy Duty PiezometerDocument4 pagesW4 Heavy Duty PiezometerJorge Armando Ysuiza RomeroNo ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- TD Pressure 001-EnDocument8 pagesTD Pressure 001-EnPanner2009No ratings yet

- NFXI-BEAM Lineare PDFDocument6 pagesNFXI-BEAM Lineare PDFDanielNo ratings yet

- Multi-Technology Ceiling Mounted Occupancy SensorDocument2 pagesMulti-Technology Ceiling Mounted Occupancy Sensorproyectos serimetcNo ratings yet

- Sherwood RX-4109 Stereo Receiver Data SheetDocument23 pagesSherwood RX-4109 Stereo Receiver Data Sheetgoga1990No ratings yet

- Oil Watchman SonicDocument2 pagesOil Watchman SonicDaniel Lastra EncaboNo ratings yet

- Open-to-Wireless Solution GuideDocument7 pagesOpen-to-Wireless Solution GuideErdinc KlimaNo ratings yet

- FS2009 3031Document25 pagesFS2009 3031SanjayNo ratings yet

- S3000-Nvent E1290B-WWEN TaacsaDocument20 pagesS3000-Nvent E1290B-WWEN TaacsaFrancisco GuerreroNo ratings yet

- OM High Purity DO en 52201072F Sep13Document14 pagesOM High Purity DO en 52201072F Sep13Renato KumamotoNo ratings yet

- The Dos and Donts of Pressure Transducers DyniscoDocument5 pagesThe Dos and Donts of Pressure Transducers Dyniscogeninho3No ratings yet

- Broadband AntennasDocument2 pagesBroadband AntennasJuan Guillermo Palacio UribeNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Analox Koolwaterstoffen Hydrocarbon Analyser (Hyper Gas MKII)Document4 pagesAnalox Koolwaterstoffen Hydrocarbon Analyser (Hyper Gas MKII)Elsad HasanliNo ratings yet

- Analox Hyper-Gas Mkii Hydrocarbon Monitor: World Leaders in Diving Equipment TechnologyDocument2 pagesAnalox Hyper-Gas Mkii Hydrocarbon Monitor: World Leaders in Diving Equipment TechnologyElsad HasanliNo ratings yet

- Spare Parts List For Mini Portable 2-26-07Document1 pageSpare Parts List For Mini Portable 2-26-07Elsad HasanliNo ratings yet

- Now We'Re Talking: Part No: CP3Document1 pageNow We'Re Talking: Part No: CP3Elsad HasanliNo ratings yet

- Hyper-Gas Mkii: Discover The HypeDocument2 pagesHyper-Gas Mkii: Discover The HypeElsad HasanliNo ratings yet

- 3 Diver Rack Mounted CommsDocument1 page3 Diver Rack Mounted CommsElsad HasanliNo ratings yet

- Apollo Valves: Technical Data ForDocument48 pagesApollo Valves: Technical Data ForElsad HasanliNo ratings yet

- KAP-H Breathing Air Compressor, Diving, Fire Service, Ship, Compressor For In-Vehicle ApplicationsDocument2 pagesKAP-H Breathing Air Compressor, Diving, Fire Service, Ship, Compressor For In-Vehicle ApplicationsElsad Hasanli100% (1)

- UWS-3310/dc: - Complete Ac/Dc Portable Video System - Light Weight - SD DVR - Led LightDocument2 pagesUWS-3310/dc: - Complete Ac/Dc Portable Video System - Light Weight - SD DVR - Led LightElsad HasanliNo ratings yet

- S.Tec Lifting Bags 174 Psi: The Next Generation of High-Pressure Lifting BagsDocument3 pagesS.Tec Lifting Bags 174 Psi: The Next Generation of High-Pressure Lifting BagsElsad HasanliNo ratings yet

- STSS OwnersManualDocument6 pagesSTSS OwnersManual123098qwepoiNo ratings yet

- X24C44 256 Bit 16 X 16 Bit: Features DescriptionDocument16 pagesX24C44 256 Bit 16 X 16 Bit: Features DescriptionMarinaBogaoNo ratings yet

- 560 200 Pi T 006 - 2Document1 page560 200 Pi T 006 - 2discotopNo ratings yet

- PRT RDM2Document42 pagesPRT RDM2jstclmethan100% (1)

- Bhiwandi WH1Document10 pagesBhiwandi WH1HashirNo ratings yet

- Review: Module 33 - Strength of Materials 4 - Part 1Document2 pagesReview: Module 33 - Strength of Materials 4 - Part 1John andre MarianoNo ratings yet

- Drrdock Repair Jobs (Excluding DD Routines) No 1Document15 pagesDrrdock Repair Jobs (Excluding DD Routines) No 1Amit Raj AnandNo ratings yet

- MIL-PRF-39014/Radial Leads: How To OrderDocument14 pagesMIL-PRF-39014/Radial Leads: How To Orderjonatas priscoNo ratings yet

- 07-08 Panasonic Wall Split BrochureDocument16 pages07-08 Panasonic Wall Split BrochureAravindan MuthuNo ratings yet

- Fundamentals of Drafting - Freehand Sketching: ObjectivesDocument6 pagesFundamentals of Drafting - Freehand Sketching: Objectiveskay chikwandaNo ratings yet

- Certificate of Calibration: National Metrology Institute of Ethiopia (Nmie) Industrial Metrology DirectorateDocument3 pagesCertificate of Calibration: National Metrology Institute of Ethiopia (Nmie) Industrial Metrology DirectorateephremNo ratings yet

- Data Warehouse DatabasesDocument28 pagesData Warehouse DatabasesGiri SaranuNo ratings yet

- Terminating SSL On SAP Web DispatcherDocument15 pagesTerminating SSL On SAP Web DispatcherMaria Joseph VimalNo ratings yet

- MaxigardDocument17 pagesMaxigardrizqi dwikiNo ratings yet

- R400 Manual Basic en PDFDocument73 pagesR400 Manual Basic en PDFOum Younes0% (1)

- Ultrasonic Sensor PDFDocument36 pagesUltrasonic Sensor PDFRoberto RizaldyNo ratings yet

- Coatings For Solder Able Wires For The Modern Electric IndustryDocument14 pagesCoatings For Solder Able Wires For The Modern Electric IndustryanilkolekarNo ratings yet

- RTR Bearing PDFDocument52 pagesRTR Bearing PDFkamelNo ratings yet

- Industrial Cooling Systems (ICS) TAE 031 ChillerDocument2 pagesIndustrial Cooling Systems (ICS) TAE 031 ChillerzeljkoNo ratings yet

- Research ReportDocument81 pagesResearch ReportSuraj DubeyNo ratings yet

- Packer Testing Program Design and Management: August 2013Document7 pagesPacker Testing Program Design and Management: August 2013wily784No ratings yet

- Continuous Position Indicator: Innovation and Quality - Made by Pleiger!Document2 pagesContinuous Position Indicator: Innovation and Quality - Made by Pleiger!PamellaNo ratings yet

- FX 201108Document124 pagesFX 201108Jebe94No ratings yet

- Automation Solution Guide 2008Document312 pagesAutomation Solution Guide 2008Freddy SuhartonoNo ratings yet

- Cocoa Butter HACCPDocument5 pagesCocoa Butter HACCPmamasita25100% (1)

- Sheet Metal Forming Simulation Suite: Pam-Stamp 2GDocument2 pagesSheet Metal Forming Simulation Suite: Pam-Stamp 2GKrishna VamsiNo ratings yet

- Nonlinear Op-Amp Circuits: - Most Typical Applications Require Op Amp and Its Components To Act LinearlyDocument31 pagesNonlinear Op-Amp Circuits: - Most Typical Applications Require Op Amp and Its Components To Act LinearlyBeth ValerdiNo ratings yet

- Lead Gloves Revolution InfabDocument1 pageLead Gloves Revolution InfabFranklin FiallosNo ratings yet

- AME OIE WhitepaperDocument34 pagesAME OIE Whitepaperanishajohins100% (2)