Professional Documents

Culture Documents

Division IV - Page 163 Section 9 - Lime Stabilization

Division IV - Page 163 Section 9 - Lime Stabilization

Uploaded by

yamanta_rajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Division IV - Page 163 Section 9 - Lime Stabilization

Division IV - Page 163 Section 9 - Lime Stabilization

Uploaded by

yamanta_rajCopyright:

Available Formats

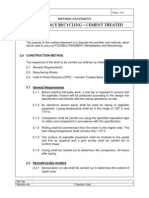

SECTION 9

LIME STABILIZATION

9.01 DESCRIPTION

Lime stabilization shall conform to Section 24 of the State Standard Specifications

except as noted herein.

9.02 MATERIALS

Materials to be lime stabilized shall be clayey soils free of rubble, rubbish, and

vegetation and shall be tested by the Contractor at his expense and approved by

the City Engineer prior to commencement of lime treatment operations.

Lime shall be high-calcium or dolomitic quicklime conforming to the definitions

in ASTM Designation C51. When sampled by the City Engineer from the lime

spreader or during the spreading operations, the sample of lime shall conform to

the following requirements:

High-calcium quicklime shall contain not less than one hundred and thirteen

percent (113%) calcium hydroxide Ca(OH) 2, as determined by California Test

Method 414.

Dolomitic quicklime shall contain less than fifty-seven percent (57%) calcium

oxide, CaO, and not less than ninety-five percent (95%) combined calcium oxide,

CaO, and magnesium oxide, MgO, as determined by California Test 404.

A Certificate of Compliance in accordance with the provisions in Section 6-107 of

the State Standard Specifications shall be furnished wi th each delivery of lime and

shall be submitted to the City Engineer with a certificate copy of the weight of

each delivery.

Water for use in subgrade stabilization shall be clean and potable and shall be

added during mixing, remixing and compaction operations, and during the curing

period to keep the cured material moist until covered.

9.03 PREPARING MATERIAL

The minimum depth of lime treatment shall be twelve (12) inches. The material to

be treated shall contain no rocks or solids larger than one and one-half inches (1-

1/2” inches) in maximum dimension. Removing and disposing of rocks or solids

larger than 1-1/2 inches in maximum dimension shall be the sole responsibility of

the Contractor.

9.04 MIXING

The rate of spread per linear foot of blanket shall no t vary more than five percent

(5%) from the designated rate.

Mixing equipment shall be equipped with a visual depth indicator showing mixing

depth, an odometer, or foot meter to indicate travel speed and a controllable water

additive system for regulating water added to the mixture.

Mixing equipment shall be the type that can mix the full depth of the treatment

specified and leave a relatively smooth bottom of the treated section.

Division IV – Page 163

Section 9 – Lime Stabilization

Mixing and re-mixing, regardless of equipment used, will continue until the

material is uniformly mixed (free of streaks or pockets of lime), moisture is at

least two percent (2%) over optimum and the mixture complies with the following

requirements:

Sieve Size Minimum Percent Passing

1-1/2” inches 100

1” inch 95

No. 4 60

The entire mixing operation shall be completed within seventy-two (72) hours of

the initial spreading of lime, unless otherwise approved by the City Engineer.

9.05 SPREADING AND COMPAC TING

In lieu of construction joints, the Contractor may mix three (3”) inches into the

previous day’s work to assure a good bond to the adjoining work provided that the

lime treatment operation is being performed using cross shaft rotary mixers as

determined by the City Engineer.

The lime treated soil shall be compacted to a relative compaction of not less than

95%, unless otherwise approved by the City Engineer.

9.06 CURING

The surface of each compacted layer of lime -treated material shall be kept moist

until covered by a subsequent layer of lime -treated or other material for a period

not to exceed three (3) days or by applying a curing seal immediately following

final trimming and rolling of the lime -treated layer.

Curing seal shall be applied at a rate of 0.15 gallons per square yard of surface.

No traffic of any kind will be allowed on the grade for a minimum of 3 days (72)

hours following application of the curing seal.

Asphalt concrete shall not be placed within seven (7) days following application

of the curing seal, unless otherwise approved by the City Engineer.

9.07 TESTING AND OBSERVATION

All lime-treatment of the subgrades shall be tested and observed by the

Geotechnical Engineer serving as the representative of the City Engineer. This

does not preclude testing by the design Engineer and shall be at the City Engineers

discretion. Field density tests shall be made by the Geotechnical Engineer after the

completion of the final compaction of the treated soils, prior to application of the

curing seal.

Lime-treatment shall not be performed without the notification or approval of the

City. The Contractor shall notify the City in writing at least two (2) working days

prior to commencement of lime treatment.

No deviations from the specifications shall be made except upon written approval

from the City Engineer.

Division IV – Page 164

Section 9 – Lime Stabilization

9.08 PAYMENT OF FEES AND RELATED COSTS

The Developer/Contractor shall pay all fees incurred by the City in the retaining

of a Geotechnical Engineer and/or City staff time related to lime treatment design

and/or inspection requirements.

Division IV – Page 165

Section 9 – Lime Stabilization

You might also like

- Qa-Qc Q and A Notes.Document9 pagesQa-Qc Q and A Notes.Arputharaj Maria Louis100% (4)

- Method Statement For Cold In-Place Recycling - CementDocument6 pagesMethod Statement For Cold In-Place Recycling - CementNordin Yunus100% (2)

- Shotcrete RequirementsDocument16 pagesShotcrete Requirementstinz_3100% (2)

- Section 3 - Water & Sewerage Services by NWCDocument105 pagesSection 3 - Water & Sewerage Services by NWCfaisal100% (1)

- Book Chapter - Oxidation of Metals and AlloysDocument42 pagesBook Chapter - Oxidation of Metals and AlloysFrederico FernandesNo ratings yet

- 1001Document6 pages1001enterlogNo ratings yet

- Irc DLCDocument56 pagesIrc DLCAniket Salvi100% (5)

- Soil Cement SpecificationDocument4 pagesSoil Cement SpecificationHoa PhamNo ratings yet

- Construction Specification 28-Lime Treated EarthfillDocument3 pagesConstruction Specification 28-Lime Treated EarthfillImran SikandarNo ratings yet

- 04-400. Sub-Bases, (Non-Bituminous) and ShouldersDocument29 pages04-400. Sub-Bases, (Non-Bituminous) and ShouldersAnonymous g1LSaANo ratings yet

- Embankment Construction MethodologyDocument16 pagesEmbankment Construction MethodologyTinwin HtutNo ratings yet

- Ag Layer in Sub-Base/Base Construction 1. ScopeDocument3 pagesAg Layer in Sub-Base/Base Construction 1. ScopeAnish Panchal100% (1)

- Specification For Road ReinstatementDocument10 pagesSpecification For Road Reinstatementyamanta_rajNo ratings yet

- Bituminous Prime Coat: DescriptionDocument4 pagesBituminous Prime Coat: DescriptionHurriyat AliNo ratings yet

- Methodology For Soil ShoulderDocument7 pagesMethodology For Soil ShoulderAkash SarkarNo ratings yet

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001No ratings yet

- Six Lan Road ConstructionDocument25 pagesSix Lan Road ConstructionDevendra SharmaNo ratings yet

- Reclamation SpecifiactionDocument24 pagesReclamation SpecifiactiongedekhresnaNo ratings yet

- Grading General Notes - of CountyDocument3 pagesGrading General Notes - of CountyÓscar SalazarNo ratings yet

- Priming MethodologyDocument5 pagesPriming MethodologyPanashe ChikomweNo ratings yet

- Soil - FillingDocument6 pagesSoil - FillingGiora RozmarinNo ratings yet

- Upgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanDocument8 pagesUpgrading of Approximately 104Km of Road D104/D791 Chipata To Mfuwe in Eastern Province Surfacing PlanSidney MusondaNo ratings yet

- 4.3 Item 7 Soil Subbase Stabilization With TS+ZB Specs Using RotavatorDocument7 pages4.3 Item 7 Soil Subbase Stabilization With TS+ZB Specs Using Rotavatorjitu2968No ratings yet

- CRT Coastal Reclamation PDFDocument24 pagesCRT Coastal Reclamation PDFDeraman AbdullahNo ratings yet

- SA Standard NotesDocument22 pagesSA Standard Notesatiq0592No ratings yet

- Method Statement For Approval of Layer Thickness - Rev.01Document9 pagesMethod Statement For Approval of Layer Thickness - Rev.01Jox Biol100% (1)

- Atk SSA Presentation R2Document38 pagesAtk SSA Presentation R2Gaurav MathurNo ratings yet

- Quality AssuranceDocument7 pagesQuality AssurancevishwaskhatriNo ratings yet

- Highway RehabilitationDocument31 pagesHighway Rehabilitationketh patrickNo ratings yet

- Section 8 - Reclamation Technical SpecificationDocument42 pagesSection 8 - Reclamation Technical SpecificationRocky Situmorang100% (1)

- Geotextile Fabric General SpecificationDocument3 pagesGeotextile Fabric General SpecificationjovindhaNo ratings yet

- Department of Transportation Engineering: Dry Lean Cement ConcreteDocument19 pagesDepartment of Transportation Engineering: Dry Lean Cement ConcreteMOHANSHU BHARDWAJ 22910013No ratings yet

- Embankment MethodologyDocument4 pagesEmbankment MethodologyAVP PAFCDO ProjectNo ratings yet

- Cellular Concrete Specifications Latest On 4-13Document3 pagesCellular Concrete Specifications Latest On 4-13diracmoutinhoNo ratings yet

- DPWH Standard Specifications On Prime Coat, TackDocument8 pagesDPWH Standard Specifications On Prime Coat, TackChesterMercado100% (2)

- EDM Master - 03chapter 3Document4 pagesEDM Master - 03chapter 3lutardsNo ratings yet

- Extracted Pages From SAES-Q-006Document2 pagesExtracted Pages From SAES-Q-006Sarah AzizNo ratings yet

- Earthwork SpecificationDocument5 pagesEarthwork Specificationmzrosfaizal100% (1)

- 6sec.600 (Concrete Pavement)Document35 pages6sec.600 (Concrete Pavement)aalignup arc & const. pvt ltdNo ratings yet

- 3510 - Specification For Sand Base Course 3510 - 1 DescriptionDocument4 pages3510 - Specification For Sand Base Course 3510 - 1 DescriptionShe Timbancaya100% (1)

- 1iiiiinlllili: Department of Public Works and MghwaysDocument6 pages1iiiiinlllili: Department of Public Works and MghwaysBenjo FaustoNo ratings yet

- Embankment PDFDocument3 pagesEmbankment PDFahmed tahameemNo ratings yet

- Embankment PDFDocument3 pagesEmbankment PDFSugumarRaviNo ratings yet

- Cement Kiln Dust (CKD) Treated SubgradeDocument4 pagesCement Kiln Dust (CKD) Treated SubgradeDevrim GürselNo ratings yet

- Section 2Document44 pagesSection 2ali nasserNo ratings yet

- 4fii Maricopa Spec PDFDocument25 pages4fii Maricopa Spec PDFSusana Chuy TaiNo ratings yet

- Bitumenous SurfacingDocument6 pagesBitumenous SurfacingChemicro Holdings100% (1)

- Sow Road Construction 022610Document25 pagesSow Road Construction 022610Nercio BulaundeNo ratings yet

- SQUID Sample Specification Version 1 Aug 17 2018Document5 pagesSQUID Sample Specification Version 1 Aug 17 2018jfsianturi1No ratings yet

- IS008 Soil Cement BlocksDocument4 pagesIS008 Soil Cement BlocksCiddarthnNo ratings yet

- Sub BaseDocument4 pagesSub BaseAnonymous Dk3ItoC8MFNo ratings yet

- Road Pav LayerwDocument10 pagesRoad Pav LayerwAurelius GoraNo ratings yet

- MOS - Flexible Pavement RehabilitationDocument6 pagesMOS - Flexible Pavement RehabilitationcdipcinNo ratings yet

- Water Bound Macadam Base: DescriptionDocument4 pagesWater Bound Macadam Base: DescriptionHurriyat AliNo ratings yet

- Spread The LoveDocument5 pagesSpread The LoveRAMPALLI GATTAIAHNo ratings yet

- LAPRIL-C102 enDocument7 pagesLAPRIL-C102 enalpha NEPALNo ratings yet

- Section 400 - (Granular-Sub-Base) - Finally CorrectedDocument16 pagesSection 400 - (Granular-Sub-Base) - Finally CorrectedTousifAnwar MundaragiNo ratings yet

- Section 02610 - Prime CoatDocument26 pagesSection 02610 - Prime Coatmail3shenNo ratings yet

- Methodology For Subgrade Construction - Highway GuideDocument4 pagesMethodology For Subgrade Construction - Highway GuidesvsrnbNo ratings yet

- Spec - Rev A.groundworksDocument10 pagesSpec - Rev A.groundworksery achjariNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Master's Handbook For Construction ManagementDocument15 pagesMaster's Handbook For Construction Managementyamanta_rajNo ratings yet

- Annex 5: Bill of Quantities (Boqs) : Unicef Jco - RFPDocument8 pagesAnnex 5: Bill of Quantities (Boqs) : Unicef Jco - RFPyamanta_rajNo ratings yet

- Bill of Quantity:: Tiger Circle - ManipalDocument8 pagesBill of Quantity:: Tiger Circle - Manipalyamanta_rajNo ratings yet

- Proposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at KiamwathiDocument49 pagesProposed Construction of 3 No. Classrooms Block and 2 No. Eco Toilet Blocks at Kiamwathiyamanta_rajNo ratings yet

- Unprised PSF BoQsDocument6 pagesUnprised PSF BoQsyamanta_rajNo ratings yet

- BOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITDocument3 pagesBOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITyamanta_rajNo ratings yet

- Institute For Empirical Research in Economics University of ZurichDocument23 pagesInstitute For Empirical Research in Economics University of Zurichyamanta_rajNo ratings yet

- Construction Specification Chain Link FenceDocument2 pagesConstruction Specification Chain Link Fenceyamanta_rajNo ratings yet

- 2nd - PPM E-CourseDocument12 pages2nd - PPM E-Courseyamanta_rajNo ratings yet

- Rate Analysis-Norms 1Document10 pagesRate Analysis-Norms 1yamanta_rajNo ratings yet

- SP15Document38 pagesSP15yamanta_rajNo ratings yet

- Project Management OfficeDocument10 pagesProject Management Officeyamanta_rajNo ratings yet

- Metal Fencing SpecificationsDocument6 pagesMetal Fencing Specificationsyamanta_rajNo ratings yet

- PKG - 1 TEKU Dovan Area BoQ - FinalDocument48 pagesPKG - 1 TEKU Dovan Area BoQ - Finalyamanta_raj0% (1)

- Assessment of Hire Rate Analysis of Heavy Equipment in NepalDocument13 pagesAssessment of Hire Rate Analysis of Heavy Equipment in Nepalyamanta_raj100% (1)

- Existing Footway/Cycleway Widening: Road Category 1 2 3 4 Dimension "X" (MM) 260 200 170 110Document1 pageExisting Footway/Cycleway Widening: Road Category 1 2 3 4 Dimension "X" (MM) 260 200 170 110yamanta_rajNo ratings yet

- Specification Sheet - Ubp Kerbs PDFDocument1 pageSpecification Sheet - Ubp Kerbs PDFyamanta_rajNo ratings yet

- ToR Construction EngineerDocument6 pagesToR Construction Engineeryamanta_rajNo ratings yet

- Schedule of Works RevADocument14 pagesSchedule of Works RevAyamanta_rajNo ratings yet

- Evaluation of The Causes of Concrete Kerbs Fast DaDocument8 pagesEvaluation of The Causes of Concrete Kerbs Fast Dayamanta_rajNo ratings yet

- Renewable Energy: Murat Kadir YesilyurtDocument18 pagesRenewable Energy: Murat Kadir YesilyurtMUHAMMAD ABIEL PRADIPTANo ratings yet

- Design of Vertical Drop Weir PG, Example, 2020Document9 pagesDesign of Vertical Drop Weir PG, Example, 2020zelalemniguse75% (4)

- Project ReportDocument14 pagesProject ReportGitanshu kumarNo ratings yet

- Isobutanol MSDSDocument11 pagesIsobutanol MSDSElías VillegasNo ratings yet

- GI For Local Government PDFDocument42 pagesGI For Local Government PDFTri WahyuningsihNo ratings yet

- Awardees SpeechDocument2 pagesAwardees SpeechDijah Mie Molines RicoNo ratings yet

- 2011 Techcross Brochure (Ballast Treatment)Document6 pages2011 Techcross Brochure (Ballast Treatment)Amr MoroNo ratings yet

- Department of Labor: 96 18130Document3 pagesDepartment of Labor: 96 18130USA_DepartmentOfLaborNo ratings yet

- Bromine AVPP Other DPD Eng OdyDocument4 pagesBromine AVPP Other DPD Eng Odytsvs58No ratings yet

- Costanza, R.,The Value of The Ecosystem Services and Natural CapitalDocument9 pagesCostanza, R.,The Value of The Ecosystem Services and Natural CapitalkethilinNo ratings yet

- 2013 Maharastra DroughtDocument8 pages2013 Maharastra Droughtdaniyal rasheedNo ratings yet

- Dpu 2-36 Cas125Document83 pagesDpu 2-36 Cas125Absar Mamun100% (2)

- Ss2 Bio TRM 2 WK 4 - 5Document64 pagesSs2 Bio TRM 2 WK 4 - 5ALPHEAUS-MBA AwajibenejiNo ratings yet

- Unit I Multidisciplinary Nature of ESDocument216 pagesUnit I Multidisciplinary Nature of ESPurna BhavnariNo ratings yet

- Commercial Installation Guide Maxr-100 Air Conditioning & RefrigerationDocument2 pagesCommercial Installation Guide Maxr-100 Air Conditioning & Refrigerationgviswa75No ratings yet

- Final Report - NEERI Project Godavari BeautificationDocument7 pagesFinal Report - NEERI Project Godavari BeautificationUnati WatwaniNo ratings yet

- Soybean Oil SDSDocument8 pagesSoybean Oil SDSSyed Waheed Ul HasanNo ratings yet

- Ventsorb Ventsorb: Description Specifications Carbon Life EstimateDocument4 pagesVentsorb Ventsorb: Description Specifications Carbon Life EstimateEvert AlexNo ratings yet

- Stabilame B-EPD - 200102 - 001 - CLT ClouéDocument17 pagesStabilame B-EPD - 200102 - 001 - CLT ClouéLaurent BriotNo ratings yet

- ĐỀ 41-60Document64 pagesĐỀ 41-60HuyềnNo ratings yet

- List of PublicationsDocument2 pagesList of PublicationsAddisuNo ratings yet

- Minor Ports Survey Organization of India (Mpso) Minor Ports Survey Organization of India (Mpso)Document6 pagesMinor Ports Survey Organization of India (Mpso) Minor Ports Survey Organization of India (Mpso)Shubham GhandadeNo ratings yet

- EPD EGGER Eurodekor enDocument13 pagesEPD EGGER Eurodekor enAlexander AvramovNo ratings yet

- Study of Ice and Snow Melting Process On Conductive Asphalt Solar CollectorDocument10 pagesStudy of Ice and Snow Melting Process On Conductive Asphalt Solar CollectorNgocTraiNguyenNo ratings yet

- EoD DesignDocument99 pagesEoD DesignPabita Shahi100% (1)

- 750-0020 Seawaterecbiofouling Sept15Document8 pages750-0020 Seawaterecbiofouling Sept15Anonymous 1ykzuaxWgYNo ratings yet

- Syllabus 4 3Document4 pagesSyllabus 4 3John RongNo ratings yet

- Labo III Appendix A Gunt Ce602eDocument26 pagesLabo III Appendix A Gunt Ce602eMijhael Anatholi Romero MamaniNo ratings yet