Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

25 viewsMachine Design Day 5

Machine Design Day 5

Uploaded by

Kers CelestialThe document discusses different types of gears:

1) A worm gear problem where the helix angle of a triple thread worm gear is calculated.

2) A worm gear transmitting 10 hp at 1200 rpm is given, and the lead angle, speed ratio, and center distance are calculated.

3) A bevel gear problem where the angles of the gear and pinion are determined given the diameter of the gear and a velocity ratio of 1/2.

4) Two helical gear problems where gear parameters like pitch, diameter, and number of teeth are calculated based on information like helix angle, pitch, and angular speed ratio.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- Gear PrimeDocument7 pagesGear PrimeEjNo ratings yet

- MDSP Set 2Document9 pagesMDSP Set 2iaton77100% (2)

- Assignment Shaft DesignDocument4 pagesAssignment Shaft DesignHasham Mehmood100% (1)

- QBDocument8 pagesQBrahulNo ratings yet

- Assignment Unit - 1: 2) .A Pair of Involute Gears Is in Mesh. The Application Restricts The Space To Accommodate TheseDocument4 pagesAssignment Unit - 1: 2) .A Pair of Involute Gears Is in Mesh. The Application Restricts The Space To Accommodate TheserahulNo ratings yet

- GEARDocument11 pagesGEAREjNo ratings yet

- Asignment Tutorial 3 Toothed Gears and Gear TrainsDocument4 pagesAsignment Tutorial 3 Toothed Gears and Gear TrainsMOJALEFA JACOB MOLEFINo ratings yet

- 01 Helical Gear ONLY ProblemsDocument2 pages01 Helical Gear ONLY Problemskamal0% (1)

- Bevel Gears: Gear DrivesDocument11 pagesBevel Gears: Gear DrivesNeil RubsNo ratings yet

- Assignment 5 - Worm GearDocument1 pageAssignment 5 - Worm GearSR SuryaNo ratings yet

- Problem Set-Md 2Document11 pagesProblem Set-Md 2kim dianonNo ratings yet

- Seatwork No.1Document1 pageSeatwork No.1Easy WriteNo ratings yet

- Tutorial Worm GearDocument1 pageTutorial Worm GearpshretankNo ratings yet

- Gearing - ProblemsDocument7 pagesGearing - ProblemsmanuNo ratings yet

- Assignment No 1 NME 602 MD 2Document2 pagesAssignment No 1 NME 602 MD 2nitin_johri0% (1)

- 330:148 (G) Machine Design Assignment: 6 Spur Gears (CH 11) To Be Submitted by October 15, 2007Document2 pages330:148 (G) Machine Design Assignment: 6 Spur Gears (CH 11) To Be Submitted by October 15, 2007CalvinJosh Gadon FrueldaNo ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of Machinessameer_m_daniNo ratings yet

- Design of Transmission System Unit IIIDocument57 pagesDesign of Transmission System Unit IIIRaj MohanNo ratings yet

- Machine Designe - IIDocument2 pagesMachine Designe - IIAndrea DouglasNo ratings yet

- Md2 Problems On Gears Direction: Answer The Following Problems Using Long Bond Papers. The SolutionsDocument2 pagesMd2 Problems On Gears Direction: Answer The Following Problems Using Long Bond Papers. The SolutionsLordFifth 451No ratings yet

- 12-Worm Gears PDFDocument2 pages12-Worm Gears PDFSarvesh MishraNo ratings yet

- Theoretical QuestionsDocument17 pagesTheoretical Questionsanbamech50% (2)

- Our Official Android App - REJINPAUL NETWORK FromDocument3 pagesOur Official Android App - REJINPAUL NETWORK FromAjay KumarNo ratings yet

- Module3 TutorialDocument7 pagesModule3 TutorialAayush KNo ratings yet

- Instructions:: Gujarat Technological UniversityDocument2 pagesInstructions:: Gujarat Technological Universitysameer_m_daniNo ratings yet

- UNit-2 Numerical ProblemsDocument16 pagesUNit-2 Numerical ProblemsMarthandeNo ratings yet

- Kinematics of Machinery UNIT 4Document4 pagesKinematics of Machinery UNIT 4MugilNo ratings yet

- Mod-3B-Helical GearDocument2 pagesMod-3B-Helical GearSharthak GhoshNo ratings yet

- Iat-I QPDocument2 pagesIat-I QPBalaChandarNo ratings yet

- Sheet 5Document3 pagesSheet 5Fouad MohamedNo ratings yet

- LABORATORY Experiment# 07 Gears Theory and Calculations FEDocument8 pagesLABORATORY Experiment# 07 Gears Theory and Calculations FECARLO JEMBO JAMAGO LABISNo ratings yet

- Module-5 Toothed GearingDocument4 pagesModule-5 Toothed Gearingonkarlamkane4No ratings yet

- Asus TufDocument2 pagesAsus TufKabirNo ratings yet

- Tutorial 3 - Gear CalculationsDocument9 pagesTutorial 3 - Gear CalculationsMohammad AzmudinNo ratings yet

- Assignment 3Document20 pagesAssignment 3Siddhesh RaulNo ratings yet

- DTS Model PaperDocument3 pagesDTS Model PaperrajkumardotcomNo ratings yet

- Bevel and Worm GearsDocument1 pageBevel and Worm GearsDevansh ChhajlaniNo ratings yet

- Tutorial MD II 2015 3Document1 pageTutorial MD II 2015 3rip111176No ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of Machinessameer_m_daniNo ratings yet

- Dme-2 2017-18 Ist AssignmentDocument1 pageDme-2 2017-18 Ist Assignmentmallesh mendaNo ratings yet

- Find The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inDocument4 pagesFind The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inGeoffrey GolbequeNo ratings yet

- UnitDocument6 pagesUnitPreethi SharmiNo ratings yet

- GFHGDocument5 pagesGFHGjoshua espiritu0% (1)

- Tutorial 5 - GearsDocument2 pagesTutorial 5 - GearsAbhishek SharmaNo ratings yet

- Sheet No. 1 Design of GearsDocument3 pagesSheet No. 1 Design of GearssallyNo ratings yet

- Tutorial MD II 2015 4Document1 pageTutorial MD II 2015 4rip111176No ratings yet

- Kom Assignments PDFDocument6 pagesKom Assignments PDFapi-263237278No ratings yet

- R8 Nov-Dec-2015Document3 pagesR8 Nov-Dec-2015Hari VenkitNo ratings yet

- Plate No RaDocument5 pagesPlate No RaEdelleNo ratings yet

- 9A14402 Theory of MachinesDocument8 pages9A14402 Theory of MachinessivabharathamurthyNo ratings yet

- GEARDocument21 pagesGEARraidahNo ratings yet

- MD P3 Answer Key GearsDocument8 pagesMD P3 Answer Key GearsmomonitwiceNo ratings yet

- Theory of Machines - II: T.E./Insem. - 108Document2 pagesTheory of Machines - II: T.E./Insem. - 108palashNo ratings yet

- Problem Set MD Day 4Document4 pagesProblem Set MD Day 4DE GUZMAN, MELVIN CARLO A.No ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- FiltrationDocument7 pagesFiltrationKers CelestialNo ratings yet

- Preparation and Characterization of Cellulose Acetate From Pineapple (Ananas Comosus) LeavesDocument6 pagesPreparation and Characterization of Cellulose Acetate From Pineapple (Ananas Comosus) LeavesKers CelestialNo ratings yet

- Problem 138Document2 pagesProblem 138Kers CelestialNo ratings yet

- Machine Design Problems - DAY 4Document1 pageMachine Design Problems - DAY 4Kers CelestialNo ratings yet

- Problem 141Document1 pageProblem 141Kers CelestialNo ratings yet

- Cf =Mω X ¯ M =Ρv=Ρaπr X =2R/ΠDocument1 pageCf =Mω X ¯ M =Ρv=Ρaπr X =2R/ΠKers CelestialNo ratings yet

- Abstract Cellulose AcetateDocument1 pageAbstract Cellulose AcetateKers CelestialNo ratings yet

- Machine Design - Day 6roller Chain and Sprockets: BeltsDocument1 pageMachine Design - Day 6roller Chain and Sprockets: BeltsKers CelestialNo ratings yet

- F =σA F =3.5 (π (430) ) F =508270.42N: Problem 142Document2 pagesF =σA F =3.5 (π (430) ) F =508270.42N: Problem 142Kers CelestialNo ratings yet

- From Machineries HandbookDocument1 pageFrom Machineries HandbookKers CelestialNo ratings yet

- Machine Design Day 7Document1 pageMachine Design Day 7Kers CelestialNo ratings yet

- Cf =Mω X ¯ M =Wg Γvg=Γπraq Ω =V/R X ¯=2R/Π: Problem 139Document2 pagesCf =Mω X ¯ M =Wg Γvg=Γπraq Ω =V/R X ¯=2R/Π: Problem 139Kers CelestialNo ratings yet

- Alcorcon Engineering Review Center: STRESS AND STRAIN and Poisons RatioDocument1 pageAlcorcon Engineering Review Center: STRESS AND STRAIN and Poisons RatioKers CelestialNo ratings yet

- Holding Tank Oil Water Tank: WastewaterDocument1 pageHolding Tank Oil Water Tank: WastewaterKers CelestialNo ratings yet

- FEAR KendrickDocument1 pageFEAR KendrickKers CelestialNo ratings yet

- Machine Design Problems - DAY 3KEYSDocument1 pageMachine Design Problems - DAY 3KEYSKers CelestialNo ratings yet

- Machine Design Problems - DAY 1MACHINE ELEMENTSDocument1 pageMachine Design Problems - DAY 1MACHINE ELEMENTSKers CelestialNo ratings yet

- Nitric Acid Production Chap 5Document2 pagesNitric Acid Production Chap 5Kers CelestialNo ratings yet

- Fuel Conversion and Ash Formation Interactions: A Thermochemical Study On Lignocellulosic BiomassDocument78 pagesFuel Conversion and Ash Formation Interactions: A Thermochemical Study On Lignocellulosic BiomassKers CelestialNo ratings yet

- Best Friend: Rex Orange CountyDocument2 pagesBest Friend: Rex Orange CountyKers CelestialNo ratings yet

- Biomolecules: Submitted By: Group 1 Margielyn Dinglasan Efren Cacao Jr. Jessibel MalaluanDocument6 pagesBiomolecules: Submitted By: Group 1 Margielyn Dinglasan Efren Cacao Jr. Jessibel MalaluanKers CelestialNo ratings yet

- Surface MethodologiesDocument1 pageSurface MethodologiesKers CelestialNo ratings yet

- Dmso MembraneDocument21 pagesDmso MembraneKers CelestialNo ratings yet

Machine Design Day 5

Machine Design Day 5

Uploaded by

Kers Celestial0 ratings0% found this document useful (0 votes)

25 views1 pageThe document discusses different types of gears:

1) A worm gear problem where the helix angle of a triple thread worm gear is calculated.

2) A worm gear transmitting 10 hp at 1200 rpm is given, and the lead angle, speed ratio, and center distance are calculated.

3) A bevel gear problem where the angles of the gear and pinion are determined given the diameter of the gear and a velocity ratio of 1/2.

4) Two helical gear problems where gear parameters like pitch, diameter, and number of teeth are calculated based on information like helix angle, pitch, and angular speed ratio.

Original Description:

Original Title

machine design day 5

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses different types of gears:

1) A worm gear problem where the helix angle of a triple thread worm gear is calculated.

2) A worm gear transmitting 10 hp at 1200 rpm is given, and the lead angle, speed ratio, and center distance are calculated.

3) A bevel gear problem where the angles of the gear and pinion are determined given the diameter of the gear and a velocity ratio of 1/2.

4) Two helical gear problems where gear parameters like pitch, diameter, and number of teeth are calculated based on information like helix angle, pitch, and angular speed ratio.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

25 views1 pageMachine Design Day 5

Machine Design Day 5

Uploaded by

Kers CelestialThe document discusses different types of gears:

1) A worm gear problem where the helix angle of a triple thread worm gear is calculated.

2) A worm gear transmitting 10 hp at 1200 rpm is given, and the lead angle, speed ratio, and center distance are calculated.

3) A bevel gear problem where the angles of the gear and pinion are determined given the diameter of the gear and a velocity ratio of 1/2.

4) Two helical gear problems where gear parameters like pitch, diameter, and number of teeth are calculated based on information like helix angle, pitch, and angular speed ratio.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

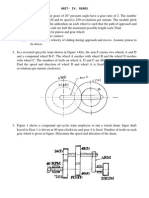

MACHINE DESIGN – DAY 5WORM GEAR1. (ME Bd. Oct.

97)A triple thread worm has a pitch diameter of 3

inches. The wheel has 25 teeth and a pitch diameter of 5 inches.Material for both the worm and the wheel is of

phosphor bronze. Compute the helix angle (tan ).A. 0.20B. 0.30C. 0.40D. 142. Two-thread worm gear, rotating

at 1200 rpm, drives a 26-tooth worm gear and transmit 10 hp. The worm has14.5o teeth with 0.5 pitch, 2 in pitch

diameter, and an included face angle of 60o. The coefficient of friction is 0.06. (Assume: y = 0.212)A. Determine

the lead angle of the worm.B. Determine the speed ratio.C. Determine the center distance.BEVEL GEAR1. A pair of

straight-tooth bevel gears are mounted on the shafts that intersect each other at an angle of 70o. The velocity ratio is

½. Determine the angles of the gear and pinion. Also determine the pitch diameter of the pinion if gear diameter is

15 cm.HELICAL GEARS:1. A helical gear has a helix angle of 25o and transverse circular pitch of π/5. The

number of teeth for the pinion and gear 15 and 45, respectively.A) determine the normal circular pitchB) determine

the pitch diameter of the pinion and gearC) determine the center distance2. A steel pinion having a diameter of

about 254mm meshes with a helical gear which turns one-fifth the angularspeed of the pinion. The normal diametral

pitch to be 4 and the teeth is to be 20o. Determine the required number of teeth for the pinion and gear.

You might also like

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- Gear PrimeDocument7 pagesGear PrimeEjNo ratings yet

- MDSP Set 2Document9 pagesMDSP Set 2iaton77100% (2)

- Assignment Shaft DesignDocument4 pagesAssignment Shaft DesignHasham Mehmood100% (1)

- QBDocument8 pagesQBrahulNo ratings yet

- Assignment Unit - 1: 2) .A Pair of Involute Gears Is in Mesh. The Application Restricts The Space To Accommodate TheseDocument4 pagesAssignment Unit - 1: 2) .A Pair of Involute Gears Is in Mesh. The Application Restricts The Space To Accommodate TheserahulNo ratings yet

- GEARDocument11 pagesGEAREjNo ratings yet

- Asignment Tutorial 3 Toothed Gears and Gear TrainsDocument4 pagesAsignment Tutorial 3 Toothed Gears and Gear TrainsMOJALEFA JACOB MOLEFINo ratings yet

- 01 Helical Gear ONLY ProblemsDocument2 pages01 Helical Gear ONLY Problemskamal0% (1)

- Bevel Gears: Gear DrivesDocument11 pagesBevel Gears: Gear DrivesNeil RubsNo ratings yet

- Assignment 5 - Worm GearDocument1 pageAssignment 5 - Worm GearSR SuryaNo ratings yet

- Problem Set-Md 2Document11 pagesProblem Set-Md 2kim dianonNo ratings yet

- Seatwork No.1Document1 pageSeatwork No.1Easy WriteNo ratings yet

- Tutorial Worm GearDocument1 pageTutorial Worm GearpshretankNo ratings yet

- Gearing - ProblemsDocument7 pagesGearing - ProblemsmanuNo ratings yet

- Assignment No 1 NME 602 MD 2Document2 pagesAssignment No 1 NME 602 MD 2nitin_johri0% (1)

- 330:148 (G) Machine Design Assignment: 6 Spur Gears (CH 11) To Be Submitted by October 15, 2007Document2 pages330:148 (G) Machine Design Assignment: 6 Spur Gears (CH 11) To Be Submitted by October 15, 2007CalvinJosh Gadon FrueldaNo ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of Machinessameer_m_daniNo ratings yet

- Design of Transmission System Unit IIIDocument57 pagesDesign of Transmission System Unit IIIRaj MohanNo ratings yet

- Machine Designe - IIDocument2 pagesMachine Designe - IIAndrea DouglasNo ratings yet

- Md2 Problems On Gears Direction: Answer The Following Problems Using Long Bond Papers. The SolutionsDocument2 pagesMd2 Problems On Gears Direction: Answer The Following Problems Using Long Bond Papers. The SolutionsLordFifth 451No ratings yet

- 12-Worm Gears PDFDocument2 pages12-Worm Gears PDFSarvesh MishraNo ratings yet

- Theoretical QuestionsDocument17 pagesTheoretical Questionsanbamech50% (2)

- Our Official Android App - REJINPAUL NETWORK FromDocument3 pagesOur Official Android App - REJINPAUL NETWORK FromAjay KumarNo ratings yet

- Module3 TutorialDocument7 pagesModule3 TutorialAayush KNo ratings yet

- Instructions:: Gujarat Technological UniversityDocument2 pagesInstructions:: Gujarat Technological Universitysameer_m_daniNo ratings yet

- UNit-2 Numerical ProblemsDocument16 pagesUNit-2 Numerical ProblemsMarthandeNo ratings yet

- Kinematics of Machinery UNIT 4Document4 pagesKinematics of Machinery UNIT 4MugilNo ratings yet

- Mod-3B-Helical GearDocument2 pagesMod-3B-Helical GearSharthak GhoshNo ratings yet

- Iat-I QPDocument2 pagesIat-I QPBalaChandarNo ratings yet

- Sheet 5Document3 pagesSheet 5Fouad MohamedNo ratings yet

- LABORATORY Experiment# 07 Gears Theory and Calculations FEDocument8 pagesLABORATORY Experiment# 07 Gears Theory and Calculations FECARLO JEMBO JAMAGO LABISNo ratings yet

- Module-5 Toothed GearingDocument4 pagesModule-5 Toothed Gearingonkarlamkane4No ratings yet

- Asus TufDocument2 pagesAsus TufKabirNo ratings yet

- Tutorial 3 - Gear CalculationsDocument9 pagesTutorial 3 - Gear CalculationsMohammad AzmudinNo ratings yet

- Assignment 3Document20 pagesAssignment 3Siddhesh RaulNo ratings yet

- DTS Model PaperDocument3 pagesDTS Model PaperrajkumardotcomNo ratings yet

- Bevel and Worm GearsDocument1 pageBevel and Worm GearsDevansh ChhajlaniNo ratings yet

- Tutorial MD II 2015 3Document1 pageTutorial MD II 2015 3rip111176No ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of Machinessameer_m_daniNo ratings yet

- Dme-2 2017-18 Ist AssignmentDocument1 pageDme-2 2017-18 Ist Assignmentmallesh mendaNo ratings yet

- Find The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inDocument4 pagesFind The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inGeoffrey GolbequeNo ratings yet

- UnitDocument6 pagesUnitPreethi SharmiNo ratings yet

- GFHGDocument5 pagesGFHGjoshua espiritu0% (1)

- Tutorial 5 - GearsDocument2 pagesTutorial 5 - GearsAbhishek SharmaNo ratings yet

- Sheet No. 1 Design of GearsDocument3 pagesSheet No. 1 Design of GearssallyNo ratings yet

- Tutorial MD II 2015 4Document1 pageTutorial MD II 2015 4rip111176No ratings yet

- Kom Assignments PDFDocument6 pagesKom Assignments PDFapi-263237278No ratings yet

- R8 Nov-Dec-2015Document3 pagesR8 Nov-Dec-2015Hari VenkitNo ratings yet

- Plate No RaDocument5 pagesPlate No RaEdelleNo ratings yet

- 9A14402 Theory of MachinesDocument8 pages9A14402 Theory of MachinessivabharathamurthyNo ratings yet

- GEARDocument21 pagesGEARraidahNo ratings yet

- MD P3 Answer Key GearsDocument8 pagesMD P3 Answer Key GearsmomonitwiceNo ratings yet

- Theory of Machines - II: T.E./Insem. - 108Document2 pagesTheory of Machines - II: T.E./Insem. - 108palashNo ratings yet

- Problem Set MD Day 4Document4 pagesProblem Set MD Day 4DE GUZMAN, MELVIN CARLO A.No ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- FiltrationDocument7 pagesFiltrationKers CelestialNo ratings yet

- Preparation and Characterization of Cellulose Acetate From Pineapple (Ananas Comosus) LeavesDocument6 pagesPreparation and Characterization of Cellulose Acetate From Pineapple (Ananas Comosus) LeavesKers CelestialNo ratings yet

- Problem 138Document2 pagesProblem 138Kers CelestialNo ratings yet

- Machine Design Problems - DAY 4Document1 pageMachine Design Problems - DAY 4Kers CelestialNo ratings yet

- Problem 141Document1 pageProblem 141Kers CelestialNo ratings yet

- Cf =Mω X ¯ M =Ρv=Ρaπr X =2R/ΠDocument1 pageCf =Mω X ¯ M =Ρv=Ρaπr X =2R/ΠKers CelestialNo ratings yet

- Abstract Cellulose AcetateDocument1 pageAbstract Cellulose AcetateKers CelestialNo ratings yet

- Machine Design - Day 6roller Chain and Sprockets: BeltsDocument1 pageMachine Design - Day 6roller Chain and Sprockets: BeltsKers CelestialNo ratings yet

- F =σA F =3.5 (π (430) ) F =508270.42N: Problem 142Document2 pagesF =σA F =3.5 (π (430) ) F =508270.42N: Problem 142Kers CelestialNo ratings yet

- From Machineries HandbookDocument1 pageFrom Machineries HandbookKers CelestialNo ratings yet

- Machine Design Day 7Document1 pageMachine Design Day 7Kers CelestialNo ratings yet

- Cf =Mω X ¯ M =Wg Γvg=Γπraq Ω =V/R X ¯=2R/Π: Problem 139Document2 pagesCf =Mω X ¯ M =Wg Γvg=Γπraq Ω =V/R X ¯=2R/Π: Problem 139Kers CelestialNo ratings yet

- Alcorcon Engineering Review Center: STRESS AND STRAIN and Poisons RatioDocument1 pageAlcorcon Engineering Review Center: STRESS AND STRAIN and Poisons RatioKers CelestialNo ratings yet

- Holding Tank Oil Water Tank: WastewaterDocument1 pageHolding Tank Oil Water Tank: WastewaterKers CelestialNo ratings yet

- FEAR KendrickDocument1 pageFEAR KendrickKers CelestialNo ratings yet

- Machine Design Problems - DAY 3KEYSDocument1 pageMachine Design Problems - DAY 3KEYSKers CelestialNo ratings yet

- Machine Design Problems - DAY 1MACHINE ELEMENTSDocument1 pageMachine Design Problems - DAY 1MACHINE ELEMENTSKers CelestialNo ratings yet

- Nitric Acid Production Chap 5Document2 pagesNitric Acid Production Chap 5Kers CelestialNo ratings yet

- Fuel Conversion and Ash Formation Interactions: A Thermochemical Study On Lignocellulosic BiomassDocument78 pagesFuel Conversion and Ash Formation Interactions: A Thermochemical Study On Lignocellulosic BiomassKers CelestialNo ratings yet

- Best Friend: Rex Orange CountyDocument2 pagesBest Friend: Rex Orange CountyKers CelestialNo ratings yet

- Biomolecules: Submitted By: Group 1 Margielyn Dinglasan Efren Cacao Jr. Jessibel MalaluanDocument6 pagesBiomolecules: Submitted By: Group 1 Margielyn Dinglasan Efren Cacao Jr. Jessibel MalaluanKers CelestialNo ratings yet

- Surface MethodologiesDocument1 pageSurface MethodologiesKers CelestialNo ratings yet

- Dmso MembraneDocument21 pagesDmso MembraneKers CelestialNo ratings yet