Professional Documents

Culture Documents

Powertakeoffs E2018 v2.0 en

Powertakeoffs E2018 v2.0 en

Uploaded by

fugegaCopyright:

Available Formats

You might also like

- MAN D0836 - CR - enDocument121 pagesMAN D0836 - CR - enSilas F Pimenta86% (58)

- Scania Opticruse GRS905Document2 pagesScania Opticruse GRS905fugega100% (17)

- 08.1 - Electro-Pnuematic Shift, EPS (GS) 1 - Functional Diagram ACTROS, Models 950-954 With Transmission 715.55Document1 page08.1 - Electro-Pnuematic Shift, EPS (GS) 1 - Functional Diagram ACTROS, Models 950-954 With Transmission 715.55fugega83% (12)

- Electrical System BEA2Document92 pagesElectrical System BEA2fugega100% (6)

- Motor 4jj1-Tc NKR 85Document169 pagesMotor 4jj1-Tc NKR 85Miguel Alvarez Guerra100% (40)

- User Manual Operation Maintenance Repair: HY-404-En 04-08Document35 pagesUser Manual Operation Maintenance Repair: HY-404-En 04-08phankhoa83-1No ratings yet

- 1380967670zfecolife PDFDocument2 pages1380967670zfecolife PDFSebastian Andres Sepulveda GolerNo ratings yet

- Product Data Sheet ServotwinDocument2 pagesProduct Data Sheet Servotwinurl295100% (1)

- Transfer CasesDocument4 pagesTransfer CasesJuan Jose Alcaina MuñozNo ratings yet

- Volvo EDC OldDocument12 pagesVolvo EDC OldMircea Gilca100% (2)

- Volvo-FH-Series Specifications Cab UKDocument3 pagesVolvo-FH-Series Specifications Cab UKWagner Nascimento Gonçalves100% (1)

- Telma PartsDocument28 pagesTelma Partsfugega100% (3)

- Current Flow Diagram Seats Heating VW Golf 5Document5 pagesCurrent Flow Diagram Seats Heating VW Golf 5Marius NeaguNo ratings yet

- Powertakeoffs GBDocument23 pagesPowertakeoffs GBAvneet MaanNo ratings yet

- Wabco Pan 22-1 - ADB-5th Ed - 01-2013Document40 pagesWabco Pan 22-1 - ADB-5th Ed - 01-2013ramon montoya50% (2)

- TelmaDocument8 pagesTelmaAlvaro2882100% (1)

- Mercedes Transmission OverviewDocument12 pagesMercedes Transmission OverviewMoez Karoui100% (1)

- DW03195104 PDFDocument146 pagesDW03195104 PDFUmar Shamsudin100% (2)

- Component Description For Quantity Control ValveDocument1 pageComponent Description For Quantity Control ValveTamer MoustafaNo ratings yet

- MAN TGX26.440 6x2Document4 pagesMAN TGX26.440 6x2Abrar Hussain100% (1)

- Https WWW - Ale-Heavylift - Com Wp-Content Uploads 2014 01 EQUIPMENT-DATA-SHEET-SPT-Nicolas PDFDocument1 pageHttps WWW - Ale-Heavylift - Com Wp-Content Uploads 2014 01 EQUIPMENT-DATA-SHEET-SPT-Nicolas PDFRyan LeeNo ratings yet

- EBS Raid: System and Functional DescriptionDocument40 pagesEBS Raid: System and Functional DescriptionraidhemedNo ratings yet

- Me 3-1008Document212 pagesMe 3-1008marcosluna68No ratings yet

- MERITOR SimplexZCamDocument6 pagesMERITOR SimplexZCamLevi LinosNo ratings yet

- Man GN PDF 3Document26 pagesMan GN PDF 3Adrian A UPD100% (1)

- Grove-RT9130E Product Guide PDFDocument27 pagesGrove-RT9130E Product Guide PDFdacem torres cruzNo ratings yet

- Actros Automatic Shift SystemDocument1 pageActros Automatic Shift SystemRowan CorneliusNo ratings yet

- R&I Air Brake System - Learning PDFDocument67 pagesR&I Air Brake System - Learning PDFprasetyo nugrohoNo ratings yet

- EcsDocument25 pagesEcsRocio Panez Julcarima100% (3)

- Service Bulletin Trucks: Exhaust Pressure Governor, Fault TracingDocument9 pagesService Bulletin Trucks: Exhaust Pressure Governor, Fault TracingCristhian Samuel Yacila OrdinolaNo ratings yet

- Volvo FH Wymiana Uszczelniacza Skrzyni IshiftDocument7 pagesVolvo FH Wymiana Uszczelniacza Skrzyni IshiftRafal Wojciechowicz100% (1)

- Current Fault Codes: Code Text StatusDocument4 pagesCurrent Fault Codes: Code Text StatusnaftaliNo ratings yet

- LT-11a Gesamt EngDocument77 pagesLT-11a Gesamt EngPetar Nikolaev100% (3)

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- TRUCK - Volvos Steer SystemDocument75 pagesTRUCK - Volvos Steer SystemNuttenNo ratings yet

- Neral Info MANDocument18 pagesNeral Info MANMohan Preeth100% (1)

- WHB R133Document210 pagesWHB R133nagy_istván_zoltán100% (2)

- ZF As Tronic DescriptionDocument24 pagesZF As Tronic DescriptionBienvenu MassouanguiNo ratings yet

- Actros WS SystemDocument43 pagesActros WS Systemabdulrahman elsaiedNo ratings yet

- V Stay DescriptionDocument3 pagesV Stay DescriptionariwibowoNo ratings yet

- TelmaDocument7 pagesTelmafugega100% (1)

- Special Tools 3Document20 pagesSpecial Tools 3p_jankoNo ratings yet

- WABCO Technical Sheet 4324101020Document2 pagesWABCO Technical Sheet 4324101020DhinesuBaabu Anbu ThangaveluNo ratings yet

- AMG Error CodesDocument1 pageAMG Error CodesSarra Chouchene100% (1)

- Abs PDFDocument17 pagesAbs PDFReffi NaldiNo ratings yet

- Actros BrochureDocument4 pagesActros BrochureAliNo ratings yet

- 89438353-Wiring Diagram, Led Tail Lamps (ENG)Document7 pages89438353-Wiring Diagram, Led Tail Lamps (ENG)Gerson FloresNo ratings yet

- Tractor Series Manual-Wc7p1FCqDocument17 pagesTractor Series Manual-Wc7p1FCqReynaldo Juanito Ludo LafortezaNo ratings yet

- TGX 6x2 Tag Axle TractorDocument4 pagesTGX 6x2 Tag Axle TractorAbrar Hussain100% (1)

- 2021 03 04 - Transmissão ZF TraXon - Worshop MBB (Bus) - Rev00Document42 pages2021 03 04 - Transmissão ZF TraXon - Worshop MBB (Bus) - Rev00Luis LeyvaNo ratings yet

- D13 800 PDFDocument2 pagesD13 800 PDFkhalidfarooq009No ratings yet

- Service Bulletin Trucks: Electric Fuel Pump, Fault TracingDocument10 pagesService Bulletin Trucks: Electric Fuel Pump, Fault Tracingedge_575No ratings yet

- 00 MaintenanceDocument145 pages00 MaintenanceBeary McBearyNo ratings yet

- Voss 232 38104 - SuspensionPart - Katalog - Gesamt KomprimiertDocument320 pagesVoss 232 38104 - SuspensionPart - Katalog - Gesamt KomprimiertMatt NagyNo ratings yet

- 952 12Document7 pages952 12RuthAnayaNo ratings yet

- ZF-16S151 Rebuild PDFDocument66 pagesZF-16S151 Rebuild PDFslipsittin100% (4)

- Volvo D16 Engine Family: Volvo Trucks. Driving ProgressDocument6 pagesVolvo D16 Engine Family: Volvo Trucks. Driving ProgressinduramNo ratings yet

- TGS 4x2 DrawbarDocument4 pagesTGS 4x2 DrawbarAbrar Hussain100% (1)

- Actros Spec Brochure 2018 PDFDocument18 pagesActros Spec Brochure 2018 PDFJose Ivan Rios OrjuelaNo ratings yet

- BBG201122ENDocument438 pagesBBG201122ENLja CsaNo ratings yet

- Traxon Automated Gearbox: Ready To Meet The ChallengeDocument1 pageTraxon Automated Gearbox: Ready To Meet The ChallengeRaved JonesNo ratings yet

- Powertakeoffs E2016 v1 enDocument52 pagesPowertakeoffs E2016 v1 enRonit ManojcumarNo ratings yet

- Man Engine Shop Manual - D0834 Loh 40Document296 pagesMan Engine Shop Manual - D0834 Loh 40kingtiger.bkNo ratings yet

- AGN E2021 V2.0 enDocument215 pagesAGN E2021 V2.0 enelectro.luksaNo ratings yet

- s60mcc8 PDFDocument399 pagess60mcc8 PDFRuslan ZhitarNo ratings yet

- Installing Cable Harness (Preliminary) B9LDocument7 pagesInstalling Cable Harness (Preliminary) B9Lfugega100% (1)

- Dataexpert EXP8J61 User ManualDocument28 pagesDataexpert EXP8J61 User ManualfugegaNo ratings yet

- Muncie CS12 PTO Part ListDocument2 pagesMuncie CS12 PTO Part ListfugegaNo ratings yet

- DIWA List of Approved Oils-Oil Change Interval Up To 120000 and 180000 KMDocument9 pagesDIWA List of Approved Oils-Oil Change Interval Up To 120000 and 180000 KMfugegaNo ratings yet

- Allison Serie 600 Patts Cataog PDFDocument8 pagesAllison Serie 600 Patts Cataog PDFAdal VeraNo ratings yet

- Component Index For Wiring Diagrams BEA2Document5 pagesComponent Index For Wiring Diagrams BEA2fugegaNo ratings yet

- Damper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionDocument8 pagesDamper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionfugegaNo ratings yet

- Connection of Communication Unit 9998555Document5 pagesConnection of Communication Unit 9998555fugegaNo ratings yet

- Scania Retarder TID - 0000788 - 01Document2 pagesScania Retarder TID - 0000788 - 01fugega100% (1)

- Unimog Oil Spec 231 3Document2 pagesUnimog Oil Spec 231 3fugegaNo ratings yet

- GS3.3 Test 02 2010 InstructionsDocument2 pagesGS3.3 Test 02 2010 Instructionsfugega100% (1)

- ZF Ecosplit 12 Speed - 1325 - 751 - 101 - en 2009 PDFDocument110 pagesZF Ecosplit 12 Speed - 1325 - 751 - 101 - en 2009 PDFfugega83% (6)

- Telma Bova H03 GBDocument62 pagesTelma Bova H03 GBfugega100% (2)

- TelmaDocument7 pagesTelmafugega100% (1)

- SHCS DimsDocument4 pagesSHCS DimsKris RowlandsNo ratings yet

- BLDC Pump Dc50eDocument4 pagesBLDC Pump Dc50eErick Lira QuinteroNo ratings yet

- 49cd247039c68100 600v Wiring Voltage Drop Spreadsheet 1Document3 pages49cd247039c68100 600v Wiring Voltage Drop Spreadsheet 1Víctor RojasNo ratings yet

- 201 19-RP4Document80 pages201 19-RP4iwanNo ratings yet

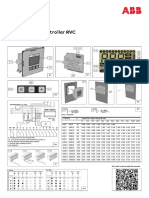

- 9AKK107045A6911-RVC Manual Part 1 - Quick Start - REV CDocument2 pages9AKK107045A6911-RVC Manual Part 1 - Quick Start - REV CHpnoteNo ratings yet

- Iot Based Irrigation SystemDocument77 pagesIot Based Irrigation System19E45A0286 SDESEEENo ratings yet

- Carraro Repair KitsDocument8 pagesCarraro Repair KitsOfftap's100% (2)

- Basic Transformer Training - Chapter 3 - Federal PacificDocument5 pagesBasic Transformer Training - Chapter 3 - Federal PacificfluxNo ratings yet

- Endevco 7270AM6Document2 pagesEndevco 7270AM6DizzixxNo ratings yet

- Quiet Connect Series RS36: Specification SheetDocument6 pagesQuiet Connect Series RS36: Specification SheetjechurchNo ratings yet

- Pfaff Expression 2028 Sewing Machine Instruction ManualDocument52 pagesPfaff Expression 2028 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- Heater & A - C (A - C Kit) (Metal Housing) - S630Document3 pagesHeater & A - C (A - C Kit) (Metal Housing) - S630Romero JhonNo ratings yet

- Abb-Mcc Method StatementDocument50 pagesAbb-Mcc Method StatementKrishnakumar PaiNo ratings yet

- Panasonic CS-S10PKH Service ManualDocument187 pagesPanasonic CS-S10PKH Service ManualZulfikar FirdausNo ratings yet

- Different Elevator Controls: Technical CatalogDocument57 pagesDifferent Elevator Controls: Technical Catalogabaelwalid01No ratings yet

- Iii. Programmable Logic Controller (PLC) Omron Cpm1ADocument17 pagesIii. Programmable Logic Controller (PLC) Omron Cpm1AMuhammad Reihan IskandarNo ratings yet

- Practice Exam No. 2 2018 PDFDocument23 pagesPractice Exam No. 2 2018 PDFJevan CalaqueNo ratings yet

- Moc3za Kaz33d3 - 2013 11 06 - 04 23 39Document8 pagesMoc3za Kaz33d3 - 2013 11 06 - 04 23 39Renato AlmeidaNo ratings yet

- Ae 036884 008Document1 pageAe 036884 008RanielNo ratings yet

- Master View KVM Switch: User ManualDocument19 pagesMaster View KVM Switch: User ManualMax Zamora R.No ratings yet

- Series N55B and LFN55B Installation InstructionsDocument2 pagesSeries N55B and LFN55B Installation InstructionsWattsNo ratings yet

- 50kW TX Operation ManualDocument161 pages50kW TX Operation ManualtamiratNo ratings yet

- Atmel DatasheetDocument27 pagesAtmel DatasheetKhoa DangNo ratings yet

- Renewal Parts YK (Stype F)Document56 pagesRenewal Parts YK (Stype F)Thang TV100% (2)

- Sanwa-Cd800a + - Datasheet PDFDocument2 pagesSanwa-Cd800a + - Datasheet PDFcpt_yahoo.esNo ratings yet

- Temperature Controlled Fan ReportDocument26 pagesTemperature Controlled Fan ReportHemant Shah43% (7)

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) PneumaticDocument50 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) PneumaticAnh NguyenXuanNo ratings yet

- White Paper Encoder Mounting 9-4-13Document4 pagesWhite Paper Encoder Mounting 9-4-13baaakNo ratings yet

Powertakeoffs E2018 v2.0 en

Powertakeoffs E2018 v2.0 en

Uploaded by

fugegaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Powertakeoffs E2018 v2.0 en

Powertakeoffs E2018 v2.0 en

Uploaded by

fugegaCopyright:

Available Formats

MAN GUIDELINES

TO FITTING BODIES TRUCK

Power take-offs

Edition 2018 V2.0

P U B L I S H E R

MAN Truck & Bus AG

(hereinafter referred to as MAN)

Engineering Vehicle Truck

Application Engineering

Dachauer Str. 667

D-80995 Munich

E-Mail: info.manted@man.eu

Fax: + 49 (0) 89 1580 4264

www.manted.de

This English version is a translation.

In case of doubt or conflict the valid German language original will govern.

We reserve the right to make technical modifications in the course of further development.

© 2018 MAN Truck & Bus AG

Not to be reprinted, duplicated by any means whatsoever or translated – in whole or in part – without the prior

written consent of MAN Truck & Bus AG. All rights, especially those deriving from copyright law, are expressly

reserved by MAN.

Trucknology® and MANTED® are registered trademarks of MAN Truck & Bus AG.

If names constitute trademarks, they are also recognised as protected by the relevant owner without use of

the appropriate symbols (® ™).

I Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Content

1.0 General principles.............................................................................. 3

1.1 Calculating power and torque............................................................ 6

1.2 Propshaft connection to power take-off............................................ 8

1.2.1. Connection to propshaft on the power take-off in MAN

gearboxes........................................................................................ 10

2.0 Regulating engine speed................................................................. 12

2.1 Regulating the engine speed using cruise-control controls............. 12

2.2 Engine speed regulation via the ISC interface................................. 14

2.3 Starting and stopping the engine from outside the cab.................. 15

2.4 Gear-shift inhibitor and neutral selection switch.............................. 16

2.5 Stationary and non-stationary operation......................................... 17

2.6 Diesel particulate filter (DPF) regeneration (DPF)............................. 17

3.0 Technical description of power take-offs......................................... 18

3.1 MAN power take-offs....................................................................... 18

3.1.1 V-belt pulley..................................................................................... 18

3.1.1.1 Mounting brackets........................................................................... 20

3.1.2 Power take-off on air compressor................................................... 21

3.1.3 Camshaft power take-off, flywheel-side power take-off.................. 23

3.1.4 Outrigger support for hydraulic pumps on the flywheel-side

power take-off.................................................................................. 37

3.1.5 Power take-off on transfer case....................................................... 41

3.2 Gearbox power take-off................................................................... 48

3.2.1 Differentiation................................................................................... 48

3.2.2 Clutch-dependent power take-off ................................................... 48

3.2.2.1 Clutch-dependent power take-off on the ZF gearbox..................... 48

3.2.2.2 Clutch-dependent power take-offs on the MAN gearbox............... 54

3.2.3 Engine-dependent power take-offs................................................. 59

3.2.4 Power take-offs on gearboxes with converter-clutch units............. 62

3.2.5 Power take-offs on ZF HP automatic gearboxes............................. 63

3.2.6 Power take-offs and Intarders.......................................................... 65

3.2.7 Power take-offs with MAN HydroDrive............................................ 66

3.2.8 Power take-offs on ZF gearboxes (technical specifications

and tables) ....................................................................................... 66

3.2.9 Power take-off on EATON gearbox (technical specifications

and tables)........................................................................................ 66

If not otherwise specified: all dimensions are in mm, all weights and loads are in kg.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 II

These Guidelines to fitting bodies aimed at professional bodybuilder. Therefore, in this guideline, background

knowledge is assumed.

It should be noted that some work may only be carried out by suitably qualified personnel in order to avoid the risk

of injury and to achieve the necessary quality for construction work.

Notational conventions

In this guideline the following notational conventions are used:

Information

This notice points out further information to you.

Important notice

This notice draws your attention to possible damage to the vehicle.

Environmental notice

An environmental notice provides you with tips for environmental protection.

Warning notice

A hazard warning notice points out possible risks of accident or injury to you and others.

2 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

1.0 General principles

Power take-offs connect the vehicle‘s engine with the units to be driven, for example compressors or hydraulic

pumps.

Careful selection of the power take-off and a study of the installation situation are essential for subsequent

trouble-free operation of the vehicle.

MAN (for address see “Publisher“ above) will be happy to provide advice in this regard.

The guidelines for power take-offs are not designed to replace the vehicles‘ operating instructions.

Information

Power take-offs not offered ex works for the respective vehicle are installed at the installer‘s risk.

Power take-offs can be installed at the following locations, in some cases at several of them at once:

• On the engine

- On the front end of the engine (e.g. on the front end of the crankshaft, using a twin-groove

V-belt pulley, as a pump directly connected to the air compressor)

- On the engine rear (e.g. camshaft power take-off, flywheel-side power take-off)

• On the gearbox

• On the transfer case.

When selecting a power take-off, the following factors must be taken into consideration:

• Permissible torques

• Direction of rotation

• Impact factors

• Service life

• Critical engine speed

• Maximum length of the propshaft

• The maximum deflection angle and installation space for the propshaft

• Transmission ratio

• Gearbox technology (OD/DD)

• Cooling (no trapped heat at power take-off)

• Assembly and access

• Pump attachment

• The instructions of the power take-off manufacturer

• The instructions of the pump manufacturer

• The instructions of the propshaft manufacturer

The manufacturers of power take-offs have issued their own publications, which provide detailed information on:

• Correct choice of power take-off

• Correct utilisation

• Avoidance and elimination of vibration.

The maximum torque allowed for the power take-off can only be utilised if it is operated without any impacts and

vibrations. This is rarely possible, which is why in practice impact factors must be taken into consideration when

selecting the power take-off. A jolt or impact is understood to be a rapid increase in torque that decreases again

rapidly after a very short period of time. The quotient of maximum and minimum torque is known as the impact

factor.

The dimensioning must be based on the maximum occurring torque including the impact factor.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 3

The reduction in torque value at the power take-off must not fall below the maximum torque value of the engine.

Engine diagrams which provide information about performance and torque value can be requested from MAN

(for address see “Publisher” above).

Power take-offs must be protected against overheating; if necessary, the fan wheel offered by MAN must be

installed. Besides the fan wheel, various other heat-exchanger solutions for cooling gearboxes and power take-offs

are available. These make it possible to achieve fatigue strength for certain types of power take-off. More detailed

information can be obtained from MAN (for address see “Publisher“ above).

The heat exchanger solutions offered by MAN are retrofittable. The service information no. 230803a for the TGL

and TGM series is also accessible via the MAN After Sales Portal. A retrofitting guide for the TGS and TGX series is

available on the MAN After Sales Portal via the VirtTruck® system.

If applicable, modifying the vehicle parameters is required.

If you have any questions about the heat exchanger solutions offered by MAN, please contact MAN (for address,

see above under “Editor”).

Important notice

Heat must not be trapped; inadequate heat dissipation will cause damage.

Important notice

Note on gearbox-oil temperature:

The gearbox and the power take-off‘s nominal oil temperature may not exceed 110°C during operation.

Peak temperatures of max. 130°C are still permissible for brief periods (a maximum of 30 minutes).

If a check reveals that the oil temperature reaches higher values, then some form of external cooling

(e.g. a fan wheel) must be provided.

If parts of the engine enclosure have to be removed in order to install power take-offs, they must be replaced by

suitable items provided by the installing company. It must be ensured that excessive noise is not emitted.

The instructions in the section of the series-editions, chapter III Chassis, 6.3 “Engine environment“ must be observed.

Power take-offs are not designed to accept radial bearing loads imposed by chains or V-belt drives.

For this reason, chain sprockets or V-belt pulleys may not to be connected directly to the power take-off.

If the equipment to be driven could overload the power take-off, some form of overload protection must be installed.

This also applies if only occasional peak torques beyond the permitted limit occur. MAN workshops can use the

standard interface to configure and provide wiring for speed and torque limiters for TG vehicles

More detailed descriptions of the interfaces, pin assignments and information on parameterisation can be found in

the series-editions, chapter III-Chassis, 8.3 “Interfaces on the vehicle, preparations for the body“.

As is customary in mechanical engineering, all directions of rotation are quoted “looking at the shaft journal“,

that is to say at the output point.

4 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

The rotational speed at the power take-off‘s output is calculated by multiplying the engine speed by the respective

PTO‘s speed factor.

Important notice

The following are not permitted:

• Engine speeds < 800/minute with the power take-off engaged and under load.

• Even-numbered transmission ratios such as 1:1, 1:2 etc., since vibration could occur as a result of resonance.

At engine speeds of < 800/minute, unfavourable relations in conjunction with drive shafts may lead to

the development of excessive noise and vibrations on the power take-offs.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 5

1.1 Calculating power and torque

Before the correct power take-off can be selected, the following details of the equipment it is to drive must

be available:

• Power requirement, torque

• Direction of rotation

• Period of operation

• Speed

• Impact factors.

The output torque stated for clutch- and engine-dependent power take-offs connected to the gearbox is based on

a PTO output with a nominal speed of 1500 rpm. Output torque decreases at higher speeds.

As a constant, output power at 1500 rpm is used here.

Formula 01: Calculation of nominal output power

M [Nm] · nPTO [min-1]

P [kW]

= __________________

9552

P = Nominal output power in kilowatts

M = Permissible output torque according to data sheet

nPTO = Rotational speed of power take-off – here, the nominal speed of 1,500 rpm

Using this constant it is then possible to calculate the available output torque at higher speeds.

Formula 02: Calculation of the permissible output torque at power take-off speeds > 1,500 rpm

P [kW] · 9552

Mmax [Nm] = ____________

nPTO [min-1]

Mmax = Permissible output torque at a speed > 1,500 rpm

P = Nominal output power in kilowatts (ascertained in the previous step of the calculation)

nPTO = Rotational speed of power take-off – here, the actual rotational speed

6 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Parallel use of two outputs

If both outputs are being used at the same time in a clutch-dependent power take-off with two outputs, the

countershaft of the gearbox must not be overloaded.

In this case, the transmission of the power take-off and the gearbox must be considered.

If, for example, the output torque of the top output is completely exhausted, there is residual torque for the bottom

output that is under its maximum permissible load capacity.

Formula 03: Calculation of the remaining residual torque at the countershaft

f

MVR = MV - __o ٠ Mo

fv

Mo = output torque at the top output

MV = maximum permissible output torque at the countershaft

MVR = remaining residual torque at the countershaft

fo = DN factor of the top output

fV = transmission of the countershaft

The maximum extractable output torque at the bottom output can be calculated using the remaining residual torque

on the countershaft.

Formula 04: Calculation of the permissible output torque at the second output

fu

Mu = MVR ٠ __

fv

Mu = maximum permissible output torque at the bottom output

MVR = remaining residual torque at the countershaft

fu = DN factor of the bottom output

fV = transmission of the countershaft

If the output torque at the bottom output is completely exhausted, the remaining maximum permissible output

torque at the top output must be determined in line with the formulas above.

The values required for this calculation can be found on www.manted.de in the power take-off on the gearbox

section.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 7

1.2 Propshaft connection to power take-off

With regard to the propshaft connection, the fundamentals laid down in the “Propshaft” section of the

chapter 6.5 “Gearbox and propshafts” (in the booklet applicable to the respective model range) apply.

The following conditions apply to the deflection angle of both single-plane and three-dimensional shaft systems:

• Deflection angle ≤ 7°, a tolerance of +1° is permissible

• Absolute difference in angle of ≤ 1° between the two deflection angles of a shaft; 0° is to be aimed for.

Fig. 01: Geometry of a propshaft train for power take-offs

5

4

2 3

T_364_000007_0001_G

1) Gearbox

2) Unit

3+4) Flanges must be aligned parallel

5) Deflection angles of the propshaft

8 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

When specifying the length of the propshaft, the length of any flexible coupling that may have to be installed must

be taken into consideration.

The stated values apply to both single-plane and three-dimensional propshaft systems.

In the case of three-dimensional propshaft systems, the resultant three-dimensional deflection angle must

be taken into account. Exceptions to the stated values must be expressly approved by MAN

(for address see “Publisher” above).

Propshafts close to where persons move or work must be encased or covered.

In certain cases it may be necessary to modify individual cross members in order to ensure a permissible angle for

the propshaft. MAN offers its own solutions for this.

On the TGL/TGM vehicle series, for example, a height-adjustable portal cross member can be installed. If one or

more PTOs are assembled to the gearbox ex works, then the first frame cross member (portal cross member) behind

the gearbox can be a height-adjustable design.

This allows the installation of propshafts on the PTO that take the maximum permissible deflection

angle of 7° (+1° tolerance) into account. In the standard position, the cross member, including the bolt head, extends

up to 100 mm above the top edge of the frame. The height-adjustable cross member can be retrofitted

(for example when a PTO is retrofitted).

If these solutions are inadequate, the planned measures must be approved by MAN beforehand

(for address see „Publisher“ above).

Fig. 02: Height-adjustable portal cross member for power take-off on gearbox

1

70

30 4x 4x 30

T_327_000003_0001_G

1) Driving direction

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 9

1.2.1. Connection to propshaft on the power take-off in MAN gearboxes

Unlike the gearboxes produced by ZF described in the previous chapter, the following modifications to the

clutch-dependent power take-offs on the MAN TipMatic 12+2 gearbox arise.

Evaluation of irregular rotational position

For the lowest possible vibrations during the operation of the propshaft line, the correct alignment of the universal

joints must be ensured.

Fig. 03: Propshafts

Correct rotational position of the prop shafts Twisted universal joints

The irregularity is evaluated with a simple formula, in which the prop shaft deflection angles α1 and α2 are used.

If the universal joints are correctly aligned, these are:

Irregularity = α12 - α22

If the universal joints are mounted in a twisted position, the following formula can be used:

Irregularity = α12 + α22

The irregularity must not be greater than +25 and not lower than -25, in order to avoid vibration problems.

The universal joint angles must be more than 1°, since smaller angles can cause pressure damage to the universal

joints, which results in a shortening of service life.

If α1 = α2, the angles are correctly set.

10 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Deflection angles and permissible output torque

Too large prop shaft deflection angles limit the max. permissible output torque of the power take-off.

The max. permissible output torque must only be decreased if the prop shaft deflection angle is not greater than 7°.

In the case of larger prop shaft deflection angles, the max. permissible output torque reduces to the value specified

in the following diagram.

Fig. 04: Diagramm: highest possible torque of the power take-off

100% = highest possible torque of the power take-off.

T_391_000003_0001_D

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 11

2.0 Regulating engine speed

Whether the vehicle is being driven or used to operate power take-offs, the power required from the engine is not

normally constant. The fluctuation in power requirement at a constant speed of rotation has to be equalised by

varying the amount of injected fuel.

At a constant speed of rotation, the following therefore applies:

• Less power required - less fuel injected

• More power required - more fuel injected.

Depending on the vehicle’s body and its intended purpose, the power take-off and therefore the engine are required

to run either at a minimum, a constant or a maximum speed. In most cases more than one of these requirements

has to be fulfilled simultaneously. All MAN diesel engines regulate speed and load by means of EDC

(EDC= Electronic Diesel Control). Interventions by the bodybuilder are made via the ISC (Intermediate Speed

Control) interface.

The ISC can also be actuated via the CSM (customer-specific control module).

The set speeds are maintained at a constant level even when the load varies; the accuracy of this system is always

greater than that of a mechanical system.

Lower speeds when operating the power take-off do not necessarily result in lower consumption or less noise.

The engines are optimised for certain operating situations that ensure economical and quiet operation.

2.1 Regulating the engine speed using cruise-control controls

MAN trucks and tractor units are fitted with a cruise control lever to regulate the vehicle’s speed. Alternatively, the

cruise-control function can also be controlled by means of the function keys on the multifunction steering wheel.

At road speeds ≤ 20 km/h this allows the engine speed to be regulated even without intervention in

the ZDR interface.

The memory button (Fig. 05 Pos. 1 / Fig. 06 Pos. 1) allows a constant speed to be set, with the + and - buttons

setting a working speed between an upper and lower limit. This then remains constant until the off button

(Fig. 05 Pos. 2 / Fig. 06 Pos. 2) is pressed or another switch-off condition (e.g. operating the brakes) occurs.

The engine-speed value can be permanently saved by pressing the memory button (depress Button 1 in Fig. 05, Pos. 1

for two seconds) and called up again by briefly pressing the memory button (Fig. 05 / Pos. 1), even after the engine

has been turned off and/or the vehicle has been driven in the interim.

12 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Fig. 05: Layout and function of cruise control lever

T_255_000001_0001_G

1 2

1) Memory button

2) Off button

Fig. 06: Layout and function of the multifunction steering wheel

T_464_000003_0001_G

1) Memory button

2) Off button

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 13

2.2 Engine speed regulation via the ISC interface

The EDC control unit can be programmed to obtain suitable engine speed settings when power take-offs are to be

used.

The following can be set:

• Speeds (i.e. reduced top speed when power take-off is in use)

• Intermediate speeds

• Speed limits if intermediate speed control is required (e.g. for protection of the unit)

• Regulating behaviour and characteristic

• Switching preconditions.

The body-mounted equipment control system intervenes (e.g. by a switching signal to run up to a predetermined

intermediate speed) and registers the operating status (e.g. parking brake, gearbox in neutral, power take-off switch

setting) via the ISC interface. In order for these programmable options to be used, the following information

is required:

• ISC interface (for the 2000 model ranges L2000, M2000 and F2000)

• Interface for intermediate speed control at the vehicle management computer ISC at VMC

(standard equipment on all vehicles in the TG ranges).

• Customer-specific control module (optional, standard equipment on all vehicles in the TG ranges).

Information

A detailed description of the VMC and CSM interfaces with examples of use and current documentation on

the hard and software can be found in the series-editions, chapter III-chassis, 8.3 “Interfaces on the vehicle,

preparations for the body“ booklet. Please note that only the interface is offered ex works but none of the wiring.

Industry-specific parameters can already be programmed at the factory if the desired values are provided in good

time to the MAN salesperson by the bodybuilder. Changes can be made at a later date using the MAN-cats

diagnostic system.

14 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

2.3 Starting and stopping the engine from outside the cab

Certain body-side equipment requires that the vehicle’s engine can be started or stopped from outside the cab.

MAN offers a „preparation for engine start/stop facility at frame end“ independent of intermediate engine speeds

control (see chapter 2.2 “Engine speed regulation via the ISC interface”) .

The following always apply when this package is fitted.

• Gearbox neutral selection switch; the engine can be started only if neutral has been selected, i.e. if no

gear is engaged.

• Parking brake signal recognition; the engine can be started only if the parking brake has been applied.

• Start inhibit relay; the engine cannot be started again if it is already running.

Retrofitting the interface is possible but requires detailed knowledge of electrical/electronic systems and the

MAN on-board network. We therefore advise ordering it from the factory.

The connecting cable is rolled up at the frame end. If the vehicle must not be moved during power take-off

operation, we advise the additional fitting of a gear-shift inhibitor (see next section 2.4, „Gear-shift inhibitor and

neutral selection switch“).

In the currently available TGL/TGM and TGS/TGX model ranges, in addition to the preparation at the frame end an

engine start/stop facility beneath the front flap is also offered. The scope of functions is identical with that of the

preparation at the frame end. However, no wiring harness is routed to the frame end.

Start/stop facilities developed by bodybuilders themselves must comply with the instructions as set down in

the separate interface booklets.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 15

2.4 Gear-shift inhibitor and neutral selection switch

On certain vehicles/types of body it is necessary to ensure that the power take-off can be engaged only if the vehicle

is not in gear. This function is enabled by a neutral selection switch. A gear-shift inhibitor also covers the reverse

situation, in that it prevents a gear being selected if the power take-off is already operating.

The MAN gear-shift inhibitor has the effect of an „exclusive OR“ switch, i.e. either a gear or the power take-off can

be selected but not both at the same time.

In the case of vehicles with manual gearboxes, gear shift is mechanically inhibited, while in the case of vehicles with

automatic gearboxes (TipMatic), gear shift is inhibited by means of software parameters.

Warning notice

We advise fitting a gear-shift inhibitor if engine speed is to be regulated and/or the engine is to be started from

outside the cab and the vehicle cannot or must not be moved.

Fig. 07: Gear-shift inhibitor on manual gearbox

T_327_000001_0001_G

1) Gear-shift inhibitor

If a mechanical gear shift blocker is subsequently installed, the function must be tested in accordance with the

following procedure before starting up the vehicle:

• Gearbox remains in neutral

• Supply air must be in contact with the blocking valve when the power take-off is activated.

• Moving-off gears check

- Engage gear 1 → if the gear cannot be engaged, function OK.

- Engage gear 2 → if the gear cannot be engaged, function OK.

- Engage gear 3 → if the gear cannot be engaged, function OK.

- Engage gear 4 → if the gear cannot be engaged, function OK.

- Engage R-gear → if the gear cannot be engaged, function OK.

• If a gear can be engaged, function not ok.

Important notice

The implementing workshop is responsible for proper and professional installation, as well as for the functional

test of the gear shift blocker.

16 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

2.5 Stationary and non-stationary operation

Warning notice

We advise fitting a gear-shift inhibitor if engine speed is to be regulated and/or the engine is to be started from

outside the cab and the vehicle cannot or must not be moved..

As standard, power take-offs at the ends of gearboxes are designed for non-stationary operation, i.e. the power

take-off can also be used while the vehicle is in motion in a moving-off gear. If gear-shift inhibition has been

selected, the power take-off is switched to stationary operation. It can then only be operated when the vehicle is not

moving. If more than one power take-off is installed, each one can be configured as either a stationary or a

non-stationary power take-off.

If a power take-off configured as stationary is in operation, it is then not possible to engage gear, irrespective of

whether a power take-off configured as non-stationary is present or in operation.

If only power take-offs configured as non-stationary are in operation, a moving-off gear can be engaged and the

vehicle can be set in motion. Engaging gear and changing gear are possible only while the vehicle is not in motion.

2.6 Diesel particulate filter (DPF) regeneration (DPF)

Depending on the use of the vehicle, a regeneration of the diesel particulate filter is necessary at certain intervals.

The diesel particulate filter (DPF) collects the particulate and converts it into CO2. This process is known as

regeneration. For this purpose, a high exhaust gas temperature is required prior to the DPF. Regeneration usually

takes place automatically during driving operation and is not noticed.

For special applications, e.g. rental of vehicles with skylifters, the possibility of initiating DPF regeneration, even if

this is not yet required, may be useful. For this purpose, MAN offers a retrofitting solution for vehicles in the TGL

and TGM series. The relevant procedure and additional information is described in the Service Information 6109TA.

For vehicles that are predominantly operated in stationary conditions and are operated outside the cab, there is the

option to display the information for a necessary regeneration of the DPF as a transmitted message via the CAN

body on the control unit. Exact information can be found in the electrical interface description of the

customer-specific control module from step 2.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 17

3.0 Technical description of power take-offs

Information

We wish to point out that the power take-off variants described in the guidelines to fitting bodies are possibly not

available ex works. The power take-offs available as standard can be found in our currently applicable sales

documents.

With regard to a change in the intended purpose of a vehicle and/or increasing its resale value, it is recommended

that the vehicle be equipped with the necessary electrical preparation for retrofitting a power take-off.

3.1 MAN power take-offs

MAN manufactures the following power take-offs itself:

• V-belt pulley, engine-dependent; for description see Section 3.1.1

• Power take-off at the air compressor, engine-dependent; see Section 3.1.2

• Camshaft or flywheel-side power take-off, engine-dependent; for description see Section 3.1.3

• Power take-off on transfer case; depending on switch position, engine-, gearbox- or distance-dependent;

for description see Section 3.1.4.

3.1.1 V-belt pulley

It is possible to fit a V-belt pulley with an effective diameter dw = Ø 242 mm with two grooves at the front end of

the crankshaft on the D08 engine.

This V-belt pulley is installed at the factory in conjunction with a hydraulic pump, on the right-hand side in the

direction of travel. In addition, a poly-V belt pulley with a diameter dw = Ø 224.8 mm is fitted to the crankshaft on

vehicles fitted with air conditioning in order to drive the air-conditioning compressor.

• L2000 / M2000: If air conditioning is fitted, this output point is occupied by the air-conditioning compressor.

• TGL/TGM: Air conditioning and power take-off can be combined.

Narrow V-belts as per DIN 7753 (air-conditioning compressor) or internationally ISO 2790 are to be used as

the transmission element. When calculating the power rating, proceed in accordance with DIN 7753 Part 2 or in

accordance with the information provided by the belt manufacturer.

MAN can supply ex works various units driven by V-belts or poly V-belts, in particular hydraulic pumps.

The current range of products available for delivery can be found in the sales systems.

18 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Fig. 08: Hydraulic pump on D08 engine

T_327_000002_0001_G

1) Hydraulic pump

Table 01: Technical specifications of hydraulic pumps driven by V-belt pulleys

Engine Volume per Pressure during constant

Speed factor Hydraulic pump

model revolution in cm³ operation in bar:

19 190

Hydraulic pump

16 230

D08 1,175

14 + 5,5 200

Dual hydraulic pump

16 + 8 250

Hydraulic pumps fitted at the factory are fastened to the crankcase yoke.

Other units may also be mounted here if they do not weigh more than 11 kg.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 19

3.1.1.1 Mounting brackets

A mounting bracket is available as a works solution for engines of the type D08 for subsequent installation of units

that are driven by a V-belt on the front side of the engine. Retrofitting is possible.

D08 engines with emission standard EURO 5, EEV and EURO 6 (without SCR only technology)

MAN part numbers and installation instructions for retrofitting are shown in drawing 51.19100-8000. This drawing is

available from MAN (for address, see above under “Publisher”).

D08 engines with emission standard EURO 6 with SCR only technology

MAN part numbers and installation instructions for retrofitting are shown in drawing 51.19100-8041. This drawing is

available from MAN (for address, see above under “Publisher”).

Retrofitting for engines with emission standard EURO 6 with SCR only technology is more complex as it is nec-

essary to replace the oil sump. It is therefore recommended to purchase this equipment option directly ex-works.

The following conditions apply to both versions:

• Max. perm. power rating: 10 kW

• Max. unit weight (incl. intermediate plate): 40 kg

• Refer to the specified drawings for further information

Fig. 09: Mounting bracket D08 SCR only

T_026_000001_0001_G

20 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

3.1.2 Power take-off on air compressor

It is possible to flange hydraulic pumps directly onto the front ends of the two-cylinder air compressors on

six-cylinder D28 engines (vehicles in the model ranges F2000, E2000 and TGA built up to 2003).

Fig. 10: Illustration on left: Output point on front end of two-cylinder air compressor on D28 Euro 3

engine

Illustration on right: Examples of hydraulic pumps on front end of two-cylinder

air compressor on D28 Euro 3 engine

4 5

1 3

2

6

7

T_327_000004_0001_G T_327_000005_0001_G

1) Alternator

2) Refrigerant compressor for cab air conditioning

3) Output at the two-cylinder air compressor

4) Single pump

5) Pump for hydraulic power steering

6) Tandem pump

7) Pump for hydraulic power steering

MAN can fit different hydraulic pumps ex works to the front end of the air compressor. Information on the sales

program of the respective country can be obtained from the MAN salesperson or branch responsible. Drawings are

available from MAN (for address see “Publisher” above).

Table 02: Technical specifications of hydraulic pumps for assembly on the air compressors

of D28 engines

Pressure during

Engine Volume per revolution

Speed factor Hydraulic pump constant operation

model in cm³

in bar:

Hydraulic pump 32 210

D28 1,15

Dual hydraulic pump 25 + 11 210

For 6-cylinder engines of the D20/D26 series (vehicle series TGA, TGS and TGX) with one and two-cylinder air com-

pressors, it is possible to flange hydraulic pumps directly to the front end of the air compressor.

An air compressor with a second output shaft is required for this purpose. The air compressor cannot subsequently

be equipped with a second output shaft. Retrofitting requires replacement of the air compressor.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 21

Preparation for retrofitting pumps on air compressors is available and can be ordered ex works. Before hydraulic

pumps not provided and released ex works are attached, the installation space must be checked by the body

manufacturer. 3D models for checking installation space are available from MAN (for address, see “Publisher”

above).

MAN can fit different hydraulic pumps ex works to the front end of the air compressor. Information on the sales

program of the respective country can be obtained from the MAN salesperson or branch responsible. Drawings are

available from MAN (for address see “Publisher” above).

Table 03: Technical specifications of hydraulic pumps for assembly on the air compressors of

D20/26 engines

Pressure during

Volume per revolution

Engine model Speed factor Hydraulic pump constant operation

in cm³

in bar:

32 250

D20 Hydraulic pump 22,5 230

and 1,194 11 280

D26 22,5 + 32 230

Dual hydraulic pump

11 + 22,5 230

The single-cylinder air compressor is able to deliver the following torque:

• Lower power take-off: max. 180 Nm

Table 04: Technical data for hydraulic pumps for assembly on the two-cylinder air compressor for

engines D20/D26

Volume per revolution Pressure during cons-

Engine model Speed factor Hydraulic pump

in cm³ tant operation in bar:

32 250

D20

Hydraulic pump 22,5 230

and 1,194

11 280

D26

Dual hydraulic pump 11 + 22,5 230

The two-cylinder air compressor is able to deliver the following torque:

• Lower power take-off: max. 180 Nm

Information

Hydraulic pumps cannot be fitted to the air compressors of six-cylinder engines in the D38 model range.

Please note that the hydraulic pumps on the air compressor are not connected with the air compressor output shaft

when the vehicle is delivered. In order to do this, the clutch drive plates located in the vehicle interior first have to

be inserted. This prevents the pumps running while dry and possibly being damaged.

Optionally, a dual-circuit hydraulic system (e.g. for operating a snowplough and a gritter) can be delivered ex works.

On vehicles equipped with MAN HydroDrive the supply pump for the hydrostatic drive is attached to the lower

output shaft. In this case it is not possible to attach an additional hydraulic pump.

On vehicles equipped with Air Pressure Management (APM) - that is, with an air compressor that switches off

automatically - it is currently not possible to attach power take offs to the air compressor.

Any possible changes can be found in the sales systems.

22 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

3.1.3 Camshaft power take-off, flywheel-side power take-off

The output point is at the rear end of the engine. These power take-offs are not switchable but are permanently

engaged. However, the bodybuilder many install an electromagnetic coupling in the propshaft train.

The camshaft power take-off is available for engines with the D28 designation (vehicles in the model ranges F2000,

E2000 and TGA built up to 2003).

The flywheel-side PTO can be delivered for 6-cylinder engines with the designation D38 (vehicle series TGX),

D20/D26 (vehicle series TGA, TGS/TGX) and D08 (vehicle series TGL and TGM).

It is not possible to retrofit the flywheel-side PTO. For the engines D38/D20/D26, a preparation for the flywheel-side

PTO is available. The respective adaptors for the drive shaft connection or for direct pump attachment can then be

easily retrofitted.

With regard to the variants for the direct fitting of a pump, the following must be observed:

When fitting units (e.g. hydraulic pumps) to the flywheel-side PTO the respective maximum moment of weight must

not be exceeded.

In calculating the moment of weight, the weight of

• the pump,

• the fittings,

• the hoses and

• the respective hydraulic fluid

must be considered.

Units with a higher gravity torque must be supported correspondingly. Notes on outrigger support for hydraulic

pumps on the flywheel-side power take-off are given in chapter 3.1.4.

Important notice

Prior to assembly of the pump, the shaft/hub connection must be adequately greased with a high-temperature

grease as per MAN works standard MAN 284 Li-H2. No pastes containing metal (copper, aluminium, etc.) must

be used.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 23

Environmental notice

Important!

The surface of the flange for connecting the pump is treated with preserving wax. Prior to installation of the pump,

this surface must be cleaned using commercially available cleaning agents containing solvents, for example

naphtha. The various country-specific regulations concerning disposal must be observed.

MAN works standards can be obtained from www.ptd.man.eu - registration is required.

With regard to the variants with output flange, the following must be observed.

It is essential to comply with the maximum permissible propshaft deflection angle of 7° (see also the section entitled

“Propshaft connection to power take-off”) and to ensure low-impact and low-vibration operation. In certain cases

it may be necessary to modify individual cross members in order to ensure a permissible angle for the propshaft.

MAN offers its own solutions for this. If these are inadequate, the planned measures must be approved by MAN

beforehand (for address see “Publisher” above).

Flexible double-flange couplings to fit the respective flywheel-side power take-offs are available ex works. It is

mandatory to install them when driving units with an impact factor of Mmax / Mmin ≥ 2. They are also recommended

for all other bodies in order to prevent noise / resonance and protect against overloading. Double-flange couplings

are to be fitted between the power take-off and the unit to be driven (on the unit side).

Flywheel-side power take-off data for D38 engine:

Variant for direct fitting of pump as per SAE-B (2-hole) delivering 300 Nm max. output torque in continuous

operation (see Fig. 11)

• Pump connection, toothed hub profile as per ANSI B92.1, 15T, 16/32 DP

• Speed = 1.42 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations.

• Maximum rated torque ≤ 300 Nm in continuous operation.

• Maximum peak torque ≤ 420 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 11: Flywheel-side PTO for D38 engine for direct fitting of pump

121,5

146 ± 0,15

G8

Ø 101,6

365

69

T_327_000030_0001_G

1

1) Center of crankshaft

24 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Variant for direct fitting of pump as per DIN ISO 14 delivering 400 Nm max. output torque in continuous operation

(see Fig. 12)

• Pump connection, splined hub profile DIN ISO 14 –8x32x36

• Speed = 1,42 x engine speed

• Permissible gravity torque max. 30 Nm (pump with valves, e.g. hydraulic hoses, hydraulic oil, etc.)

• Direction of rotation same as engine’s rotation direction, on the left in the direction of travel

• Engine speed ≥ 800 rpm with flywheel-side PTO under load

• During speed build-up, temporary engine speeds of < 800 rpm are possible, whereby it must be ensured

that the maximum permissible weight balance is not exceeded due to torsional vibrations.

• Maximum rated torque ≤ 400 Nm in continuous operation

• Maximum peak torque ≤ 570 Nm for short-term operation (“short-term operation” is defined as

max. three minutes per operating hour).

Fig. 12: Flywheel-side PTO with engine D38 for direct pump attachment (DIN ISO 14)

80 (153)

(40.7)

B

80

A

A

365

69

T_327_000041_0001_G

1) Center of crankshaft

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 25

Camshaft power take-off data for the D28 engine (see Fig. 13):

• Flange Ø 100 6-hole 8 mm

• Speed = 1.075 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on camshaft power take-off.

• Maximum rated torque ≤ 600 Nm in continuous operation.

• Maximum peak torque ≤ 720 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 13: Camshaft power take-off on D28 engine

15

T_327_000006_0001_G

1

1) Center of crankshaft

Flywheel-side power take-off data for D20 and D26 engines

Variant delivering 650 Nm max. output torque in continuous operation (see Fig. 13)

• Flange Ø 100 6-hole 8 mm

• Speed = 1.233 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations. In applications with

an impact factor > 2, it is necessary to install the flexible flange coupling offered ex works on the unit.

• Maximum rated torque ≤ 650 Nm in continuous operation.

• Maximum peak torque ≤ 720 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

26 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Variant delivering 870 Nm max. output torque in continuous operation (see Fig. 14)

• Flange Ø 100 6-hole 8 mm

• Speed = 1.233 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations. It is mandatory to install

the flexible flange coupling offered ex works on the unit.

• Maximum rated torque ≤ 870 Nm in continuous operation.

• Maximum peak torque ≤ 950 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 14: Flywheel-side power take-off on D20 and D26 engines with output flange

60

336

78,7

1

T_327_000007_0001_G

1) Center of crankshaft

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 27

Variant for direct fitting of pump as per DIN ISO 14 delivering 400 Nm max. output torque in continuous operation

(see Fig. 15):

• Pump connection, splined hub profile as per DIN ISO 14 - 8 x 32 x 36

• Speed = 1.233 x engine speed

• Permissible moment of weight of hydraulic pump max. 30 Nm (pump with fitting, e.g. hydraulic hoses,

hydraulic oil and so on).

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations.

• Maximum rated torque ≤ 400 Nm in continuous operation.

• Maximum peak torque ≤ 570 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 15: Flywheel-side PTO for D20 and D26 engines for direct fitting of pump

80

121,5

80

336

60

T_327_000031_0001_G

1) Center of crankshaft

28 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Variant for direct fitting of pump as per SAE-A (2-hole) delivering 100 Nm max. output torque in continuous opera-

tion (see Fig. 16):

• Pump connection, toothed hub profile as per ANSI B92.1, 9T, 16/32 DP

• Speed = 1.233 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations.

• Maximum rated torque ≤ 100 Nm in continuous operation.

• Maximum peak torque ≤ 140 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 16: Flywheel-side PTO for D20 and D26 engines for direct fitting of pump (SAE-A)

±0.15

106.4

121.5

G8

15 °

Ø 82.6

336

60

T_327_000032_0001_G

1

1) Center of crankshaft

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 29

Variant for direct fitting of pump as per SAE-B (2-hole) delivering 300 Nm max. output torque in continuous opera-

tion (see Fig. 17):

• Pump connection, toothed hub profile as per ANSI B92.1, 13T, 16/32 DP

• Speed = 1.233 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations.

• Maximum rated torque ≤ 300 Nm in continuous operation.

• Maximum peak torque ≤ 420 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 17: Flywheel-side PTO for D20 and D26 engines for direct fitting of pump (SAE-B)

121,5

146 ±0,15

G8

Ø 101,6

336

60

T_327_000033_0001_G

1) Center of crankshaft

30 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

SSNA PTO data for engine D15:

Variant delivering 870 Nm max. output torque in continuous operation (see Fig. 18)

• Flange dia. 100 6-hole 8 mm

• Speed = 1.27 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel

• Engine speed ≥ 800 rpm with load on flywheel-side PTO

• During speed build-up, temporary speeds of < 800 rpm are possible, whereby it must be ensured that the

maximum permissible torque is not exceeded due to torsional vibrations. Unit-side installation of the flexible

flange coupling offered ex-works is mandatory.

• Maximum permitted rotational acceleration 800 (rpm)/s

• Maximum rated torque ≤ 870 Nm in continuous operation

• Maximum peak torque ≤ 1000 Nm for short-term operation (“short-term operation” is defined as max. three

minutes per operating hour).

Fig. 18: Flywheel-side PTO for engine D15 with output flange (51.38500-8018)

169

88,3

342

1) Centre of crankshaft

T_327_000047_0001_G

Variant for direct pump mounting as per SAE-A (2-hole) delivering 100 Nm max. output torque in continuous oper-

ation (see Fig. 19):

• Pump connection, toothed hub profile ANSI B92.1, 9 T, 16/32 DP

• Speed = 1.27 x engine speed

• Permissible weight balance max. 30 Nm (pump with fittings, e.g. hydraulic hoses, hydraulic oil, etc.)

• Direction of rotation same as engine, anticlockwise as seen in direction of travel

• Engine speed ≥ 800 rpm with load on flywheel-side PTO

• During speed build-up, temporary speeds of < 800 rpm are possible, whereby it must be ensured that the

maximum permissible torque is not exceeded due to torsional vibrations.

• Maximum rated torque ≤ 100 Nm in continuous operation

• Maximum peak torque ≤ 140 Nm for short-term operation (“short-term operation” is defined as max. three

minutes per operating hour).

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 31

Fig. 19: Flywheel-side PTO for engine D15 for direct pump mounting (SAE-A)( 51.38500-8019)

169

71,5

342

1

T_327_000048_0001_G

1) Centre of crankshaft

Variant for direct pump mounting as per SAE-B (2-hole) delivering 300 Nm max. output torque in continuous oper-

ation (see Fig. 20)

• Pump connection, toothed hub profile ANSI B92.1, 13 T, 16/32 DP

• Speed = 1.27 x engine speed

• Permissible weight balance max. 30 Nm (pump with fittings, e.g. hydraulic hoses, hydraulic oil, etc.)

• Direction of rotation same as engine, anticlockwise as seen in direction of travel

• Engine speed ≥ 800 rpm with load on flywheel-side PTO

• During speed build-up, temporary speeds of < 800 rpm are possible, whereby it must be ensured that the

maximum permissible torque is not exceeded due to torsional vibrations.

• Maximum rated torque ≤ 300 Nm in continuous operation

• Maximum peak torque ≤ 420 Nm for short-term operation (“short-term operation” is defined as max. three

minutes per operating hour).

32 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Fig. 20: Flywheel-side PTO for engine D15 for direct pump mounting (SAE-B) ( 51.38500-8020)

169

78,5

1 342

T_327_000049_0001_G

1) Centre of crankshaft

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 33

Flywheel-side power take-off data for D08 engine:

A flywheel-side power take-off on vehicles in the TGL/TGM model ranges is possible only in conjunction with

C or crew cabs. The flywheel side PTO is available independently of the cab for vehicles complying with exhaust

standard Euro 6.

Variant up to Euro 4 (see Fig. 21):

• Flange Ø 100 6-hole 8 mm

• Speed = 1.195 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Maximum rated torque ≤ 300 Nm in continuous operation.

• Maximum peak torque ≤ 350 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Variant up to Euro 5 (see Fig. 21)

• Flange Ø 100 6-hole 8 mm

• Speed = 1.219 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations. In applications with an

impact factor > 2, it is necessary to install the flexible flange coupling offered ex works on the unit.

• Maximum rated torque ≤ 600 Nm in continuous operation.

• Maximum peak torque ≤ 720 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 21: Flywheel-side power take-off data for six-cylinder D08 engine

Ø84 ±0.1 +0.15

Ø8,1 0

60°

328

87.4

16

T_327_000024_0002_G

1

1) Center of crankshaft

34 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Variant from Euro 6 on:

Variant with output flange (see Fig. 21)

• Flange Ø 100 6-hole 8 mm

• Speed = 1.219 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must be taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations. In applications with an

impact factor > 2, it is necessary to install the flexible flange coupling offered ex works on the unit.

• Maximum rated torque ≤ 600 Nm in continuous operation.

• Maximum peak torque ≤ 720 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Variant for direct fitting of pump as per SAE-B (2-hole) (see Fig. 22):

• Pump connection, toothed-hub profile as per ANSI B92.1 (hub diameter optionally 7/8” or 1”, see Fig. 19

and Table 05)

• Speed = 1.219 x engine speed

• Direction of rotation same as engine, anticlockwise as seen in direction of travel.

• Engine speed ≥ 800 rpm with load on flywheel-side power take-off.

• While speed is still building up, speeds of < 800 rpm are temporarily possible. Care must taken to ensure

that the maximum permissible torque is not exceeded due to torsional vibrations.

• Maximum permissible acceleration at pump’s center of gravity 20 g.

• Maximal permissible support torque on the intermediate section: 50 Nm.

• Maximum centroidal distance of connecting flange: 160 mm.

• Maximum torque ≤ 320 Nm in continuous operation.

• Maximum peak torque ≤ 380 Nm for short-term operation (“short-term operation” is defined as max.

three minutes per operating hour).

Fig. 22: Variant for direct connection of pump as per SAE-B for the six-cylinder D08 engine

l max = 160mm

146

. .

m

328

16

T_327_000034_0001_G

1) Center of crankshaft

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 35

Fig. 23: Overview of hub profiles

A ISO

30 °

4

Ø8

T_327_000035_0001_G

Table 05: Hub profiles

Nominal size Pitch (module) P Pressure angle No. of teeth Z

7/8” 16/32 30° 13

1” 13/32 30° 15

36 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

3.1.4 Outrigger support for hydraulic pumps on the flywheel-side power take-off

Support for hydraulic pumps fitted directly to the flywheel-side PTO on the gearbox is permissible under the following

conditions and only for vehicles in the TGS and TGX ranges with D20, D26 or D38 engines.

Important notice

The gravity torque of the hydraulic pump (incl. oil, hoses and valves) may not exceed 50 Nm, even with support.

The maximum permissible output torque remains unchanged at 400 Nm during continuous operation (570 Nm for

short-time operation; maximum 3 minutes per operating hour).

Notes:

• Only approved attachment points may be used for mounting the outrigger.

• The structural design of the outrigger is incumbent upon the body manufacturer.

• The outrigger must be implemented on both sides. A retainer which e.g. only supports the pump on

the left-hand side is not permissible.

• It must be ensured that no collision between the outrigger with other, partly moveable vehicle parts

can occur.

• The pump must be held in an exactly horizontal position by the outrigger. Distortion-free attachment must

be ensured. Axial transmission of force in the power take-off is not permissible.

• The length of the screws and the thread for fixing the outrigger to the gearbox must be selected so that

no damage to the gearbox occurs

Threaded holes on the manual gearbox (ZF 16S Ecosplit)

Threaded holes on the clutch case (to be used in preference)

Requirements for the screw connection

Requirement Value

Screw depth max. 34 mm

Tightening torque max. 240 Nm

Thread (item 1) M16 x 1,5 1

• Screws with sufficient strength should be used. 1

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 37

Threaded holes on the manual gearbox (ZF 16S Ecosplit)

Threaded holes on the gearbox housing (optional)

Requirements for the screw connection 1

Requirement Value 2

Screw depth See drawing

see drawing

(1) M8, 18 mm

Thread (items 1-3)

(2) M8, 22 mm

(3) M12, 22 mm

• Screws with sufficient strength should be used.

Threaded holes on the semi-automatic TipMatic gearbox (ZF 12AS AS Tronic)

Threaded holes on the clutch case (on the right in the direction of travel)

Requirements for the screw connection 1

Requirement Value

Screw depth max. 34 mm

Tightening torque max. 240 Nm

Thread (item 1) M16 x 1,5

• Screws with sufficient strength should be used.

38 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

Threaded holes on the semi-automatic TipMatic gearbox (ZF 12AS AS Tronic)

Threaded holes on the clutch case (on the left in the direction of travel)

Requirements for the screw connection 1

Requirement Value

Screw depth max. 34 mm

Tightening torque max. 240 Nm

Thread (item 1) M16 x 1,5

• Screws with sufficient strength should be used.

Threaded holes on the semi-automatic TipMatic gearbox (ZF 12AS AS Tronic)

Screw connection on the clutch case (optional)

Requirements for the screw connection

Requirement Value 1

Tightening torque 50 Nm

Thread (item 1) M10

• The screws must be longer than the standard

screws, due to the thickness of the retainer

material.

• Screw quality as for standard screws

• The retainer may only be supported within

the screw contact surface area.

• The gearbox must be inspected for oil

tightness at the screw connection.

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 39

Threaded holes on the automatic TipMatic gearbox (ZF 12TX TraXon)

Bolted connection on the gearbox

Requirements for the bolt connection

Requirement Value 1

Depth of engagement max. 25 mm

Tightening torque max. 225 Nm

Thread M16 x 1.5

• Bolts of sufficient strength must be used.

Threaded holes on the semi-automatic TipMatic gearbox (ZF 12TX TraXon)

Bolted connection on the clutch case

Requirements for the bolt connection

Requirement Value

Thread M12 x 1.5 1

• The bracket must be made from steel

- max. material thickness ≤ 4mm

- Painting with layer thickness ≤ 30 µ

- No alternative cataphoretic dip-priming

(due to decrease in torques)

- Alternative zinc/nickel coating

• A maximum of two screws of the bolt connection can be used

• The loosened screws DIN960 M12 x 1.5 x 95 Z1 300HV 10.9 MAN183 B1

(with integrated washer) must be replaced with two screws DIN960 M12 x 1.5 x 95 10.9 MAN183 B1

(without washer).

40 Edition 2018 V2.0 MAN Guide to fitting bodies Power take-offs

3.1.5 Power take-off on transfer case

On the two-gear version of the transfer case (in each case with driver-engaged off-road ratio) a flange for a

power take-off can be installed in addition to the output points for the front and rear axles. Transfer cases enabling

a power take-off are listed in Table 08+Table 09. The output point is at the rear of the transfer case (see Fig. 24+

Fig. 25).

The power take-off can be engaged and disengaged independently of gear changes or the additional off-road

transmission ratio in the transfer case. The transfer-case power take-off can also be used when the vehicle is

stationary. For this purpose, a gear must be engaged and the transfer case placed in neutral.

Vehicles with automated TipMatic gearbox

ZF TipMatic (12 AS gearbox)

On vehicles with a 480 hp EURO 6 engine (D2676LF45) and automated gearbox (ZF AS Tronic), MAN Service can

implement stationary operation of a power take-off on the transfer case. This requires parameterisation of the

vehicle and installation of a modified DNR switch.

Further information on this can be requested from MAN (for address see “Publisher” above).

We recommend installing the oil/water heat exchanger available ex works for cooling the gearbox oil.

ZF TipMatic (12 TX gearbox)

On vehicles of all emission classes produced from March 2018 on, both stationary and non-stationary operation

of a transfer case PTO can be realised (for non-stationary operation, further conditions, for example engine-speed

request, must be taken into consideration and checked). Gearboxes with older software statuses can under certain

circumstances be updated. Information on this can be requested from MAN (for address see “Publisher” above).

MAN Guide to fitting bodies Power take-offs Edition 2018 V2.0 41