Professional Documents

Culture Documents

Material Guide For Horizontal and Vertical In-Line Pumps

Material Guide For Horizontal and Vertical In-Line Pumps

Uploaded by

Er Bishwonath ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Guide For Horizontal and Vertical In-Line Pumps

Material Guide For Horizontal and Vertical In-Line Pumps

Uploaded by

Er Bishwonath ShahCopyright:

Available Formats

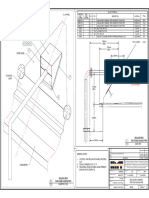

Saudi Aramco SA2636-ENG (03/1999)

NOTES:

MATERIAL GUIDE FOR HORIZONTAL AND VERTICAL IN-LINE PUMPS (1) (8) 316SS IS ACCEPTABLE FOR ASME PUMP

(1) FOR PUMPS IN SOUR SERVICE, MATERIALS SHALL MEET THE

SHAFTS.

REQUIREMENTS OF SAES-A-301, WHERE APPLICABLE.

(9) A434 TYPE 4140 IS AN ACCEPTABLE (2) MATERIALS LISTED BELOW ARE ACCEPTABLE. OTHER

ALTERNATIVE SHAFT MATERIAL. MATERIALS ARE ALSO ACCEPTABLE PROVIDED THAT

THEIR PREN=40 MINIMUM AND VENDOR DEMONSTRATES

(10) DUCTILE IRON IS ACCEPTABLE MATERIAL FOR SUCCESSFUL EXPERIENCE ON SIMILAR WATER

ASME PUMP BEARING BRACKETS. COMPOSITION:

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

(11) FOR PACKED FIREWATER PUMPS, CAST STEEL ASTM A743/A744 CN3MN (UNS J94651) / ASTM A182 F62 (UNS

BEARING BRACKETS SHALL BE INTERNALLY S08367)(MIN PREN 40) (15)

COATED WITH EPOXY TO PREVENT CORROSION ASTM A743/A744 CK3MCuN (UNS J93254) / ASTM A182 F44 (UNS

FROM NORMAL PACKING LEAKAGE. S31254)(MIN PREN 40) (15)

MATERIAL CODE HFB1 HKA2 HKA4 HSX HSI HK HSZ (2) ASTM A351 CK3MCuN (UNS J93254) / ASTM A182 F44 (UNS S31254)

(12) WETTED FASTENERS SHALL BE COMPATIBLE (MIN PREN 40) (15)

WITH THE PUMP METALLURGY AND PUMPED ASTM A995 5A (UNS J93404) / ASTM A182 F53 (UNS S32750) (MIN

SPECIAL

CASING A278 CL30 A216 WCB A216 WCB A487 CA6NM A743 CF3M (3) A352 (4) LIQUID. PREN 40) (16)

STAINLESS ASTM A995 6A (UNS J93380) / ASTM A182 F55 (UNS S32760) (MIN

PREN 40) (16)

(13) ASTM A182 F55 / A276 UNS 32760 IS AN

ASTM A890 1C (UNS J93373) / ASTM A182 F61 (UNS S32550) (MIN

SPECIAL ACCEPTABLE FOR SHAFT MATERIALS IF

IMPELLER A48 CL30 A216 WCB A487 CA6NM A487 CA6NM A743 CF3M (3) A352 (4) PREN 40) (17)

APPROVED BY STANDARD COMMITTEE

STAINLESS CHAIRMAN, PUMPS, SEALS AND MIXERS.

ASTM A105 WELD OVERLAID WITH AWS A5.14 ERNiCrMo-3 (UNS

N06625) (14)

NOTE: PREN = %Cr + 3.3 X %Mo + 16 X %N. MATERIALS SHALL BE

CASING WEAR RINGS A276 410 (6) SPECIAL (14) THE USE OF WELD OVERLAY REQUIRES THE IN THE SOLUTION ANNEALED CONDITION AFTER WELDING,

A48 CL30 A276 410 (6) A276 410 (6) A276 XM33 B584 C93700 APPROVAL OF STANDARD COMMITTEE GALVANICALLY COMPATIBLE AND SHALL HAVE SIMILAR

(5) STAINLESS (7)

CHAIRMAN; PUMPS, SEALS AND MIXERS. COMPOSITION IF WELDED.

WELD OVERLAY MUST CONSIST OF AT LEAST

IMPELLER WEAR- SPECIAL FOUR LAYERS OF WELD METAL TO ACHIEVE

NA A276 410 (6) A276 410 (6) A276 410 (6) A276 XM19 B148 C95400 HT UNDILUTED WELD METAL COMPOSITION AFTER

RINGS (5) STAINLESS (7) FINAL MACHINING. REFER TO SAES-W-014.

ADDITIONAL LAYERS MAY BE NEEDED FOR (3) A743 CF8M IS ACCEPTABLE FOR HIGH SPEED LOW FLOW

INCREASED EROSION AND CORROSION PUMP IMPELLERS, ASME AND MANUFACTURER'S

INCONEL 625 RESISTANCE. ONLY GMAW, GTAW OR

SHAFT A276 410 (6) A322 4140 (9) A322 4140 (18) A276 410 (6) (18) A276 XM19 (8) A322 4140 STANDARD PUMP CASING AND IMPELLERS.

(13) PTAW PROCESS ALLOWED. CONFIRM OVERLAY

COMPOSITION BY PMI PER SAES-A-206. EACH (4) MANUFACTURER TO PROPOSE A SUITABLE MATERIAL

WPS TO BE APPROVED BY THE COORDINATOR GRADE FOR THE SERVICE.

SHAFT SLEEVE OF ME&CCD/CSD.

A276 410 (6) NA NA NA 316L SS (7) NA NA

PACKED PUMP (5) FOR MATING WEAR PARTS HAVING HARDNESS LESS THAN

BHN 400, THEY SHALL HAVE A HARDNESS DIFFERENCE

EQUIVALENT TO BHN 50.

SPECIAL

THROAT BUSHINGS (5) A48 CL30 A276 XM33 A276 410 (6) A276 410 (6) A276 XM33 B584 C93700 (15) ALL WELD REPAIRS ON THE WETTED SURFACE (6) ALL TYPE 410 (ALTERNATIVELY 420) MARTENSITIC

STAINLESS (7) STAINLESS STEEL MUST BE IN THE QUENCHED AND

SHALL HAVE PWHT PER ASTM A743 S13

INCLUDING S3 & S5 (FOR MINOR AND MAJOR TEMPERED CONDITION. NITRONIC 50/60 AND A743 CA15

REPAIRS) AND S2 & S7 (FOR MAJOR REPAIRS ARE ACCEPTABLE ALTERNATIVE MATERIALS FOR WEAR

INTER-STAGE SPECIAL RINGS. A276 TYPE 420 SHALL NOT BE USED FOR SOUR.

A276 410 (6) A276 410 (6) A276 410 (6) A276 410 (6) A276 XM19 B148 C95400 HT ONLY).

SLEEVES (5) STAINLESS (7) SERVICES.

(16) MATERIAL MUST HAVE 40-60% FERRITE FOR

BASE METAL AND 30-60% FOR WELD JOINTS,

INTER-STAGE SPECIAL AND SHALL COMPLY WITH SUPPLEMENTARY

(7) IMPELLER WEAR RINGS, SHAFT SLEEVES, CASING WEAR

A48 CL30 A276 410 (6) A276 410 (6) A276 410 (6) A276 XM33 B584 C93700 RINGS AND BUSHINGS SHALL BE OVERLAID WITH HARD

BUSHINGS (5) STAINLESS (7) REQUIREMENT S50. ALL WELD REPAIRS ON THE MATERIALS. MANUFACTURER STANDARD MATERIALS

WETTED SURFACE SHALL HAVE PWHT PER

ARE ACCEPTABLE PROVIDED THAT THE PROPOSED

ASTM A995 S11 INCLUDING S6 & S10 (FOR

MATERIALS ARE USED IN SIMILAR SERVICE AND ARE

BEARING BRACKET MINOR AND MAJOR REPAIRS) AND S5 & S12

A48 CL30 A216 WCB A216 WCB A216 WCB A216 WCB (11) A216 WCB A216 WCB (FOR MAJOR REPAIRS ONLY).

OPERATING SUCCESSFULLY.

(10)

BASE PLATE FOR ALL MATERIAL CODES: ASTM A36 AND EN10028 GRADE S235J2 G2 OR G3 ARE ACCEPTABLE MATERIALS. (17) MATERIAL MUST HAVE 40-60% FERRITE FOR

BASE METAL AND 30-60% FOR WELD JOINTS,

AND SHALL COMPLY WITH SUPPLEMENTARY

REQUIREMENT S31. ALL WELD REPAIRS ON THE

WETTED SURFACE SHALL HAVE PWHT PER

ASTM A890 S33 INCLUDING S3 & S5 (FOR 04 01/21/06 GENERAL RIVISION

MINOR AND MAJOR REPAIRS) AND S2 & S34

(FOR MAJOR REPAIRS ONLY). REV. DATE JO / EWO DESCRIPTION ENGG. CERT. PMT OPRNS.

NO.

THIS REVISION IS NOT TO BE USED FOR CONSTRUCTION DESIGN REVIEW FOR

UNTIL CERTIFIED AND DATED. CERTIFICATION KEY DRAWINGS

NON-WETTED BOLTING MATERIAL (12) (18) FOR WET HYDROCARBON, THE SHAFT

MATERIAL SHALL BE A276 XM19. DESIGN CERTIFICATION

ALL MAT. CODES EXCEPT

MATERIAL CODE HK

CODE HK DRAWN BY CHECKED BY

DATE STARTED DATE COMPLETED

STUDS ASTM A193 GRADE B-7 ASTM A320 GRADE L43 DISCIPLINE ENGINEER

PROJECT ENGINEER

NUTS ASTM A194 GRADE 2H ASTM A194 GRADE 7 S3 CERTIFIED BY:

THIS DRAWING IS NOT TO BE

USED FOR CONSTRUCTION (NAME)

UNTIL CERTIFIED AND DATED. SIGNATURE DATE

DRAIN, VENT AND MECH. SEAL PIPING SAUDI ARABIAN OIL COMPANY

MATERIAL CODES MATERIAL CODES MATERIAL CODE REVIEW FOR KEY DRAWINGS REQUIRED NOT REQUIRED

HFB1, HKA2 & HKA4 HSX, HSI & HK HSZ CONSTRUCTION AGENCY

OPERATIONS

PIPE ASTM A 106 GRADE B ATSM A312 TP316L UNS N08024

OTHER

DRAWING TYPE

FITTINGS ASTM A 105 ASTM A182 F316L UNS N08024 MATERIAL GUIDE FOR CETRIFUGAL PUMPS STD

HORIZONTAL AND VERTICAL IN-LINE

STD. DWG. SAUDI ARABIA

PLANT NO. INDEX DRAWING NUMBER ARABIA REV. NO.

SHT.NO.

990 G A D--036821 1 OF 2 04

Saudi Aramco 2636-ENG. (03/99)

EXCEL

You might also like

- AMS5688Document7 pagesAMS5688Federica FiorentiniNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- Ad 036821 001Document1 pageAd 036821 001AmolNo ratings yet

- Mesc Spe 74 014 2016 PDFDocument15 pagesMesc Spe 74 014 2016 PDFSalahuddin FarooquiNo ratings yet

- 175 012000Document2 pages175 012000Abu Anas M.SalaheldinNo ratings yet

- 01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFDocument8 pages01-SAMSS-049 Reinforced Thermoset Resin (RTR) Pipe, Fittings and Adhesive Packing, Handling, Transportation and Storage 21-FEB-2012 PDFasiqnaNo ratings yet

- SAIC-L-2014 Rev. 5Document10 pagesSAIC-L-2014 Rev. 5Jagadeesh PuppalaNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.Salaheldin100% (1)

- Sae Ams5545e 2006 PDFDocument8 pagesSae Ams5545e 2006 PDFwangxiaomin1977No ratings yet

- Ad 036821 002Document1 pageAd 036821 002AmolNo ratings yet

- 32 Samss 017Document11 pages32 Samss 017naruto256No ratings yet

- 1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Document2 pages1 SATIP-E-007-01 Air Cooled HExch - Fin Fan-Rev 01Anonymous S9qBDVkyNo ratings yet

- 175 030100Document2 pages175 030100Abu Anas M.Salaheldin100% (1)

- Satip - S-050-01Document4 pagesSatip - S-050-01LIJINNo ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection ChecklistAhdal NoushadNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- 02 Samss 001Document6 pages02 Samss 001Florante NoblezaNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System SpecificationZubair RaoofNo ratings yet

- 01-SAMSS-333-HF Welded Line Pipe PDFDocument35 pages01-SAMSS-333-HF Welded Line Pipe PDFmunnaNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSelvakpm06No ratings yet

- 175 100100 PDFDocument2 pages175 100100 PDFThaksenNo ratings yet

- SAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesDocument6 pagesSAIC-L-2042 Rev 6 Field Hydrostatic Testing of Isolation ValvesAhdal NoushadNo ratings yet

- 34 Samss 711 PDFDocument26 pages34 Samss 711 PDFFlorin Daniel AnghelNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Saep 122Document18 pagesSaep 122Handa Bin AdiNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersionDocument13 pagesSAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersiondanishNo ratings yet

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDocument13 pages01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNo ratings yet

- OMN-FAC-200 Coating Specification For Surface Production FacilitiesDocument20 pagesOMN-FAC-200 Coating Specification For Surface Production FacilitiesSaifullahNo ratings yet

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216No ratings yet

- Materials System SpecificationDocument9 pagesMaterials System SpecificationFAPM1285No ratings yet

- Saes A 004Document17 pagesSaes A 004Arvind ShakyaNo ratings yet

- SAIC-D-2002 Rev 2Document5 pagesSAIC-D-2002 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- SAES-L-450 PDF Download - On-Land and Near-Shore Pipelines - PDFYARDocument5 pagesSAES-L-450 PDF Download - On-Land and Near-Shore Pipelines - PDFYARZahidRafiqueNo ratings yet

- SAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARDocument7 pagesSAES-L-150 PDF Download - Pressure Testing of Plant Pipelines - PDFYARZahidRafiqueNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 MechDocument18 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Positive Displacement Pumps SAIC-G-2009 30-Apr-17 Mechkarthi51289No ratings yet

- HGP-Coating ProcedureDocument115 pagesHGP-Coating ProcedureShamas TabraizNo ratings yet

- SAIC W 2069 in Process Welding InspectionDocument8 pagesSAIC W 2069 in Process Welding InspectionAbdul Gafoor ShaikhNo ratings yet

- 01 Samss 029Document15 pages01 Samss 029Cherukunnon Jubu100% (1)

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- 175-022501 Flanges (WN, BL, Forged Steel & As)Document2 pages175-022501 Flanges (WN, BL, Forged Steel & As)ALINo ratings yet

- Satr Nde 2011Document2 pagesSatr Nde 2011JaseelKanhirathinkalNo ratings yet

- Saudi Aramco Inspection Checklist: Mounting Plate Installation and Leveling For Pumps SAIC-G-2021 30-Apr-17 MechDocument15 pagesSaudi Aramco Inspection Checklist: Mounting Plate Installation and Leveling For Pumps SAIC-G-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- Saes L 132Document38 pagesSaes L 132BM TECH100% (1)

- Saes L 100Document12 pagesSaes L 100samsurendran_mech4020No ratings yet

- Saudi Aramco Typical Inspection PlanDocument3 pagesSaudi Aramco Typical Inspection PlanOmer ali100% (1)

- Ad 036821 001Document1 pageAd 036821 001hai sunNo ratings yet

- MRCSB-HMT-T-GA-0001 Dome Construction Drawings - Rev-0 - pg19Document1 pageMRCSB-HMT-T-GA-0001 Dome Construction Drawings - Rev-0 - pg19arshi LerwickMNo ratings yet

- Sae Ams 5387Document8 pagesSae Ams 5387desingbuschprojectsNo ratings yet

- Ams 4985CDocument13 pagesAms 4985CBacksniper100% (1)

- Sae 4676dDocument6 pagesSae 4676dwilsao77No ratings yet

- Aerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress RelievedDocument9 pagesAerospace Material Specification: Titanium Alloy Tubing, Seamless, Hydraulic 3.0al - 2.5V Cold Worked, Stress Relievedvsraju2No ratings yet

- Sae Ams 4157D - 2007Document5 pagesSae Ams 4157D - 2007مرکز پژوهش متالورژی رازی RMRCNo ratings yet

- Aerospace Material SpecificationDocument6 pagesAerospace Material Specificationvsraju2No ratings yet

- Sae Ams5837f 1999Document7 pagesSae Ams5837f 1999이연지No ratings yet

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationAnonymous T6GllLl0No ratings yet

- Appendix A Architectural Interior Finishes Requirments: Floor Base Wall CeilingDocument9 pagesAppendix A Architectural Interior Finishes Requirments: Floor Base Wall CeilingEr Bishwonath Shah100% (1)

- Without This Message by Purchasing Novapdf : Print To PDFDocument18 pagesWithout This Message by Purchasing Novapdf : Print To PDFEr Bishwonath ShahNo ratings yet

- Appendix B Architectural Interior Finishes Requirments/ Healthcare FacilitiesDocument2 pagesAppendix B Architectural Interior Finishes Requirments/ Healthcare FacilitiesEr Bishwonath ShahNo ratings yet

- Appendix C Architectural Exterior Finishes RequirmentsDocument2 pagesAppendix C Architectural Exterior Finishes RequirmentsEr Bishwonath ShahNo ratings yet

- Advance Level - Ic Engines and Power PlantDocument22 pagesAdvance Level - Ic Engines and Power PlantEr Bishwonath ShahNo ratings yet

- Without This Message by Purchasing Novapdf : Print To PDFDocument23 pagesWithout This Message by Purchasing Novapdf : Print To PDFEr Bishwonath ShahNo ratings yet

- Without This Message by Purchasing Novapdf : Print To PDFDocument23 pagesWithout This Message by Purchasing Novapdf : Print To PDFEr Bishwonath ShahNo ratings yet

- List of Crosby Rvs Need To Be Fixed ImmediatelyDocument6 pagesList of Crosby Rvs Need To Be Fixed ImmediatelyEr Bishwonath ShahNo ratings yet

- ReportDocument9 pagesReportEr Bishwonath ShahNo ratings yet

- Cleaning Details of T16 and T19Document4 pagesCleaning Details of T16 and T19Er Bishwonath ShahNo ratings yet

- 27-11-2019 Status of Work With Drawings,, by BishwonathDocument9 pages27-11-2019 Status of Work With Drawings,, by BishwonathEr Bishwonath ShahNo ratings yet

- Saep 1650 PDFDocument21 pagesSaep 1650 PDFEr Bishwonath ShahNo ratings yet

- 27-11-2019 Status of Work With Drawings,, by BishwonathDocument9 pages27-11-2019 Status of Work With Drawings,, by BishwonathEr Bishwonath ShahNo ratings yet

- Cleaning Details of T16 and T19Document4 pagesCleaning Details of T16 and T19Er Bishwonath ShahNo ratings yet

- Saep 1662Document52 pagesSaep 1662Er Bishwonath ShahNo ratings yet

- Engineering Procedure: Saudi Aramco Desktop StandardsDocument18 pagesEngineering Procedure: Saudi Aramco Desktop StandardsEr Bishwonath ShahNo ratings yet

- Saep 1661Document7 pagesSaep 1661Er Bishwonath ShahNo ratings yet

- Process Industry Practices Process Control: Pip Pcign300 General Instrument Accessory DetailsDocument10 pagesProcess Industry Practices Process Control: Pip Pcign300 General Instrument Accessory DetailsEr Bishwonath ShahNo ratings yet

- Process Industry Practices Process Control: Pip Pcili100 Level Transmitter Installation DetailsDocument14 pagesProcess Industry Practices Process Control: Pip Pcili100 Level Transmitter Installation DetailsEr Bishwonath ShahNo ratings yet

- Budget by Arlapan SirDocument1 pageBudget by Arlapan SirEr Bishwonath ShahNo ratings yet

- Experiment No 2 Flame TestDocument2 pagesExperiment No 2 Flame TestBalangNo ratings yet

- Explosives SynthesisDocument5 pagesExplosives SynthesisMatthew93100% (1)

- Factors Affecting CO2 Absorption Efficiency in Packed Column: A ReviewDocument12 pagesFactors Affecting CO2 Absorption Efficiency in Packed Column: A ReviewARYAN_FATHONI_AMRINo ratings yet

- Nippon Steel Carbon Neutral Vision 2050: March 30, 2021Document54 pagesNippon Steel Carbon Neutral Vision 2050: March 30, 2021Kedar BhaveNo ratings yet

- Phosphoric Acid Flow Sheet of Dihydrate ProcessDocument3 pagesPhosphoric Acid Flow Sheet of Dihydrate ProcessPrakash Mylar100% (1)

- Kairos Company ProfileDocument2 pagesKairos Company Profileapi-326437421No ratings yet

- Lesson 2 - Molten ElectrolysisnnDocument13 pagesLesson 2 - Molten Electrolysisnncharlie markouNo ratings yet

- Chapter 19Document74 pagesChapter 194B19 LIM Sze ManNo ratings yet

- Iron-Nickel-Cobalt Sealing Alloy: Standard Specification ForDocument7 pagesIron-Nickel-Cobalt Sealing Alloy: Standard Specification ForAhmad Zubair RasulyNo ratings yet

- RefineryDocument100 pagesRefineryshaliq28No ratings yet

- CalderaDocument24 pagesCalderaMaximilianoRodrigoCabestreroNo ratings yet

- Simulated Distillation Analysis Middle Distillates PDFDocument8 pagesSimulated Distillation Analysis Middle Distillates PDFgraciela areinamoNo ratings yet

- 7 - OligomerizationDocument16 pages7 - OligomerizationAn Lê TrườngNo ratings yet

- Organic Chemistry 9th Edition Mcmurry Test BankDocument18 pagesOrganic Chemistry 9th Edition Mcmurry Test Bankrobertadelatkmu100% (25)

- Esterification Salicylic AcidDocument3 pagesEsterification Salicylic AcidBobbyGunarsoNo ratings yet

- Flowchart of Palm Oil Mill ProcessingDocument15 pagesFlowchart of Palm Oil Mill ProcessingAndy Tander100% (5)

- Us 4378342Document9 pagesUs 4378342هیمن مNo ratings yet

- Chapter 15 - Acid-Base EquilibriaDocument59 pagesChapter 15 - Acid-Base EquilibriaPatel MswaziNo ratings yet

- Module - Naming Writing Compounds MoleculesDocument6 pagesModule - Naming Writing Compounds MoleculesMaricris MoralesNo ratings yet

- Erowid LSD (Acid) Vault - ChemistryDocument1 pageErowid LSD (Acid) Vault - ChemistryAdam BruhNo ratings yet

- Salt 2 - Lead NitrateDocument2 pagesSalt 2 - Lead NitrateaaravNo ratings yet

- Koi Water QualityDocument11 pagesKoi Water QualityIffahFahmiNo ratings yet

- Rene Industries Limited General Test ProcedureDocument2 pagesRene Industries Limited General Test ProcedureMubarak PatelNo ratings yet

- TB Midalloy 2535R Bare WireDocument2 pagesTB Midalloy 2535R Bare WireAydogan CanNo ratings yet

- Tabla de PotencialesDocument6 pagesTabla de PotencialesLuis AntonioNo ratings yet

- Chromatographic Methods Part 2Document113 pagesChromatographic Methods Part 2hamidNo ratings yet

- Alk EnesDocument22 pagesAlk EnesgasNo ratings yet

- Carolina: Carolina's Solution Preparation ManualDocument15 pagesCarolina: Carolina's Solution Preparation ManualMohan MondalNo ratings yet

- Current Advances in Catalysis Toward Sustainable Biodiesel ProductionDocument12 pagesCurrent Advances in Catalysis Toward Sustainable Biodiesel Productionfitri rowiyahNo ratings yet

- Ascotran: Flash-Rust / In-Can ProtectionDocument6 pagesAscotran: Flash-Rust / In-Can ProtectiondiablomatiNo ratings yet