Professional Documents

Culture Documents

Purpose:: Validation Type: In-House Validation Critical Limit: Absence

Purpose:: Validation Type: In-House Validation Critical Limit: Absence

Uploaded by

Milan BankOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Purpose:: Validation Type: In-House Validation Critical Limit: Absence

Purpose:: Validation Type: In-House Validation Critical Limit: Absence

Uploaded by

Milan BankCopyright:

Available Formats

1.

PURPOSE:

This procedure describes the minimum requirements for inspection and testing of

material and product, to assure application of appropriate controls.

2. SCOPE:

The procedure is applicable for testing the cleanliness of wheat Flour against the

Iron Pieces and to ensure the removal of iron after passing it through the various

magnets in the milling section.

3. ROLES AND RESPONSIBILITIES

Quality In-Charge Shall be responsible for handling the sampling and testing

according to defined procedure.

Shall ensure the implementation of defined procedures

Production Supervisor

& standards.

4. Frequency : - Monthly Basis

5. Validation Type: In-house Validation

6. Critical Limit: Absence

7. PROCEDURE

10 Kgs of wheat flour will be taken after the final production and spread over a plain bag. A

standard magnet of 10000 gauss will be taken and moved over the same to ensure that

and the residue that will be 5 kg of standard sample of pure wheat flour deliberately

contaminated with 1 g of iron impurities is passed through cleaned magnet (8000

gauss) and the output wheat flour is checked for iron impurities that must be nil. For

this the weight of iron impurities adhered to the magnet is checked & it must be 1 g.

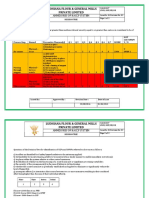

8. Validation Result:

The validation process successfully done & it was proved from the observation that the control

measure (Destoner) for the OPRP 2 is working correctly as mentioned in the HACCP Plan.

Reference: - F/LFGM/PRP/04/06

You might also like

- Allergen Control Program TemplateDocument2 pagesAllergen Control Program TemplateJanara Aline Rocha0% (1)

- Power Point-Traceability TrainingDocument36 pagesPower Point-Traceability TrainingGreatman Charles100% (1)

- 1.3 Food Safety Policy Statement WebDocument1 page1.3 Food Safety Policy Statement Webジョンナ メイ ハイミNo ratings yet

- A Cheese Company: (Links To Logs)Document2 pagesA Cheese Company: (Links To Logs)mahsen2000No ratings yet

- Quality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodDocument1 pageQuality Manual: Pt. Ani Mitra Jaya Frozen ChepalopodMia AgustinNo ratings yet

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixNo ratings yet

- Quality Food Safety Policy 08Document2 pagesQuality Food Safety Policy 08Mohit ShuklaNo ratings yet

- QM 001 Food Safety Quality Management SystemDocument5 pagesQM 001 Food Safety Quality Management SystemVikram PathrikarNo ratings yet

- 31 Validation, Verification and Improvement of The FSMSDocument5 pages31 Validation, Verification and Improvement of The FSMSVeera Venkatesh Mareedu100% (1)

- Basic Elements of A Sanitation Program For Food ProcessingDocument5 pagesBasic Elements of A Sanitation Program For Food ProcessingJohn Henry Wells100% (2)

- Procedure For Sampling of RM and PMDocument7 pagesProcedure For Sampling of RM and PMMilan BankNo ratings yet

- SOP For Rawmaterial SievingDocument2 pagesSOP For Rawmaterial SievingarunNo ratings yet

- Clause Requirements: Interpretation Food Safety CultureDocument2 pagesClause Requirements: Interpretation Food Safety CultureMario HaimovichNo ratings yet

- G.2 Allergen Validation RecordDocument1 pageG.2 Allergen Validation RecordBibekNo ratings yet

- F - 07.01 - Daily PRP ChecklistDocument2 pagesF - 07.01 - Daily PRP ChecklistSAMEER JAVEDNo ratings yet

- Methodology For Determination of Hazard Controls CCP S and OPRP SDocument4 pagesMethodology For Determination of Hazard Controls CCP S and OPRP SRosinanteNo ratings yet

- SOP Facility and Equipment HygieneDocument6 pagesSOP Facility and Equipment HygieneHenry Taguma100% (1)

- PRP 10.3 Allergen Control SystemDocument3 pagesPRP 10.3 Allergen Control SystemAnggerNo ratings yet

- Quality & Food Safety Manual: Wilverley Trading Estate 813/815 Bath Road Brislington Bristol Bs4 5NlDocument23 pagesQuality & Food Safety Manual: Wilverley Trading Estate 813/815 Bath Road Brislington Bristol Bs4 5NlMohamed100% (1)

- QA 5.15 Allergens Materials Handling General ProcedureDocument3 pagesQA 5.15 Allergens Materials Handling General ProcedureangeldrandevNo ratings yet

- Guideline For The Validation of Food Safety Control MeasuresDocument16 pagesGuideline For The Validation of Food Safety Control MeasuresKriston EdwardNo ratings yet

- 2 Food Loss and WasteDocument61 pages2 Food Loss and Wastemarani.1952816No ratings yet

- Food TraceabilityDocument14 pagesFood Traceabilitydwivanjava100% (1)

- Food Safety Policy: 1. PurposeDocument3 pagesFood Safety Policy: 1. PurposeAbhishek Kumar SinghNo ratings yet

- Foreign Material Control PolicyDocument5 pagesForeign Material Control Policymonik manuel100% (1)

- Food Fraud: Impact On FlavorsDocument37 pagesFood Fraud: Impact On Flavorssowmya.mas1542No ratings yet

- Allergen Management: Quality Systems ManualDocument9 pagesAllergen Management: Quality Systems ManualRiri JuniartiNo ratings yet

- FOOD-DEFENSEDocument45 pagesFOOD-DEFENSEMaria Fe DiazNo ratings yet

- Sop For in - Process Fill Weight DeterminationDocument1 pageSop For in - Process Fill Weight DeterminationPrince MoniNo ratings yet

- Crisis Managemen & Food DefenceDocument3 pagesCrisis Managemen & Food DefenceAgus WaluyoNo ratings yet

- GMP Food Manufacturing Audit Checklist - SafetyCultureDocument22 pagesGMP Food Manufacturing Audit Checklist - SafetyCultureNaeema100% (1)

- Standard Operational Sanitation Procedure - Equipment and Facility CleaningDocument1 pageStandard Operational Sanitation Procedure - Equipment and Facility CleaningSyarmine Aqila IsaNo ratings yet

- Ludhiana Flour & General Mills Private Limited: Annexures of Haccp SystemDocument2 pagesLudhiana Flour & General Mills Private Limited: Annexures of Haccp SystemMilan BankNo ratings yet

- Implementing HACCP Based Food Quality and Safety Programs at IndustriesDocument3 pagesImplementing HACCP Based Food Quality and Safety Programs at IndustriesAdapa Prabhakara Gandhi100% (2)

- Environmental Monitoring ProgramDocument8 pagesEnvironmental Monitoring Programmonik manuelNo ratings yet

- Food Fraud Mitigation Guidance FSSC 22000 V6Document11 pagesFood Fraud Mitigation Guidance FSSC 22000 V6Mohamed ThabetNo ratings yet

- Organization Structure: L L M L L MDocument9 pagesOrganization Structure: L L M L L MNasef Mohd0% (1)

- Food Safety Statement June 2012Document1 pageFood Safety Statement June 2012Mohit ShuklaNo ratings yet

- M. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense PlanDocument1 pageM. S. Asia Group Page 1 of 1 Document No.: SOP/ANA/PDP Effective Date: 21-6-2021 Rev. No.: 0 Document Title: Product Defense Plannurhafizah jabarNo ratings yet

- HACCP - Identification of CCPS, CPS, PRPS, OPRPs...Document5 pagesHACCP - Identification of CCPS, CPS, PRPS, OPRPs...cher28100% (1)

- Hazard Identification Decision TreeDocument2 pagesHazard Identification Decision TreeDutch CharmingNo ratings yet

- CERT-SC-F 01-G Self Assessment Checklist GMP GHPDocument23 pagesCERT-SC-F 01-G Self Assessment Checklist GMP GHPAsma DahaboNo ratings yet

- MD-QMS ObjectivesDocument1 pageMD-QMS Objectivessfda.badrmedicalNo ratings yet

- 09 GMP SOP 08 Quality Control LaboratoryDocument5 pages09 GMP SOP 08 Quality Control Laboratorykishan chiraniaNo ratings yet

- Saftey Culture: PrioritiesDocument8 pagesSaftey Culture: PrioritiesMutiara NadilaNo ratings yet

- Guidance For Allergen Management and TestingDocument13 pagesGuidance For Allergen Management and TestingVasil TsonkovNo ratings yet

- Culture Plan E.GDocument5 pagesCulture Plan E.GSQF PractitionerNo ratings yet

- Prerequisite Program Our CompanyDocument29 pagesPrerequisite Program Our CompanysridharanNo ratings yet

- Food Allergen Information SheetDocument7 pagesFood Allergen Information SheetJohn Henry WellsNo ratings yet

- FSSC-22000-V6-for-Food-Manufacturing-ChecklistDocument48 pagesFSSC-22000-V6-for-Food-Manufacturing-ChecklistNaveed Noor MemonNo ratings yet

- BRC HACCP Plan Review ChecklistDocument4 pagesBRC HACCP Plan Review ChecklistVijay KumarNo ratings yet

- OPRP 4 Management of Cleaning ValidationDocument1 pageOPRP 4 Management of Cleaning ValidationJuan Pablo Azcuña C.No ratings yet

- HACCP and SSOP BasicsDocument35 pagesHACCP and SSOP Basicsfitria lindasariNo ratings yet

- VERIFICATION PLAN HaccpDocument4 pagesVERIFICATION PLAN HaccpnasuhaNo ratings yet

- Food Microbiology Quality Control Nov 14Document36 pagesFood Microbiology Quality Control Nov 14Harith AtrisNo ratings yet

- Critical Elements For EMPDocument54 pagesCritical Elements For EMPGaganpreet KaurNo ratings yet

- Good GMP PolicyDocument4 pagesGood GMP PolicyNainggolan Taruli100% (1)

- Principle 6: Verification: How Is This Stage Achieved?Document4 pagesPrinciple 6: Verification: How Is This Stage Achieved?Misarda BerishaNo ratings yet

- Quantitative Microbiology in Food Processing: Modeling the Microbial EcologyFrom EverandQuantitative Microbiology in Food Processing: Modeling the Microbial EcologyAnderson de Souza Sant'AnaNo ratings yet

- FSMS Atta.Document1 pageFSMS Atta.Milan BankNo ratings yet

- Ludhiana Flour & General Mills Private Limited: Annexures of Haccp SystemDocument2 pagesLudhiana Flour & General Mills Private Limited: Annexures of Haccp SystemMilan BankNo ratings yet

- Wheat Norms As Per FssaiDocument1 pageWheat Norms As Per FssaiMilan BankNo ratings yet

- Ludhiana Flour & General Mills Private Limited: M L SOPDocument3 pagesLudhiana Flour & General Mills Private Limited: M L SOPMilan BankNo ratings yet

- Executive Profile Key Impact Areas: Quality Management & Control, Food Safety Management and Operations ManagementDocument2 pagesExecutive Profile Key Impact Areas: Quality Management & Control, Food Safety Management and Operations ManagementMilan BankNo ratings yet

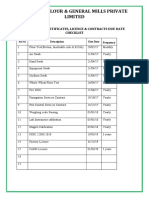

- Ludhiana Flour & General Mills Private Limited: Important Certificates, Licence & Contracts Due Date ChecklistDocument1 pageLudhiana Flour & General Mills Private Limited: Important Certificates, Licence & Contracts Due Date ChecklistMilan BankNo ratings yet

- Food Technologist Cover Letter NewDocument1 pageFood Technologist Cover Letter NewMilan BankNo ratings yet

- Education/Qualifications: Technician Assurance Manager Assurance Executive AssuranceDocument1 pageEducation/Qualifications: Technician Assurance Manager Assurance Executive AssuranceMilan BankNo ratings yet