Professional Documents

Culture Documents

DN 50 MANUFACTURING DRAWING-rotated

DN 50 MANUFACTURING DRAWING-rotated

Uploaded by

khai ruleOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DN 50 MANUFACTURING DRAWING-rotated

DN 50 MANUFACTURING DRAWING-rotated

Uploaded by

khai ruleCopyright:

Available Formats

18

17

16

14

WET EPOXY PAINT THICKNESS(min.) 250µm

63.0 PODWER EPOXY PAINT THICKNESS(min.) 250µm

13

18 CAP Ductile Iron BS EN 1563 500/7

15 17 BOLTS Steel BS 3692 Grade 5

Stainless Steel BS EN 10088-3 431S29

12 16 DUST-PROOF Rubber MS 672 EPDM

COVER BS EN 681 (66-75 IRHD Hardness)

15 GLAND Ductile Iron BS EN 1563 500/7

11

14 O-RING Rubber MS 672 EPDM

290.0 10 BS EN 681 (66-75 IRHD Hardness)

13 NYLON BUSH Nylon ASTM D4066 PA 11

12 O-RING Rubber MS 672 EPDM

9

BS EN 681 (66-75 IRHD Hardness)

11 O-RING Rubber MS 672 EPDM

8 BS EN 681 (66-75 IRHD Hardness)

10 TRUST COLLAR Gun Metal BS 1400 LG2

7 9 O-RING Rubber MS 672:99 EPDM

BS EN 681 (66-75 IRHD Hardness)

8 BONNET Ductile Iron BS EN 1563 500/7

6

7 CAP SCREW Stainless Steel BS EN 10088-3 304S31

6 GASKET Rubber MS 672 EPDM

5 BS EN 681 (66-75 IRHD Hardness)

5 STEM Stainless Steel BS EN 10088-3 431S29

4 STEM NUT Gun Metal BS 1400 LG2

4

3 WEDGE Ductile Iron BS EN 1563 500/7

2 RUBBER COATING Ruber MS 672 EPDM

3 BS EN 681 (66-75 IRHD Hardness)

1 BODY Ductile Iron BS EN 1563 500/7

106.0 2

125.0 50.0 LIST FOR MAIN COMPONENTS

167.0 1

HYDRO SHELL 24 BAR

HYDRO VALVE SEAT 17.6 BAR

RESILENT PRESSURE 17.6 BAR

L Y

19.0 R

E

Part Name:

16.0 3.0

178.0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bs en 14901Document20 pagesBs en 14901khai rule100% (1)

- BSI Standards Publication - BS 5834-2 - 2011Document34 pagesBSI Standards Publication - BS 5834-2 - 2011khai rule67% (3)

- MSE 2021 Stereology Lab Grade SheetDocument11 pagesMSE 2021 Stereology Lab Grade SheetantNo ratings yet

- SDS - Ashapura Ultrabond - V3Document6 pagesSDS - Ashapura Ultrabond - V3khai ruleNo ratings yet

- Bentonite MSDSDocument10 pagesBentonite MSDSkhai ruleNo ratings yet

- BROCHUREWMOTOXTREME150iN1 Xtreme150i 20230914164943Document4 pagesBROCHUREWMOTOXTREME150iN1 Xtreme150i 20230914164943khai ruleNo ratings yet

- Standardsmark Licence As 4181.2013 Repair and Offtake ClampsDocument28 pagesStandardsmark Licence As 4181.2013 Repair and Offtake Clampskhai ruleNo ratings yet

- Coal Dust MsdsDocument4 pagesCoal Dust Msdskhai ruleNo ratings yet

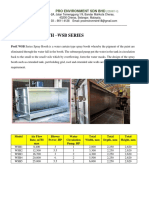

- COMPANY Catalogue - PROEDocument18 pagesCOMPANY Catalogue - PROEkhai ruleNo ratings yet

- Vital Technical Sdn. BHD.: VT-210 High Performance SealantDocument4 pagesVital Technical Sdn. BHD.: VT-210 High Performance Sealantkhai ruleNo ratings yet

- RUBBER FLAP TYPE CHECK VALVE-front-BDocument1 pageRUBBER FLAP TYPE CHECK VALVE-front-Bkhai ruleNo ratings yet

- Wet Spray Booth - WSB Series: Pro Environment SDN BHDDocument2 pagesWet Spray Booth - WSB Series: Pro Environment SDN BHDkhai ruleNo ratings yet

- Iteh Standard Preview (Standards - Iteh.ai) : Graphite Structure European Standard Designation Short NameDocument1 pageIteh Standard Preview (Standards - Iteh.ai) : Graphite Structure European Standard Designation Short Namekhai ruleNo ratings yet

- NYY006.18 VA 5001 WRAS CertificationDocument1 pageNYY006.18 VA 5001 WRAS Certificationkhai ruleNo ratings yet

- Irca Iso 90012015Document1 pageIrca Iso 90012015khai ruleNo ratings yet

- Avk Fabricated Flange Adaptor, Pn16 260: Features: OptionsDocument2 pagesAvk Fabricated Flange Adaptor, Pn16 260: Features: Optionskhai ruleNo ratings yet

- C220-E001E Shimadzu General Testing MachineDocument10 pagesC220-E001E Shimadzu General Testing Machinekhai ruleNo ratings yet

- BODY DN100-mergedDocument9 pagesBODY DN100-mergedkhai ruleNo ratings yet

- BODY DN150-mergedDocument10 pagesBODY DN150-mergedkhai ruleNo ratings yet

- Ofm Part Number B14-H0015 RECIEVED ON 08-10-2018: RevisionsDocument1 pageOfm Part Number B14-H0015 RECIEVED ON 08-10-2018: Revisionskhai ruleNo ratings yet

- Outsource DrawingDocument1 pageOutsource Drawingkhai ruleNo ratings yet

- E-Soft E-HR System Manual (Login As Employee) PDFDocument22 pagesE-Soft E-HR System Manual (Login As Employee) PDFkhai rule0% (1)

- HWA GUAN Material Spec PDFDocument12 pagesHWA GUAN Material Spec PDFkhai ruleNo ratings yet

- What Are The Different Investigation Methods Carried Out Before Grouting?Document17 pagesWhat Are The Different Investigation Methods Carried Out Before Grouting?himabindugvsd71No ratings yet

- Columbus Tubes 2018 Catalogue V3 PDFDocument34 pagesColumbus Tubes 2018 Catalogue V3 PDFAlex StihiNo ratings yet

- Kids Toothpaste: Phase Ingredients % W/WDocument2 pagesKids Toothpaste: Phase Ingredients % W/WrekhilaNo ratings yet

- Chem NotesDocument148 pagesChem Noteskiruba devi .kNo ratings yet

- Stay-C 50Document9 pagesStay-C 50Santi ApriyaniNo ratings yet

- Design of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayDocument57 pagesDesign of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayKC Paguinto100% (1)

- Polymetron 8810-ORP Ion Selective Electrode ISE Calcium Analyzer Installation Procedure PDFDocument13 pagesPolymetron 8810-ORP Ion Selective Electrode ISE Calcium Analyzer Installation Procedure PDFqasim_maqboolNo ratings yet

- CHM111 Lab GuideDocument45 pagesCHM111 Lab GuidechrisakaleziNo ratings yet

- Electronics 1 - Lesson 1Document11 pagesElectronics 1 - Lesson 1Yousef BobadillaNo ratings yet

- Fire ExtinguisherDocument8 pagesFire ExtinguisherAzrif MoskamNo ratings yet

- 2 Spe 96798 HPWBM - HodderDocument12 pages2 Spe 96798 HPWBM - HodderPT100% (1)

- Solubility Rules Practice WorksheetDocument2 pagesSolubility Rules Practice WorksheetSarah Yetti0% (1)

- Sterile Formulation MCQsDocument5 pagesSterile Formulation MCQsbalamurugan75% (8)

- Bioprocess Engineering Part 2 Solved ProblemsDocument21 pagesBioprocess Engineering Part 2 Solved ProblemsProy LangNo ratings yet

- Org Synthesis QuizDocument71 pagesOrg Synthesis Quizlianchen251110100% (1)

- Solid Waste Incinerator ManufacturersDocument2 pagesSolid Waste Incinerator Manufacturersbl engineeringNo ratings yet

- Irl GekkoDocument51 pagesIrl GekkojcNo ratings yet

- Oil Spill EmulsifierDocument13 pagesOil Spill EmulsifierPlinio José Gálvez PerníaNo ratings yet

- Answers To Student Book Questions Rates of ReactionDocument3 pagesAnswers To Student Book Questions Rates of Reactionhamzaabdulhadi474No ratings yet

- Services Offered 1Document5 pagesServices Offered 1chinnybrucalNo ratings yet

- Nitinol: by Keshav Jasoriya BARCH/10028/18Document6 pagesNitinol: by Keshav Jasoriya BARCH/10028/18Keshav JasoriyaNo ratings yet

- TDC OliveDocument31 pagesTDC OliveFrancesco La Cara100% (1)

- H C CH O HC CH: Chemistry 17 Lecture Problem Set 4A A. Fundamentals of Organic and Biological MoleculesDocument2 pagesH C CH O HC CH: Chemistry 17 Lecture Problem Set 4A A. Fundamentals of Organic and Biological MoleculesSeamus AlaricNo ratings yet

- Topic: Metals and Non-Metals Worksheet KeyDocument6 pagesTopic: Metals and Non-Metals Worksheet KeyPranav SaiNo ratings yet

- Indole MetallationDocument51 pagesIndole MetallationHerman Nikolayevskiy100% (1)

- Lames Equation & JustificationDocument14 pagesLames Equation & Justificationjamil vora100% (1)

- EnzymesDocument13 pagesEnzymesAna Liza DolomandingNo ratings yet

- Carbohydrates and Amino Acids Polymers-01-TheoryDocument36 pagesCarbohydrates and Amino Acids Polymers-01-TheoryRaju SinghNo ratings yet

- Chapter 19 Chemical ThermodynamicsDocument8 pagesChapter 19 Chemical ThermodynamicsRSLNo ratings yet