Professional Documents

Culture Documents

Incinerator PDF

Incinerator PDF

Uploaded by

Borys0 ratings0% found this document useful (0 votes)

79 views52 pagesOriginal Title

incinerator.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

79 views52 pagesIncinerator PDF

Incinerator PDF

Uploaded by

BorysCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 52

WESTERN TIDE © \wi018i8 PLAN

AZ BOILER.

FINAL DRAWING

ee

WASTE OIL INCINERATOR BGW-20

MESSRS.

__TSUNEISHL SHIPBUILDING CO.,LTD.

sno.1065

°99194361

LIST No

T.Horie-cho, Matsuyama, Ehime. Japan.

Tel: 0899-79-11 1

C2Miuv

Specification of Waste Oil Incinerator

BE th BE j

pe BGW- 20

Se

‘95% 3A 308 te Be

mB BR B i te

@

No. B-219C

B-219C

SAFES

SPECIFICATION FOR INCINERATOR MODEL BGR-20

1. RSL

(1) BRVABRN-T REAL THETOT,

BEIT > THN SAA EES.

Bei \— 7 Eh CENT L ET 0

(2) WYN S—F SHER ESIC LD

AOMLLEAR EAA TW SRT ORE

IRIS SHASHKET

() UDF eB. AZAR

TWSEDCILABEIM ( PROD

FRRMNAE) OBABELPOSBI

FRET.

(4) BRIS - FO 7 AIVOEIA. 3am DS

ORAL THD. PaO Bess DE

the

(5) HR AY TV MTIC ED BE

BER (BET DAF > DH) PEMNUBIC

CHU SRAM SER ABP 5 HAE

FD, FORM ERICHA ET.

(6) SMMC ED. BEMLeN cy

BOT. WRATH»

(1) SAREE THBOT, Bb

LU CREE To

1. Features

(1) An air atomizing burner is applied to

nake stable conbustion, even though vaste

oil includes 40-percent water.

(2) An ouxiliary burner is applied to make

perfect combustion, even though waste oil

includes 40-percent or more water.

(3) An ejector is applied and internal

pressure is kept to be negative, so that

a solid material (include a solid waste of

high molecular) such as waste cloth may

(4) A burner nozzle has a 3nm orifice size

against. blockade.

(5) By erosion-proof castable lining, furnace is

protected fron high temperature and chlorine gas

with high molecular solid waste (plastics etc.)

burning disposal, and be proof against hard use.

(6) An automatic combustion device is

utilized for handy operation.

(1) Other various devices are designed for

safe operation.

B-219C

EB

Wain Specification

AD LR- UNS

Class

An AB (VY 2-)

Flag Foreign Flag (Norway)

(1) Beaiseenie

Waste Oil Burning Capacity : 20x10* : keal/h

(2) BRWEE (8)

Allowable Back Pressure at Funnel Base : 30

(3) ger

Electric Source = ACA4O 3 Volt.

60 2 He

3 2o

(4) seme

Total Electric Capacity 129 kW

(5) sia. » SSAC

Control System Automatic Control System

(6) ekOF ROMER

Total Weight

(7) ERUPT (Be x th xB)

‘Setting Dimension

8) Fry V7 RR

Color of Casing

(9) eee

Color of Control Box

(10) aM — 7 FARR

Fuel Oil for Aux. Burner

(LL) Beg + AEA OE

‘Automizing Air Press. for Waste Oil Burner

2 730 kg

: HeightxWidth Depth

1650 x 870 x 1340

2 Wt

Silver

2M 7.586 1/2

+ ABR

A Oil

: 1 ~ 10 (Max.10 ) 2 kg/en®

3. CRRBAA

Specification In Detail

(1) BREE

Furnace

a) &

Furnace Volume

(b) PABBA

Inside Construction

(2) Beit s—>

Waste Oil Burner

@) BX

Type

(b) 7 AVE

©) a)

Air Pressure

(a) GH

‘Atomizing Air Flow

(3) ihe — 7

‘Auxiliary Burner

(a) BX

‘Type

(b) SERRE

Fuel Oil

(c) REABREE

Capacity

(@) ORBEA

Fuel Oil Atomizing Press.

(e) JANF VF

Nozzle Tip

(8) KAR

Ignition System

(c) koe

Flane Detector

2 0.176 rm

2 eRADT VT

Castable Lining

2 See

‘Air Autonizing Burner

3 2am

0.5 2 kg/en®

20.35 Na /ain

2 HYVATN-F

Gun-type Burner

ABE

AOL

25.0 : of

rhs 6

BEAN-2 HK

: High-voltage Sparking System -

1 IL—bTt

Flame Eye ( cds )

(4) BORN —7 MEER 7

Fuel Oil Pump Aux. Burner

@) BK

Type

(b) MEHREEZI

Delivery Pressure

() wR

Electric Power

(8) HID 7

Cooling Fan

fa) OK

‘Type

) A

Capacity

(c) BL EE

Dilivery Pressure

(@) Babes

Hotor

(6) MRAIIVY

Flange of Funnel Base

(7) BeHAD 9 >

- Inlet Flange of Waste Oil Line

(8) Be 9 7

Return Flange of Waste Oil Line

B-219C

: BRR

Solenoid Pump

7 + ke/on®

10.03 2 kW

ACLIOV 1

2 IKI Y

Turbo-fan

1a + Na /ain

2 200 + monkg,

122 2 kW

2 : poles

2 ACA40V 60Hz 3@ 4.04

+ 3460 + rpm

+ 300A ( JISK Flange )

+ 25A ( JISSK Flange )

: 20k ( JIS5K Flange )

(9) BHF AACS

Inlet Flange of Aux. Burner Oil Line

(10) BRAAOZ IY

Inlet Flange of Atomizing Air Line

(1) Bete 7

Waste Oil Pump

@) % HK

‘Type

(b) ELH

Discharge Capacity

(c) ULtHEEZ]

Discharge Pressure

(12) BEA bL—

Waste Oil Strainer

a) BK

Type

219C

+ 15A ( JISSK Flange )

: 15A ( JISLOK Flange )

TRYST

Gear Pump

+ 150

ae

Single Type

‘JISIOK-25A Flange 10 Mesh

: Of

+ ke/on®

4. Rew

(Ll) N4 Oy bN-FORERKBORK

Rid, BEAN —TRAOR, MULES

Si

DY TER, AVE

(2) 4 ay KF HE OMEFL

Ze. HRNEEIRRaT

tt DY TBR, CV

(BEIEII: 4 ke/om* )

(3) BEa/\—F OZER DIANE L tee

PEELE

DU TR, CER

(@EFEN]: 0.1 ke/om* )

(4) RID 7 DOSE Ll

{Bik

SO DYTRR, CR

(5) HEA ARERR LACK, PIER

set

1 DYER, ARR

(BE = 360 TC)

(6) Beriiaseassek LL EF

1 DYTRR, AG

(BE: 150 TC)

(1), (3), (4), (8), (9) 8th

B-219C

4, Safety Devices

(1) In the event of misfire and flame

failure of the pilot burner, or

flame failure of the waste oil burner,

the combustion circuit is cut off.

At the same time, the pilot lamp comes

on and the bell rings.

(2) If the fuel oil pressure of the

pilot burner drops, the combustion

circuit is cut off .

At the same time, the pilot lamp cones

on and the bell rings .

(Set pressure : 4 ke/em® )

(3) If the air pressure of the waste oil

burner drops, the conbustion circuit is

cut off.

At the same time, the pilot lamp cones

on and the bell rings.

(Set pressure : 0.1 ke/cn® )

(4) If the cooling fan abnormal stops,

the running is stoped .

At the same time, the pilot lamp comes

on and the bell rings.

(5) If the temperature of exhaust gas

abnormally increases, the combustion

circuit is cut off.

At the same time, the pilot lamp comes

on and the bell rings.

(Set-temperature : 350°C )

(6) If the temperature of waste oil ©

abnormally increases, the pilot Lamp

comes on and the bell rings.

(Set-temperature : 150°C )

(1), (8), (4), (8) and (8) are shown one lamp.

(1) BEtRELISEASSR ASE EL fel

+ DYTRA

(BE : 90 C)

EL

(8) BRIE. SAPS SIRS LE

Lfel. BRSEEIEAEWT

1 DY TRE, CER

(SE : 1400 °C)

(9) Bed THANE. APPLE AS

FORE FL 70, REI ERIET

+ DY TBR, CR

(HE = 150 °C)

(10) si, bes’ Suva.

PURINES, PHT

Ytey hLiRWE, FEIT SHAT

BW.

(11) aReP ARN & RATEDS. Stik L

HG. DROBO L C bile

AL VFRONEFSET BANE

Bh LRVEZ OTS.

(12) APA DAY TV SIRAE TI

RUSE ASEWTS 11TH D. HABERT »

FRONIELTOBKL QUMIBE ZO

ThSe

(13) RUA y FASO Nicteo THE

B-219C

(7) If the temperature of waste oil

abnormally drops, the pilot lamp

cones on and the bell rings.

(Set-temperature : 90°C )

(8) For during the combustion, if the

‘temperature of furnase abnormally inereses,

‘the pilot Lamp comes on and the bell rings.

(Set-temperature : 140°C )

(9) For during the waste oil burners

conbustion, if the temperature uf furnase

abnormally drops, the pilot lamp comes on

and the bell rings.

(Set-temperature : 150°C )

(10) When the running is stoped or the

combustion circuit is cut off, they

have to be reseted manually. If not they

cannot restart.

(11) In case that every system on the plant

is powerless because of interruption of

electric supply, certainly press the running

switch again after recovering.

Failure to do so will not allow the burners

to restart automatically.

(12) then the solid vaste supplying port open,

the combustion circuit is cut off. And when

‘the conbustion switch is on, it can't be

fired.

(13) The structure of the solid waste supplying

port can't open during the combustion switch

is on.

SPARE, PARTS LIST NO, 39-80-078 (1/1) PAGE

WASTE OIL_INCINERATOR SHIP NO.

‘BOX NO.

oat Sle

no} NNE SKETCH MATERIAL Fig ono. NO. | REMARKS

WEIGHT (KG) it ila

CELLO LIFE FUSE 2

1-4 [ELEMENT ===} 1 | 1 | 1529-0 HeBt0V

tv bohe ak

mbAye a

0, 004

CONTACT OF

1-2| NAGNET C.T.1. —=-—}- 1 fa [aio |S80;3632

BMA

fo. 004

AUXILIARY

1-3] RELAY 5 | 1 | 5942-0 — | SACSO-2F

aman TE SE

Be 0.3

_ | FLAME EYE I 807-220, =

M4)oU-ar4 1 te 1] 1 | Sooan-0 | O19

IGNITION ——

881-104

4-5) INSULATOR 2)2

BRATS ad ~0002-0

0.05

_g|NOZZLE TIP A 509-600 .

ue v1 a | orea-0 |0 ¥1-898

1-7

T-HOAIE, MATSUYAMA, EHIME, JAPAN

Lilo MIURA CO., LTD. “Ter pée9-79-1235 mruRh JAPAN

& ADORESS FAX, 0899-79-2515

—————

TOOLS

LIST NO. 39-C0-037 (1/1) PAGE

WASTE OTL_INCINERATOR SHIP NO

_— BOX NO

ott Ship

No. NAME SKETCH MATERIAL Jor CORD. NO. | REMARKS

WEIGHT KG) TN SPE)

_;| SPANNER

1) no a ene are

0.06

» 200.

tp} SPARE PARTS BOX ‘i

Fim Ha gq

4

13

14

15

15

1-7]

MFR'S NAME,

& ADDRESS

MIURA CO., LTO.

T-HORIE, MATSUYAMA, EHIME, JAPAN

TEL. 0899-79-4235 MIURA JAPAN

FAX. 0899-79-2515

FILE GHEE BGO /PIPING

1%

aur

Staple machinery end apparatus supplied by MIURA

(a Furnace and purnors

(2yag77y cooling Fan

(G)eee7 Waste ott pum

Cea Hontrol Dox

semen

Machinery and apparatus suppited end arranged vy

shipyard.

Case :A-grade heavy of! prping

Ameo ousiironn7szoee

From the Agrade heavy ol! tank to the Inlet

flengs of the Inctnarator,

Ama DD 5 moap > OREECRERE TD

8c

From the A-grade heavy oll tank to tne waste ol!

pipiag outgoing from the waste ol! tank, KO

(2 Re Waste ol! piping

pho op sipnaayoEe

From the waste ol! tank to the Inlet tienge of

the Incinerator,

papo7S pas 29 2 CORR

From tho outiot flenge of tho Incinerator to waste

bri cane, (Heturn piping)

rd :Flus oa piping

anna 7 3 AOR

From the outiet flange of the Incinerator to

funnel,

(Ayer orneR

Power Supply wiring to the control box,

(5) anawRvERETRORNR

Control wiring for remote emargency shutdown and

Femote Indications out of the contro! box,

(3 )asraayisonett

‘Arrengoment fluegas expansion Joint.

eter B ORE

Waste ol! tank and auxiitary pfping,

(2) tetera 3 22 EO TER

‘Ale piping to the Intet flange of the Incinerator.

ark

Instructions

Casas ecco

Iprmasicianan —be

we

T BOLEATH

Sit—-

U

L

vil |Z

. L

908 ‘1x,09 {1 i

ngz/7ss sa[t eT

T ERG ABV TXT

La 3/58

i) arg

~ oO STS

Ea | o00s-000-r6Ev

ArFENYLRE

USZIWOLY 110 3LSvA

"oN eC

ert &

REEBWIME

JENI 10 SMH

oY as -—

2/1 Sd

5 Tae EN

fisw a saznuv oe Bours

OYSSH ee IB DET TTIBOBETA TiO wav |e

Dixew Je SHEUDS Tas | aa eRew

ABET U/_IN 06-12 OTEATY ONTZINOLY [5

BIE Oo Eeuseey

' £en_o ff 8784 6 "O "BERT ONTETWOLY WIV

T BNIBYO[g CuenyE

boa & byaw 905 "WRT BuTEMRLY 10 ava

T Bald SI2zON |p CueDw

eeyure WT 08-08 Tae Wel

i FiseiN fp FERRY

NEG M AS BR-Are i caw

i WON 10 aisva >

UE ORM

T SYD FIZZON |];

L- 40 Xe

ey Sea a

Reviston a a oF Si as

Description | Deston Roview ‘Approve ha, | Gesoriptics matt’ spec |g ty| Remarks

36 ACd4ov 60Hz «= * NFB, F1, F2:LR APPROVED TYPE 4 Lisle

9, 9, a -

je mm : is je Ie i

ye Acasov/110¥ ;

F250) a yl q a 3

ce 5 fg fon

al so

: fede ae = ° ee Z

jesse = 3 * . “| lease caine

: Su fev |" L- oe FP] 4

# ie per yer Fie fon ee foe]

J 3 [be "i v 4 del ge

wn lh

women 2) ©®@ ® & vi “Ie? #2 @® @©

7 & 58 ODO! :

fe O19) “oes

: " {if i

“2 we xy 49

cat a

. Re

Soe 4 go z¢ 5 &

28 © § 8 g& ¢

. Bri 5 ¢ £ 6 =

aad fag Cand Gnd Cees basd bed 6 l Bu b6te 2 FS 2 Bw §

reese es € ¢ F of

o eter Fw a ia c i

— Biraiacaee cps ists ase sees

Seeeek es Cox ue E

i x uo

q Rg e| El Z| g| 3| 3 3 Kame ic 5 « “” hal *

i oe ge a gy FRG BE

‘SOLENOID Lock fe OOOO! eu

8e: WARE BLT ET.

LINED BY MeKER WITH DELIVERY.

Saasteat atass,atneratae SeeeHTTO® Tos wy | onaranoe ov | Cons ang efcctied cre n| diorene » | Sesie | Bow a2 noe eosenee DIAGRAM

MIURA CO., LTD. [uaa Pron 3h 78 Ban. 3°5 ee He nev, no]

ereres Om. Sniee 28 ds. Gel | BOM promis | ASO3—410-6020 8°

OLOS—SOF—-r6EV

(xX09-OTP-€6E¥)

avn

3en 9 BnYN ern 3on 9 SRN yayn zea 9 SnWN TI aon 9 SMWN

a3 eatin a3 sack a @ sacle a3 cacti

WET HT FAUT Tae SSE TY RT ST TENE ATO ST SONOS

sauce] 02 | gnmamaiscays | XVE9 £obx4Rt-yvmy| O88-€ wage | IM

3Xa_SAVTd WIV eis wos Sant WS dos 7136 AVI ONT HIME

bav-nz| SP9 aréut#ssey 1V0Z £6 be mews | ISC—E bweag| 1M

THY WORT SMVA GTORSTOS S000 BENS VF wos UaMT TS WEROSONVHO”USNuNE SAVY WOTISTEROS

e¥mnews| VOz areuigeae LOEo éarxthe—| SEP bwewn| 19

mS Seaua UV TOT GREY savin wos aA WEISEL T1307 auld ssin

£oreunwea| VES abewipaEMs LLES| carviveny ere Pler—e weeyan| be

avo WORT Bnav TTONTTOT wasvaus Sond OW TRE BUTTOES OUT AIS TSR dO1s-Ava

ymmumy| 002 wangy-ta-7| 85N BiWidmee a TaESHNME AV] 5pm

SSATUMRITOW “LR. Sem oe 2cpsee

0000-90r-vé6éEv

* . dOUG “SS3Yd “0 ‘4 HOS YRWIL LoEeg

geo AS Gt LICE

* * Yiv dOlS 4OS Y3BWIL

2880'S aseurmanemene | LVOe

13S SAWN

=a ae

(UI) aL

MOT ‘dW3L 110 31SvM

sy] 209 qv 2.06 BELSIER

— 1 5 1gz

aoe HOYsan Tost AS 20S1L HOIH “dWAL 119 ppsve

(9,098F ~0027) HOIH ‘dWaL 3OVNUNS

A00EL] As | OSL Hamat, | L7Z

MOT “dW3L 3OVNUNS

Fem} 200% qv 20S L eg

soselas : “he HOIH “dWaL SVO "HX3 oe

aoseMOWanaL aos MOT ama 3098 AS | soge REC

(AHBATT3O HLM HEA AG 13S UETIOUINOD' gASL 38 | NOILISOd

SMe CRSTI ERATE! “SEV WE Ba BE | aM) del Aid SNVN

(USTIOGINGO'cHAL 3HL ONTLL3S) warmesse mE (a6) BH ua id

. (HSTIOUINOO' EL) SeierE

“HBATL QW HSTIOBINOD' GAL FHL ONTLI3S

BRA) COW HER

: Fovieren as ae |e) a

EARTH BOLT ZI description | destoh Review ‘App FOvE ener eee Mati Spec iq ty] Remarks

M8 7--AKW bE A

a

NO] BAXF NAME

. a RHA BE EXH, GAS TEMP.

Z| 88 SOURCE,

3 88 RUNNING

4 8 ‘COMBUSTION

5 Rit WASTE OIL BURNER

6 KR- FOR BURNER CHANGE OVER

7 RSK MISS FIRE

g| HORBE FAN STOP.

9 a ET F, 0, PRESS, DROP

1o| BREAET AIR PRESS, DROP

pi] #x ABA EXH, GAS TEMP, HIGH

12| $F AB eT FURNACE TEMP, LOW

13) Av Hae BELL STOP

fala - 14) 947 -AwFart LAMP: BELL TEST

BELL 15] 3 FT F, 0. TEMP, LOW

K 715. 16| #B ER F, 0, TEMP, HIGH

17

20, 660 200. 3] FARE FURNACE TEMP, HIGH

Oo ' i

a7

(3) |)

3 eA

8 f EXH, GAS TEMP, INDICATOR

s

d & 0 ssast

g 10 PILOT LAMP

Ola

ia) @ seteratee

6a) & PUSH BUTTON SW,

TS | 12 .

(8) | (8) | (2) @ sees pace

SELECT SW,

° one

di

| 400 y

eo 250 al COAMING

SaLsestett aiens otneretse 39001714 | pron oy | ovstoned oy | Center, Eng 1 Giatce n] omer 7 [Sesto | Bab nie ours ioe tt ee paneu

| 7 ay, i 7 ;

i MIURA CO. + LTD.) yrrsa nate ovsten fee | FE Fh TSF [Pb IS | 5 | pow # rev. 0]

° Cg: A) An pera oh ahwlS beainitn,| AZ93—-410-5010

By. LA

Ad

=

Rev, No,

goad beak

9907 GIONaTOS

Hoy BESA

ON) TNANBL SVO "HX

[oi[o2)

je

A394-405-6010

sR:

‘ony dona,

"SSaud 0's

= Cae Fe

( ‘gWal%O"S)

B1dn0o o1wLoTTIONYaHL

\

lst epeclaey

%

01 ara

ON) Horn ‘anes "od

\

e (wad toe

E (aad BovNuns)

S1sn0d O1uLoa1g0WUSHL

L WIRING

a gape

ON) goua “anau "Oa

z

& Title

3F ob Be BD

5 (sre He

2 (“aN SvO “HX3)

Srsnod SidiogTaONUSHL

i

1A

ERN.

SYSTEM DIAGRAM

2133[34[35]36]37138]39|40|41

[= 9% saaay EE

1s sa reieae

IS ms ‘ss3¥a 110 [eal

ExT

9% ee

[}-- 0%). norusnantt

Td

30[31

1s fe veins

eae ws Seaus Ty

Bow

ty

17] 7 [18] 9] 20]2 7 [Malev ve [ae ve]

i

Review

fata

wOLON Gauva0

(110 auswin yos)

BATA G1ONS108

Tam

TH STRS,

(a1 gos)

BATWA GIONS 108

Paver

RH yvIS aot

kta]

parang

a3 Ania

Man. 24s MOT, St

eas

Ph LTT,

LINKED BY MAKER WITH DELIVERY

SHIPYARD ARRANGEMENT

~ BORRIBIA, BAK

eam cod H

(1091d wos) 7

BAIA GIONSI08 g

2 AE

PEPEA GS

mS LUNI

16 @) 6

co

7

Drewa oy

ran

ar] Con.

ned

SNVUL NOILINOT

MOTOR

RBDTLR—9

LTO,

ard

aiind G10NS108

j

‘Syeten

RIs[t]u[v[w

SOURCE COOLING FAN

aR

(ass)

oral

o{ginoo 3Lonay)

ms dOLs AD Na

if2Ts[4atr[sttl[él7[ slr siehiol t [aap

T

T ¢

iT RRAS A

MIURA CO.

“A Zz wpa

00 - PIMP OE FATWA ayes | ane’ _ eee 5

pb Sat on ap. oe. gee bt | TL

Na & 0 % @ [aa wi aan 2 ad ae

ap~s gdh Wve a = =

_ ee)

PPS EWP 0 FANSSILA AAVINODIS waa

__

(avn) g = 7/ Big FANSSIAE Bevcream

ete

ibys) FANSSBEE AVE

uy 7

Wark¥a ch s348 ls

‘eH ie,

sanyA

u WARS 2

Bwads FAI,

— 1 SAS] abet

I xen) eo oe 7

=H Bares aA ———}

' ce AAO 9 LUM

tear ASST _gAT

2504 cane,

DNL 0

' oo 6700

Glan wecans

Ivo SHES:

bho chee whe

ne 7maa25

Cj

8

t

T| ear] 35s¥ Weveraid |g

s

y

&

ae hoy abe

7] eens] prot Be

eee al! | ov PS 2

Reanetsed | s | 90v Aare

aw = aay

| er Ree ST [pr aE | oa eae TV Be =EE

on

x zi & a. 8 pe s

Review Kpereve Description Matt Spee

Heras Did ad Sek. Tea seek lessee i<~o}

di 5 Mid Toh pane 3 Lec

7 Fob Fa

eT fons Giresel +

(acer sal Ix 79-2 sis 1

~ eee Baw + £ t

Ly al Se NK fs

FE same of Parcs | Mecertat | e-% % a

[acawa | Hage Data otha |

lsax| & | cel te | ae |Hel4 Tat est et ole x {n-£4

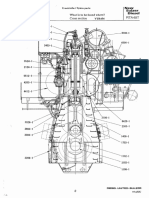

7351 B2 | 92 | ast sa| 87 |

3__| Insulation castable lining 9 | Waste oll burner _ |

4 | Refractory castable lining 40 | Front casing -

3 | Tenor casing 11 | ceoaing fan

6 | “Outer casing 12 [Furnace ai Fake

‘Shown above are the internal structure and nomenclature of the incinerator.

As illustrated above, the incinerator is divided into two major parts: inner furnace and outer

casing. The space between them is cooled with air driven by a cooling fan. in addition, since an

ejector is provided at the top of the outer casing, cooling air, draws the flue gas to maintain the

‘combustion chamber at a negative pressure and ensure safely combustion of waste oil. The

inner casing is totally lined with refractory castable and the front and rear casings of Model

BGW-10 and the rear casings of Model BGW-20 & 30 are lined with insulation castable to protect -

the outer casings from fire-damaging and overheating,

During maintenance of the furnace inside the front casing is removed as shown in the above

figure. The inner casing is provided with furnace air intakes in three positions to promote

incineration of solid waste

Since the flue gas is diluted and cooled directly with air sent from the cooling fan, its temperature

will never rise above the setting of the flue gas temperature indicator/regulator.

e

BOILER

4. List of Functions and Descriptions of Components

4-1. Cooling Fan

‘The cooling fan used in-the incinerator serves the following purposes.

1) to cool and protect the incinerator shell from overheating;

2) to keep the combustion chamber at a negative pressure by the flue gas ejector provided

below the chimney;

3) to keep the flue gas temperature below its safety limit by diluting the flue gas with the cooling

air.

In the event of a cooling fan failure, both the waste oil bumer and auxiliary burner are brought

toa shutdown, Namely, the system is so designed that the incinerator cannot be operated unless

the cooling fan is in operation. Thus, it is important to inspect and maintain the cooling fan

system, including its motor, for the maximum safety. On the occasion of periodic inspection or

overhaul for ball bearing replacement, etc, be sure to inspect and clean all the components, and

verify that the impeller is balanced in working order. When restarting the cooling fan system after

maintenance or repair, check the direction of motor rotation, and check it for noise and vibration.

‘Also examine whether the combustion chamber is held at the specified negative pressure.

BOILER

4-2. Waste Oil Solenoid Valve (GEV-H323G) @

28

\

(

NO. Name WO. Name

1 | Bonnet assy | Plunger

2 | Bott 6 | Valve Body

3 | Coll assy 7_| Spring

4 | Plunger spring 8 | Valve

The waste oil solenoid valve is constructed as illustrated above. The waste oil solenoid valve is

installed just before the waste oil bumer. It is actuated by working the waste oil burner switch.

When burning of the waste oilis discontinued for some reason or other, the flame-eye functions

to close the waste oil solenoid valve, preventing live waste oll leaking into the combustion

chamber.

The waste oil line is provided with a strainer at the outlet of the waste oil tank. it may happen,

however, that the waste oil solenoid valve is jammed with foreign objects and kept open even

when it is deenergized. If this situation lasts for a fong time, waste oil may gravitate from the

‘waste oil tank toward the solenoid valve and waste oil burner and finally leak into the combustion

‘chamber. If the burner is ignited carelessly a backfire may result. tis therefore imperative to make

sure before ignition that there is no waste oil leakage in the combustion chamber.

4-3. Auxiliary Bumer

No. Nam

1 | Bale aise

2 Ignition Insulator

3_|_ Nozzle tip (60°%1.56)

‘This burner is used to preheat the entire combustion chamber up to a temperature satisfactory

for complete combustion of waste oil and, in case the waste oil contains much water or fith and

cannot sustain burning by itself, to assist the waste oil in burning. The applicable fuel is “A”

heavy oll, and is supplied by means of a solenoid pump and a solenoid valve.

When the running switch is tumed on for ignition, the fuel solenoid pump will be operated. For

the first 35 sec., however, the fuel passage is cut off by the fuel solenoid valve for the purpose

‘of prepurging the combustion chamber. At the end of prepurge, the fuel solenoid valve opens,

the nozzle tip atomizes the fuel, and at the same time the ignition transformer as high a voltage as

40,000V to energize the ignition plug. The ignition plug sparks repeatedly (for about 10 sec.) to

ensure ignition. When the ignition plug is renewed due to its wear or so on, be sure to observe

the dimensional relationships illustrated above. (When it is shipped from the factory, its

dimensions have been set as shown above.) If the ignition plug fails to ignite or is liable to cause

misfire when it has been installed and set as specified, make necessary adjustments and locate

the optimum position. The nozzle tip ignition plug, baffle disc, etc. trend to be fouled with carbon,

etc., and should be cleaned occasionally to keep them in good working order all the time.

ABOILER

4-4. Solenoid Pump (Fuel Pump for Auxiliary Burner)

‘There is used a solenoid pump as illustrated above for the purpose of feeding */

the auxiliary burer. lis operating principle is as follows:

When supplied with 100V A.C, the rectifier element of the solenoid pump develops chopped

signals, which in turn energize the solenoid col to force the plunger up and down. The up and

down motion of the plunger is converted into the reciprocating motion of the position below it, :

‘opening and closing the suction and delivery valves alternatively to deliver the fuel oil to the >

aunilary bumer. VS-3GN is provided with a built-in relief valve to feed back to the pump inlet the

delivery prossure in excess of setting (7.0 kg/cm) to be developed when the nozzle or delivery

line is blocked up for pressure regulation. The upward stroke of the plunger opens the suction

valve and closes the delivery valve, taking in the fuel oil in between. The downward stroke to

follow it functions to close the suction valve and open the delivery valve, discharging the fuel ol

to the delivery port. When the delivery pressure rises above the setting, the relief valve will work

to send the excess pressure back to the inlet por.

heavy oil to

(1) Operation Principle

The solenoid pump is a kind of reciprocating

pumps. When an input of the half-wave rectified

alternative current is applied to the solenoid coil,

the piston is forced up and down by the repetitive

magnetic attraction and spring reaction forces.

This up and down motion is converted into the

piston suction stroke to such oil through the

suction and delivery valves during magnetic

attraction and into the piston compression stroke

during spring repulsion.

When the solenoid pump is supplied with the

electric current, the cut-off valve is attracted by

the fixed magnetic rod at the same time with the

motion of the solenoid plunger, and the solenoid

valve opens to open the space between the

nozzle and the solenoid pump inside.

When cil is sucked into the pump inside and

discharged through the discharge part (2) and

the pump inside pressure is in excess of the

specified pressure because of the resistance of

the nozzle or so on, oil inside the pump forces

the return valve open and excess oil returns to

the suction side through the retum port to keep

the pressure and delivery flow at their respective

‘constant values,

(2) Checking Solenoid Pump

pipes. Put on power to solenoid

pump (with sanseanductan,

2

ome.

Discharge Port (2)

Cuvolt Valve

+ Fixed Magnetic

od

Upper Spring

‘Solenoid Punger

Suction Check Valve

Way of testing Criterion

1) Taking out sucton and delivery [Normal as big as pip sound.

‘when pcp sound is low, puton | When sound is as same as above,

power (RG TOV) to solenoid Semiconductor is broken down,

HLL

—— Piston

J~Retumn Valve

oyinder

1

vate

Feetim ‘Staines

Ghannet

‘Treatment

Carry out testing (2)

Conte (1), after

renewed semiconductor.

'3) When thore are no working sound

and vibration, check solenoid

= 200v

| caliMoretrteste: Resistance beet

Normal

Blue and rea Ton

Blue and yellow an} |

a 4) Solenoid col is good, but pump | No working of piston part which is

tannot work st Inside of pump. Contin (1), after

erhaulng ahd leaning

When resistance is to0 large or 20°.

| Renew solenoid pumg

| Fenew um.

Ronew solenoid pump

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5824)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rta48 - Operation ManualDocument13 pagesRta48 - Operation ManualBorysNo ratings yet

- Rta48 - Sea Trail TestsDocument16 pagesRta48 - Sea Trail TestsBorysNo ratings yet

- 1d Dvs Sulzer Rta48t Codebook 812Document812 pages1d Dvs Sulzer Rta48t Codebook 812BorysNo ratings yet

- Air ComDocument54 pagesAir ComBorysNo ratings yet

- Instruction Manual For Hydraulic Driven Deck MachineryDocument180 pagesInstruction Manual For Hydraulic Driven Deck MachineryBorysNo ratings yet

- Atoyac:) Usttifiw-26Document60 pagesAtoyac:) Usttifiw-26BorysNo ratings yet

- Atoyac: Flistnllhf-20Document85 pagesAtoyac: Flistnllhf-20BorysNo ratings yet

- FlowmeterDocument22 pagesFlowmeterBorysNo ratings yet

- Atoyac: (Listnolhf-23Document70 pagesAtoyac: (Listnolhf-23BorysNo ratings yet

- Arr. of Pilot Ladder: Tsunelshi Shipbuilding Co .. LTDDocument33 pagesArr. of Pilot Ladder: Tsunelshi Shipbuilding Co .. LTDBorysNo ratings yet

- HF-7 Rudder CarrierDocument22 pagesHF-7 Rudder CarrierBorysNo ratings yet

- Atoyac: Listnol HF - 1Document124 pagesAtoyac: Listnol HF - 1BorysNo ratings yet

- HF-19 Anchor Chain CableDocument3 pagesHF-19 Anchor Chain CableBorysNo ratings yet

- Ea-4 Test Record of Generator Control SystemDocument54 pagesEa-4 Test Record of Generator Control SystemBorysNo ratings yet

- HG-4 Docking PlanDocument3 pagesHG-4 Docking PlanBorysNo ratings yet

- Ed-15 Electric Propeller Shaft Revolutions and Electric Revolution Counter (Incl Inst and Test Report)Document58 pagesEd-15 Electric Propeller Shaft Revolutions and Electric Revolution Counter (Incl Inst and Test Report)BorysNo ratings yet

- Ed-10 Magnetic CompassDocument7 pagesEd-10 Magnetic CompassBorysNo ratings yet

- Ec-5 MotorDocument38 pagesEc-5 MotorBorysNo ratings yet

- Tsa/Ssr Type: Instruction Book For Roots BlowerDocument19 pagesTsa/Ssr Type: Instruction Book For Roots BlowerBorysNo ratings yet

- Ec-10 Emergency Switchboard (Incl Test Report)Document72 pagesEc-10 Emergency Switchboard (Incl Test Report)Borys100% (1)

- Docking PlanDocument1 pageDocking PlanBorysNo ratings yet

- List No: Nishishiba Electric Co., LTDDocument17 pagesList No: Nishishiba Electric Co., LTDBorys100% (1)

- MD-7-0005 Emergency Diesel GeneratorDocument152 pagesMD-7-0005 Emergency Diesel GeneratorBorysNo ratings yet

- Ed-2 Electro Magnetic Log (Incl Inst and Test)Document75 pagesEd-2 Electro Magnetic Log (Incl Inst and Test)Borys100% (1)

- Ed-1 Digital Auto PilotDocument256 pagesEd-1 Digital Auto PilotBorys100% (3)

- MD-1 Main Diesel Generator EngineDocument49 pagesMD-1 Main Diesel Generator EngineBorys100% (1)

- Sulzer 6RTA 48T General DrawingDocument1 pageSulzer 6RTA 48T General DrawingBorysNo ratings yet

- Sulzer 6RTA 48T General DrawingDocument1 pageSulzer 6RTA 48T General DrawingBorysNo ratings yet

- Mb-4 Operation and DataDocument348 pagesMb-4 Operation and DataBorysNo ratings yet

- CPM 500 PDFDocument14 pagesCPM 500 PDFBorysNo ratings yet