Professional Documents

Culture Documents

Microfluidizer SOP

Microfluidizer SOP

Uploaded by

Ben Woodard0 ratings0% found this document useful (0 votes)

79 views2 pagesThis document provides standard operating procedures for using a Microfluidizer to lyse bacterial and yeast cells. Key steps include:

1) Wearing proper safety equipment like goggles and gloves when operating the high pressure Microfluidizer.

2) Preparing cell samples by re-suspending frozen cell pellets in buffer and keeping them cold.

3) Priming the Microfluidizer with buffer and gradually increasing pressure to 5000 psi during priming.

4) Running cell samples through the Microfluidizer at pressures up to 27,000 psi to lyse over 95% of E. coli or 65% of yeast cells.

Original Description:

Standard Operating Procedure for running a Microfluidzer 110-EH

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides standard operating procedures for using a Microfluidizer to lyse bacterial and yeast cells. Key steps include:

1) Wearing proper safety equipment like goggles and gloves when operating the high pressure Microfluidizer.

2) Preparing cell samples by re-suspending frozen cell pellets in buffer and keeping them cold.

3) Priming the Microfluidizer with buffer and gradually increasing pressure to 5000 psi during priming.

4) Running cell samples through the Microfluidizer at pressures up to 27,000 psi to lyse over 95% of E. coli or 65% of yeast cells.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

79 views2 pagesMicrofluidizer SOP

Microfluidizer SOP

Uploaded by

Ben WoodardThis document provides standard operating procedures for using a Microfluidizer to lyse bacterial and yeast cells. Key steps include:

1) Wearing proper safety equipment like goggles and gloves when operating the high pressure Microfluidizer.

2) Preparing cell samples by re-suspending frozen cell pellets in buffer and keeping them cold.

3) Priming the Microfluidizer with buffer and gradually increasing pressure to 5000 psi during priming.

4) Running cell samples through the Microfluidizer at pressures up to 27,000 psi to lyse over 95% of E. coli or 65% of yeast cells.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Microfluidizer SOP

1.0 Safety

1.1 Understand the SOP before beginning

1.2 Wear proper safety attire, including: safety goggles, lab coats, and latex gloves.

1.3 The Microfluidizer runs at very high pressure so safety glasses must be worn at all times.

2.1 Sample prep

2.1 Re-suspend frozen cell pellets in 3:1 or 4:1 of cracking buffer until it forms a slurry.

2.2 The suspension of cells and buffer should remain below 10°C.

3.0 Microfluidizer prep

3.1 For >5L of sample to be cracked, connect the water supply and turn on the cold water.

3.2 Record the length of usage when you are done. (The oil needs to be changed at 50 hours).

3.3 Turn the air on and verify the pressure is at 60psi

3.4 Turn on the main power.

3.5 Surround the cracking chamber and cooling coil with ice and allow it to cool.

4.0 Priming the unit

4.1 Fill the reservoir with ~50mL of chilled buffer (without cells)

4.2 Turn the prime handle (located at the base of the reservoir) counter clockwise.

4.3 Turn the process pressure knob counter clockwise so it is set to minimum.

4.4 Pull the red intensifier button to start the flow of buffer.

4.5 Turn the process pressure knob clockwise to increase the pressure. Do not exceed 5000psi during

the prime step.

4.6 Once buffer comes out of the prime line, turn the prime handle clockwise to close the line.

4.7 Allow nearly all the remaining buffer to drain through the cracking chamber, checking for leaks.

If a leak occurs, stop and tighten as needed.

4.8 Press the intensifier button to stop flow once the buffer is below the tapered end of the reservoir.

If you let the buffer drain out of the reservoir you'll need to re-prime the unit.

5.0 Running the Microfluidizer

5.1 Verify the unit has been primed and your slurry is below 10C.

5.2 Pour the cell slurry into the reservoir.

5.3 Turn the process pressure knob counter clockwise so it is set to minimum.

5.4 Pull the red intensifier button to turn the start the flow of buffer.

5.5 Turn the process pressure knob clockwise to increase the pressure. Increase the pressure to the

desired level. E. coli will crack at 15,000 psi while yeast will need close to the maximum of

27,000 psi.

5.6 Collect the slurry into a container on ice.

5.7 Stop the unit once the cell/buffer mixture is below the tapered end of the reservoir. If you allow

the unit to run dry, you will need to prime it again.

5.8 Turn the process pressure knob counter clockwise so it is set to minimum

5.9 View the cell slurry under the microscope. It may take several passes through the cracking

chamber to disrupt the cells. ~95% of cells should be cracked for E. coli and ~65% for yeasts.

5.10 If needed, repeat 5.1 – 5.9 after the temperature is below 10°C.

5.11 Centrifuge the entire slurry at max speed for 30minutes – proceed with clean up.

5.12 After centrifugation, save the supernatant as it will be used for further processing.

6.0 Clean Up

6.1 Fill the reservoir with ~500ml of Spore-Klenz.

6.2 Pull the red intensifier button to turn the start the flow of buffer.

6.3 Turn the process pressure knob clockwise to increase the pressure. Allow ~95% of the volume of

Spore-Klenz to flow through.

6.4 Fill the reservoir with ~1Lof 70% ethanol.

6.5 Turn the process pressure knob clockwise to increase the pressure. Stop the unit when ~750ml of

the ethanol solution has run through the system.

6.6 Turn the process pressure knob counter clockwise so it is set to minimum.

6.7 Cover the reservoir with parafilm and record the time used into the time log.

You might also like

- Statement of Account: Customer Name Start DateDocument6 pagesStatement of Account: Customer Name Start DateAGBESE GODWIN OCHEPANo ratings yet

- Course Caterpillar 3408 3412 3126b Heui Engines Components Oil Flow System IDocument24 pagesCourse Caterpillar 3408 3412 3126b Heui Engines Components Oil Flow System IX'mix ĐreamerNo ratings yet

- 5L Super Reflux Still InstructionsDocument16 pages5L Super Reflux Still InstructionsAndréRochaNo ratings yet

- 2010 Stool Extraction ProtocolDocument6 pages2010 Stool Extraction ProtocolwiwienNo ratings yet

- Miniaturized Ice Plant MANUALDocument6 pagesMiniaturized Ice Plant MANUALGold BlandoNo ratings yet

- Flow Chart Exp 2Document4 pagesFlow Chart Exp 2sf444wgt8rNo ratings yet

- Spray Drier Lab ManualDocument11 pagesSpray Drier Lab ManualJay Wong100% (1)

- 201.022 110 Bottle Sampler User GuideDocument11 pages201.022 110 Bottle Sampler User GuidesujithNo ratings yet

- Laboratory Chemical ProcedureDocument20 pagesLaboratory Chemical ProcedureRimil GeorgeNo ratings yet

- Topic:: 1: Commissioning 2: Shut DownDocument6 pagesTopic:: 1: Commissioning 2: Shut DownKaleemNo ratings yet

- Expression of Recombinant Proteins in The Methylotrophic Yeast Pichia PastorisDocument5 pagesExpression of Recombinant Proteins in The Methylotrophic Yeast Pichia PastorisAlexis TorresNo ratings yet

- Western Blot: Protein Extraction From Adherent CellsDocument3 pagesWestern Blot: Protein Extraction From Adherent CellsgomelisaNo ratings yet

- Acid Detergent Fiber Procedure (ADF) : 1. ApplicationDocument4 pagesAcid Detergent Fiber Procedure (ADF) : 1. ApplicationFarai FaustosNo ratings yet

- W08g09an Mha 1.1. A Pan OperationsDocument4 pagesW08g09an Mha 1.1. A Pan Operationswaziri maulidiNo ratings yet

- Waters 2695 Troubleshooting CSUDocument17 pagesWaters 2695 Troubleshooting CSUstflock100% (1)

- MELUH Yeast ChIP ProtocolDocument8 pagesMELUH Yeast ChIP ProtocolsurendrasrawanNo ratings yet

- DARASL-EQ-004 Work InstructionsDocument6 pagesDARASL-EQ-004 Work InstructionsAndrea KakuruNo ratings yet

- Lab Manual Separation Tech Jan 2020Document48 pagesLab Manual Separation Tech Jan 2020nisasoberi0% (1)

- Sop MeeDocument5 pagesSop MeeYogesh Dhekale100% (5)

- Phosphorous SOPDocument6 pagesPhosphorous SOPmicheal terryNo ratings yet

- HB-0979-002 1101285 - PCard - GEF - miRNY - Micro - 0316 - WW - WEBDocument2 pagesHB-0979-002 1101285 - PCard - GEF - miRNY - Micro - 0316 - WW - WEBgermanav.osowskiNo ratings yet

- NuPage Gel ProtocolDocument3 pagesNuPage Gel ProtocolShannon HughesNo ratings yet

- Western Blotting: Gel Casting PreparationDocument5 pagesWestern Blotting: Gel Casting Preparationsrividya84No ratings yet

- Chem2521 W5 DistillationDocument4 pagesChem2521 W5 DistillationWiwit Zuriati UnoNo ratings yet

- SDD Age Sds Agarose GelDocument2 pagesSDD Age Sds Agarose GelZelha NilNo ratings yet

- Sperm Freezing Protocol PDFDocument2 pagesSperm Freezing Protocol PDFminh3010No ratings yet

- Determin of Aero Anaerobic Spore FormersDocument6 pagesDetermin of Aero Anaerobic Spore FormersbhaleshNo ratings yet

- Lab: No: 1 Culture Media Preparartion: Student NameDocument4 pagesLab: No: 1 Culture Media Preparartion: Student NameShafici CqadirNo ratings yet

- Protocol For RnaDocument6 pagesProtocol For RnaTrustNo ratings yet

- Updated Training manual for Cartridge and TEAA Buffer making Aug 2022Document6 pagesUpdated Training manual for Cartridge and TEAA Buffer making Aug 2022KavyaNo ratings yet

- 1 US Gallon Water PurifierDocument16 pages1 US Gallon Water Purifieremily turnerNo ratings yet

- FHP011 03Document10 pagesFHP011 03Omonigho SapeleNo ratings yet

- General Shortpath GuideDocument2 pagesGeneral Shortpath GuideAndrew TanNo ratings yet

- DNeasy Plant Maxi Kit April 2012 enDocument2 pagesDNeasy Plant Maxi Kit April 2012 enariel_jNo ratings yet

- AOCS Te1a-64 TitreDocument2 pagesAOCS Te1a-64 TitrewilNo ratings yet

- Western Blot ProtocolDocument2 pagesWestern Blot ProtocolyrysupermanNo ratings yet

- SopvacuumDocument14 pagesSopvacuumapi-280316582No ratings yet

- Blow Moulder UkDocument10 pagesBlow Moulder UkAnonymous 8VsLvQKNo ratings yet

- Service Selcoperm: Fig. 1 Exchange Meter DiscDocument13 pagesService Selcoperm: Fig. 1 Exchange Meter DiscGabrielNo ratings yet

- Simplified Procedure CyclesDocument6 pagesSimplified Procedure CyclesVĩ ĐặngNo ratings yet

- Chapter_6Document4 pagesChapter_6sobhyahmed433No ratings yet

- Lab Manual Separation Tech Jan 2021Document43 pagesLab Manual Separation Tech Jan 2021Abdul QayyumNo ratings yet

- CHEM 110 Laboratory Assignment 3 Part I: The Hydrolysis of An Ester Part Ii: Spectroscopic Structure DeterminationDocument11 pagesCHEM 110 Laboratory Assignment 3 Part I: The Hydrolysis of An Ester Part Ii: Spectroscopic Structure DeterminationAngie UngNo ratings yet

- Rapid Extr Caffeine From NodozDocument5 pagesRapid Extr Caffeine From NodozHidil Hirdin100% (1)

- 119015-ENG 311 - Aparna KSDocument16 pages119015-ENG 311 - Aparna KSdiksha singhNo ratings yet

- Xylene SolubaleDocument4 pagesXylene Solubale6850079No ratings yet

- Membraneand Cytosol Preparation MODDocument2 pagesMembraneand Cytosol Preparation MODFadia KamalNo ratings yet

- Operating Procedure Part 1Document3 pagesOperating Procedure Part 1jayson canonNo ratings yet

- Wizard SV Genomic DNA Purification System Quick Protocol PDFDocument4 pagesWizard SV Genomic DNA Purification System Quick Protocol PDFPramusita Yoga DaniswaraNo ratings yet

- Manual Usuario OptimamsDocument24 pagesManual Usuario OptimamsOscar OcañoNo ratings yet

- Heat Inactivation ProtocolDocument1 pageHeat Inactivation ProtocoldupuytrenNo ratings yet

- Assignment Title: Submitted To: Submitted byDocument18 pagesAssignment Title: Submitted To: Submitted bySyed UmairNo ratings yet

- South SPTP Laboratory TrainingDocument22 pagesSouth SPTP Laboratory TrainingGerald ParamioNo ratings yet

- SOP009 DNA& RNA Extraction From Fecal SamplesDocument6 pagesSOP009 DNA& RNA Extraction From Fecal SamplesHayleyNo ratings yet

- Manual Human IL23 Canvax ELISADocument11 pagesManual Human IL23 Canvax ELISALuis Arístides Torres SánchezNo ratings yet

- Fixation and Embedding TissueDocument2 pagesFixation and Embedding TissueLorenzo OlivacciaNo ratings yet

- Ninh Binh Rua Hoa ChatDocument3 pagesNinh Binh Rua Hoa Chathuy LuongNo ratings yet

- 308 2017 Application Note Determination of Oil Content in Seed Samples 0Document8 pages308 2017 Application Note Determination of Oil Content in Seed Samples 0Hà Thị Thanh TịnhNo ratings yet

- PortfolioAshley Sutton Instruction SetDocument5 pagesPortfolioAshley Sutton Instruction SetAshley SuttonNo ratings yet

- The "I Love My Instant Pot®" Affordable Meals Recipe Book: From Cold Start Yogurt to Honey Garlic Salmon, 175 Easy, Family-Favorite Meals You Can Make for under $12From EverandThe "I Love My Instant Pot®" Affordable Meals Recipe Book: From Cold Start Yogurt to Honey Garlic Salmon, 175 Easy, Family-Favorite Meals You Can Make for under $12No ratings yet

- The Ultimate Guide to Use an Instant Pot: Accessories, Directions, Cleaning Hacks, Tips & MoreFrom EverandThe Ultimate Guide to Use an Instant Pot: Accessories, Directions, Cleaning Hacks, Tips & MoreNo ratings yet

- 2isp MikrotikDocument3 pages2isp MikrotikamirulmNo ratings yet

- Amrutvahini Polytechnic, Sangamner: Submitted byDocument15 pagesAmrutvahini Polytechnic, Sangamner: Submitted byPankaj SangaleNo ratings yet

- Microsoft Copilot Studio - Implementation Guide (1.4)Document88 pagesMicrosoft Copilot Studio - Implementation Guide (1.4)giovanny.buitrago@setecsa.comNo ratings yet

- 03 EquilibriumDocument15 pages03 EquilibriumAndy BayuNo ratings yet

- Typ 08417 1 enDocument1 pageTyp 08417 1 enSanthoesh srinivasanNo ratings yet

- Hotkeys TWSDocument9 pagesHotkeys TWSvasseNo ratings yet

- Operating System AssessmentsDocument37 pagesOperating System AssessmentsNandu NarayananNo ratings yet

- DBMS Project ReportDocument37 pagesDBMS Project Reportps2848No ratings yet

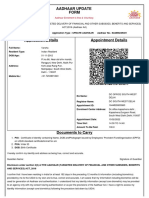

- Aadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryDocument4 pagesAadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryyogeshNo ratings yet

- Calculation SheetDocument2 pagesCalculation SheetSamwailNo ratings yet

- Lab #8 Ce336Document10 pagesLab #8 Ce336husseinfarhatmNo ratings yet

- Cavity WallsDocument19 pagesCavity Wallstideci1953No ratings yet

- Activity 1. Going Through An ArticleDocument2 pagesActivity 1. Going Through An ArticleEmanuel Andrei VeluzNo ratings yet

- Unit 1Document211 pagesUnit 1Thiriveedhi SubbarayuduNo ratings yet

- Computer System Servicing 10 w1 2Document43 pagesComputer System Servicing 10 w1 2Catherine IlaganNo ratings yet

- TOR - Hydrogen PipelineDocument5 pagesTOR - Hydrogen PipelineAnbu KumarNo ratings yet

- ASTM A240 A240M 13cDocument14 pagesASTM A240 A240M 13cislamaktham100% (3)

- RAW DATA US 2020 Election Interference ItalyDocument39 pagesRAW DATA US 2020 Election Interference ItalyDGB DGB100% (1)

- DSP CEP Part3&4Document7 pagesDSP CEP Part3&4Huzaifa YasirNo ratings yet

- Quectel Rm502Q-Ae: Iot/Embb-Optimized 5G Sub-6 GHZ M.2 ModuleDocument3 pagesQuectel Rm502Q-Ae: Iot/Embb-Optimized 5G Sub-6 GHZ M.2 ModuleRosarioNo ratings yet

- AcumaticaERP IntegrationDevelopmentGuideDocument331 pagesAcumaticaERP IntegrationDevelopmentGuidecrudbugNo ratings yet

- Smart Glasses For Blind - A Personal Assistant Using PaperDocument4 pagesSmart Glasses For Blind - A Personal Assistant Using PaperRamesh reddy DNo ratings yet

- Sentinel-2 Calibration and Validation - From The Instrument To LevDocument27 pagesSentinel-2 Calibration and Validation - From The Instrument To LevIoana VizireanuNo ratings yet

- Veunex - IsomaxDocument12 pagesVeunex - IsomaxViron BaxhiaNo ratings yet

- VECTOR 1850 / 1850 Mt° Spare Parts ManualDocument80 pagesVECTOR 1850 / 1850 Mt° Spare Parts ManualRodrigo HernandezNo ratings yet

- P633 OrderForm - v52 - 112021Document14 pagesP633 OrderForm - v52 - 112021keglobalNo ratings yet

- 795 Al Ict P1, 2 Guide Lit 2024Document8 pages795 Al Ict P1, 2 Guide Lit 2024Wilfried MangadouNo ratings yet

- Data Presentation and AnalysisDocument22 pagesData Presentation and AnalysisUsma Nisar100% (1)