Professional Documents

Culture Documents

Cold Work

Cold Work

Uploaded by

Giorgi KandelakiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cold Work

Cold Work

Uploaded by

Giorgi KandelakiCopyright:

Available Formats

Cold Work

Cold Work is the work which cannot create a source of ignition or generate temperature

conditions likely to be of sufficient intensity to cause ignition of combustible gases,

vapours or liquids in or adjacent to the area involved.

Cold work includes but not limited to:

1. Opening vessels, pipes or enclosed spaces

2. Where equipment requires decontamination

3. Mechanical maintenance work

4. Civil maintenance work

5. Erection removal of scaffolding

6. Insulation and painting

7. Blanking/de-blanking.

8. Disconnecting and connecting pipelines.

9. Removing and fitting of valves, blanks, spades or blinds.

10. Work on pumps

Before carrying out cold work, the

following is to be taken care of:

1. Determining that the area is safe for work and sign the permit.

2. Complete the Cold Work Permit form, jointly with the person/s involved in the

work.

3. Ensure that the work is carried out as per the conditions mentioned in the Cold

Work permit.

4. Retract the permit if safe working conditions are breached.

Procedures

Prior to the commencement of cold work in hazardous or dangerous area, the cold work

permit shall be filled and all its provisions are to be satisfied. In Tankers, attention shall

be drawn towards vapours from leaking bulkheads of adjacent tanks and passing

pipelines. Personnel involved must understand the requirements, procedures and

hazards involved. In case of a violation of any of the provisions during the course of

work, the permit shall be cancelled and work may be resumed only after the violations

are corrected.

The cold work permit should contain a clear indication as to its maximum period of

validity.

Hazards Involved:

Personal injury, Slipping / tripping depending on the location of cold work, Personnel

Injury whilst Working with Tools.

Control Measures:

1. Proper PPE shall be donned at all times.

2. All equipment and ropes to be used for the job shall be thoroughly inspected

prior operation.

3. Ensure area is clear of any slipping hazard.

4. Safety harness shall be used where applicable.

5. A tool box meeting to be conducted prior commencement of the job.

6. Use right tool for the job.

7. Examine each tool for damage before use.

8. Operate tools according to the manufacturer’s instructions.

9. Disconnect tools when they are not in use and when changing accessories such

as blades, bits and cutters etc.

Follow safe practices as per Code of Safe Working Practices for Merchant Seamen

(COSWP).

You might also like

- Work Method Statement (Dismantling Works)Document7 pagesWork Method Statement (Dismantling Works)Angelo Castro75% (8)

- FIXTURE NOTE - SAMPLE-dikonversiDocument7 pagesFIXTURE NOTE - SAMPLE-dikonversiSsa SaaNo ratings yet

- Strand7 TutorialDocument219 pagesStrand7 TutorialJay Ryan Santos67% (3)

- J-1999-Control of Jet Engines, SpangDocument17 pagesJ-1999-Control of Jet Engines, SpangMohammadReza AminiNo ratings yet

- SOP Vessel PlanningDocument3 pagesSOP Vessel PlanningbkwsubantingNo ratings yet

- Questions For Phase 1, 1st Internals, Cargo Handling and StowageDocument1 pageQuestions For Phase 1, 1st Internals, Cargo Handling and Stowagepramodkb_cusatNo ratings yet

- GUIDELINE FOR MARITIME TRAINING INSTITUTE Malaysia PDFDocument50 pagesGUIDELINE FOR MARITIME TRAINING INSTITUTE Malaysia PDFJOHN KHANNo ratings yet

- One Minute Card 2010Document1 pageOne Minute Card 2010Sumeet GuptaNo ratings yet

- Glossary of Chartering TermsDocument84 pagesGlossary of Chartering TermsrubinoestelaNo ratings yet

- Ud11t4106-Cargo Handling - Stowage and Seamanship - QP1-MDocument2 pagesUd11t4106-Cargo Handling - Stowage and Seamanship - QP1-MParminder singh parmarNo ratings yet

- Cargo Piping SystemDocument4 pagesCargo Piping Systemdinar rosandy100% (1)

- Understanding Intact & Damage Stability of ShipsDocument3 pagesUnderstanding Intact & Damage Stability of ShipsGiorgi KandelakiNo ratings yet

- Hợp đồng thuê tàu chuyếnDocument7 pagesHợp đồng thuê tàu chuyếnVũ Hồng NhungNo ratings yet

- Loadline & Draft MarksDocument13 pagesLoadline & Draft MarksTushar DeepNo ratings yet

- Time in Ship CharterDocument15 pagesTime in Ship CharterNUR SORAYA BT MOHD ZAMRI gisNo ratings yet

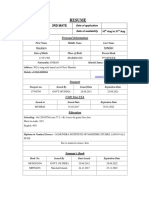

- Curriculum Vitae For Third Officer 2 Copy 2Document4 pagesCurriculum Vitae For Third Officer 2 Copy 2Sumeet GhugeNo ratings yet

- CV Master UpdateDocument2 pagesCV Master UpdateAlfa Arafah GroupNo ratings yet

- PMMRR 1997 - Book PDFDocument113 pagesPMMRR 1997 - Book PDFwasita wadariNo ratings yet

- Appendix B Master Pilot Exchange of Essential Information On Boarding Mar 2014 PDFDocument1 pageAppendix B Master Pilot Exchange of Essential Information On Boarding Mar 2014 PDFCapt. Sikandar MhaisaleNo ratings yet

- Drydocking in Damaged ConditionDocument2 pagesDrydocking in Damaged ConditionGAMMA FACULTYNo ratings yet

- 2nd Mate NavigationDocument2 pages2nd Mate NavigationMahmoud KhalafNo ratings yet

- Procedure How To Swing The Rescue Boat Davit by Three Different MethodDocument1 pageProcedure How To Swing The Rescue Boat Davit by Three Different MethodMico LazaroNo ratings yet

- Ballast Water Reporting Form PORT HEALTH VOY 4Document2 pagesBallast Water Reporting Form PORT HEALTH VOY 4anilNo ratings yet

- Passage Planning NotebookDocument4 pagesPassage Planning NotebookRobert M. Maluya100% (1)

- Cargo Shortage: Magnus Carriers CorporationDocument1 pageCargo Shortage: Magnus Carriers CorporationIhwan AsrulNo ratings yet

- Recommended Principles - BIMCODocument1 pageRecommended Principles - BIMCOpgupta71No ratings yet

- DWT & Drafts Capacity PDFDocument7 pagesDWT & Drafts Capacity PDFRafaelsligerNo ratings yet

- Registration of Ship PPT PresentationDocument13 pagesRegistration of Ship PPT PresentationsibinmgNo ratings yet

- 1 What Is The Reasons For A General Inspection of HoldsDocument2 pages1 What Is The Reasons For A General Inspection of HoldsMark Gapasangra100% (1)

- Module General Ship KnowledgeDocument5 pagesModule General Ship Knowledgepothirajkalyan0% (1)

- Life After Seafaring A Guide To Post Sea CareersDocument4 pagesLife After Seafaring A Guide To Post Sea CareersJeric SorianoNo ratings yet

- What Seafarers Should Do After The Vessel Receives Storm WarningDocument2 pagesWhat Seafarers Should Do After The Vessel Receives Storm WarningCyrus Bumalo100% (1)

- Section (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load LinesDocument6 pagesSection (1) : 1. With Respect To Loading Timber Cargo in Question A) Explain Under What Circumstances, Vessel Is Able To Load To Lumber Load Linescanigetaccess100% (1)

- Hand OverDocument3 pagesHand OverBernard Mamora100% (1)

- GME ApplicationDocument8 pagesGME ApplicationmechsterNo ratings yet

- Ship StabilityDocument22 pagesShip Stabilityanz_izwanNo ratings yet

- Mv. Jin YangDocument5 pagesMv. Jin YangcarlomaderazoNo ratings yet

- Sample Copy Barecon 89Document9 pagesSample Copy Barecon 89Cae Carlos Eduardo PereiraNo ratings yet

- Sea SpanDocument29 pagesSea SpanshivpsrNo ratings yet

- Note of ProtestDocument16 pagesNote of ProtestPrem VikasNo ratings yet

- Unit06 - Cargo Damage ClaimsDocument6 pagesUnit06 - Cargo Damage ClaimsFouad OuazzaniNo ratings yet

- Synacomex 2000Document5 pagesSynacomex 2000Giurca RaduNo ratings yet

- Rank: Chief Officer Onboard IDSM Bulk/Log CarrierDocument4 pagesRank: Chief Officer Onboard IDSM Bulk/Log Carrierravishukla100% (1)

- Container ShipDocument33 pagesContainer ShipJaime David100% (1)

- IBF-ITF-Reederei NORD CBA 2012-2014 PDFDocument29 pagesIBF-ITF-Reederei NORD CBA 2012-2014 PDFGeorge TopoleanuNo ratings yet

- What Is Beaching of The ShipDocument4 pagesWhat Is Beaching of The ShipGAMMA FACULTY0% (1)

- Interview HintsDocument4 pagesInterview HintsAgnes Llanes CruzNo ratings yet

- Deckhand Job DescDocument10 pagesDeckhand Job Descaqua2376No ratings yet

- How Gas Carriers Are Classified As Per Its Survival CapabilitiesDocument6 pagesHow Gas Carriers Are Classified As Per Its Survival Capabilitiessidadams2No ratings yet

- Mooring Master VacancyDocument2 pagesMooring Master VacancyAnonymous UCveMQNo ratings yet

- Fixture Note: NO. FN.537/BULK/-IMP/55K/NICKEL ORE/VII/2019Document4 pagesFixture Note: NO. FN.537/BULK/-IMP/55K/NICKEL ORE/VII/2019Ahmad RidoneNo ratings yet

- CH Mate Farid-8Document5 pagesCH Mate Farid-8Farid Girnari100% (1)

- SEAMANSHIP 3 - QUIZ 3 ABUCEJO, Antonie Peter QDocument1 pageSEAMANSHIP 3 - QUIZ 3 ABUCEJO, Antonie Peter QAntonie Peter AbucejoNo ratings yet

- Safe Bunkering PracticesDocument2 pagesSafe Bunkering Practiceskabirsharma76No ratings yet

- IMC - Lesson 1 Introduction To ShippingDocument92 pagesIMC - Lesson 1 Introduction To Shippingropes mongi100% (1)

- Azimuth Proforma STARDocument1 pageAzimuth Proforma STARBen KleinNo ratings yet

- Preparing The Ship For Dry Dock RickyDocument4 pagesPreparing The Ship For Dry Dock RickyMohamedElSakaNo ratings yet

- Cargo SweatDocument10 pagesCargo Sweatyasith bhagyaNo ratings yet

- Kano Racks Methd StatementDocument8 pagesKano Racks Methd StatementOdejobi OloladeNo ratings yet

- Replacement of Bad Pipe and Gate Valve Methd StatmDocument10 pagesReplacement of Bad Pipe and Gate Valve Methd StatmOdejobi OloladeNo ratings yet

- HCCP Jsa Wo5992032Document2 pagesHCCP Jsa Wo5992032Forida EasminNo ratings yet

- OHS Work PermitsDocument17 pagesOHS Work PermitsNada100% (1)

- Work Permit Compliance (Presentation)Document52 pagesWork Permit Compliance (Presentation)Ramzan Nazir100% (1)

- Rule 1 - ApplicationDocument3 pagesRule 1 - ApplicationGiorgi Kandelaki100% (1)

- General Intact Stability Criteria For All ShipsDocument7 pagesGeneral Intact Stability Criteria For All ShipsGiorgi KandelakiNo ratings yet

- Understanding Heavy Lift Vessels (HLVS) Design, Operation and TypesDocument10 pagesUnderstanding Heavy Lift Vessels (HLVS) Design, Operation and TypesGiorgi KandelakiNo ratings yet

- Understanding Design of Oil Tanker ShipsDocument11 pagesUnderstanding Design of Oil Tanker ShipsGiorgi Kandelaki100% (1)

- Types of Knots, Bends and Hitches Used at SeaDocument6 pagesTypes of Knots, Bends and Hitches Used at SeaGiorgi KandelakiNo ratings yet

- Understanding Different Types of Manoeuvres of A VesselDocument9 pagesUnderstanding Different Types of Manoeuvres of A VesselGiorgi Kandelaki100% (1)

- Understanding Heavy Lifting Operations and Vessel StabilityDocument6 pagesUnderstanding Heavy Lifting Operations and Vessel StabilityGiorgi KandelakiNo ratings yet

- Understanding Ship Stability During Dry DockDocument5 pagesUnderstanding Ship Stability During Dry DockGiorgi KandelakiNo ratings yet

- Using Toggle PinDocument3 pagesUsing Toggle PinGiorgi KandelakiNo ratings yet

- Using MS Excel To Evaluate The Stability of Existing BargesDocument13 pagesUsing MS Excel To Evaluate The Stability of Existing BargesGiorgi KandelakiNo ratings yet

- What Is A Mooring BuoyDocument2 pagesWhat Is A Mooring BuoyGiorgi KandelakiNo ratings yet

- What Is Ballast Water Management PlanDocument2 pagesWhat Is Ballast Water Management PlanGiorgi KandelakiNo ratings yet

- Vessel Size Groups Major Ship Size Groups Include:: Handy and HandymaxDocument3 pagesVessel Size Groups Major Ship Size Groups Include:: Handy and HandymaxGiorgi KandelakiNo ratings yet

- Verified Gross Mass (VMG)Document1 pageVerified Gross Mass (VMG)Giorgi KandelakiNo ratings yet

- What Is An Intermodal ContainerDocument2 pagesWhat Is An Intermodal ContainerGiorgi KandelakiNo ratings yet

- Worksheet 18Document4 pagesWorksheet 18Vijay BhaskarNo ratings yet

- Modern Sewer Design: CSP Sewers Are Designed For The Deepest InstallationsDocument28 pagesModern Sewer Design: CSP Sewers Are Designed For The Deepest InstallationsJuan GrajalesNo ratings yet

- Ez Pallet Lift Truck DJ PDFDocument124 pagesEz Pallet Lift Truck DJ PDFDmitry100% (1)

- BMS Interfacing Points ChecklistDocument3 pagesBMS Interfacing Points ChecklistSMW6 Matara (SMW6MTR)100% (1)

- Pergola Detail & PlanDocument5 pagesPergola Detail & PlanKhalil BalanNo ratings yet

- SUMMATIVE TEST 1 (Quarter 3 Science 7) A4 SIZEDocument6 pagesSUMMATIVE TEST 1 (Quarter 3 Science 7) A4 SIZEZayn Daniel World of GamesNo ratings yet

- 3d Woven Composite FatigueDocument11 pages3d Woven Composite FatigueSri SaiNo ratings yet

- Wedling ModelingDocument32 pagesWedling ModelingManish KumarNo ratings yet

- Silo DesignDocument42 pagesSilo Designchaithra_14No ratings yet

- Compaction of Soils: CompressibilityDocument12 pagesCompaction of Soils: CompressibilityRoopesh KumarNo ratings yet

- IP8000Document24 pagesIP8000Raju Gopinathan NairNo ratings yet

- Kidde - Spec - ECS - Novec 1230 - 8-14 PDFDocument7 pagesKidde - Spec - ECS - Novec 1230 - 8-14 PDFMarcio BritoNo ratings yet

- E Weldone Nov 2017Document7 pagesE Weldone Nov 2017chinmayNo ratings yet

- Numerical Modelling of Hydrodynamics and Gas Dispersion in An Autoclave - Appa Et Al 2013-1Document9 pagesNumerical Modelling of Hydrodynamics and Gas Dispersion in An Autoclave - Appa Et Al 2013-1ninaNo ratings yet

- Aermec NSM - Free CoolingDocument11 pagesAermec NSM - Free CoolingTrottiNo ratings yet

- S. R. ChakravarthyDocument7 pagesS. R. ChakravarthyDevangMarvaniaNo ratings yet

- Analyzing Mathematical and Software Methods For Selecting and Designing Francis Turbine in Hydro-Power PlantsDocument28 pagesAnalyzing Mathematical and Software Methods For Selecting and Designing Francis Turbine in Hydro-Power PlantstalalbinahmedNo ratings yet

- X Series 2t-16t Service Manual 2021.01Document74 pagesX Series 2t-16t Service Manual 2021.01Jose ZarateNo ratings yet

- Flow Through An Orifice: Experiment No. 05Document2 pagesFlow Through An Orifice: Experiment No. 05ChristopherHiladoNo ratings yet

- Shaftless Screw BrochureDocument4 pagesShaftless Screw BrochureProtec MetalmecanicaNo ratings yet

- Separ FilterprogrammDocument26 pagesSepar FilterprogrammАлександър ГиневNo ratings yet

- SKS Scope Mount InstructionsDocument4 pagesSKS Scope Mount Instructions王欢No ratings yet

- Unit 9 - Week 8: Assessment 08Document3 pagesUnit 9 - Week 8: Assessment 08Abhishek PandeyNo ratings yet

- DIN 13 - en - 2005-08-01 - 25418Document19 pagesDIN 13 - en - 2005-08-01 - 25418Gabriel MesquitaNo ratings yet

- RCD - PPT - Part 4 PDFDocument11 pagesRCD - PPT - Part 4 PDFJohnri RamirezNo ratings yet

- 856h Stage IVDocument28 pages856h Stage IVChristopher100% (1)

- JLG m600jDocument2 pagesJLG m600jrawassatNo ratings yet

- IIT Physics Sample Paper - Rotational Kinematics & DynamicsDocument2 pagesIIT Physics Sample Paper - Rotational Kinematics & DynamicsVikash TiwariNo ratings yet