Professional Documents

Culture Documents

Delrin Mat PDF

Delrin Mat PDF

Uploaded by

yajneshwaradixitCopyright:

Available Formats

You might also like

- Final Drilling Fuild Lab ReportDocument19 pagesFinal Drilling Fuild Lab ReportTaufik Zainuddin100% (2)

- Study of Laminar and Turbulent Flow On Flat Plate Using SOLIDWORKSDocument14 pagesStudy of Laminar and Turbulent Flow On Flat Plate Using SOLIDWORKSMohd Amman SadiqueNo ratings yet

- Delrin MaterialDocument2 pagesDelrin MaterialyajneshwaradixitNo ratings yet

- Delrin PDFDocument2 pagesDelrin PDFA. Kumar RaiNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETDocument2 pagesTECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETFeby Shyntia AfirantiNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsabhijitNo ratings yet

- Delrin - Mechanical PropertyDocument1 pageDelrin - Mechanical PropertyGovarthanan GovaNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsGrimmo1979No ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Craftechind PtfeDocument2 pagesCraftechind PtfeZubair AamirNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Ptfe PDFDocument1 pagePtfe PDFXiwen CloudNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Teflon® FEP (Fluorinated Ethylene Propylene)Document1 pageTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaNo ratings yet

- Polypropylene PDFDocument2 pagesPolypropylene PDFSabuj SaikiaNo ratings yet

- CHRAFTECHIND Pai Bearing GradeDocument2 pagesCHRAFTECHIND Pai Bearing GradeZubair AamirNo ratings yet

- HDHR-242U: High Density PolyethyleneDocument1 pageHDHR-242U: High Density Polyethylenefrancisca ulloa riveraNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- MC 907 Natural NylonDocument2 pagesMC 907 Natural NylonJunior TaHuaNo ratings yet

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityDocument1 pageVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986No ratings yet

- ABS (Acrylonitrile-Butadiene-Styrene) : Property ASTM Test Method UnitsDocument1 pageABS (Acrylonitrile-Butadiene-Styrene) : Property ASTM Test Method UnitsFong Ka YengNo ratings yet

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavNo ratings yet

- Current Material - 5323-70-Epdm-Seals - 020217Document2 pagesCurrent Material - 5323-70-Epdm-Seals - 020217Brent TairaNo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- Delrin 150Document1 pageDelrin 150Sardar. Vikramjit Singh RandhawaNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- High Density Polyethylene: Melt - 7.0Document1 pageHigh Density Polyethylene: Melt - 7.0Plastex EcuadorNo ratings yet

- Data Sheet PPSUDocument2 pagesData Sheet PPSUluuiissNo ratings yet

- De 150Document1 pageDe 150omar reyesNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- Teflon PTFE - PSG - Mechanical PropertyDocument1 pageTeflon PTFE - PSG - Mechanical PropertyGovarthanan GovaNo ratings yet

- Anti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeDocument1 pageAnti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeVC KannanNo ratings yet

- DP03HDocument1 pageDP03HDiadam SharmaNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- TOTAL Polystyrene 1441: Material DatasheetDocument3 pagesTOTAL Polystyrene 1441: Material DatasheetAlbert FortunatoNo ratings yet

- PEEK (Polyetheretherketone) : PossibilitiesDocument2 pagesPEEK (Polyetheretherketone) : PossibilitiesMilan BojovicNo ratings yet

- Devlon v-API OriginalDocument1 pageDevlon v-API OriginalCarlosIkedaNo ratings yet

- Wear Plate BrochureDocument2 pagesWear Plate Brochurec3512No ratings yet

- Nylatron® 4.6 - BoedekerDocument6 pagesNylatron® 4.6 - BoedekerMas ZuhadNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- E Isoplast 302EZ ETPDocument1 pageE Isoplast 302EZ ETPaldozenNo ratings yet

- Duraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)Document4 pagesDuraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)FrancoNo ratings yet

- 2018 Hy Therm 707 PdsDocument1 page2018 Hy Therm 707 PdsLuz Adriana MorenoNo ratings yet

- Material Data Sheet: HDPE NaturalDocument2 pagesMaterial Data Sheet: HDPE NaturalSyed MoinNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- Impactos Ingles 7600Document2 pagesImpactos Ingles 7600casillasfigjcNo ratings yet

- Tds Ral 7037 Haa Hfhr02s8Document1 pageTds Ral 7037 Haa Hfhr02s8Jaskaran SinghNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- Terluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Jose VillarrealNo ratings yet

- Design A Plain ConcreteDocument1 pageDesign A Plain Concretesola omokehindeNo ratings yet

- SCHOEMA Operation ManualDocument90 pagesSCHOEMA Operation ManualMarco Soto CallejaNo ratings yet

- BVI-HSE Daily Report 20220818Document3 pagesBVI-HSE Daily Report 20220818Muhammad IrfanNo ratings yet

- 04-1 QCS 2014Document7 pages04-1 QCS 2014Raja Ahmed Hassan100% (1)

- P03MSV PDR Pressure ReducingRelieving Valve Form 1013019 Rev. 12 19Document6 pagesP03MSV PDR Pressure ReducingRelieving Valve Form 1013019 Rev. 12 19moonstarNo ratings yet

- 20) 01.+FF-000 Deluge+water+system+general+notesDocument1 page20) 01.+FF-000 Deluge+water+system+general+notesshahnawaznNo ratings yet

- Shriram Epc LTD.: Daily Progress ReportDocument4 pagesShriram Epc LTD.: Daily Progress ReportJagadeesan S MNo ratings yet

- The Cost Efficiency by Using Outriggers in Tall Buildings: December 2018Document8 pagesThe Cost Efficiency by Using Outriggers in Tall Buildings: December 2018AbhishekNo ratings yet

- 04 Aust CE 333 Lecture4 Pour Flush Sanitation DesignDocument26 pages04 Aust CE 333 Lecture4 Pour Flush Sanitation DesignTanjim IrtizaNo ratings yet

- Mander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteDocument23 pagesMander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteSalvatore MirandaNo ratings yet

- Civil Engineering: Academic Regulations Course Structure AND Detailed SyllabiDocument240 pagesCivil Engineering: Academic Regulations Course Structure AND Detailed SyllabiLost AloneNo ratings yet

- Failure of A Helicopter Component For APFF 2012Document14 pagesFailure of A Helicopter Component For APFF 2012athulpcucekNo ratings yet

- Sarangani Standard: Product SpecificationsDocument23 pagesSarangani Standard: Product SpecificationsLang AwNo ratings yet

- ENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1Document15 pagesENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1jimyNo ratings yet

- Juno 2021.12.03 Ifc Car Park A-Aa (A1)Document5 pagesJuno 2021.12.03 Ifc Car Park A-Aa (A1)AGIP MATRIXNo ratings yet

- Blasius PDFDocument2 pagesBlasius PDFSãröj ShâhNo ratings yet

- Testing & Commissioning ChecklistsDocument18 pagesTesting & Commissioning Checklistsmoh khNo ratings yet

- Ronald.E.Hamilton: 626 1/2 W 3rd Street SDocument4 pagesRonald.E.Hamilton: 626 1/2 W 3rd Street Sapi-27778945No ratings yet

- BM Europe Stainless Steel Expansion Joints KR8L-BLDocument6 pagesBM Europe Stainless Steel Expansion Joints KR8L-BLRadicalNo ratings yet

- Aiv01102019 Airmatic Flow Aid Application Data SheetDocument2 pagesAiv01102019 Airmatic Flow Aid Application Data SheetIldico KovacsNo ratings yet

- LESSON 8 Pipe NetworksDocument18 pagesLESSON 8 Pipe NetworksChandima K PriyamalNo ratings yet

- ArticledesignandconstructionofliquidtightconcretestrucDocument3 pagesArticledesignandconstructionofliquidtightconcretestrucalbertoxinaNo ratings yet

- Argo-hyto-High Pressure Filter Kits 40.95 EN US PDFDocument10 pagesArgo-hyto-High Pressure Filter Kits 40.95 EN US PDFhydrola 2021No ratings yet

- Wellcap® Iadc Well Control Accreditation Program WellDocument44 pagesWellcap® Iadc Well Control Accreditation Program Welldepope100% (1)

- Crossection of A RoadDocument27 pagesCrossection of A RoadFatima KamranNo ratings yet

- Guidelines For Pipe Support AnalysisDocument31 pagesGuidelines For Pipe Support AnalysisgvlanushaNo ratings yet

- 6.bending Moment ManualDocument6 pages6.bending Moment ManualLaksh RameshNo ratings yet

- Interim Report Replaceable Unbonded Tendons For Post-Tensioned Dridges BDV-31-977-15-Task1Document97 pagesInterim Report Replaceable Unbonded Tendons For Post-Tensioned Dridges BDV-31-977-15-Task1ScottNo ratings yet

Delrin Mat PDF

Delrin Mat PDF

Uploaded by

yajneshwaradixitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Delrin Mat PDF

Delrin Mat PDF

Uploaded by

yajneshwaradixitCopyright:

Available Formats

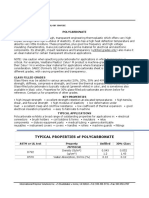

DELRIN®

DELRIN

(Acetal Homopolymer)

®

DELRIN® is a crys- strength, creep resist- properties along with

talline plastic which ance and toughness. its fatigue endurance

offers an excellent It also exhibits low make DELRIN® ideal

balance of properties moisture absorption. for many industrial

that bridge the gap It is chemically resist- applications.

between metals and ant to hydrocarbons,

plastics. DELRIN® solvents and neutral

possesses high tensile chemicals. These

• Good dimensional stability

• Low moisture absorption

DELRIN® can operate in wet environments with little effect on

performance or dimensions.

• Excellent machinability

• High fatigue endurance

• High strength and stiffness properties

• Superior impact and creep resistance

• Chemical resistance to fuels and solvents

• Natural grade is FDA, NSF and USDA compliant

• Good wear and abrasion properties

With its low coefficient of friction and hard and resilient surface,

DELRIN® is the material of choice in many wear applications.

DELRIN®s overall combination of physical, tribological and environmental properties

make it ideal for many industrial wear and mechanical applications. Parts exposed

to a moist or wet environment, such as pump and valve components, are especially

appropriate. Other common uses for DELRIN® include gears, bearings, bushings,

rollers, fittings and electrical insulator parts.

TYPICAL PROPERTY VALUES

ASTM

PROPERTIES Test Units Delrin® 150

Method

PHYSICAL

Density D792 lbs/in3 0.0513

Specific Gravity D792 g/cc 1.42

Water Absorption, @24 hours, 73°F D570 % 0.25

@Saturation, 73°F D570 % 0.9

Tensile Strength @ Yield, 73°F D638 psi 9,000

Tensile Modulus D639 psi 350,000

MECHANICAL

Elongation @ Break, 73°F D638 % 25

Flexural Strength, 73°F D790 psi 11,500

Flexural Modulus, 73°F D790 psi 420,000

Compressive Strength D695 psi 5,200

Izod Impact Strength, 73°F D256 ft-lbs/in 1.5

Rockwell Hardness, 73°F D785 M (R) Scale M 94 (120)

Shure Hardness - D Scale -

Wear Factor Against Steel, 40 psi, 50 fpm D3702 in 3 x 1 55 x 10-10

- hr PV -

Static Coefficient of Friction D3702 -

Dynamic Coefficient of Friction, 40 psi, 50 fpm D3702 0.2

Heat Deflection Temperature @ 66 psi D648 °F 336

@264 psi D648 °F 257

THERMAL

Coefficient of Linear Thermal Expansion D696 in/in/°F 6.8 x 10-5

Maximum Servicing Temperature, Intermittent - °F 300

Long Term UL746B °F 185

Specific Heat - BTU/lb-°F 0.35

Thermal Conductivity - - -

Vicate Softening Point - °F -

Melting Point D2133 °F 347

Flammability UL94 HB (1.47)

ELECTRICAL

Surface Resistivity D257 ohm/square -

Volume Resistivity D257 ohm-cm 1015

Dielectric Strength D149 V/mil 500

Dielectric Constant, @ 60 Hz, 73°F, 50% RH D150 3.7

@ 1 MHz D150 3.7

@ 20 GHz D150 -

@ 30 GHz D150 -

Dissipation Factor, @ 60 HZ, 73°F D150 0.005

This information is only to assist and advise you on current technical knowledge and is given without obligation or liability.

All trade and patent rights should be observed. All rights reserved. Data obtained from extruded shapes material.

MATERIAL AVAILABILITY

Rods: Diameters: 4 3/4”, 10’ length Plates: 1/4” to 2” thickness inclusive are 2’ x 4’, 4’ x 8’, 4’ x 10’

Length: 5” and greater diameter, 5’ length 2-1/4” to 4” thickness inclusive are 2’ x 4’

Primary Specification (Resin) (Typical) Shapes Specification (Typical)

ASTM-D-4181 POM110B34330 ASTM-D-6100 S-POM0111

Profiles, tubes, and special sizes are custom-produced on request.

DISTRIBUTED BY

Division of Ensinger, Inc.

HEADQUARTERS CANADA

365 Meadowlands Boulevard Ensinger-Plastifab

Washington, Pennsylvania 15301 8115 Lafrenaie Street

Montreal, Quebec H1P 2B1

Telephone: 800-243-3221 Sales

800-869-4029 Technical Telephone: 514-325-9840

Fax: 724-746-9209 Fax: 514-325-5222

e-mail: sales@ensinger-ind.com Web site: www.plastifab.ca

E-mail: infoprod@plastifab.ca PD/03-03

You might also like

- Final Drilling Fuild Lab ReportDocument19 pagesFinal Drilling Fuild Lab ReportTaufik Zainuddin100% (2)

- Study of Laminar and Turbulent Flow On Flat Plate Using SOLIDWORKSDocument14 pagesStudy of Laminar and Turbulent Flow On Flat Plate Using SOLIDWORKSMohd Amman SadiqueNo ratings yet

- Delrin MaterialDocument2 pagesDelrin MaterialyajneshwaradixitNo ratings yet

- Delrin PDFDocument2 pagesDelrin PDFA. Kumar RaiNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- TECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETDocument2 pagesTECAPET® PET and 1400® PET (Polyethylene Terephthalate) : Property ASTM Test Method Units Tecapet® PET 1400HI® PETFeby Shyntia AfirantiNo ratings yet

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Document1 pageTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsabhijitNo ratings yet

- Delrin - Mechanical PropertyDocument1 pageDelrin - Mechanical PropertyGovarthanan GovaNo ratings yet

- Delrin SpecsDocument1 pageDelrin SpecsGrimmo1979No ratings yet

- LdpeDocument1 pageLdpeArdy WiyogoNo ratings yet

- Craftechind PtfeDocument2 pagesCraftechind PtfeZubair AamirNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Ptfe PDFDocument1 pagePtfe PDFXiwen CloudNo ratings yet

- Polye PDocument2 pagesPolye PFranco Gabriel MercadoNo ratings yet

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneDocument1 pageTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamNo ratings yet

- Teflon® FEP (Fluorinated Ethylene Propylene)Document1 pageTeflon® FEP (Fluorinated Ethylene Propylene)mohammed goudaNo ratings yet

- Polypropylene PDFDocument2 pagesPolypropylene PDFSabuj SaikiaNo ratings yet

- CHRAFTECHIND Pai Bearing GradeDocument2 pagesCHRAFTECHIND Pai Bearing GradeZubair AamirNo ratings yet

- HDHR-242U: High Density PolyethyleneDocument1 pageHDHR-242U: High Density Polyethylenefrancisca ulloa riveraNo ratings yet

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Document1 pageTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PNo ratings yet

- PolystyreneDocument1 pagePolystyrenejoshkajasmineNo ratings yet

- MC 907 Natural NylonDocument2 pagesMC 907 Natural NylonJunior TaHuaNo ratings yet

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityDocument1 pageVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986No ratings yet

- ABS (Acrylonitrile-Butadiene-Styrene) : Property ASTM Test Method UnitsDocument1 pageABS (Acrylonitrile-Butadiene-Styrene) : Property ASTM Test Method UnitsFong Ka YengNo ratings yet

- Acrylic Not Recc For ChlorinatedDocument2 pagesAcrylic Not Recc For ChlorinatedoktavNo ratings yet

- Current Material - 5323-70-Epdm-Seals - 020217Document2 pagesCurrent Material - 5323-70-Epdm-Seals - 020217Brent TairaNo ratings yet

- Teflon (PTFE) Data SheetDocument1 pageTeflon (PTFE) Data SheetMarisa Yuni Nur AzizaNo ratings yet

- Delrin 150Document1 pageDelrin 150Sardar. Vikramjit Singh RandhawaNo ratings yet

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Document1 pageTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyNo ratings yet

- Technical Data Sheet Polyimide: Benefits ApplicationsDocument3 pagesTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekDocument2 pagesTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinNo ratings yet

- Typical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesDocument2 pagesTypical Properties of PVC and CPVC: Reference Information Supplied by Our SourcesAdnan KhanNo ratings yet

- High Density Polyethylene: Melt - 7.0Document1 pageHigh Density Polyethylene: Melt - 7.0Plastex EcuadorNo ratings yet

- Data Sheet PPSUDocument2 pagesData Sheet PPSUluuiissNo ratings yet

- De 150Document1 pageDe 150omar reyesNo ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Technical Data Sheet PVC: (Polyvinyl Chloride)Document1 pageTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanNo ratings yet

- Teflon PTFE - PSG - Mechanical PropertyDocument1 pageTeflon PTFE - PSG - Mechanical PropertyGovarthanan GovaNo ratings yet

- Anti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeDocument1 pageAnti-Static Ultra-High Molecular Weight Polyethylene/Anti-Static Uhmw PeVC KannanNo ratings yet

- DP03HDocument1 pageDP03HDiadam SharmaNo ratings yet

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Document1 pageTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoNo ratings yet

- TOTAL Polystyrene 1441: Material DatasheetDocument3 pagesTOTAL Polystyrene 1441: Material DatasheetAlbert FortunatoNo ratings yet

- PEEK (Polyetheretherketone) : PossibilitiesDocument2 pagesPEEK (Polyetheretherketone) : PossibilitiesMilan BojovicNo ratings yet

- Devlon v-API OriginalDocument1 pageDevlon v-API OriginalCarlosIkedaNo ratings yet

- Wear Plate BrochureDocument2 pagesWear Plate Brochurec3512No ratings yet

- Nylatron® 4.6 - BoedekerDocument6 pagesNylatron® 4.6 - BoedekerMas ZuhadNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- E Isoplast 302EZ ETPDocument1 pageE Isoplast 302EZ ETPaldozenNo ratings yet

- Duraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)Document4 pagesDuraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)FrancoNo ratings yet

- 2018 Hy Therm 707 PdsDocument1 page2018 Hy Therm 707 PdsLuz Adriana MorenoNo ratings yet

- Material Data Sheet: HDPE NaturalDocument2 pagesMaterial Data Sheet: HDPE NaturalSyed MoinNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Ptfe Data SheetDocument1 pagePtfe Data SheetEko PrastyoNo ratings yet

- Impactos Ingles 7600Document2 pagesImpactos Ingles 7600casillasfigjcNo ratings yet

- Tds Ral 7037 Haa Hfhr02s8Document1 pageTds Ral 7037 Haa Hfhr02s8Jaskaran SinghNo ratings yet

- Dfense Blok™: Technical Data SheetDocument1 pageDfense Blok™: Technical Data SheetjohnNo ratings yet

- Terluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Jose VillarrealNo ratings yet

- Design A Plain ConcreteDocument1 pageDesign A Plain Concretesola omokehindeNo ratings yet

- SCHOEMA Operation ManualDocument90 pagesSCHOEMA Operation ManualMarco Soto CallejaNo ratings yet

- BVI-HSE Daily Report 20220818Document3 pagesBVI-HSE Daily Report 20220818Muhammad IrfanNo ratings yet

- 04-1 QCS 2014Document7 pages04-1 QCS 2014Raja Ahmed Hassan100% (1)

- P03MSV PDR Pressure ReducingRelieving Valve Form 1013019 Rev. 12 19Document6 pagesP03MSV PDR Pressure ReducingRelieving Valve Form 1013019 Rev. 12 19moonstarNo ratings yet

- 20) 01.+FF-000 Deluge+water+system+general+notesDocument1 page20) 01.+FF-000 Deluge+water+system+general+notesshahnawaznNo ratings yet

- Shriram Epc LTD.: Daily Progress ReportDocument4 pagesShriram Epc LTD.: Daily Progress ReportJagadeesan S MNo ratings yet

- The Cost Efficiency by Using Outriggers in Tall Buildings: December 2018Document8 pagesThe Cost Efficiency by Using Outriggers in Tall Buildings: December 2018AbhishekNo ratings yet

- 04 Aust CE 333 Lecture4 Pour Flush Sanitation DesignDocument26 pages04 Aust CE 333 Lecture4 Pour Flush Sanitation DesignTanjim IrtizaNo ratings yet

- Mander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteDocument23 pagesMander - Priestley - Park (1988) - Observed Stress-Strain Behavior of Confined ConcreteSalvatore MirandaNo ratings yet

- Civil Engineering: Academic Regulations Course Structure AND Detailed SyllabiDocument240 pagesCivil Engineering: Academic Regulations Course Structure AND Detailed SyllabiLost AloneNo ratings yet

- Failure of A Helicopter Component For APFF 2012Document14 pagesFailure of A Helicopter Component For APFF 2012athulpcucekNo ratings yet

- Sarangani Standard: Product SpecificationsDocument23 pagesSarangani Standard: Product SpecificationsLang AwNo ratings yet

- ENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1Document15 pagesENR202 Mechanics of Materials Lecture 7A Slides and Notes: Slide 1jimyNo ratings yet

- Juno 2021.12.03 Ifc Car Park A-Aa (A1)Document5 pagesJuno 2021.12.03 Ifc Car Park A-Aa (A1)AGIP MATRIXNo ratings yet

- Blasius PDFDocument2 pagesBlasius PDFSãröj ShâhNo ratings yet

- Testing & Commissioning ChecklistsDocument18 pagesTesting & Commissioning Checklistsmoh khNo ratings yet

- Ronald.E.Hamilton: 626 1/2 W 3rd Street SDocument4 pagesRonald.E.Hamilton: 626 1/2 W 3rd Street Sapi-27778945No ratings yet

- BM Europe Stainless Steel Expansion Joints KR8L-BLDocument6 pagesBM Europe Stainless Steel Expansion Joints KR8L-BLRadicalNo ratings yet

- Aiv01102019 Airmatic Flow Aid Application Data SheetDocument2 pagesAiv01102019 Airmatic Flow Aid Application Data SheetIldico KovacsNo ratings yet

- LESSON 8 Pipe NetworksDocument18 pagesLESSON 8 Pipe NetworksChandima K PriyamalNo ratings yet

- ArticledesignandconstructionofliquidtightconcretestrucDocument3 pagesArticledesignandconstructionofliquidtightconcretestrucalbertoxinaNo ratings yet

- Argo-hyto-High Pressure Filter Kits 40.95 EN US PDFDocument10 pagesArgo-hyto-High Pressure Filter Kits 40.95 EN US PDFhydrola 2021No ratings yet

- Wellcap® Iadc Well Control Accreditation Program WellDocument44 pagesWellcap® Iadc Well Control Accreditation Program Welldepope100% (1)

- Crossection of A RoadDocument27 pagesCrossection of A RoadFatima KamranNo ratings yet

- Guidelines For Pipe Support AnalysisDocument31 pagesGuidelines For Pipe Support AnalysisgvlanushaNo ratings yet

- 6.bending Moment ManualDocument6 pages6.bending Moment ManualLaksh RameshNo ratings yet

- Interim Report Replaceable Unbonded Tendons For Post-Tensioned Dridges BDV-31-977-15-Task1Document97 pagesInterim Report Replaceable Unbonded Tendons For Post-Tensioned Dridges BDV-31-977-15-Task1ScottNo ratings yet