Professional Documents

Culture Documents

Anybus X-Gateway Gateway Installation Sheet: Front View Concept DIN Rail Mounting (Standard)

Anybus X-Gateway Gateway Installation Sheet: Front View Concept DIN Rail Mounting (Standard)

Uploaded by

Ecaterina IrimiaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anybus X-Gateway Gateway Installation Sheet: Front View Concept DIN Rail Mounting (Standard)

Anybus X-Gateway Gateway Installation Sheet: Front View Concept DIN Rail Mounting (Standard)

Uploaded by

Ecaterina IrimiaCopyright:

Available Formats

Anybus X-gateway Gateway Installation Sheet

Concept Front view DIN Rail Mounting (standard)

The Anybus X-gateway acts as a translation device between two Align the gateway with the DIN rail connector, then press firmly on the

different fieldbus networks. top end and push the lower end into place.

To dismount the gateway, press firmly on the top end, then pull the

lower end away from the DIN rail.

Network 1

1 Mount 1 Dismount

Top-mounted interface

GW Status Gateway Status LED

24 VDC

2–4 interface-specific LED Indicators

(see Network Installation Sheet)

USB Bottom-mounted interface 2

GW Status Gateway Status LED 2

2–4 interface-specific LED Indicators

Network 2 (see Network Installation Sheet)

DIN Rail Mounting (sideways)

Internally the gateway consists of two separate network interfaces,

USB Connector (X4) Remove the sticker covering the screw holes on the right side panel.

mounted at the top and bottom end of the gateway respectively, and a

translation device handling communication between the interfaces. Unscrew the DIN clip from the back and refit it to the side panel.

For more information about the specific interfaces, please refer to the Mount/dismount the gateway the same way as in standard mounting.

Network Installation Sheet for each fieldbus network. Screw holes behind sticker

Top view Gateway Status LED

Power Connector (X3) Indication Meaning

Green Communication running Remove for optional DIN refitting

Red Communication error

See Network Installation Sheet

for connector details Red (flashing) Network interface error T10

The interface-specific LED indicators are described in the Network

Installation Sheets for the respective fieldbus network interfaces.

Technical Specifications

Power supply 24 VDC ±20 % Class 2

Power consumption 200 mA at 24 VDC (typical)

Bottom view 400 mA at 24 VDC (maximum)

Power Connector (X3) Operating temperature -25 to +65 °C @ 400 mA/24 VDC

Non-operating temperature -40 to +85 °C

Pin Signal Relative humidity 5–95 % non-condensing

See Network Installation Sheet

for connector details + 24 VDC ±20 % Class 2 Protective Earth (PE) Internal connection to PE via the DIN rail

– Ground

Technical Support

Technical support, documentation and software downloads are

available at www.anybus.com.

SP1747, rev. 2.10, Oct 2015 www.anybus.com

Anybus X-gateway Gateway Installation Sheet

Additional Installation and Operating Instructions Warnings Attention!

Field wiring terminal markings (wire type (Cu only, 14-30 AWG)) • WARNING - EXPLOSION HAZARD - SUBSTITUTION OF ANY COM- • ATTENTION – RISQUE D’EXPLOSION – LE REMPLACEMENT DE

Use 105 °C copper (Cu) wire only. PONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2. TOUT COMPOSANTS INVALIDE LA CERTIFICATION CLASS I,

Terminal tightening torque: 5–7 lb-in (0.5–0.8 Nm) DIVISION 2.

• WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LO-

Use in Overvoltage Category I Pollution Degree 2 Environment CATIONS, TURN OFF POWER BEFORE REPLACING OR WIRING • ATTENTION – RISQUE D’EXPLOSION – EN ZONE EXPLOSIVE,

MODULES. VEUILLEZ COUPER L’ALIMENTATION ÉLECTRIQUE AVANT LE

conforming to EN 60664-1.

REMPLACEMENT OU LE RACCORDEMENT DES MODULES.

• WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

Operating temperature/Surrounding temperature:

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR • ATTENTION – RISQUE D’EXPLOSION – NE PAS DÉCONNECTER

-25 to +65 °C @ 300 mA @ 24 V DC THE AREA IS KNOWN TO BE NONHAZARDOUS. L’ÉQUIPEMENT TANT QUE L’ALIMENTATION EST TOUJOURS

-25 to +50 °C @ 300 mA @ 24 V DC (Profinet IRT Fiber Optics) PRÉSENTE OU QUE LE PRODUIT EST TOUJOURS EN ZONE

• WARNING - EXPLOSION HAZARD- THE USB CONNECTOR IS NOT

Maximum surface temperature: 135 °C EXPLOSIVE ACTIVE.

FOR USE IN HAZARDOUS LOCATIONS AND FOR TEMPORARY

Pressure: 850–1050 millibar (85–105 kPa) CONNECTION ONLY. DO NOT USE, CONNECT OR DISCONNECT • ATTENTION – RISQUE D’EXPLOSION – LE CONNECTEUR USB

UNLESS THE AREA IS KNOWN TO BE NONHAZARDOUS. CON- N’EST PAS FAIT POUR UN USAGE EN MILIEU EXPLOSIF. NE PAS,

This product is designed to safely operate in class I, division 2 Haz- NECTION OR DISCONNECTION IN AN EXPLOSIVE ATMOSPHERE BRANCHER ET DEBRANCHER SANS SAVOIR SI LA ZONE N’EST

ardous location according to ANSI/ISA 12.12.01-2013 and category 3, COULD RESULT IN AN EXPLOSION. PAS IDENTIFIEE NON EXPLOSIVE. BRANCHER OU DEBRAN-

zone 2 according to EN 60079-0:2012 and EN 60079-15:2010. CHER EN ZONE EXPLOSIVE PEUT ENTRAINER UNE EXPLOSION.

• WARNING - INSTALL IN A TOOL LOCKED ENCLOSURE CONSID-

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C ERED REPRESENTATIVE OF THE INTENDED USE. • AVERTISSEMENT – INSTALLER DANS UNE ARMOIRE VER-

AND D HAZARDOUS LOCATIONS, OR NONHAZARDOUS ROUILLEE VALIDANT L’ACTE VOLONTAIRE D’UTILISATION.

LOCATIONS ONLY.

To comply with ATEX directives, the equipment must be installed

within an IP54 enclosure and must be installed with a transient sup-

pressor on the supply that does not exceed 140 % (33.6 V DC) of the

nominal rated supply voltage.

Label Markings UL Certification EMC Compliance (CE)

IND: CONT. EQ.

FOR HAZ LOC.

Warnings

W CL1, DIV 2

GP A,B,C,D

Product name,

P TEMP

CODE

T4 This product is in accordance with the EMC directive 2004/108/EC

number, description

n 67 AM through conformance with the following standards:

E203225

Electrical rating

E

• EN 61000-6-4 (2007)

Emission standard for industrial environment

ATEX Certification EN 55016-2-3, Class A (2010)

Surrounding

S

ttemperature rating EX nA IIC T4 Gc

• EN 61000-6-2 (2005)

Y

Immunity for industrial environment

Name and address

N EN 61000-4-2 (2009)

II 3 G

of manufacturer EN 61000-4-3 (2006)

EN 61000-4-4 (2012)

EN 61000-4-5 (2014)

Certification markings EN 61000-4-6 (2014)

Demko 03 ATEX 135419X

SP1747, rev. 2.10, Oct 2015 www.anybus.com

You might also like

- DSP2 Manual PDFDocument147 pagesDSP2 Manual PDFEcaterina Irimia100% (2)

- SOP For Masters in Computer Science: Phone: +91 9946991401Document1 pageSOP For Masters in Computer Science: Phone: +91 9946991401Sushant GiriNo ratings yet

- Panasonic DMR-EX768E Service ManualDocument102 pagesPanasonic DMR-EX768E Service Manualjal809No ratings yet

- Materi - Roni Sadrah - ISO SNI 27037 - Posisi Ahli Forensik Digital - RevisiDocument23 pagesMateri - Roni Sadrah - ISO SNI 27037 - Posisi Ahli Forensik Digital - RevisiLKPD Pessel 2020100% (1)

- Copper Network Card: Installation InstructionsDocument2 pagesCopper Network Card: Installation InstructionsMitsubishi FA Riyadh-Saudi ArabiaNo ratings yet

- EKI-1221 Startup Ed1Document3 pagesEKI-1221 Startup Ed1Henrique NonakaNo ratings yet

- 2.0 VISION 2020i: 2.1 PrecautionsDocument3 pages2.0 VISION 2020i: 2.1 PrecautionsTran Van TienNo ratings yet

- DSR-250N A1 QIG v1.00 (WW)Document78 pagesDSR-250N A1 QIG v1.00 (WW)angus.jamiesonNo ratings yet

- MDL Vnet Ip Gs33j50c10 01enDocument2 pagesMDL Vnet Ip Gs33j50c10 01enWellington MachadoNo ratings yet

- Nabco Net-Ds Caltalog PDFDocument8 pagesNabco Net-Ds Caltalog PDFhulman bancinNo ratings yet

- 2.8 Inch Palm & FP Terminal General Quick Start Guide - V1.0 - 20170512Document18 pages2.8 Inch Palm & FP Terminal General Quick Start Guide - V1.0 - 20170512Daniel BholahNo ratings yet

- Sure Cross Nodes Wireless SolutionsDocument2 pagesSure Cross Nodes Wireless SolutionsJose BarrenoNo ratings yet

- AR1739-GB Ed E - Wiser For KNXDocument1 pageAR1739-GB Ed E - Wiser For KNXMohammad Hossein SajjadNo ratings yet

- BROSUR AUTOMATIC DOOR Nabco - Net-Ds - CaltalogDocument8 pagesBROSUR AUTOMATIC DOOR Nabco - Net-Ds - CaltalogRangga BayuNo ratings yet

- NL-SWDK2 DatasheetDocument15 pagesNL-SWDK2 DatasheetMichael DjimelNo ratings yet

- Package Contents: LED IndicatorDocument4 pagesPackage Contents: LED IndicatorPterNo ratings yet

- ZoneFlex 7055 QSG - 800-70432-001 - Rev B - 20130614Document2 pagesZoneFlex 7055 QSG - 800-70432-001 - Rev B - 20130614BaBaGoukNo ratings yet

- ABB I-Bus® KNX: SA/S 4.16.6.2 Switch ActuatorDocument9 pagesABB I-Bus® KNX: SA/S 4.16.6.2 Switch ActuatorJulián HernándezNo ratings yet

- Z-Lte: Installation ManualDocument6 pagesZ-Lte: Installation ManualOmair FarooqNo ratings yet

- Weighing Indicator For Modbus-RTU Interface Ax-Abcc-Modbus: Instruction ManualDocument22 pagesWeighing Indicator For Modbus-RTU Interface Ax-Abcc-Modbus: Instruction ManualLuis Alberto Garcia CaychoNo ratings yet

- Cisco-DPC3828 Specs PDFDocument5 pagesCisco-DPC3828 Specs PDFRamadhania RamadhaniaNo ratings yet

- Datasheet: Smart Solutions For New Energy SystemsDocument3 pagesDatasheet: Smart Solutions For New Energy SystemsCarlos GomezNo ratings yet

- Whitepaper - M12 Power L Coding - EN PDFDocument15 pagesWhitepaper - M12 Power L Coding - EN PDFCarlos CrescenzoNo ratings yet

- Crestron DIN Rail 2-Channel DALI® Interface Operations & Installation GuideDocument2 pagesCrestron DIN Rail 2-Channel DALI® Interface Operations & Installation Guiderihards_zeile4368No ratings yet

- FX2N 232 BD - UsersGuide - JY992D63201 DDocument1 pageFX2N 232 BD - UsersGuide - JY992D63201 Dvuitinhnhd9817No ratings yet

- Anybus X-Gateway - Controlnet™ Adapter Interface Network Installation SheetDocument1 pageAnybus X-Gateway - Controlnet™ Adapter Interface Network Installation SheetEcaterina IrimiaNo ratings yet

- FDI302 FDI302 FDI302 FDI302 FDI302: Field Device InterfaceDocument2 pagesFDI302 FDI302 FDI302 FDI302 FDI302: Field Device InterfaceLuis MilanNo ratings yet

- Fingerprint and 125 EM RFID Reader: User ManualDocument5 pagesFingerprint and 125 EM RFID Reader: User ManualWilmer MartínezNo ratings yet

- DS2100N QuickDocument19 pagesDS2100N QuickcharlyplasNo ratings yet

- 4 Level InterfaceDocument2 pages4 Level InterfaceReneNo ratings yet

- Poseidon2 4002 ManualDocument25 pagesPoseidon2 4002 Manualrojas MNo ratings yet

- DFM 1600Document2 pagesDFM 1600amirin_kingNo ratings yet

- Hms sp1752Document1 pageHms sp1752bvi.keravtNo ratings yet

- FR EpnDocument56 pagesFR EpnmazehNo ratings yet

- Introducing A New Open Field Network Communication Unit: For SR-700 and BL-1300 Series Ultra-Compact Code ReadersDocument2 pagesIntroducing A New Open Field Network Communication Unit: For SR-700 and BL-1300 Series Ultra-Compact Code ReadersSanti Diaz MonteroNo ratings yet

- B574 PC 803 DatasheetDocument9 pagesB574 PC 803 DatasheetNguyễn Công Ngọc SơnNo ratings yet

- Anybus X-Gateway - Modbus-TCP Server Interface Network Installation SheetDocument1 pageAnybus X-Gateway - Modbus-TCP Server Interface Network Installation Sheetpercymv45No ratings yet

- DeviceNet Module For Use With Motor Insight C440 and S611Document4 pagesDeviceNet Module For Use With Motor Insight C440 and S611carlosNo ratings yet

- Anviz W SerieDocument10 pagesAnviz W Seriedidit rahadiartoNo ratings yet

- Telephony and PSTN Architecture: Tomassi Ch-16,17,18 Telecommunication Essentials Plus Class Material Week - 14Document31 pagesTelephony and PSTN Architecture: Tomassi Ch-16,17,18 Telecommunication Essentials Plus Class Material Week - 14AnGel MEndozaNo ratings yet

- J x02 XPR 24 - MtgWiringDocument36 pagesJ x02 XPR 24 - MtgWiringJosh HabingNo ratings yet

- Hardware Manual: FX - 232if Rs232C Interface BlockDocument7 pagesHardware Manual: FX - 232if Rs232C Interface Blockhuertourbano27No ratings yet

- User Manual2 1350971Document40 pagesUser Manual2 1350971Chacho ChocosNo ratings yet

- Wlink WL-G510 Cellular Router User ManualDocument65 pagesWlink WL-G510 Cellular Router User ManualWLINK SHENZHENNo ratings yet

- Wifi 2.4G Adapter: 1. OverviewDocument2 pagesWifi 2.4G Adapter: 1. OverviewAzmi EmranNo ratings yet

- iCAM7100S - Hardware - Guide - 160215 - Ver 1.1Document16 pagesiCAM7100S - Hardware - Guide - 160215 - Ver 1.1Santosh KiranNo ratings yet

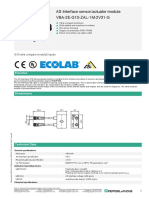

- AS-Interface Sensor/actuator Module VBA-2E-G10-ZAL-1M-2V31-GDocument4 pagesAS-Interface Sensor/actuator Module VBA-2E-G10-ZAL-1M-2V31-GPaulo HardyNo ratings yet

- Benefits and Features Pin Assignment: DS2502 1Kb Add-Only MemoryDocument24 pagesBenefits and Features Pin Assignment: DS2502 1Kb Add-Only MemoryFariasNo ratings yet

- Reyax RYWDB00 - ENDocument10 pagesReyax RYWDB00 - ENAMNo ratings yet

- Remote Keypad "TP-E1U": 1. Acceptance InspectionDocument8 pagesRemote Keypad "TP-E1U": 1. Acceptance InspectionPearl JamNo ratings yet

- Single Wire CAN Click-1900564Document3 pagesSingle Wire CAN Click-1900564Mohammad AbdullahNo ratings yet

- EC710 Modbus GatewayDocument3 pagesEC710 Modbus GatewayChinnoor RasheedNo ratings yet

- 1830 171 B 4 10 - TCP IP - ConverterDocument2 pages1830 171 B 4 10 - TCP IP - ConverterdazedpyrroNo ratings yet

- Intel®: Socket LGA1155 2 Generation Core I7/i5/i3 32nm CPU uATX Motherboard User's Quick Start CardDocument5 pagesIntel®: Socket LGA1155 2 Generation Core I7/i5/i3 32nm CPU uATX Motherboard User's Quick Start CardBohdanNo ratings yet

- Cautions and Warnings: 4100/4120 AC Ground Network Assembly Installation Instructions (International Version)Document4 pagesCautions and Warnings: 4100/4120 AC Ground Network Assembly Installation Instructions (International Version)Eng M ElseaidyNo ratings yet

- Anybus X-Gateway - PROFINET IO Device Interface Network Installation SheetDocument1 pageAnybus X-Gateway - PROFINET IO Device Interface Network Installation SheetEcaterina IrimiaNo ratings yet

- 502011349【b】mecd说明书ver1 1 (英臻wifi)Document13 pages502011349【b】mecd说明书ver1 1 (英臻wifi)Hussein TalibNo ratings yet

- FR1200 Installation & Wiring Guide: 1. Install DeviceDocument2 pagesFR1200 Installation & Wiring Guide: 1. Install DeviceKike Jimenez RomeroNo ratings yet

- ESR-1221 EXT DatasheetDocument2 pagesESR-1221 EXT DatasheetALEX LUIS GOMEZ CALLANo ratings yet

- F18 Quick Start GuideDocument4 pagesF18 Quick Start GuideLionel SaudinNo ratings yet

- Seneca Z SG ManualDocument2 pagesSeneca Z SG ManualED-Daaif M'barkNo ratings yet

- Bin 4X: Universal Interface With 4 Configurable Binary Inputs / LED Outputs Zio-Bin4X Technical Documentation FeaturesDocument2 pagesBin 4X: Universal Interface With 4 Configurable Binary Inputs / LED Outputs Zio-Bin4X Technical Documentation FeaturesДимитър МирчевNo ratings yet

- E981-10 Elmos DsDocument19 pagesE981-10 Elmos DsgreemaxNo ratings yet

- Simatic Wincc Unified System: Ordering InformationDocument41 pagesSimatic Wincc Unified System: Ordering InformationEcaterina Irimia100% (1)

- DAC-004 Diode Line Camera Sensor Operating Manual: For Multi Edge Detection Using Virtual Scope Configuration SoftwareDocument33 pagesDAC-004 Diode Line Camera Sensor Operating Manual: For Multi Edge Detection Using Virtual Scope Configuration SoftwareEcaterina IrimiaNo ratings yet

- How To Configure An Anybus Controlnet Adapter/Slave Module With Rsnetworx For ControlnetDocument26 pagesHow To Configure An Anybus Controlnet Adapter/Slave Module With Rsnetworx For ControlnetEcaterina IrimiaNo ratings yet

- Commissioning The GSI Sensor Operating Manual: Application: Edge Guiding With Inductive Sensor and SDE-02 ModuleDocument5 pagesCommissioning The GSI Sensor Operating Manual: Application: Edge Guiding With Inductive Sensor and SDE-02 ModuleEcaterina IrimiaNo ratings yet

- Anybus X-Gateway - PROFINET IO Device Interface Network Installation SheetDocument1 pageAnybus X-Gateway - PROFINET IO Device Interface Network Installation SheetEcaterina IrimiaNo ratings yet

- Profinet IO Slave: X-Gateway Interface AddendumDocument50 pagesProfinet IO Slave: X-Gateway Interface AddendumEcaterina IrimiaNo ratings yet

- Controlnet Adapter: X-Gateway Interface AddendumDocument23 pagesControlnet Adapter: X-Gateway Interface AddendumEcaterina IrimiaNo ratings yet

- ET 200 Tutorial 5 eDocument8 pagesET 200 Tutorial 5 eEcaterina IrimiaNo ratings yet

- VAI PCS7 Library Installation EDocument3 pagesVAI PCS7 Library Installation EEcaterina IrimiaNo ratings yet

- v130 33 Ta24 - Dts v130 Ta24 - 10 07Document6 pagesv130 33 Ta24 - Dts v130 Ta24 - 10 07Ecaterina IrimiaNo ratings yet

- VisiVolt A4-En - W3 - Lo-ResDocument2 pagesVisiVolt A4-En - W3 - Lo-ResEcaterina IrimiaNo ratings yet

- Masterys Ip PDFDocument60 pagesMasterys Ip PDFEcaterina IrimiaNo ratings yet

- eTOP300 ManualDocument28 pageseTOP300 ManualEcaterina IrimiaNo ratings yet

- Masterys Ip PDFDocument60 pagesMasterys Ip PDFEcaterina IrimiaNo ratings yet

- It's A Small World: A Couple A Guest The HostDocument1 pageIt's A Small World: A Couple A Guest The HostNatalieNo ratings yet

- D-Morphology User Manual PDFDocument140 pagesD-Morphology User Manual PDFAnonymous K02EhzNo ratings yet

- House Hearing, 109TH Congress - The Internet in China: Atool For Freedom or Suppression?Document289 pagesHouse Hearing, 109TH Congress - The Internet in China: Atool For Freedom or Suppression?Scribd Government DocsNo ratings yet

- Standard MCCBDocument1 pageStandard MCCBalageshvijayNo ratings yet

- How To Create Presentations in SwayDocument10 pagesHow To Create Presentations in SwayceyrangulhuseynovaNo ratings yet

- RH124 - ch11s03Document4 pagesRH124 - ch11s03felipNo ratings yet

- The Nature of Ismail Zain Art - A Different Vision On Malaysian Contemporary ArtDocument22 pagesThe Nature of Ismail Zain Art - A Different Vision On Malaysian Contemporary ArtAzzad Diah Ahmad Zabidi100% (2)

- Flexify GuideDocument63 pagesFlexify GuideNguyễn Thị Bích TrangNo ratings yet

- 2012 IT Risk Management Framework Based On ISO 31000 2009 PDFDocument8 pages2012 IT Risk Management Framework Based On ISO 31000 2009 PDFCONDOR ROJAS JHAIRNo ratings yet

- Assessment Task 1: Matching. Match The Description Listed in The Right Column With The InformationDocument2 pagesAssessment Task 1: Matching. Match The Description Listed in The Right Column With The InformationJoy ConsigeneNo ratings yet

- CHAPTER 3.Cls 3.notesDocument2 pagesCHAPTER 3.Cls 3.notesSruthy GNo ratings yet

- BR Lyomega en 0113Document8 pagesBR Lyomega en 0113XANPHOXYL KIBETNo ratings yet

- 06 Udf Flow PDFDocument19 pages06 Udf Flow PDFAdrian García MoyanoNo ratings yet

- Pdms Admin: Command Reference ManualDocument247 pagesPdms Admin: Command Reference ManualBhardwaj TrivediNo ratings yet

- Polynomials Class 9 Notes CBSE Maths Chapter 2 (PDF)Document9 pagesPolynomials Class 9 Notes CBSE Maths Chapter 2 (PDF)sas28No ratings yet

- SQP - Set 3-IP - XIIDocument4 pagesSQP - Set 3-IP - XIINaveen KumarNo ratings yet

- Havells Enviro Gti: Web Monitoring ManualDocument26 pagesHavells Enviro Gti: Web Monitoring ManualnitinNo ratings yet

- Mid Term Mathematics For Grade 4 FixDocument5 pagesMid Term Mathematics For Grade 4 Fixphildo nugrohoNo ratings yet

- Base PaperDocument5 pagesBase PaperRavi ShankarNo ratings yet

- R - OverviewDocument178 pagesR - OverviewYUviNo ratings yet

- Users Manual 3034007Document8 pagesUsers Manual 3034007cristian herediaNo ratings yet

- Speck Komputer Telemedicine I Dan IIDocument8 pagesSpeck Komputer Telemedicine I Dan IIJohanes BudiNo ratings yet

- Median Nerve Exercises: Gentler MovementsDocument4 pagesMedian Nerve Exercises: Gentler MovementsFunkey Darshan PatelNo ratings yet

- DE023031 EN V1.3 WA-9XX+ InstDocument45 pagesDE023031 EN V1.3 WA-9XX+ InstJorge FSMNo ratings yet

- Customer Satisfaction of Nepal TelecomDocument4 pagesCustomer Satisfaction of Nepal TelecomKarena Thapa100% (2)

- Gigabyte Ga M61pme s2 Manual de UsuarioDocument96 pagesGigabyte Ga M61pme s2 Manual de UsuarioClaudiaDiazNo ratings yet

- A Visual Introduction To Apache Kafka PDFDocument84 pagesA Visual Introduction To Apache Kafka PDFtim2421No ratings yet