Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

14 viewsVertical Surge Tank Ps PDF

Vertical Surge Tank Ps PDF

Uploaded by

Wibowo ArieCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- As 3004.1.2014Document25 pagesAs 3004.1.2014lougheed.craigNo ratings yet

- DIN 51506 Classification of Piston Air Compressor LubricantsDocument1 pageDIN 51506 Classification of Piston Air Compressor LubricantsShaNo ratings yet

- MSDS Portland Cement PDFDocument5 pagesMSDS Portland Cement PDFMohamad TaufikNo ratings yet

- Balmoral Bunded Tank InstallationDocument4 pagesBalmoral Bunded Tank InstallationAlberto DiazNo ratings yet

- Design of Oil Tank FoundationDocument2 pagesDesign of Oil Tank FoundationbipinagarwalNo ratings yet

- General Design of An 8000 DWT Product Oil TankerDocument100 pagesGeneral Design of An 8000 DWT Product Oil TankerYangNo ratings yet

- 1 Identification of The Substance/preparation and of The Company/undertakingDocument7 pages1 Identification of The Substance/preparation and of The Company/undertakingShadin Asari ArabaniNo ratings yet

- IACS P PipeDocument75 pagesIACS P PipeEren Hürcan100% (1)

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- How and Why To Take Manual Sounding On ShipDocument4 pagesHow and Why To Take Manual Sounding On ShipBea Heart GargaceranNo ratings yet

- Equipment Used During VentingDocument9 pagesEquipment Used During VentingRahulChoudharyNo ratings yet

- Optimum Detailed Design of 13000 m3 Oil Storage TaDocument6 pagesOptimum Detailed Design of 13000 m3 Oil Storage TaHenrikNo ratings yet

- Bilge Keels PDFDocument3 pagesBilge Keels PDFUtpalSahaNo ratings yet

- Product Sheet Stan Tug 1606Document2 pagesProduct Sheet Stan Tug 1606Roda NiagaNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Lecture 5 - MDPE - Introduction To Design of Pressure VesselDocument24 pagesLecture 5 - MDPE - Introduction To Design of Pressure VesselPatel DhruvilNo ratings yet

- Doors in Cargo and Passenger ShipsDocument6 pagesDoors in Cargo and Passenger Shipspasanac77No ratings yet

- 4 - TEMA StandardDocument16 pages4 - TEMA StandardM.H vafaeiNo ratings yet

- Project D2 - Bilge, Ballast Systems, Brem PavloDocument7 pagesProject D2 - Bilge, Ballast Systems, Brem PavloПавел БремNo ratings yet

- Tonnage Calculation General Formula For Press Tonnage RequiredDocument1 pageTonnage Calculation General Formula For Press Tonnage RequiredKarthick BalajiNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- Technical Specification For NDC 40 NO Rescue Boat DavitDocument7 pagesTechnical Specification For NDC 40 NO Rescue Boat DavitSRARNo ratings yet

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- Excavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURDocument5 pagesExcavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURAl Patrick Dela CalzadaNo ratings yet

- Marine Loading ArmDocument2 pagesMarine Loading ArmAfolabi OlaniyiNo ratings yet

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocument4 pagesDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNo ratings yet

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocument4 pagesDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahNo ratings yet

- Safe Working LoadDocument16 pagesSafe Working LoadHugo Vco RvaNo ratings yet

- Installation/Operation Manual Pig Launcher: Franz Schuck GMBHDocument28 pagesInstallation/Operation Manual Pig Launcher: Franz Schuck GMBHWan Ah-LunNo ratings yet

- B-1H Circular Letter No 2285Document14 pagesB-1H Circular Letter No 2285Federico BabichNo ratings yet

- Tank Jet MixersDocument2 pagesTank Jet MixersGabriela Axinte100% (1)

- Marine Side Scuttle: Code of MaterialDocument11 pagesMarine Side Scuttle: Code of MaterialcnfguyNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Electrical and Electronic Installation For IACSDocument60 pagesElectrical and Electronic Installation For IACSKenneth TanNo ratings yet

- Butterfly Valve BeierDocument31 pagesButterfly Valve BeierMostafa MehrjerdiNo ratings yet

- 03 Metal Packing Support PlatesDocument3 pages03 Metal Packing Support PlatesypatelsNo ratings yet

- Adsobtion Chiller SpecDocument6 pagesAdsobtion Chiller Specioan1946No ratings yet

- SgateDocument436 pagesSgateAyyanrajNo ratings yet

- How Vci WorkDocument21 pagesHow Vci Work同道文档中心100% (1)

- AGRU-Technical-Butt WeldingDocument4 pagesAGRU-Technical-Butt Weldingrenne_mujicaNo ratings yet

- Ship in Operation Renewal CriteriaDocument8 pagesShip in Operation Renewal CriteriaThe MatrixNo ratings yet

- Specification Lightening Protection SystemsDocument4 pagesSpecification Lightening Protection SystemssriramNo ratings yet

- Compliance Sheet For Air Outlets and DamperDocument3 pagesCompliance Sheet For Air Outlets and DamperMichael FaridNo ratings yet

- Narrow Gap FcawDocument33 pagesNarrow Gap FcawNitin Bajpai100% (1)

- Quality Plan For Vessel Structural ModificationDocument9 pagesQuality Plan For Vessel Structural ModificationEbuka NwankwoNo ratings yet

- PE ASME Boiler Initial Report NB-405Document3 pagesPE ASME Boiler Initial Report NB-405Jeanette BeukesNo ratings yet

- Live Graving Dry DockDocument36 pagesLive Graving Dry DockAshiq AbdullahNo ratings yet

- Iso 7824 1986Document8 pagesIso 7824 1986Sai NadhNo ratings yet

- Special Instruction Heat ExchangerDocument26 pagesSpecial Instruction Heat ExchangerDhiyo MulyadiNo ratings yet

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNo ratings yet

- Pipe Purging BrochureDocument19 pagesPipe Purging BrochurejmsmechNo ratings yet

- Advanced Tank Cleaning Technology Using The Blabo® System (Crude Oil Washing)Document2 pagesAdvanced Tank Cleaning Technology Using The Blabo® System (Crude Oil Washing)aquialguien100% (1)

- ASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementDocument3 pagesASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementRyan LasacaNo ratings yet

- Topic: Bulkheads Learning ObjectivesDocument7 pagesTopic: Bulkheads Learning Objectiveskarthika sNo ratings yet

- Investigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Document7 pagesInvestigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Darmawan PutrantoNo ratings yet

- Decks: Deck ConstructionDocument7 pagesDecks: Deck ConstructionBrian FreemanNo ratings yet

- Shop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsDocument4 pagesShop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsdurraaiNo ratings yet

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 pagesUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNo ratings yet

- Vertical Surge Tank PsDocument2 pagesVertical Surge Tank PsliganozonaruNo ratings yet

- Vertical Surge TankDocument2 pagesVertical Surge Tankihllhm100% (1)

- Line Sizing Philosophy Line Sizing PhilosophyDocument21 pagesLine Sizing Philosophy Line Sizing Philosophyjenish parekhNo ratings yet

- Chapter 8Document21 pagesChapter 8mohamedbadawyNo ratings yet

- Fluid Mechanics PDFDocument48 pagesFluid Mechanics PDFrakib hasanNo ratings yet

- Hydrocyclone FiltersDocument2 pagesHydrocyclone FiltersKapwell LimitedNo ratings yet

- Installation, Operation and Maintenance Manual: 3AV 1 To 3AV 430Document21 pagesInstallation, Operation and Maintenance Manual: 3AV 1 To 3AV 430KevinNo ratings yet

- List of ProductsDocument6 pagesList of Productsahmed hamdyNo ratings yet

- Distillation ColumnDocument18 pagesDistillation Columnㄱ먀ㅜNo ratings yet

- Absolute Zero PDFDocument2 pagesAbsolute Zero PDFFeroz AkhtarNo ratings yet

- ASCONumaticsTodayCatalogueANTC R4!11!12 12until09!30!13Document48 pagesASCONumaticsTodayCatalogueANTC R4!11!12 12until09!30!13FreijNo ratings yet

- Boiler Furnace PDFDocument8 pagesBoiler Furnace PDFசுந்தர மூர்த்தி சேப்பிளையார்No ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022Document31 pagesIM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022acurvz2005No ratings yet

- Safety Scope MSA CatalogDocument144 pagesSafety Scope MSA Catalogykresna1631No ratings yet

- Excel Calculations Excel Calculations: The IGT Distribution Equation For Natural Gas FlowDocument2 pagesExcel Calculations Excel Calculations: The IGT Distribution Equation For Natural Gas Flowleonel TintayaNo ratings yet

- Question IIIDocument2 pagesQuestion IIISweta SumanNo ratings yet

- Power HydraulicsDocument75 pagesPower HydraulicsKavinda Gehan100% (1)

- User Manual: High Pressure Manifolds For Medical GasesDocument6 pagesUser Manual: High Pressure Manifolds For Medical GasesBashir MtwaklNo ratings yet

- Material Balance MethodDocument25 pagesMaterial Balance MethodUzumaki28No ratings yet

- B737-6 21 Jar B1 e (Jun2004 CMP)Document198 pagesB737-6 21 Jar B1 e (Jun2004 CMP)Belisario Sergio Llacchas rodasNo ratings yet

- BFC21103 Chapter4Document113 pagesBFC21103 Chapter4Mohd Zulhairi100% (2)

- Bops Stack 11 5M GRS 158wrotating NG HeadDocument2 pagesBops Stack 11 5M GRS 158wrotating NG HeadRamiro Acosta Cepeda100% (1)

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam SystemMPham100% (1)

- PERU Piping Washing Cleaning Spec - Rev 4Document6 pagesPERU Piping Washing Cleaning Spec - Rev 4David Garriazo VivarNo ratings yet

- Tare A 1Document2 pagesTare A 1Francisco Celestino Guajardo0% (1)

- Adcatraining Control Valve 5 Rev 01Document36 pagesAdcatraining Control Valve 5 Rev 01Fendy ShirahNo ratings yet

- Project Report of POL Terminals2 PDFDocument31 pagesProject Report of POL Terminals2 PDFRashmi RanjanNo ratings yet

- Mse 223 Introduction To Fluid Mechanics Spring 2015: Instructor: TasDocument3 pagesMse 223 Introduction To Fluid Mechanics Spring 2015: Instructor: TasbobNo ratings yet

- Ponchon SavaritDocument14 pagesPonchon SavaritAbdulhamid Ben-NajmaNo ratings yet

- Stationary Combustion Tool (Version4-1)Document18 pagesStationary Combustion Tool (Version4-1)hartiniNo ratings yet

- Manual 99 Pressure Reducing Regulator Fisher en 123040Document24 pagesManual 99 Pressure Reducing Regulator Fisher en 123040Jholman SanchezNo ratings yet

Vertical Surge Tank Ps PDF

Vertical Surge Tank Ps PDF

Uploaded by

Wibowo Arie0 ratings0% found this document useful (0 votes)

14 views2 pagesOriginal Title

vertical-surge-tank-ps.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views2 pagesVertical Surge Tank Ps PDF

Vertical Surge Tank Ps PDF

Uploaded by

Wibowo ArieCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

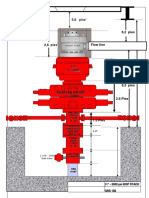

Vertical Surge Tank

Store liquid hydrocarbons after separation

APPLICATIONS The vertical surge tank (VST) is an H2S service

■■ Onshore and offshore exploration and vessel designed to store liquid hydrocarbons

development oil and gas well testing after separation. The VST is used to measure

■■ Production wells liquid flow rates and the combined shrinkage

and meter factor. It can also be used as a

ADVANTAGES second-stage separator and can hold a

■■ Liquid flow rate, shrinkage factor, constant backpressure by using its automatic

and meter factor measurement pressure control valve on the gas outlet.

■■ Large-volume dead oil sampling

The VST usually consists of either a single-

■■ Constant backpressure maintenance or a double-compartment vessel and a

when used as a second-stage separator level-measuring system with sight glasses

■■ Single or double compartment or magnetic levels. Dual-compartment VSTs

■■ Sight glasses or magnetic provide a way to empty one tank compartment

level indicators while filling another. To prevent overpressure

and overfilling, the VST is fitted with a pressure-

■■ High- and low-level alarm system

relief valve and a high- and low-level alarm

on each compartment

system. The VST is designed with a diverter,

■■ Automatic pressure controlled valve a vortex breaker, and stiffening rings capable

that is open on gas outlet of withstanding a vacuum in the vessel. It

■■ Diverter, vortex breaker, is also fitted with sampling, pressure, and

and stiffening rings temperature ports, and a bypass manifold

■■ Bypass manifold that allows isolating is included.

the surge tank from the flow process

All VSTs are shock protected by a frame,

■■ Sampling points and pressure and the latest models are designed to the

and temperature ports Det Norske Veritas (DNV) 2.7-1 standard.

■■ Overpressure protection by relief valves VSTs operate in the vertical position, but

■■ Shock-protection frame they are transported in a horizontal position.

All surge tanks are manufactured under Type

Approval or Design Verification Review and

are provided with a Certificate of Conformity

Vertical surge tank.

and full quality file.

Vertical Surge Tank

Specifications

Model Vessel Oil Working Temperature Maximum Gas Level Safety DNV

Capacity, Capacity, Pressure, Range, Flow Rate, Measurement Valves Rating

bbl [m3] bbl [m3] psi [kPa] degF [degC] Mcf/d [m3/d]† System 2.7-1

VST-A 1 × 80 46.5 50 32 to 212 4,500 Sight glass 1 No

[1 × 12.7] [7.4] [345] [0 to 100] [127,425]

VST-B 1 × 80 46.5 50 –4 to 212 4,500 Sight glass 1 No

[1 × 12.7] [7.4] [345] [–20 to 100] [127,425]

VST-D 2 × 50 58 150 32 to 212 10,000 Magnetic level 2 No

[2 × 7.95] [9.2] [1,034] [0 to 100] [283,168]

VST-BB 1 × 80 46.5 50 32 to 212 4,500 Magnetic level 2 Yes

[1 × 12.7] [7.4] [345] [0 to 100] [127,425]

VST-FA 2 × 50 58 150 –4 to 212 10,000 Magnetic level 2 Yes

[2 × 7.95] [9.2] [1,034] [–20 to 100] [283,168]

VST-FAC‡ 2 × 50 58 150 –4 to 212 10,000 Magnetic level 2 Yes

[2 × 7.95] [9.2] [1,034] [–20 to 100] [283,168]

VST-FB 2 × 50 58 150 32 to 212 10,000 Magnetic level 2 Yes

[2 × 7.95] [9.2] [1,034] [0 to 100] [283,168]

VST-FC 2 × 50 58 150 32 to 212 10,000 Sight glass and 2 Yes

[2 × 7.95] [9.2] [1,034] [0 to 100] [283,168] magnetic level

VST-FW 2 × 50 58 150 –4 to 212 10,000 Magnetic level 2 Yes

(winterized) [2 × 7.95] [9.2] [1,034] [–20 to 100] [283,168]

Specifications and Codes

Model Connections Dimensions Weight, Applied Codes

(L × W × H), ft [m] lbm [kg]

Oil Gas Oil Water Pressure

Inlet Outlet Outlet Outlet Safety

Valve

VST-A 3-in 4-in 3-in 3-in 4-in 8.04 × 7.87 × 20.0 13,420 ASME§ VIII Div. 1, ASME/ANSI††

Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.45 × 2.4 × 6.1] [6,100] B31.3, H2S (NACE MR0175)

Female Male Male Male Male

VST-B 3-in 4-in 3-in 3-in 4-in 8.04 × 7.87 × 20.0 13,420 ASME VIII Div. 1, ASME/ANSI

Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.45 × 2.4 × 6.1] [6,100] B31.3, H2S (NACE MR0175)

Female Male Male Male Male

VST-D 3-in 4-in 3-in 3-in 4-in 8.53 × 7.87 × 24.27 24,765 ASME VIII Div. 1, ASME/ANSI

Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.6 × 2.4 × 7.4] [11,400] B31.3, H2S (NACE MR0175)

Female Male Male Male Male

VST-BB 3-in 4-in 3-in 3-in 4-in 8.04 × 7.87 × 20.0 13,420 ASME VIII Div. 1, ASME/ANSI

Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.45 × 2.4 × 6.1] [6,100] B31.3, H2S (NACE MR0175)

Female Male Male Male Male

VST-FA 3-in 4-in 3-in 3-in 4-in 8.53 × 7.87 × 24.27 27,000 ASME VIII Div. 1, ASME/ANSI

Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.6 × 2.4 × 7.4] [12,000] B31.3, H2S (NACE MR0175)

Female Male Male Male Male

VST-FAC‡ 3-in 4-in 3-in 3-in 4-in 8.53 × 7.87 × 24.27 28,660 ASME VIII Div. 1, ASME/ANSI

Fig 1,502 Fig 602 Fig 602 Fig 602 Fig 602 [2.6 × 2.4 × 7.4] [13,000] B31.3, H2S (NACE MR0175)

Female Male Male Male Male

VST-FB 3-in 4-in 3-in 3-in 4-in 8.53 × 7.87 × 24.27 27,000 ASME VIII Div. 1, ASME/ANSI

Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.6 × 2.4 × 7.4] [12,000] B31.3, H2S (NACE MR0175)

Female Male Male Male Male

VST-FC 3-in 4-in 3-in 3-in 4-in 8.53 × 7.87 × 24.27 29,762 ASME VIII Div. 1 (U-Stamp),

Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.6 × 2.4 × 7.4] [13,500] ASME/ANSI B31.3, H2S (NACE

Female Male Male Male Male MR0175), DNV 2.7-1

VST-FW 3-in 4-in 3-in 3-in 4-in 8.53 × 7.87 × 24.27 29,762 ASME VIII Div. 1 (U-Stamp),

(winterized) Fig 602 Fig 602 Fig 602 Fig 602 Fig 602 [2.6 × 2.4 × 7.4] [13,500] ASME/ANSI B31.3, H2S (NACE

Female Male Male Male Male MR0175), DNV 2.7-1

†

For reference only and should be confirmed using ArchiTest* well test design and methodology software

‡

No bypass manifold–oil inlet rated to 1,440 psi

§ American Society of Mechanical Engineers

†† American National Standards Institute slb.com/welltesting

*Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright © 2016 Schlumberger. All rights reserved. 16-TS-155105

You might also like

- As 3004.1.2014Document25 pagesAs 3004.1.2014lougheed.craigNo ratings yet

- DIN 51506 Classification of Piston Air Compressor LubricantsDocument1 pageDIN 51506 Classification of Piston Air Compressor LubricantsShaNo ratings yet

- MSDS Portland Cement PDFDocument5 pagesMSDS Portland Cement PDFMohamad TaufikNo ratings yet

- Balmoral Bunded Tank InstallationDocument4 pagesBalmoral Bunded Tank InstallationAlberto DiazNo ratings yet

- Design of Oil Tank FoundationDocument2 pagesDesign of Oil Tank FoundationbipinagarwalNo ratings yet

- General Design of An 8000 DWT Product Oil TankerDocument100 pagesGeneral Design of An 8000 DWT Product Oil TankerYangNo ratings yet

- 1 Identification of The Substance/preparation and of The Company/undertakingDocument7 pages1 Identification of The Substance/preparation and of The Company/undertakingShadin Asari ArabaniNo ratings yet

- IACS P PipeDocument75 pagesIACS P PipeEren Hürcan100% (1)

- Dry Bulk Storage Tank SpecificationDocument7 pagesDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNo ratings yet

- How and Why To Take Manual Sounding On ShipDocument4 pagesHow and Why To Take Manual Sounding On ShipBea Heart GargaceranNo ratings yet

- Equipment Used During VentingDocument9 pagesEquipment Used During VentingRahulChoudharyNo ratings yet

- Optimum Detailed Design of 13000 m3 Oil Storage TaDocument6 pagesOptimum Detailed Design of 13000 m3 Oil Storage TaHenrikNo ratings yet

- Bilge Keels PDFDocument3 pagesBilge Keels PDFUtpalSahaNo ratings yet

- Product Sheet Stan Tug 1606Document2 pagesProduct Sheet Stan Tug 1606Roda NiagaNo ratings yet

- Approved Itp-Dss - 28 Sep 2016Document4 pagesApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNo ratings yet

- Lecture 5 - MDPE - Introduction To Design of Pressure VesselDocument24 pagesLecture 5 - MDPE - Introduction To Design of Pressure VesselPatel DhruvilNo ratings yet

- Doors in Cargo and Passenger ShipsDocument6 pagesDoors in Cargo and Passenger Shipspasanac77No ratings yet

- 4 - TEMA StandardDocument16 pages4 - TEMA StandardM.H vafaeiNo ratings yet

- Project D2 - Bilge, Ballast Systems, Brem PavloDocument7 pagesProject D2 - Bilge, Ballast Systems, Brem PavloПавел БремNo ratings yet

- Tonnage Calculation General Formula For Press Tonnage RequiredDocument1 pageTonnage Calculation General Formula For Press Tonnage RequiredKarthick BalajiNo ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- Technical Specification For NDC 40 NO Rescue Boat DavitDocument7 pagesTechnical Specification For NDC 40 NO Rescue Boat DavitSRARNo ratings yet

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- Excavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURDocument5 pagesExcavation Man Hour: Post Author:info - Projectestimate Post Published:november 10, 2019 Post category:MAN-HOURAl Patrick Dela CalzadaNo ratings yet

- Marine Loading ArmDocument2 pagesMarine Loading ArmAfolabi OlaniyiNo ratings yet

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocument4 pagesDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNo ratings yet

- Document Title: Technical Proposal For 6500cbm LNG Storage TankDocument4 pagesDocument Title: Technical Proposal For 6500cbm LNG Storage Tankroni_arsyahNo ratings yet

- Safe Working LoadDocument16 pagesSafe Working LoadHugo Vco RvaNo ratings yet

- Installation/Operation Manual Pig Launcher: Franz Schuck GMBHDocument28 pagesInstallation/Operation Manual Pig Launcher: Franz Schuck GMBHWan Ah-LunNo ratings yet

- B-1H Circular Letter No 2285Document14 pagesB-1H Circular Letter No 2285Federico BabichNo ratings yet

- Tank Jet MixersDocument2 pagesTank Jet MixersGabriela Axinte100% (1)

- Marine Side Scuttle: Code of MaterialDocument11 pagesMarine Side Scuttle: Code of MaterialcnfguyNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Electrical and Electronic Installation For IACSDocument60 pagesElectrical and Electronic Installation For IACSKenneth TanNo ratings yet

- Butterfly Valve BeierDocument31 pagesButterfly Valve BeierMostafa MehrjerdiNo ratings yet

- 03 Metal Packing Support PlatesDocument3 pages03 Metal Packing Support PlatesypatelsNo ratings yet

- Adsobtion Chiller SpecDocument6 pagesAdsobtion Chiller Specioan1946No ratings yet

- SgateDocument436 pagesSgateAyyanrajNo ratings yet

- How Vci WorkDocument21 pagesHow Vci Work同道文档中心100% (1)

- AGRU-Technical-Butt WeldingDocument4 pagesAGRU-Technical-Butt Weldingrenne_mujicaNo ratings yet

- Ship in Operation Renewal CriteriaDocument8 pagesShip in Operation Renewal CriteriaThe MatrixNo ratings yet

- Specification Lightening Protection SystemsDocument4 pagesSpecification Lightening Protection SystemssriramNo ratings yet

- Compliance Sheet For Air Outlets and DamperDocument3 pagesCompliance Sheet For Air Outlets and DamperMichael FaridNo ratings yet

- Narrow Gap FcawDocument33 pagesNarrow Gap FcawNitin Bajpai100% (1)

- Quality Plan For Vessel Structural ModificationDocument9 pagesQuality Plan For Vessel Structural ModificationEbuka NwankwoNo ratings yet

- PE ASME Boiler Initial Report NB-405Document3 pagesPE ASME Boiler Initial Report NB-405Jeanette BeukesNo ratings yet

- Live Graving Dry DockDocument36 pagesLive Graving Dry DockAshiq AbdullahNo ratings yet

- Iso 7824 1986Document8 pagesIso 7824 1986Sai NadhNo ratings yet

- Special Instruction Heat ExchangerDocument26 pagesSpecial Instruction Heat ExchangerDhiyo MulyadiNo ratings yet

- ETL Pressure Relief Valves Datasheet PDFDocument6 pagesETL Pressure Relief Valves Datasheet PDFNanasaheb PatilNo ratings yet

- Pipe Purging BrochureDocument19 pagesPipe Purging BrochurejmsmechNo ratings yet

- Advanced Tank Cleaning Technology Using The Blabo® System (Crude Oil Washing)Document2 pagesAdvanced Tank Cleaning Technology Using The Blabo® System (Crude Oil Washing)aquialguien100% (1)

- ASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementDocument3 pagesASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementRyan LasacaNo ratings yet

- Topic: Bulkheads Learning ObjectivesDocument7 pagesTopic: Bulkheads Learning Objectiveskarthika sNo ratings yet

- Investigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Document7 pagesInvestigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Darmawan PutrantoNo ratings yet

- Decks: Deck ConstructionDocument7 pagesDecks: Deck ConstructionBrian FreemanNo ratings yet

- Shop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsDocument4 pagesShop Inspection Requirements and Inspection and Testing Sequence For Tank ComponentsdurraaiNo ratings yet

- Un 2004-02 - Ud-Au-000-Eb-0008 PDFDocument4 pagesUn 2004-02 - Ud-Au-000-Eb-0008 PDFManjeet SainiNo ratings yet

- Vertical Surge Tank PsDocument2 pagesVertical Surge Tank PsliganozonaruNo ratings yet

- Vertical Surge TankDocument2 pagesVertical Surge Tankihllhm100% (1)

- Line Sizing Philosophy Line Sizing PhilosophyDocument21 pagesLine Sizing Philosophy Line Sizing Philosophyjenish parekhNo ratings yet

- Chapter 8Document21 pagesChapter 8mohamedbadawyNo ratings yet

- Fluid Mechanics PDFDocument48 pagesFluid Mechanics PDFrakib hasanNo ratings yet

- Hydrocyclone FiltersDocument2 pagesHydrocyclone FiltersKapwell LimitedNo ratings yet

- Installation, Operation and Maintenance Manual: 3AV 1 To 3AV 430Document21 pagesInstallation, Operation and Maintenance Manual: 3AV 1 To 3AV 430KevinNo ratings yet

- List of ProductsDocument6 pagesList of Productsahmed hamdyNo ratings yet

- Distillation ColumnDocument18 pagesDistillation Columnㄱ먀ㅜNo ratings yet

- Absolute Zero PDFDocument2 pagesAbsolute Zero PDFFeroz AkhtarNo ratings yet

- ASCONumaticsTodayCatalogueANTC R4!11!12 12until09!30!13Document48 pagesASCONumaticsTodayCatalogueANTC R4!11!12 12until09!30!13FreijNo ratings yet

- Boiler Furnace PDFDocument8 pagesBoiler Furnace PDFசுந்தர மூர்த்தி சேப்பிளையார்No ratings yet

- IM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022Document31 pagesIM BSCE 3 - Hydraulics 1 Chapter 2 2021-2022acurvz2005No ratings yet

- Safety Scope MSA CatalogDocument144 pagesSafety Scope MSA Catalogykresna1631No ratings yet

- Excel Calculations Excel Calculations: The IGT Distribution Equation For Natural Gas FlowDocument2 pagesExcel Calculations Excel Calculations: The IGT Distribution Equation For Natural Gas Flowleonel TintayaNo ratings yet

- Question IIIDocument2 pagesQuestion IIISweta SumanNo ratings yet

- Power HydraulicsDocument75 pagesPower HydraulicsKavinda Gehan100% (1)

- User Manual: High Pressure Manifolds For Medical GasesDocument6 pagesUser Manual: High Pressure Manifolds For Medical GasesBashir MtwaklNo ratings yet

- Material Balance MethodDocument25 pagesMaterial Balance MethodUzumaki28No ratings yet

- B737-6 21 Jar B1 e (Jun2004 CMP)Document198 pagesB737-6 21 Jar B1 e (Jun2004 CMP)Belisario Sergio Llacchas rodasNo ratings yet

- BFC21103 Chapter4Document113 pagesBFC21103 Chapter4Mohd Zulhairi100% (2)

- Bops Stack 11 5M GRS 158wrotating NG HeadDocument2 pagesBops Stack 11 5M GRS 158wrotating NG HeadRamiro Acosta Cepeda100% (1)

- Ehandbook Strategize Your Steam SystemDocument18 pagesEhandbook Strategize Your Steam SystemMPham100% (1)

- PERU Piping Washing Cleaning Spec - Rev 4Document6 pagesPERU Piping Washing Cleaning Spec - Rev 4David Garriazo VivarNo ratings yet

- Tare A 1Document2 pagesTare A 1Francisco Celestino Guajardo0% (1)

- Adcatraining Control Valve 5 Rev 01Document36 pagesAdcatraining Control Valve 5 Rev 01Fendy ShirahNo ratings yet

- Project Report of POL Terminals2 PDFDocument31 pagesProject Report of POL Terminals2 PDFRashmi RanjanNo ratings yet

- Mse 223 Introduction To Fluid Mechanics Spring 2015: Instructor: TasDocument3 pagesMse 223 Introduction To Fluid Mechanics Spring 2015: Instructor: TasbobNo ratings yet

- Ponchon SavaritDocument14 pagesPonchon SavaritAbdulhamid Ben-NajmaNo ratings yet

- Stationary Combustion Tool (Version4-1)Document18 pagesStationary Combustion Tool (Version4-1)hartiniNo ratings yet

- Manual 99 Pressure Reducing Regulator Fisher en 123040Document24 pagesManual 99 Pressure Reducing Regulator Fisher en 123040Jholman SanchezNo ratings yet