Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

119 viewsSelf Inspection of Enginerring

Self Inspection of Enginerring

Uploaded by

anoushia alviThis self inspection checklist is used by an engineering or maintenance department to evaluate compliance. It contains 43 check points across various categories like documentation, equipment maintenance, calibration, safety, and training. Records would be marked as yes/no and any necessary corrective or preventive actions and timelines recorded. The checklist aims to ensure standard operating procedures are followed, equipment and documentation are properly managed, personnel are adequately trained, and issues are addressed in a timely manner.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- SOP of Handling of Packaging MaterialDocument3 pagesSOP of Handling of Packaging Materialanoushia alviNo ratings yet

- Professional SummaryDocument3 pagesProfessional SummaryVijay LS SolutionsNo ratings yet

- URS (User Requirements Specification) For Vial Lyophilization ProcessDocument2 pagesURS (User Requirements Specification) For Vial Lyophilization ProcessMike SongNo ratings yet

- DiT Op C0xx-Automation-Classes SIDocument126 pagesDiT Op C0xx-Automation-Classes SIYen NguyenNo ratings yet

- A Cost Model of Industrial Maintenance For Profitability Analysis and Benchmarking PDFDocument17 pagesA Cost Model of Industrial Maintenance For Profitability Analysis and Benchmarking PDFHugoCabanillasNo ratings yet

- Case Study RMWG-03 - Functional Equivalence For Equipment Replacements (Rev 1)Document6 pagesCase Study RMWG-03 - Functional Equivalence For Equipment Replacements (Rev 1)pamy26250No ratings yet

- D106-016-008 Visionscan Manual Do UsuarioDocument99 pagesD106-016-008 Visionscan Manual Do UsuarioAlan Portela VieiraNo ratings yet

- Audit Checklist For The Engineering and MaintenanceDocument2 pagesAudit Checklist For The Engineering and MaintenanceMohanad Alashkar100% (4)

- Communication SOPDocument10 pagesCommunication SOPanoushia alvi100% (1)

- Sop For Electrical SafetyDocument3 pagesSop For Electrical Safetyanoushia alvi100% (1)

- Sro 967 (I) 2020 PDFDocument30 pagesSro 967 (I) 2020 PDFanoushia alviNo ratings yet

- Commissioning Qualification Validation Blue PaperDocument12 pagesCommissioning Qualification Validation Blue PaperVarun ZotaNo ratings yet

- Supplement 4 TS Security Fire Protection ECSPP ECBSDocument30 pagesSupplement 4 TS Security Fire Protection ECSPP ECBSJelena PopovicNo ratings yet

- VAL 210 Computer Validation Master Plan SampleDocument4 pagesVAL 210 Computer Validation Master Plan SampleSameh MostafaNo ratings yet

- Operation - Plant It WorkDocument79 pagesOperation - Plant It WorkYen NguyenNo ratings yet

- PiT Op Manager Proc CompDocument91 pagesPiT Op Manager Proc CompYen NguyenNo ratings yet

- CMMS Technical Object and Preventative Maintenance FormDocument7 pagesCMMS Technical Object and Preventative Maintenance Formken1962No ratings yet

- Rota 940 - OqDocument39 pagesRota 940 - Oqsamar elrobyNo ratings yet

- Maintenance of Refrigeration Equipment: WHO VaccineDocument24 pagesMaintenance of Refrigeration Equipment: WHO VaccineDoan Chi ThienNo ratings yet

- Liquid Chromatography BP 2017: Appendix III Chromatographic Separation TechniquesDocument11 pagesLiquid Chromatography BP 2017: Appendix III Chromatographic Separation TechniquesTaNo ratings yet

- Iq Fe001Document32 pagesIq Fe001Dhaval ChaplaNo ratings yet

- Using Empower Systemsqt Qualification Tool For Waters Modular HPLC SystemsDocument8 pagesUsing Empower Systemsqt Qualification Tool For Waters Modular HPLC SystemsПетр КрасновNo ratings yet

- Iq-Pouch Filling Machine (Kreation)Document6 pagesIq-Pouch Filling Machine (Kreation)Hemant SinghNo ratings yet

- High Performance Medical Grade Resins PDFDocument11 pagesHigh Performance Medical Grade Resins PDFGeorge CobraNo ratings yet

- USP1058 - Analytical - Instruments Qualification PDFDocument8 pagesUSP1058 - Analytical - Instruments Qualification PDFSrinivasNo ratings yet

- 8D Reort FormatDocument1 page8D Reort FormatPRABHAT RANJANNo ratings yet

- Design and Analysis of Multi-Section Variable Camber Wing: Wing, Flaps, Wingspan, RibsDocument6 pagesDesign and Analysis of Multi-Section Variable Camber Wing: Wing, Flaps, Wingspan, RibsKushal SinghNo ratings yet

- ISPE Print PageDocument1 pageISPE Print Pagesmallik3No ratings yet

- Excipact StandardsDocument96 pagesExcipact Standardselighi100% (1)

- A FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationDocument22 pagesA FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationLi NearNo ratings yet

- General Equipment TableDocument16 pagesGeneral Equipment Tablearli krisnandikaNo ratings yet

- Design Qualification Protocol Cum Report For Fluid Bed DryerDocument15 pagesDesign Qualification Protocol Cum Report For Fluid Bed DryerNur Nabi RashedNo ratings yet

- Determination of Product Shelf Life and Activation Energy For Five Drugs of Abuse PDFDocument5 pagesDetermination of Product Shelf Life and Activation Energy For Five Drugs of Abuse PDFMiguelArceMonroyNo ratings yet

- VAL - 170401 - BMAA VAL Activity 3 URS - Template PDFDocument10 pagesVAL - 170401 - BMAA VAL Activity 3 URS - Template PDFDineshNo ratings yet

- AEEE Industrial EndosDocument2 pagesAEEE Industrial EndosShashibhushan AgrawalNo ratings yet

- FMEA Vs FMECADocument10 pagesFMEA Vs FMECAAndika Haris NugrohoNo ratings yet

- Evaluating An ERP For Pharmaceutical Industry: Make Sure That These 11 Questions Are AnsweredDocument2 pagesEvaluating An ERP For Pharmaceutical Industry: Make Sure That These 11 Questions Are Answerednilay1965No ratings yet

- Reading Sample-Qualification Calibration Laboratory InstrumentsDocument12 pagesReading Sample-Qualification Calibration Laboratory InstrumentsletphuongNo ratings yet

- U R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemDocument66 pagesU R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemSurangaGNo ratings yet

- Software Quality Assurance Notes in Urdu Hindi ExplanationDocument5 pagesSoftware Quality Assurance Notes in Urdu Hindi ExplanationAli RazaNo ratings yet

- PFMEA - Process FMEADocument23 pagesPFMEA - Process FMEANavnath TamhaneNo ratings yet

- TOCV WS操作说明书 英文版Document262 pagesTOCV WS操作说明书 英文版scribd birdNo ratings yet

- Maintenance QualificationDocument5 pagesMaintenance QualificationqlfangNo ratings yet

- CMMS Selection GuideDocument6 pagesCMMS Selection GuidehamadaabdelgawadNo ratings yet

- Astm A380 06Document1 pageAstm A380 06Nguyễn Duy Biên0% (1)

- Form # 2 Gap AnalysisDocument7 pagesForm # 2 Gap AnalysisRyan ReasNo ratings yet

- Packaging Validation For Iv SetDocument39 pagesPackaging Validation For Iv SetMusyoka UrbanusNo ratings yet

- URS Contents: Blank TemplateDocument11 pagesURS Contents: Blank TemplateBREWSKI100% (1)

- Cary SpecificationsDocument8 pagesCary SpecificationsmafiwarsNo ratings yet

- Good Chromatography Practices - SOP & Guideline - Pharma BeginnersDocument46 pagesGood Chromatography Practices - SOP & Guideline - Pharma BeginnersSAISIVARAMAKRISHNA KATTULANo ratings yet

- Pic-S Steril Medicinal ProductsDocument58 pagesPic-S Steril Medicinal ProductsmerouaneNo ratings yet

- t09 - Software Verification and ValidationDocument64 pagest09 - Software Verification and ValidationophrqhbkxnuuhsmgcwNo ratings yet

- 9 Temperature Mapping Mistakes To AvoidDocument5 pages9 Temperature Mapping Mistakes To AvoidReema IshaqNo ratings yet

- Iso 14664-3Document2 pagesIso 14664-3Summiya JaveidNo ratings yet

- SaivDocument5 pagesSaivRohith korrapatiNo ratings yet

- Chapter 3 - PLC Hardware DesignDocument23 pagesChapter 3 - PLC Hardware DesignMOHD SABREENo ratings yet

- Analytical Equipment Lifecycle ManagementDocument24 pagesAnalytical Equipment Lifecycle Managementtvijayak41No ratings yet

- Protocol PQ1Document28 pagesProtocol PQ1Tuan NguyenNo ratings yet

- Omcl Annex 3 Qualification of Uv Visible SpectrophotometersDocument9 pagesOmcl Annex 3 Qualification of Uv Visible SpectrophotometersGuillaume merlaudNo ratings yet

- CalibrationDocument5 pagesCalibrationMonika KshNo ratings yet

- Tech XFRDocument6 pagesTech XFRvijendra321No ratings yet

- Preventive Maintenance of Automatic Capsule Filling - Pharmaceutical UpdatesDocument3 pagesPreventive Maintenance of Automatic Capsule Filling - Pharmaceutical UpdatesAhmad Hamouda100% (1)

- Supplementary Training Modules On Good Manufacturing PracticeDocument31 pagesSupplementary Training Modules On Good Manufacturing Practicesagaram_sNo ratings yet

- Paflbnrs Exo: of On Labeling and Rnrorrvra - UonDocument1 pagePaflbnrs Exo: of On Labeling and Rnrorrvra - Uonanoushia alviNo ratings yet

- Raw Material Identification PerformaDocument2 pagesRaw Material Identification Performaanoushia alviNo ratings yet

- USP 1664.1 LeachablesDocument6 pagesUSP 1664.1 Leachablesanoushia alviNo ratings yet

- Qa Audit Points: Syrup Manufacturing AreaDocument11 pagesQa Audit Points: Syrup Manufacturing Areaanoushia alviNo ratings yet

- Receiving of Raw & Pacheging Material SOPDocument6 pagesReceiving of Raw & Pacheging Material SOPanoushia alviNo ratings yet

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- Receiving of Packaging Material SOPDocument4 pagesReceiving of Packaging Material SOPanoushia alvi100% (1)

- Factories Act 1934 CHAPTER IIIDocument1 pageFactories Act 1934 CHAPTER IIIanoushia alviNo ratings yet

- MA 01.12 DRAFT Guideline On Non Rutine MADocument14 pagesMA 01.12 DRAFT Guideline On Non Rutine MAanoushia alviNo ratings yet

- Winthrox Laboratories Pvt. LTD: Quality Assurance DepartmentDocument2 pagesWinthrox Laboratories Pvt. LTD: Quality Assurance Departmentanoushia alviNo ratings yet

- Emergency and Action Plans-FormatsDocument12 pagesEmergency and Action Plans-Formatsanoushia alviNo ratings yet

- Quality LEGAL AND OTHER REQUIREMENTS REGISTERDocument8 pagesQuality LEGAL AND OTHER REQUIREMENTS REGISTERanoushia alviNo ratings yet

- Register - EHS Legal RequirementsDocument4 pagesRegister - EHS Legal Requirementsanoushia alviNo ratings yet

- TOOL BOX MEETING AGENDA FormatDocument1 pageTOOL BOX MEETING AGENDA Formatanoushia alviNo ratings yet

- Winthrox Laboratories (PVT) Ltd. Ehs DepartmentDocument4 pagesWinthrox Laboratories (PVT) Ltd. Ehs Departmentanoushia alviNo ratings yet

- Legal Register FormatDocument1 pageLegal Register Formatanoushia alviNo ratings yet

- Winthrox Laboratories Pvt. LTDDocument2 pagesWinthrox Laboratories Pvt. LTDanoushia alviNo ratings yet

- EHS Manual - FinalDocument53 pagesEHS Manual - Finalanoushia alviNo ratings yet

- Conservation of WaterDocument2 pagesConservation of Wateranoushia alviNo ratings yet

- Tool Box Meeting SOP AISHADocument2 pagesTool Box Meeting SOP AISHAanoushia alviNo ratings yet

- Incident SopDocument10 pagesIncident Sopanoushia alviNo ratings yet

- Conservation of EnergyDocument2 pagesConservation of Energyanoushia alviNo ratings yet

- Winthrox Laboratories Pvt. LTD: Quality Assurance DepartmentDocument2 pagesWinthrox Laboratories Pvt. LTD: Quality Assurance Departmentanoushia alviNo ratings yet

- Documents Required For CRF NOCDocument1 pageDocuments Required For CRF NOCanoushia alviNo ratings yet

- Price List For Packsize AdditionDocument5 pagesPrice List For Packsize Additionanoushia alviNo ratings yet

- Adults and Children Over 2 Years: For The Control of Trichuriasis, Ascariasis and Hookworm InfectionsDocument5 pagesAdults and Children Over 2 Years: For The Control of Trichuriasis, Ascariasis and Hookworm Infectionsanoushia alviNo ratings yet

- LogDocument12 pagesLogNida MunirahNo ratings yet

- Kuwait STC 2020 MBB Project: Huawei Technologies Co., LTDDocument4 pagesKuwait STC 2020 MBB Project: Huawei Technologies Co., LTDGayas ShaikNo ratings yet

- DLL Artsg7 Week1 2Document6 pagesDLL Artsg7 Week1 2Mae CaramancionNo ratings yet

- Create Microsoft-Signed Phishing DocumentsDocument9 pagesCreate Microsoft-Signed Phishing Documentsamir mansouriNo ratings yet

- The Myth of Quantum ConsciousnessDocument10 pagesThe Myth of Quantum ConsciousnessHenry McQualeNo ratings yet

- MTP44001Document63 pagesMTP44001Dong-seob ParkNo ratings yet

- Tascam DB 25 PinoutDocument1 pageTascam DB 25 PinoutAmro NoechiNo ratings yet

- Assignment 2Document2 pagesAssignment 2Nzan NkapNo ratings yet

- Makalah LiteratureDocument19 pagesMakalah LiteratureDenny Permana100% (1)

- Method Statement For Marble Flooring and Marble Wall CladdingDocument10 pagesMethod Statement For Marble Flooring and Marble Wall Claddingumit100% (1)

- Role of MNC in IndiaDocument41 pagesRole of MNC in IndiaKhundongbam SureshNo ratings yet

- IEEE NIGERCON Conference Paper TemplateDocument4 pagesIEEE NIGERCON Conference Paper TemplateOladeji Ifedayo RNo ratings yet

- Alkene and Alkyne - by Resonance PDFDocument45 pagesAlkene and Alkyne - by Resonance PDFPrasad Yarra100% (1)

- Function GeneratorDocument5 pagesFunction GeneratorvenkumaniNo ratings yet

- RegTech Medici Top-21Document38 pagesRegTech Medici Top-21ShakespeareWallaNo ratings yet

- Understanding The Gender Pay Gap: Women in Business and ManagementDocument8 pagesUnderstanding The Gender Pay Gap: Women in Business and Managementmostafa aliNo ratings yet

- Project (Digital Filter)Document33 pagesProject (Digital Filter)NilNo ratings yet

- Ekc 204aDocument24 pagesEkc 204aPreot Andreana CatalinNo ratings yet

- LinkedIn Powerpoint AnswersDocument2 pagesLinkedIn Powerpoint AnswersMarcel MatuschekNo ratings yet

- Online EarningDocument3 pagesOnline Earningwordwork373No ratings yet

- Eft - Makalah Pariwisata Kabupaten SikaDocument11 pagesEft - Makalah Pariwisata Kabupaten SikaRevening H. D. MauteyNo ratings yet

- Metercat 6.1.1.0 Release NotesDocument7 pagesMetercat 6.1.1.0 Release NotesCarlos Guzman BonifacioNo ratings yet

- Rtx3 Wireless Expansion V5.3: Reference and Installation ManualDocument24 pagesRtx3 Wireless Expansion V5.3: Reference and Installation ManualCatalin HoratiuNo ratings yet

- Checklist - Turning Client To Lateral or Prone PositionDocument3 pagesChecklist - Turning Client To Lateral or Prone PositionNorhaina AminNo ratings yet

- Test 05Document87 pagesTest 05MenaNo ratings yet

- Spiritual Giftings TestDocument11 pagesSpiritual Giftings TestKyl M. SrrcNo ratings yet

- When Key Employees ClashDocument4 pagesWhen Key Employees ClashRowell DizonNo ratings yet

- Nidek ICE-1200Document6 pagesNidek ICE-1200QulrafMongkonsirivatanaNo ratings yet

- Globalization More Harm Than GoodDocument4 pagesGlobalization More Harm Than GoodAnnisa Putri Sulistia100% (1)

- 10 Top Photography Composition RulesDocument6 pages10 Top Photography Composition Rulesaj4fall086050No ratings yet

Self Inspection of Enginerring

Self Inspection of Enginerring

Uploaded by

anoushia alvi0 ratings0% found this document useful (0 votes)

119 views2 pagesThis self inspection checklist is used by an engineering or maintenance department to evaluate compliance. It contains 43 check points across various categories like documentation, equipment maintenance, calibration, safety, and training. Records would be marked as yes/no and any necessary corrective or preventive actions and timelines recorded. The checklist aims to ensure standard operating procedures are followed, equipment and documentation are properly managed, personnel are adequately trained, and issues are addressed in a timely manner.

Original Description:

Original Title

Self Inspection of enginerring

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis self inspection checklist is used by an engineering or maintenance department to evaluate compliance. It contains 43 check points across various categories like documentation, equipment maintenance, calibration, safety, and training. Records would be marked as yes/no and any necessary corrective or preventive actions and timelines recorded. The checklist aims to ensure standard operating procedures are followed, equipment and documentation are properly managed, personnel are adequately trained, and issues are addressed in a timely manner.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

119 views2 pagesSelf Inspection of Enginerring

Self Inspection of Enginerring

Uploaded by

anoushia alviThis self inspection checklist is used by an engineering or maintenance department to evaluate compliance. It contains 43 check points across various categories like documentation, equipment maintenance, calibration, safety, and training. Records would be marked as yes/no and any necessary corrective or preventive actions and timelines recorded. The checklist aims to ensure standard operating procedures are followed, equipment and documentation are properly managed, personnel are adequately trained, and issues are addressed in a timely manner.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

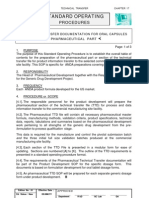

Self Inspection Check List (Engineering/ Maintenance)

Corrective &

Sr. No. Check Points Yes / No Remarks Timeline

Preventive Actions

General :

1. Is there an organogram for the dept? Yes/No

2. Are no. of personnel adequate? Yes/No

3. Is the department manual available Yes/No

for reference?

4. Is responsibility of the personnel Yes/No

available?

5. Are all SOP's w.r.t. procedures are Yes/No

correct & followed?

6. Are revision status/ date mentioned in Yes/No

all the documents?

7. Is any obsolete document found Yes/No

floating in the dept?

8. Are proper breakdown entries made Yes/No

in history card?

9. Are Boiler, D.G. set, M.S.E.B, Log Yes/No

books maintained?

10. Is the list of equipments available? Yes/No

11. Are the preventive maintenance Yes/No

schedule & plan available?

12. Is the list of critical spares available? Yes/No

13. Is proper indent given for required Yes/No

material with proper authorization?

14. What is the identification mark for Yes/No

cleaned & un-cleaned filters?

15. Are all service lines well defined by Yes/No

displaying coded/ color details?

16. Buffer stock of filter kept with proper Yes/No

identification?

17. Whether all filters with proper Yes/No

identification mark?

18. Whether all calibration carried out by Yes/No

third parties have traceability to

national standards?

19. Is the ETP tank labeled properly? Yes/No

20. Are preventive maintenance schedule Yes/No

done as per schedule?

21. Is the IQ, PQ, OQ done for new Yes/No

equipment?

22. Is the breakdown records maintained? Yes/No

23. Are levels of underground water, Yes/No

sufficient diesel, boiler & D.G. set

tanks inspected regularly?

24. Are there checks on Humidity & Yes/No

Temperature controller?

25. Are calibration tags available on each Yes/No

equipment?

26. Whether temp. & pressure gauges Yes/No

used are calibrated as per frequency?

27. What is the procedure for Out of Yes/No

Calibration' equipment?

28. Is proper status label for critical Yes/No

spares?

29. Is proper status label of filters clean? Yes/No

30. Are calibration status is available on Yes/No

calibrated equipments?

31. Is any non-conforming product / Yes/No

utility identified properly?

32. Are records maintained if Yes/No

documented procedure changes due

to corrective/ preventive action?

33. Whether proper authorisation is taken Yes/No

for any deviation?

34. Is work permit taken for critical Yes/No

activities?

35. Are critical spares stored properly? Yes/No

36. Whether safety wears are used during Yes/No

maintenance work?

37. Are all records (controlled copies) of Yes/No

SOP's kept / displayed in proper

locations?

38. Is there a retention period for each of Yes/No

these documents?

39. Are all operators & workers trained? Yes/No

40. Are records of training properly Yes/No

maintained?

41. Is employee assessed after training? Yes/No

42. Is retraining given if required? Yes/No

43. Is there a training calendar? Yes/No

You might also like

- SOP of Handling of Packaging MaterialDocument3 pagesSOP of Handling of Packaging Materialanoushia alviNo ratings yet

- Professional SummaryDocument3 pagesProfessional SummaryVijay LS SolutionsNo ratings yet

- URS (User Requirements Specification) For Vial Lyophilization ProcessDocument2 pagesURS (User Requirements Specification) For Vial Lyophilization ProcessMike SongNo ratings yet

- DiT Op C0xx-Automation-Classes SIDocument126 pagesDiT Op C0xx-Automation-Classes SIYen NguyenNo ratings yet

- A Cost Model of Industrial Maintenance For Profitability Analysis and Benchmarking PDFDocument17 pagesA Cost Model of Industrial Maintenance For Profitability Analysis and Benchmarking PDFHugoCabanillasNo ratings yet

- Case Study RMWG-03 - Functional Equivalence For Equipment Replacements (Rev 1)Document6 pagesCase Study RMWG-03 - Functional Equivalence For Equipment Replacements (Rev 1)pamy26250No ratings yet

- D106-016-008 Visionscan Manual Do UsuarioDocument99 pagesD106-016-008 Visionscan Manual Do UsuarioAlan Portela VieiraNo ratings yet

- Audit Checklist For The Engineering and MaintenanceDocument2 pagesAudit Checklist For The Engineering and MaintenanceMohanad Alashkar100% (4)

- Communication SOPDocument10 pagesCommunication SOPanoushia alvi100% (1)

- Sop For Electrical SafetyDocument3 pagesSop For Electrical Safetyanoushia alvi100% (1)

- Sro 967 (I) 2020 PDFDocument30 pagesSro 967 (I) 2020 PDFanoushia alviNo ratings yet

- Commissioning Qualification Validation Blue PaperDocument12 pagesCommissioning Qualification Validation Blue PaperVarun ZotaNo ratings yet

- Supplement 4 TS Security Fire Protection ECSPP ECBSDocument30 pagesSupplement 4 TS Security Fire Protection ECSPP ECBSJelena PopovicNo ratings yet

- VAL 210 Computer Validation Master Plan SampleDocument4 pagesVAL 210 Computer Validation Master Plan SampleSameh MostafaNo ratings yet

- Operation - Plant It WorkDocument79 pagesOperation - Plant It WorkYen NguyenNo ratings yet

- PiT Op Manager Proc CompDocument91 pagesPiT Op Manager Proc CompYen NguyenNo ratings yet

- CMMS Technical Object and Preventative Maintenance FormDocument7 pagesCMMS Technical Object and Preventative Maintenance Formken1962No ratings yet

- Rota 940 - OqDocument39 pagesRota 940 - Oqsamar elrobyNo ratings yet

- Maintenance of Refrigeration Equipment: WHO VaccineDocument24 pagesMaintenance of Refrigeration Equipment: WHO VaccineDoan Chi ThienNo ratings yet

- Liquid Chromatography BP 2017: Appendix III Chromatographic Separation TechniquesDocument11 pagesLiquid Chromatography BP 2017: Appendix III Chromatographic Separation TechniquesTaNo ratings yet

- Iq Fe001Document32 pagesIq Fe001Dhaval ChaplaNo ratings yet

- Using Empower Systemsqt Qualification Tool For Waters Modular HPLC SystemsDocument8 pagesUsing Empower Systemsqt Qualification Tool For Waters Modular HPLC SystemsПетр КрасновNo ratings yet

- Iq-Pouch Filling Machine (Kreation)Document6 pagesIq-Pouch Filling Machine (Kreation)Hemant SinghNo ratings yet

- High Performance Medical Grade Resins PDFDocument11 pagesHigh Performance Medical Grade Resins PDFGeorge CobraNo ratings yet

- USP1058 - Analytical - Instruments Qualification PDFDocument8 pagesUSP1058 - Analytical - Instruments Qualification PDFSrinivasNo ratings yet

- 8D Reort FormatDocument1 page8D Reort FormatPRABHAT RANJANNo ratings yet

- Design and Analysis of Multi-Section Variable Camber Wing: Wing, Flaps, Wingspan, RibsDocument6 pagesDesign and Analysis of Multi-Section Variable Camber Wing: Wing, Flaps, Wingspan, RibsKushal SinghNo ratings yet

- ISPE Print PageDocument1 pageISPE Print Pagesmallik3No ratings yet

- Excipact StandardsDocument96 pagesExcipact Standardselighi100% (1)

- A FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationDocument22 pagesA FMEA-based Approach To Prioritize Waste Reduction in Lean ImplementationLi NearNo ratings yet

- General Equipment TableDocument16 pagesGeneral Equipment Tablearli krisnandikaNo ratings yet

- Design Qualification Protocol Cum Report For Fluid Bed DryerDocument15 pagesDesign Qualification Protocol Cum Report For Fluid Bed DryerNur Nabi RashedNo ratings yet

- Determination of Product Shelf Life and Activation Energy For Five Drugs of Abuse PDFDocument5 pagesDetermination of Product Shelf Life and Activation Energy For Five Drugs of Abuse PDFMiguelArceMonroyNo ratings yet

- VAL - 170401 - BMAA VAL Activity 3 URS - Template PDFDocument10 pagesVAL - 170401 - BMAA VAL Activity 3 URS - Template PDFDineshNo ratings yet

- AEEE Industrial EndosDocument2 pagesAEEE Industrial EndosShashibhushan AgrawalNo ratings yet

- FMEA Vs FMECADocument10 pagesFMEA Vs FMECAAndika Haris NugrohoNo ratings yet

- Evaluating An ERP For Pharmaceutical Industry: Make Sure That These 11 Questions Are AnsweredDocument2 pagesEvaluating An ERP For Pharmaceutical Industry: Make Sure That These 11 Questions Are Answerednilay1965No ratings yet

- Reading Sample-Qualification Calibration Laboratory InstrumentsDocument12 pagesReading Sample-Qualification Calibration Laboratory InstrumentsletphuongNo ratings yet

- U R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemDocument66 pagesU R T For A Supervisory Control and Data Acquisition (SCADA) Process Control SystemSurangaGNo ratings yet

- Software Quality Assurance Notes in Urdu Hindi ExplanationDocument5 pagesSoftware Quality Assurance Notes in Urdu Hindi ExplanationAli RazaNo ratings yet

- PFMEA - Process FMEADocument23 pagesPFMEA - Process FMEANavnath TamhaneNo ratings yet

- TOCV WS操作说明书 英文版Document262 pagesTOCV WS操作说明书 英文版scribd birdNo ratings yet

- Maintenance QualificationDocument5 pagesMaintenance QualificationqlfangNo ratings yet

- CMMS Selection GuideDocument6 pagesCMMS Selection GuidehamadaabdelgawadNo ratings yet

- Astm A380 06Document1 pageAstm A380 06Nguyễn Duy Biên0% (1)

- Form # 2 Gap AnalysisDocument7 pagesForm # 2 Gap AnalysisRyan ReasNo ratings yet

- Packaging Validation For Iv SetDocument39 pagesPackaging Validation For Iv SetMusyoka UrbanusNo ratings yet

- URS Contents: Blank TemplateDocument11 pagesURS Contents: Blank TemplateBREWSKI100% (1)

- Cary SpecificationsDocument8 pagesCary SpecificationsmafiwarsNo ratings yet

- Good Chromatography Practices - SOP & Guideline - Pharma BeginnersDocument46 pagesGood Chromatography Practices - SOP & Guideline - Pharma BeginnersSAISIVARAMAKRISHNA KATTULANo ratings yet

- Pic-S Steril Medicinal ProductsDocument58 pagesPic-S Steril Medicinal ProductsmerouaneNo ratings yet

- t09 - Software Verification and ValidationDocument64 pagest09 - Software Verification and ValidationophrqhbkxnuuhsmgcwNo ratings yet

- 9 Temperature Mapping Mistakes To AvoidDocument5 pages9 Temperature Mapping Mistakes To AvoidReema IshaqNo ratings yet

- Iso 14664-3Document2 pagesIso 14664-3Summiya JaveidNo ratings yet

- SaivDocument5 pagesSaivRohith korrapatiNo ratings yet

- Chapter 3 - PLC Hardware DesignDocument23 pagesChapter 3 - PLC Hardware DesignMOHD SABREENo ratings yet

- Analytical Equipment Lifecycle ManagementDocument24 pagesAnalytical Equipment Lifecycle Managementtvijayak41No ratings yet

- Protocol PQ1Document28 pagesProtocol PQ1Tuan NguyenNo ratings yet

- Omcl Annex 3 Qualification of Uv Visible SpectrophotometersDocument9 pagesOmcl Annex 3 Qualification of Uv Visible SpectrophotometersGuillaume merlaudNo ratings yet

- CalibrationDocument5 pagesCalibrationMonika KshNo ratings yet

- Tech XFRDocument6 pagesTech XFRvijendra321No ratings yet

- Preventive Maintenance of Automatic Capsule Filling - Pharmaceutical UpdatesDocument3 pagesPreventive Maintenance of Automatic Capsule Filling - Pharmaceutical UpdatesAhmad Hamouda100% (1)

- Supplementary Training Modules On Good Manufacturing PracticeDocument31 pagesSupplementary Training Modules On Good Manufacturing Practicesagaram_sNo ratings yet

- Paflbnrs Exo: of On Labeling and Rnrorrvra - UonDocument1 pagePaflbnrs Exo: of On Labeling and Rnrorrvra - Uonanoushia alviNo ratings yet

- Raw Material Identification PerformaDocument2 pagesRaw Material Identification Performaanoushia alviNo ratings yet

- USP 1664.1 LeachablesDocument6 pagesUSP 1664.1 Leachablesanoushia alviNo ratings yet

- Qa Audit Points: Syrup Manufacturing AreaDocument11 pagesQa Audit Points: Syrup Manufacturing Areaanoushia alviNo ratings yet

- Receiving of Raw & Pacheging Material SOPDocument6 pagesReceiving of Raw & Pacheging Material SOPanoushia alviNo ratings yet

- 13 SOP Cleaning For Dispensing AreaDocument3 pages13 SOP Cleaning For Dispensing Areaanoushia alviNo ratings yet

- Receiving of Packaging Material SOPDocument4 pagesReceiving of Packaging Material SOPanoushia alvi100% (1)

- Factories Act 1934 CHAPTER IIIDocument1 pageFactories Act 1934 CHAPTER IIIanoushia alviNo ratings yet

- MA 01.12 DRAFT Guideline On Non Rutine MADocument14 pagesMA 01.12 DRAFT Guideline On Non Rutine MAanoushia alviNo ratings yet

- Winthrox Laboratories Pvt. LTD: Quality Assurance DepartmentDocument2 pagesWinthrox Laboratories Pvt. LTD: Quality Assurance Departmentanoushia alviNo ratings yet

- Emergency and Action Plans-FormatsDocument12 pagesEmergency and Action Plans-Formatsanoushia alviNo ratings yet

- Quality LEGAL AND OTHER REQUIREMENTS REGISTERDocument8 pagesQuality LEGAL AND OTHER REQUIREMENTS REGISTERanoushia alviNo ratings yet

- Register - EHS Legal RequirementsDocument4 pagesRegister - EHS Legal Requirementsanoushia alviNo ratings yet

- TOOL BOX MEETING AGENDA FormatDocument1 pageTOOL BOX MEETING AGENDA Formatanoushia alviNo ratings yet

- Winthrox Laboratories (PVT) Ltd. Ehs DepartmentDocument4 pagesWinthrox Laboratories (PVT) Ltd. Ehs Departmentanoushia alviNo ratings yet

- Legal Register FormatDocument1 pageLegal Register Formatanoushia alviNo ratings yet

- Winthrox Laboratories Pvt. LTDDocument2 pagesWinthrox Laboratories Pvt. LTDanoushia alviNo ratings yet

- EHS Manual - FinalDocument53 pagesEHS Manual - Finalanoushia alviNo ratings yet

- Conservation of WaterDocument2 pagesConservation of Wateranoushia alviNo ratings yet

- Tool Box Meeting SOP AISHADocument2 pagesTool Box Meeting SOP AISHAanoushia alviNo ratings yet

- Incident SopDocument10 pagesIncident Sopanoushia alviNo ratings yet

- Conservation of EnergyDocument2 pagesConservation of Energyanoushia alviNo ratings yet

- Winthrox Laboratories Pvt. LTD: Quality Assurance DepartmentDocument2 pagesWinthrox Laboratories Pvt. LTD: Quality Assurance Departmentanoushia alviNo ratings yet

- Documents Required For CRF NOCDocument1 pageDocuments Required For CRF NOCanoushia alviNo ratings yet

- Price List For Packsize AdditionDocument5 pagesPrice List For Packsize Additionanoushia alviNo ratings yet

- Adults and Children Over 2 Years: For The Control of Trichuriasis, Ascariasis and Hookworm InfectionsDocument5 pagesAdults and Children Over 2 Years: For The Control of Trichuriasis, Ascariasis and Hookworm Infectionsanoushia alviNo ratings yet

- LogDocument12 pagesLogNida MunirahNo ratings yet

- Kuwait STC 2020 MBB Project: Huawei Technologies Co., LTDDocument4 pagesKuwait STC 2020 MBB Project: Huawei Technologies Co., LTDGayas ShaikNo ratings yet

- DLL Artsg7 Week1 2Document6 pagesDLL Artsg7 Week1 2Mae CaramancionNo ratings yet

- Create Microsoft-Signed Phishing DocumentsDocument9 pagesCreate Microsoft-Signed Phishing Documentsamir mansouriNo ratings yet

- The Myth of Quantum ConsciousnessDocument10 pagesThe Myth of Quantum ConsciousnessHenry McQualeNo ratings yet

- MTP44001Document63 pagesMTP44001Dong-seob ParkNo ratings yet

- Tascam DB 25 PinoutDocument1 pageTascam DB 25 PinoutAmro NoechiNo ratings yet

- Assignment 2Document2 pagesAssignment 2Nzan NkapNo ratings yet

- Makalah LiteratureDocument19 pagesMakalah LiteratureDenny Permana100% (1)

- Method Statement For Marble Flooring and Marble Wall CladdingDocument10 pagesMethod Statement For Marble Flooring and Marble Wall Claddingumit100% (1)

- Role of MNC in IndiaDocument41 pagesRole of MNC in IndiaKhundongbam SureshNo ratings yet

- IEEE NIGERCON Conference Paper TemplateDocument4 pagesIEEE NIGERCON Conference Paper TemplateOladeji Ifedayo RNo ratings yet

- Alkene and Alkyne - by Resonance PDFDocument45 pagesAlkene and Alkyne - by Resonance PDFPrasad Yarra100% (1)

- Function GeneratorDocument5 pagesFunction GeneratorvenkumaniNo ratings yet

- RegTech Medici Top-21Document38 pagesRegTech Medici Top-21ShakespeareWallaNo ratings yet

- Understanding The Gender Pay Gap: Women in Business and ManagementDocument8 pagesUnderstanding The Gender Pay Gap: Women in Business and Managementmostafa aliNo ratings yet

- Project (Digital Filter)Document33 pagesProject (Digital Filter)NilNo ratings yet

- Ekc 204aDocument24 pagesEkc 204aPreot Andreana CatalinNo ratings yet

- LinkedIn Powerpoint AnswersDocument2 pagesLinkedIn Powerpoint AnswersMarcel MatuschekNo ratings yet

- Online EarningDocument3 pagesOnline Earningwordwork373No ratings yet

- Eft - Makalah Pariwisata Kabupaten SikaDocument11 pagesEft - Makalah Pariwisata Kabupaten SikaRevening H. D. MauteyNo ratings yet

- Metercat 6.1.1.0 Release NotesDocument7 pagesMetercat 6.1.1.0 Release NotesCarlos Guzman BonifacioNo ratings yet

- Rtx3 Wireless Expansion V5.3: Reference and Installation ManualDocument24 pagesRtx3 Wireless Expansion V5.3: Reference and Installation ManualCatalin HoratiuNo ratings yet

- Checklist - Turning Client To Lateral or Prone PositionDocument3 pagesChecklist - Turning Client To Lateral or Prone PositionNorhaina AminNo ratings yet

- Test 05Document87 pagesTest 05MenaNo ratings yet

- Spiritual Giftings TestDocument11 pagesSpiritual Giftings TestKyl M. SrrcNo ratings yet

- When Key Employees ClashDocument4 pagesWhen Key Employees ClashRowell DizonNo ratings yet

- Nidek ICE-1200Document6 pagesNidek ICE-1200QulrafMongkonsirivatanaNo ratings yet

- Globalization More Harm Than GoodDocument4 pagesGlobalization More Harm Than GoodAnnisa Putri Sulistia100% (1)

- 10 Top Photography Composition RulesDocument6 pages10 Top Photography Composition Rulesaj4fall086050No ratings yet