Professional Documents

Culture Documents

Op-018. Design of Geogrid For Piled Embankment To Bs8006: Work Instructions For Engineers

Op-018. Design of Geogrid For Piled Embankment To Bs8006: Work Instructions For Engineers

Uploaded by

jinwook75Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Op-018. Design of Geogrid For Piled Embankment To Bs8006: Work Instructions For Engineers

Op-018. Design of Geogrid For Piled Embankment To Bs8006: Work Instructions For Engineers

Uploaded by

jinwook75Copyright:

Available Formats

Section: OP-018

G&P GEOTECHNICS SDN BHD

Revision: 0

Date: 12-11-2002

DESIGN OF GEOGRID FOR PILED EMBANKMENT TO BS8006 Page 1 of 4

WORK INSTRUCTIONS FOR ENGINEERS

LCL

Compiled by : _____________________________________

NHB

Checked by : _____________________________________

TYC

Approved by :_____________________________________

OP-018. DESIGN OF GEOGRID FOR PILED

EMBANKMENT TO BS8006

Section: OP-018

G&P GEOTECHNICS SDN BHD

Revision: 0

Date: 12-11-2002

DESIGN OF GEOGRID FOR PILED EMBANKMENT TO BS8006 Page 2 of 4

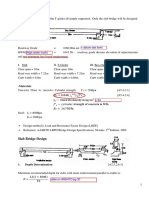

18.0 DESIGN OF GEOGRID FOR PILED EMBANKMENT TO BS8006

18.1. INTRODUCTION

1) Refer to Section 8.3.3 (Pg. 104) of BS8006.

2) Use the Partial Factors in Table 27.

3) Check for both Ultimate Limit States (ULS) and Serviceability Limit States (SLS).

4) The maximum limit state tensile load, Tr per metre ‘run’ :

(i) Along the embankment to transfer the vertical embankment load onto

pile caps, Trp (Sec. 8.3.3.6)

Tr = Trp

(ii) Across the embankment is the sum of load to transfer the vertical

embankment load onto pile caps, Trp (Sec. 8.3.3.6) & Tds to resist lateral

sliding (Sec. 8.3.3.7)

Tr = Trp + Tds

(iii) Need to check TD/fn ≥ Tr. TD is the design strength (Sec. 5.3.3), fn from

Table 3. For most critical case, fn = 1.1.

Two stages need to be checked, namely :

(a) During Construction

(b) Final (long term)

(iv) In total there is minimum of 4 Nos. of Tr obtained for each stage :

(v) Along the Embankment, Ultimate Limit State Tr

(vi) Along the Embankment, Serviceability Limit State Tr

(vii) Across the Embankment, Ultimate Limit State Tr

(viii) Across the Embankment, Serviceability Limit State Tr

18.2. Ultimate Limit States (ULS) should check for following :

1) Pile Group Capacity (Section 8.3.3.4 + Fig 67a)

2) Pile Group Extent (Section 8.3.3.5 + Fig 67b)

3) Vertical load shedding onto pile caps (Section 8.3.3.6 + Fig 67c)

4) Lateral sliding stability of the fill (Section 8.3.3.7 + Fig 67d + Fig 71)

5) Overall stability of piled embankment (Fig 67e)

Note: For Ultimate Limit States (ULS) the suggested strain to be used to be based on

Manufacturer’s strain at ultimate tensile strength (e.g. Fortrac is about 12% as from

Isochronous creep curves)

18.3. Serviceability Limit States (SLS) should check for following :

1) Excessive Stain in reinforcement (Fig 68a)

2) Settlement of Piled Foundation (Fig 68b)

18.4. Maximum allowable strain

Maximum allowable strain in reinforcement, emax (Section 8.3.3.10) ⇒ to control

differential settlement (Serviceability Limit State) :

Section: OP-018

G&P GEOTECHNICS SDN BHD

Revision: 0

Date: 12-11-2002

DESIGN OF GEOGRID FOR PILED EMBANKMENT TO BS8006 Page 3 of 4

1) The long term strain (due to creep) of reinforcement should be kept to minimum

⇒ A maximum creep strain of 2% over the design life should be allowed. MORE

CRITICAL.

2) 6% is the practical upper limit (Serviceability Limit State)

(Note : can check for “mushroom” effects)

18.5. Polymeric Reinforcement

For the design of Polymeric Reinforcement (e.g. Fortrac), the following clause shall be

followed :

1) Use Clause 5.3.3.3 (Pg 34) and Annex A (A.1.3)(Pg.142)

2) TD = TCR/fm or TCS/fm which ever is smaller :

TD = Design Tensile Strength

TCR = Extrapolated tensile creep rupture strength at the end of the

selected design life and at the maximum operational temperature.

(Annex A).

• The peak tensile creep rupture strength at the appropriate

temperature (Cl. 5.3.3.3)

• Generally to be used for Ultimate Limit State

• Can use 1million hours strength (e.g. for Fortrac use 60% of

the Short Term Strength)

TCS = Extrapolated tensile load which gives rise to a creep strain,

between the end of construction and the end of the design life,

which does not exceed prescribed serviceability limit strains.

• The average tensile strength based on creep strain

considerations at the appropriate temperature.

• Generally to be used for Serviceability Limit State

• Based on stress ratio in % of short-term strength obtained from

serviceability strain (e.g. 2% to 6% refer to Cl.8.3.3.10) (e.g. for

Fortrac about 18% of the short term strength)

3) Generally fm can be taken as 1.0

Section: OP-018

G&P GEOTECHNICS SDN BHD

Revision: 0

Date: 12-11-2002

DESIGN OF GEOGRID FOR PILED EMBANKMENT TO BS8006 Page 4 of 4

You might also like

- How To Write A Yardstick ReportDocument3 pagesHow To Write A Yardstick ReporthNo ratings yet

- 3.3.4 LRFD Composite DesignDocument34 pages3.3.4 LRFD Composite Designjosejuanmolina100% (1)

- Ford ABS Plating Spec.Document7 pagesFord ABS Plating Spec.Pieter100% (2)

- Tata Steel Designers ManualDocument163 pagesTata Steel Designers ManualEnger AlingasaNo ratings yet

- BDM Example 6 - 20180101Document23 pagesBDM Example 6 - 20180101mustafurade1No ratings yet

- Failure of Soil Nail WallsDocument13 pagesFailure of Soil Nail WallsAndy AcousticNo ratings yet

- WMM Density ExamplesDocument65 pagesWMM Density ExamplesV Venkata Narayana75% (8)

- SNT-2.01.08-99 - Seismic Code-EnDocument30 pagesSNT-2.01.08-99 - Seismic Code-EnNurul Izzah UttunggaNo ratings yet

- Section Design For Crack WidthDocument8 pagesSection Design For Crack WidthYou TubeNo ratings yet

- Ur I3 Rev.2 Jan 2023crDocument44 pagesUr I3 Rev.2 Jan 2023crhoficop838No ratings yet

- BRG Pad ExampleDocument16 pagesBRG Pad ExamplecarlosestayNo ratings yet

- AC Design - 2Document31 pagesAC Design - 2Linh GiaNo ratings yet

- Research Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDADocument4 pagesResearch Lab. Punjab, PWD.B&R Br. Patiala - Name of Road: - IGC BATHINDAAyush GoyalNo ratings yet

- Marine Standards IACSDocument8 pagesMarine Standards IACSAbhinav OjhaNo ratings yet

- T.9.1.4 Punching Shear To EUROCODE2: RAPT User ManualDocument16 pagesT.9.1.4 Punching Shear To EUROCODE2: RAPT User Manualtailieuxaydung2019No ratings yet

- Engineering Bulletin SpecimenDocument34 pagesEngineering Bulletin SpecimenNidDouNo ratings yet

- Construction Steel GirderDocument11 pagesConstruction Steel GirderAek JayNo ratings yet

- Grade of Z Chain N KGF 1 37.5d 3.82d 2 42.5d 4.33d 3 47.5d 4.84d Unit of D MM MMDocument1 pageGrade of Z Chain N KGF 1 37.5d 3.82d 2 42.5d 4.33d 3 47.5d 4.84d Unit of D MM MMstrijelavremenaNo ratings yet

- Surface Integrity Aspects in Gear ManufacturingDocument11 pagesSurface Integrity Aspects in Gear ManufacturingEko coyNo ratings yet

- Burj Vista F1 12 Panel Design Rev0 22feb16Document71 pagesBurj Vista F1 12 Panel Design Rev0 22feb16Kilaru HareeshNo ratings yet

- Ysd P02 0208 Ar SJF CD F0005 BDocument47 pagesYsd P02 0208 Ar SJF CD F0005 BChandra MohanNo ratings yet

- ACEGrid Brochure HR Final 6Document1 pageACEGrid Brochure HR Final 6Anonymous 0x2pwMCWgjNo ratings yet

- Elastomeric Bearing 1 PDFDocument9 pagesElastomeric Bearing 1 PDFSuresh YedureswaramNo ratings yet

- Elastomeric Bearing 1Document9 pagesElastomeric Bearing 1Anonymous jLLjBdrNo ratings yet

- BS-EN1992-1-1 - E - 2004 GENERAL RULES FOR BUILDING (Euro Code 2) (Page 33 +8MPa) - 56Document1 pageBS-EN1992-1-1 - E - 2004 GENERAL RULES FOR BUILDING (Euro Code 2) (Page 33 +8MPa) - 56Anh TranNo ratings yet

- Latest Amendments in IRC Codes 2Document24 pagesLatest Amendments in IRC Codes 2Pravin GundeliNo ratings yet

- Bearing Pad Design ExampleDocument16 pagesBearing Pad Design ExampleAhirul Yahya100% (1)

- Ws 38 BatteryDocument5 pagesWs 38 BatteryBjorn SchelfautNo ratings yet

- IS - 4923 - 15052018 AmendmentDocument6 pagesIS - 4923 - 15052018 Amendmentnathaji shivram chavanNo ratings yet

- 5 Design Loads: 5.2 Maxunum CombinationDocument2 pages5 Design Loads: 5.2 Maxunum CombinationAnonymous ufMAGXcskMNo ratings yet

- 12303-1987 Design of RCC HingesDocument10 pages12303-1987 Design of RCC HingesAnand EPNo ratings yet

- Bearing DesignDocument24 pagesBearing DesignPrabhakaran KarunanithiNo ratings yet

- Chapter 4.0 - Serveciability and Durability PDFDocument43 pagesChapter 4.0 - Serveciability and Durability PDFfhatiha atikaNo ratings yet

- Selection of FenderDocument11 pagesSelection of FenderOkondu ChieduNo ratings yet

- HW6 201Document4 pagesHW6 201Y7ya73No ratings yet

- Salzburg2020 Brodin8BFINALDocument9 pagesSalzburg2020 Brodin8BFINALRajish RNo ratings yet

- Road NR32 Geosynthetics Design Using BS 8006 2010Document26 pagesRoad NR32 Geosynthetics Design Using BS 8006 2010SyedNo ratings yet

- Propeller Fitting ABSDocument7 pagesPropeller Fitting ABSAngel DavidNo ratings yet

- Saddle Stress CalculationsDocument8 pagesSaddle Stress CalculationsMuthuNo ratings yet

- BALLAST SpecificationsDocument39 pagesBALLAST SpecificationsRajaram KulapakaNo ratings yet

- 60 Steam Turbine ManagementDocument25 pages60 Steam Turbine ManagementLTE002100% (1)

- End Block Design AidDocument6 pagesEnd Block Design AidAhsan KhanNo ratings yet

- LT 01 Sxrl-t1 Sen Aip v1Document1 pageLT 01 Sxrl-t1 Sen Aip v1MauroNo ratings yet

- 2019 Winter DSS 5G - M - 17505 - CEDocument29 pages2019 Winter DSS 5G - M - 17505 - CESidd SuryaNo ratings yet

- BALLAST-spec-Nov 2014Document39 pagesBALLAST-spec-Nov 2014princebh3No ratings yet

- T.7.7.6 Shrinkage Curvature: RAPT User ManualDocument16 pagesT.7.7.6 Shrinkage Curvature: RAPT User Manualtailieuxaydung2019No ratings yet

- Staad Training - Module 3 - Malaybalay City June 2011 - 2Document73 pagesStaad Training - Module 3 - Malaybalay City June 2011 - 2Joseph Cloyd L. Lamberte83% (6)

- Design and Analysis of Ground Grid System For Substation Using e Tap Software and FDM Code in Matlab IJERTV7IS100032Document4 pagesDesign and Analysis of Ground Grid System For Substation Using e Tap Software and FDM Code in Matlab IJERTV7IS100032Sivachandran RNo ratings yet

- WD-03-misc-86 (Rev. 4)Document16 pagesWD-03-misc-86 (Rev. 4)ROH BKSCNo ratings yet

- WSS M8P16 BDocument16 pagesWSS M8P16 Berik0007No ratings yet

- Design of A Slab Bridge On Abeya River A PDFDocument13 pagesDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- Tank 14m x12 M HeightDocument60 pagesTank 14m x12 M Heighthgag selim100% (1)

- 17505-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Document28 pages17505-2019-Winter-Model-Answer-Paper (Msbte Study Resources)Jose Javier JulioNo ratings yet

- Ballast Spec Nov 2014Document39 pagesBallast Spec Nov 2014Sarada DalaiNo ratings yet

- 3.2.1-LRFD Deck DesignDocument17 pages3.2.1-LRFD Deck DesignSachin SithikNo ratings yet

- Analysis Report of Residential BuildingDocument41 pagesAnalysis Report of Residential BuildingSudip Ghimire50% (2)

- Agenda Item: 650-569: Title: Shell Design VDP Method, Variable Corrosion Date: ContactDocument4 pagesAgenda Item: 650-569: Title: Shell Design VDP Method, Variable Corrosion Date: ContactMuhammad ChairulNo ratings yet

- Accropode 2Document0 pagesAccropode 2Raed Naim KhammashNo ratings yet

- Min Max Steel Reinforcement For FoundationDocument1 pageMin Max Steel Reinforcement For FoundationRodel, Jr. NatividadNo ratings yet

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingFrom EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNo ratings yet

- Myths and Common Problems Discovered in Geotechnical Forensic EngineeringDocument66 pagesMyths and Common Problems Discovered in Geotechnical Forensic Engineeringjinwook75No ratings yet

- T C H B E I G: WO ASE Istories of Asement Xcavation With Nfluence On RoundwaterDocument19 pagesT C H B E I G: WO ASE Istories of Asement Xcavation With Nfluence On Roundwaterjinwook75No ratings yet

- (매우중요) KL 11Document87 pages(매우중요) KL 11jinwook75No ratings yet

- Performance of Reinforced Soil Wall Supported On Stone ColumnsDocument9 pagesPerformance of Reinforced Soil Wall Supported On Stone Columnsjinwook75No ratings yet

- (매주중요) 2003 - 06Document13 pages(매주중요) 2003 - 06jinwook75No ratings yet

- (매우중요) SL 04Document69 pages(매우중요) SL 04jinwook75No ratings yet

- Case Studies of Support of Open Excavations and Distressed Retaining Walls in MalaysiaDocument33 pagesCase Studies of Support of Open Excavations and Distressed Retaining Walls in Malaysiajinwook75No ratings yet

- Specification For Permanent Ground Anchor For Retaining StructuresDocument21 pagesSpecification For Permanent Ground Anchor For Retaining Structuresjinwook75No ratings yet

- Design, Installation and Performance of Jack-In-Pipe Anchorage System For Temporary Retaining StructuresDocument8 pagesDesign, Installation and Performance of Jack-In-Pipe Anchorage System For Temporary Retaining Structuresjinwook75No ratings yet

- Design and Construction of Excavation Works For Klang Valley Mass Rapid Transit Underground Station at Cochrane, Kuala Lumpur, MalaysiaDocument4 pagesDesign and Construction of Excavation Works For Klang Valley Mass Rapid Transit Underground Station at Cochrane, Kuala Lumpur, Malaysiajinwook75No ratings yet

- Soil Nailing For Slope Strengthening: Liew Shaw-ShongDocument9 pagesSoil Nailing For Slope Strengthening: Liew Shaw-Shongjinwook75No ratings yet

- Geotechnical Solutions For Unstable Rock Mass at Sg. Buloh AreaDocument8 pagesGeotechnical Solutions For Unstable Rock Mass at Sg. Buloh Areajinwook75No ratings yet

- Construction Control Chart Developed From Instrumented Trial Embankment On Soft Ground at Tokai of Kedah, MalaysiaDocument8 pagesConstruction Control Chart Developed From Instrumented Trial Embankment On Soft Ground at Tokai of Kedah, Malaysiajinwook75No ratings yet

- Performance of Soil Nailed Wall and Ground Anchor As Retaining Structure For A Drill & Blast Tunnel PortalDocument4 pagesPerformance of Soil Nailed Wall and Ground Anchor As Retaining Structure For A Drill & Blast Tunnel Portaljinwook75No ratings yet

- Specification For Instrumentation and Monitoring of Reclamation WorksDocument13 pagesSpecification For Instrumentation and Monitoring of Reclamation Worksjinwook75No ratings yet

- Deep Excavation For Basement Via Soil Nailing Method: Chow, Chee-Meng & Tan, Yean-ChinDocument19 pagesDeep Excavation For Basement Via Soil Nailing Method: Chow, Chee-Meng & Tan, Yean-Chinjinwook75No ratings yet

- Geotechnical Engineering Challenges For Highway Design and Construction On Soft GroundDocument80 pagesGeotechnical Engineering Challenges For Highway Design and Construction On Soft Groundjinwook75No ratings yet

- Ground Treatment Design For 200km Electrified Double Tracks Railway Project at Northern Peninsular MalaysiaDocument15 pagesGround Treatment Design For 200km Electrified Double Tracks Railway Project at Northern Peninsular Malaysiajinwook75No ratings yet

- (중요) 2007 07Document8 pages(중요) 2007 07jinwook75No ratings yet

- Analysis of Geotechnical Problems With AbaqusDocument21 pagesAnalysis of Geotechnical Problems With Abaqusajeshsairam31620% (1)

- Atterberg Limits. DSDocument18 pagesAtterberg Limits. DSGhulam Quadir KhanNo ratings yet

- Varying Peat in Sarawak and Some Geotechnial PropertiesDocument13 pagesVarying Peat in Sarawak and Some Geotechnial PropertiesSen HuNo ratings yet

- 6-Petroleum Equipment PDFDocument16 pages6-Petroleum Equipment PDFFilipe Gonçalves FerreiraNo ratings yet

- Basement ConstructionDocument23 pagesBasement ConstructionMuskaan ChowdharyNo ratings yet

- Soil Deposits and Grain Size AnalysisDocument23 pagesSoil Deposits and Grain Size AnalysisMary Lourielle0% (1)

- Geotechnical Engineering I - Soil Mechanics Quiz 1 Batch 2021-2022 INSTRUCTION (S) : Select The Correct Answer For Each of The Following QuestionsDocument5 pagesGeotechnical Engineering I - Soil Mechanics Quiz 1 Batch 2021-2022 INSTRUCTION (S) : Select The Correct Answer For Each of The Following QuestionsCarjez LoveNo ratings yet

- 12 M High Retaining Wall Design For Seismic LoadingDocument27 pages12 M High Retaining Wall Design For Seismic Loadingaminjoles0% (1)

- Engineering Standard: IPS-E-CE-120Document30 pagesEngineering Standard: IPS-E-CE-120farzadkNo ratings yet

- Evaluation of The Remoulded Shear Strength of Offshore Clays and Application To Pipeline-Soil and Riser-Soil InteractionDocument45 pagesEvaluation of The Remoulded Shear Strength of Offshore Clays and Application To Pipeline-Soil and Riser-Soil Interactionmarius_onoNo ratings yet

- Correlation Soil Properties PDFDocument31 pagesCorrelation Soil Properties PDFBobby SetiawanNo ratings yet

- Geotechnical Failure Investigation of A Reinforced Soil Wall and Remedial Work DesignDocument11 pagesGeotechnical Failure Investigation of A Reinforced Soil Wall and Remedial Work DesignRenugopalNo ratings yet

- Earth Retaining Structures-1 PDFDocument27 pagesEarth Retaining Structures-1 PDFSury100% (1)

- Lesson Plan: Veer Surendra Sai University of Technology, BurlaDocument3 pagesLesson Plan: Veer Surendra Sai University of Technology, Burlasanthi saranyaNo ratings yet

- Curriculum Vitae - Luhut Fredianto.PDocument2 pagesCurriculum Vitae - Luhut Fredianto.PyanuarNo ratings yet

- Report - Geotechnical Investigation 2010 PDFDocument41 pagesReport - Geotechnical Investigation 2010 PDFNhieu DVNo ratings yet

- Basement FoundationDocument8 pagesBasement FoundationSayaliNo ratings yet

- A24 Appendix A Construction Risk Register PDFDocument6 pagesA24 Appendix A Construction Risk Register PDFHammad AhmedNo ratings yet

- BH 16 14 11618Document3 pagesBH 16 14 11618hamefNo ratings yet

- Abdifatah Jama: Work ExperienceDocument5 pagesAbdifatah Jama: Work ExperienceMuthomi MunyuaNo ratings yet

- Development and Application of The Coal Mine Roof Rating (CMRR)Document15 pagesDevelopment and Application of The Coal Mine Roof Rating (CMRR)Lina CardonaNo ratings yet

- Mid Term Exam With Solutions PDFDocument15 pagesMid Term Exam With Solutions PDFKristina Ormacido100% (3)

- CV - Ilham Kalami (Eng)Document2 pagesCV - Ilham Kalami (Eng)m.ilham KalamiNo ratings yet

- 12 Types of Civil Engineering BranchesDocument4 pages12 Types of Civil Engineering BranchesfeaponteNo ratings yet

- Study of Deep Foundation Performances by Frustum Confining Vessel (FCV)Document10 pagesStudy of Deep Foundation Performances by Frustum Confining Vessel (FCV)DanNo ratings yet

- Well Intervention Pressure Control Syllabus - Level 3 4Document52 pagesWell Intervention Pressure Control Syllabus - Level 3 4ryaneschultzhotmail.comNo ratings yet