Professional Documents

Culture Documents

Supplier Audit Checklist PDF

Supplier Audit Checklist PDF

Uploaded by

Barney ParadoxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supplier Audit Checklist PDF

Supplier Audit Checklist PDF

Uploaded by

Barney ParadoxCopyright:

Available Formats

Issue Date:

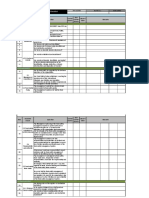

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 1 of 14

This supplier quality and food safety audit questionnaire shall be used to assess existing and

potential supplier’s/sub-contractor’s capabilities in relation to all products supplied or to be

supplied.

Questions Answers

Supplier’s Name

Full Postal Address

Manufacturer

Main Telephone Number

Main Fax Number

Main e-mail address

Technical Contact Name, Contact Number

and e-mail

Sales Contact Name, Contact Number and e-

Production Contact Name, Contact Number

and e-mail

Emergency Contact, Telephone Number, and

Company Profile and Management Y/N/ Comments/Answers

Systems

Is there a site plan?

Enclose/attach a copy of the site layout plan

State the number of personnel employed in

a) Production

b) Technical

c) Quality Assurance/Control

d) Hygiene and Cleaning

Are there sufficient resources to ensure that all

legal, standards and customer requirements can be

met if not exceeded?

Is sufficient training available to all personnel

involved in production, technical, food safety,

quality and hygiene to ensure that all legal,

standards and customer requirements can be met

if not exceeded?

Is there a nominated person responsible for

product quality, product recall, traceability, food

safety and hygiene? If so, who?

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 2 of 14

What is the means by which relevant personnel

keep abreast of legislative, scientific and technical

developments and codes of practice, and how do

they implement these as applicable?

Does the company have in place and documented

a Quality Policy, and has this been communicated

to staff on Induction?

Does the company have in place and documented

a Food Safety Policy, and has this been

communicated to staff on Induction?

Does the company have in place a documented

Ethical Trading Policy, and has this been

communicated to Staff on Induction?

What HACCP pre-requisites have been considered

and/or are in place?

Does the Supplier have a documented HACCP

system in place that complies with the principles

outlined in the Codex Alimentarius?

Does the Supplier’s HACCP include consideration

of microbiological vulnerability?

Does the Supplier’s HACCP include potential for

contamination with foreign matter?

Is fraud and mislabelling of raw materials

considered in the HACCP plan?

Does the Supplier’s HACCP include Allergen

segregation, handling and contamination risks and

controls?

Are food safety /HACCP risk assessments and

food safety/HACCP flow charts available for all

materials supplied and do the flow charts show all

Critical Control Points or CCPs? If yes, provide

HACCP flow charts.

Is there a multi-disciplinary HACCP team and is at

least the team leader appropriately qualified?

Describe its composition and detail the relevant

qualifications held.

Are records of HACCP meetings kept that show

that the HACCP team reviews HACCP studies and

is aware of and considers the implications of all

product and process developments and changes

that may affect the quality, safety and legality of the

product supplied?

Are all food handlers trained against HACCP and

CCPs and are records of such training retained?

Are there verification records for the HACCP e.g.

challenge tests for thermal processing

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 3 of 14

Site Fabrication and Services Y/N Comments/Answers

Site Perimeter

Is the site located in an area free from

objectionable odours, smoke, dust and other

contaminants?

Is the perimeter of the site secure and the

boundary intact, clean, tidy and free from excessive

uncontrolled vegetation, to prevent

a) uninvited visitors/unauthorised personnel

b) malicious damage

c) the threat or risk of contamination eg from

pests?

Is the building exterior free from structural damage

that may allow the ingress of pests?

Factor design, structure and layout

What is the age of the building (production/

warehouse sites)?

Is the factory layout and are the product and

personnel flows designed to reduce the potential

for contamination?

Is the fabric of the manufacturing facility maintained

in a good condition, so that it does not pose a

contamination risk to material supplied (smoke

dust, pests)

Does the siting of all plant and equipment within

production allow adequate access for cleaning,

maintenance and inspection purposes?

Are all production areas and associated service

areas e.g. maintenance physically separated from

each other?

Is there adequate space for cooling, refrigeration

and freezing?

Is mixing, blending and homogenising equipment

of a type which does not allow food to come into

direct contact with seals and bearings?

Are pumps designed as to be readily dismantled

for cleaning and of a suitable design?

Walls – Internal (Processing and

Warehousing)

Is there at least a 5Ocm distance between the

walls and plant, equipment, racking and materials

to allow access for cleaning, pest control,

maintenance and inspection?

Is there sealing and coving between walls, floors

and ceilings for easy cleaning?

Are all surfaces light in colour, smooth, easily

cleaned and impermeable to liquids?

Are the walls free from unsealed panelling,

exposed cavities and damage?

Are fitments, attachments and notices kept to a

minimum to reduce debris traps? These must be

wood free and staple free in production areas.

Ceilings and Overheads

Are all ceilings and overheads (girders, cables,

conduits) smooth, easily cleaned, in good condition

and free from dirt, debris, flaking material dust,

condensation and mould?

Are all external openings screened and not directly

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 4 of 14

over exposed material?

Are stairs, platforms, ladders and chutes situated

and constructed so as not to contaminate food.

Chutes should have inspection and cleaning

hatches.

Floors

Are all floors suitable for the traffic of goods? Are

they water-proof, non-absorbent, washable, non-

slip and constructed of non-toxic materials,

without crevices. Confirm the surface type.

Are all the floors in good repair and free of broken

and loose surfaces and standing pools of water?

Are junctions of floors and walls coved and

impermeable to liquids, where applicable?

Where applicable, are all drains of a suitable

structure, capacity and slope, and do they have

adequate removable grids and debris traps which

are cleaned regularly?

Are any drains pest guarded that could give access

to the inside of the building?

Doors and Windows

Can all doors be closed properly without any gaps

to prevent pest ingress and if doors open to the

exterior are they suitably screened? Are doors self

closing?

Are all the doors leading to and from the production

area of a plastic or metal construction?

Are all production and warehouse areas free from

external windows? If no, are all windows suitably

screened and logged in the glass register?

Are screens easily removable for cleaning

Are window sills, if present, sloped so as not to be

used as shelves

Ventilation

Are all areas suitably ventilated to maintain

reasonable operating temperatures and humidity?

Does ventilation remove excessive steam, heat,

condensation, dust and contaminated air?

Do the ventilation outlets exhaust outwards and

away from production areas and have screens to

prevent pest ingress where appropriate? The

direction of airflow should never be from a dirty

area to a clean area.

Are all ventilators, fans, and filters cleaned and/or

serviced at regular intervals, and records retained?

Lighting

Are all light fittings protected with a cover that will

retain any breakages and/or of a shatterproof

nature? Are they featured in the glass register?

Is all lighting clean and of a level adequate for the

operation in that area, particularly where material is

inspected? Lighting should not alter colours and

should not be less than: 540 lux at points for close

examination; 220 lux in workrooms; 110 lux in other

areas.

Maintenance

Is there a risk assessed preventative breakdown

and maintenance register?

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 5 of 14

Are all lubricants carefully controlled and suitable

for use on food contact machinery (ie food grade)?

Are there specifications and data sheets held for

food lubricants and are these jointly approved with

the Supplier?

Is all electrical trunking designed to prevent

infestation whilst allowing infestation treatment if

required?

Are plant and equipment inspected after

maintenance works and its re-use authorised by a

competent person?

If the maintenance area adjoins warehousing

and/or production areas, is it suitably physically

separated, secure and does it have a swarf mat at

its entrance/exit to capture foreign contaminants off

footwear?

Are temporary repairs controlled by Management

and only effected with the use of suitable

materials?

Water

What is water used for on site?

Is there an appropriate water distribution plan and

risk assessment in place?

Is water used for cleaning and welfare subject to a

water sampling programme and therefore regular

testing? If so, by whom, and what accreditation do

they hold?

Is food grown in areas where water used in

irrigation might constitute a health hazard? Are

methods of harvesting and production hygienic?

Is ice in contact with the product and is it of suitable

quality?

Is steam used and is it of suitable quality?

Is there an efficient effluent system that is in good

repair?

How is recirculated water treated?

Waste Management Y/N Comments/Answers

Is the site waste well managed, does it meet legal

requirements?

Is there a secure and segregated waste

management area on site that is maintained in a

clean, tidy and hygienic state at all times?

Are external waste bins at an appropriate distance

from the building and do they have lockable lids?

Are waste bins leak-proof, constructed of

impervious material, kept clean, closed properly

and emptied frequently?

Are raw food materials protected from

contamination by human, animal, domestic,

industrial and agricultural wastes

Are raw materials and finished products that are

not fit for human consumption adequately

controlled ?

Are bi-products or rework suitably controlled and

removed daily?

Are wastes (eg cardboards, plastics, metals,

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 6 of 14

hazardous etc) streamed and recycled as

legislated and/or as feasible and appropriate?

Housekeeping, Cleaning and Hygiene Y/N Comments/Answers

Who is responsible for housekeeping, cleaning

and hygiene management on site and are they

suitably competent and independent from

production?

Are disinfection facilities for washing implements

constructed of corrosion resistant materials and

easy to clean?

Are high standards of cleaning maintained

internally and externally and processing areas free

of loose foreign objects and debris at all times?

Is there a clean- as- you- go policy in place? Are

equipment and utensils cleaned and disinfected at

the end of the shift?

When are the walls, floors and drains cleaned?

Is there thorough rinsing with water after cleaning?

Is there a hygiene manual and/or are documented

cleaning procedures, schedules and records in

place and retained? Do cleaning records comply

with the schedule and are they signed and dated?

Who on site is responsible for the effectiveness of

the cleaning and hygiene procedures?

Is the cleaning of the factory contracted out?

Is all cleaning equipment and cleaning materials

food grade, free from phenolics and wood, non

frayable, appropriately stored and fit for purpose?

Is a colour coding system used for cleaning

equipment? If so please describe. Containers

previously used for toxic materials should not be

used for food.

Are specifications and material safety data sheets

to hand for all cleaning materials used

What is frequency is high level cleaning and who

carries it out? When was it last done?

Personnel Hygiene

Is there a Hygiene Policy in place? If so, please

attach a copy.

Do documented personnel hygiene standards

cover jewellery, smoking, eating and drinking, hair

covering, make-up and nail polish, perfumes and

aftershaves, personal belongings, etc and are they

adopted by all employees, including engineers,

visitors and contractors?

Is there a jewellery policy? Describe or attach.

Does this allow for the right to wear religious

jewellery in which case is there a start and end of

shift registration and inspection procedure in

place?

Is there a smoking policy? Describe or attach

What protective work wear is provided? If so,

what? Is it light coloured, with no outside pockets

or buttons, and/or metal detectable, as applicable?

Who is responsible for laundering the work wear

and is the laundry, if external, accredited and/or

subject to regular audit?

How frequently is the protective work wear

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 7 of 14

changed?

Is suitable and sufficient protection for breathing in

place as applicable to the products being handled?

Is a separate changing room available and are

personal lockers provided for personal effects

Do all personnel entering production areas wash

their hands using hot water, un-perfumed

bactericidal soaps and do they dry them suitably?

Are taps non-hand operated?

What type of hand drying facilities are available? If

paper towels are used are there adequate

dispensers and receptacles nearby?

Are meals and refreshments consumed in a

specified area away from the processing area and

are such areas kept clean and tidy and subject to

internal audit?

How many toilets are available on site and is this

number of toilet facilities adequate for the number

of employees?

Are the toilets kept clean and hygienic at all times

and are “Now wash your hands” signs clearly

displayed? Who cleans them and how often?

Do all staff complete a medical questionnaire prior

to their appointment that is assessed by a

competent person to ensure their suitability for

working in a food processing environment?

Is there a return- to- work following illness

procedure, and does such screening cover

Typhoid and Paratyphoid Fever (Salmonella) and

VTEC (E.coli), other food poisonings and related

symptoms (eg sickness and diarrhoea) etc

Do medical screening protocols include and are

they applied to temporary staff, visitors and

contractors?

How are sores and cuts controlled?

Are all sores and cuts covered with blue metal

detectable water proof dressings and are these

dressings accounted for?

Hygiene and Food Safety Training

Is the hygiene policy adequate to prevent

contamination of food and does it cover visitors

and contractors?

Do all food handlers receive appropriate induction

and on- the- job basic food hygiene and food

safety training , inc. CCPs?

Are all relevant food handling and processing staff

informed of the hazards of Allergens

Are gloves used and if so are they maintained in a

good clean condition?

Pest Control Y/N Comments/Answers

What pests does the control programme cover?

Is there a documented pest control management

programme in place

Has the pest control proofing in place on site been

recommended by appropriately qualified persons?

If so, who? Are they registered?

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 8 of 14

Is pest control externally managed? If yes, who is

the service provider/contractor and what type of

service is provided?

If internally managed, who is responsible and what

training have they received?

Are there Insectocutors/EFKs on site and what

pests are controlled by these?

Are there Pheromone traps on site and what pests

are controlled by these?

Are there Bait Boxes on site and what pests are

controlled by these

Are there pest screens on site and what pests are

controlled by these?

Is all proofing robust and well maintained?

Are records kept of infestation inspections, and are

all infestation issues followed up and subject to

corrective action and record keeping?

Are treatments applied documented and details of

the chemicals used described? Are Control of

Substances Hazardous to Health (COSHH) data

sheets held for these chemicals?

Are routine baits in the production area non-toxic?

If pesticides have to be used are they stored in a

locked room away from production?

Have there been any recent problems of

infestation in the last 12 months? If so, what?

Is fumigation carried out regularly? If ‘yes’, at what

intervals, with which chemical/s, and complying

with which regulation?

Is fogging carried out? If ‘yes’ how frequently?

Detail the chemical/s used for fogging.

Process, Quality and Food Contamination Y/N Comments/Answers

Controls

Is processing supervised by technically competent

personnel?

What start up controls are in place? Do these take

into account segregation of allergenic materials?

What in- process checks (quality, food safety) are

carried out?

Are there documented control procedures at

various stages of processing in place and are

these reviewed at appropriate intervals?

Are there documented systems for identifying and

managing process scrap and reject work?

Are all process non-conformances and corrective

actions fully documented?

Are all process steps performed without

unnecessary delay to avoid deterioration or

development of pathogens?

Is rough treatment of containers avoided to

prevent contamination?

Raw Material Checks

Are raw materials of high quality? Raw materials

destined for the production of food for infants

and children should be of high hygienic

conditions.

Food of animal origin should only be derived from

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 9 of 14

healthy stock.

Are all raw materials protected from pests, micro,

chemical and physical contamination?

Are all raw materials checked on intake for the

presence of foreign matter contamination

considered to be objectionable and injurious?

Are all raw materials micro tested and are they

positive released?

Is cross contamination controlled?

Is all equipment in contact with raw materials

thoroughly cleaned and disinfected? Is it separate

from finished goods equipment and colour coded?

Does de-boxing and/or de-bagging take place in a

room segregated from the processing area?

Wood and Cardboard

Is wood used in the production areas? If so, where

and for what?

Where wooden pallets used are used, do they

have food grade “liners” on top of the pallets

beneath the materials placed on them? If no, are

plastic pallets used?

Is there a cardboard policy in the production area?

If ‘yes’ please describe what this is or attach it

Glass, Hard Plastics and Ceramics

Is there a glass, hard plastics and ceramics policy

and breakage procedure? If ‘yes please attach

copies.

Is the use and audit of glass, hard plastic and

ceramics risk assessed, and are audit records

retained?

Magnets

What type of magnets is used?

Is the size and positioning of magnets in

processing determined by an expert ?

What is the cleaning frequency of magnets, and

how their findings investigated?

Are magnets subject to routine maintenance and

calibration? If so, by whom?

Sieves

Are sieves used in the production process? If so

state the type and range of mesh sizes employed?

At which point on the machine are the sieves

located?

Are sieve checks made and records of these

retained?

Are all sieve failures investigated and corrective

actions identified and implemented before the

material/s affected leave the Supplier’s control?

Metal Detectors

Are all finished products metal detected? If so, at

what stage in their processing does metal

detection occur?

What is the sensitivity of the metal detector/s

used?

Are all metal detectors regularly maintained,

serviced and calibrated? If so, by whom and to

what frequencies?

Are all metal detection failures investigated and

corrective actions identified and implemented

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 10 of 14

before the materials affected leave the Supplier’s

control?

Calibration

What equipment is calibrated?

Is there a documented system of calibrating

equipment, ie. scales, metal detectors, and are

such devices calibrated back to national

standards?

Are check weights to ensure balances and scales

are measuring correctly and if so at what

frequency?

Is all measuring equipment used to monitor CCPs

eg scales, metal detectors of a known accuracy

and calibrated and is the calibration status of such

equipment indicated eg by the last or next

calibration date?

Is calibration work carried out at such a frequency

that it enables the material to still be under the

Supplier’s control if issues are found?

Packaging

Is the packaging area clean and tidy?

Is all packaging and labelling used food grade and

tamper evident as applicable?

Is all packaging traceable back to origin and

inspected prior to use to ensure that it is clean?,

Are finished material packaging checks carried out

to ensure labelling and coding is correct and are

records kept of the same?

Is only packaging material required for

immediate use kept in the packing or filling area?

Is the packaging being used correct, GMO,

organic, storage instructions, weight, product type

etc.

Are the fill levels correct?

Are the BB dates correct and legible? Is the batch

code visible, correct and easily traceable? Is each

batch checked after filling? Are defects removed?

Warehousing Y/N Comments/Answers

Are all warehouses used of a design to promote

good housekeeping?

Are materials products stored and handled in such

a way as to preserve quality and food safety and

prevent contamination?

Is all stock suitably labelled and within its shelf life

and are Allergenic materials suitably segregated?

Is an appropriate stock rotation system in place eg

FIFO?

Are external contractors used for storage and if so

are standards including hygiene agreed with them

and audited accordingly?

Transport Y/N) Comments/Answers

What checks are carried out on raw material

delivery vehicles?

Are all goods transported by approved service

providers? If so, who?

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 11 of 14

Is there a documented and agreed service

agreement in place which details agreed hygiene

requirements?

Are all vehicles used for the transport of raw

materials and packaging and finished products

suitable for the purpose of carrying food materials

and maintained in good repair?

Are all vehicles checked for hygiene and

cleanliness prior to loading and screened from

adverse weather conditions during the loading

process? Are records of inspection kept?

Is wood is used during transportation eg pallets,

container back boards. If so is it appropriately

certified and stamped from a Phytosanitary

perspective, and has its use been approved?

Supplier Evaluation and Assurance Y/N Comments/Answers

Where appropriate, does the Supplier have a

Supplier Evaluation programme in place ie do they

assess and approve their suppliers eg by

a) third party accreditations

b) physical audit

c) self-audit questionnaire

d) historical performance

a) other means, etc?

Is there a risk assessed and documented supplier

audit schedule? Is there information covering the

whole supply chain?

Are supplier audits conducted against a

documented technical protocol and are audit

reports available for inspection?

Who carries out the supplier audits and what level

of competency, experience and/ or professional

qualifications (as applicable) do they hold?

Are there agreed specifications with suppliers of

raw materials, packaging, food lubricants, plant

and equipment etc., and are they jointly agreed,

signed and dated?

Is there a documented goods – in systems in place

and are records kept of goods in inspections?

What tests are carried out on incoming products to

ensure conformance to specification and where

non-conforming material is received is this referred

to the supplier’s supplier for corrective action?

Are raw materials positively released to Production

and on what basis i.e. microbiologically, physical

inspection, etc? Describe

Crisis Management, Emergency Y/N Comments/Answers

Procedures, Product Recall, Traceability,

Certification

Is there a Crisis Management/Emergency/Product

Recall procedure in place which is subject to

regular testing? State the date of the last test.

Are there robust measures in place to ensure that

in the event of disruptions to your operations you

would still be able to continue to supply?

Are there robust traceability of all materials from

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 12 of 14

grower to despatch to, and is this system internally

tested on a regular basis? State the date of the

last test.

Are certificates of analysis issued, or certificates

of conformity for all finished products supplied

Are there specifications for each ingredient

supplied. If yes check they are signed by both

parties.

Is there a unique internal product coding system

for all raw materials and the corresponding

finished goods?

Describe the product coding and how it works.

Internal Audit Y/N Comments/Answers

What is the frequency of internal audits and are

they subject to schedule, procedure, non

conformance corrective action and record keeping

What is the frequency of internal audits and are

they subject to schedule, procedure, non-

conformance corrective action and record keeping,

to demonstrate continuous improvement?

Who carries out internal audits and what levels of

competency / professional qualifications (if any) do

they hold?

Allergens Policy Y/N Comments/Answers

Is there an Allergen policy? Append a copy and/or

explain what it covers and how it works.

Is the manufacturing/supplying site allergen free?

Do you and/or your suppliers handle allergens, if so

name them and describe control measures to

prevent cross contamination

Have the supplier’s suppliers got a documented

allergen policy? If ‘yes’ attach a copy.

Organic products

Are all raw materials and processing aids used

organic. Check documentation.

Is an organic certificate available for each product

manufacture ?

GMO and GM Derivatives Y/N Comments/Answers

Note: see appendix B for classification of

potential secondary GM derivatives,

fermentation, and biotechnology products).

Are Genetically Modified Materials handled on the

suppliers processing site?

If ‘yes’ state procedures for use and storage i.e.

segregation and clearance.

Processing Aids By your In your processing

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 13 of 14

processor operations

A processing aid is a product, often a chemical,

which is used in the process that has no particular

function in the finished product. This can include

anti-caking/free flow agents, bleaching and/or

chlorination chemicals. Are any processing aids

used for product supplied?

Pesticides Y/N Comments of the auditor

Is there a Pesticide policy, and is pesticide residue

testing carried out on all materials supplied

a) Provide a policy statement

b) State the testing frequency

c) State for which pesticides testing is carried

out (or attach documentation which

describes this)

d) Are pesticide test results satisfactory?

e) Provide examples of results available?

f) State which laboratory carries out such

testing and its accreditation

Product Analysis Y/N Comments of the auditor

Are finished products positively released for

despatch?

What parameters / criteria is material positively

released against?

Is quality testing performed to the required standard

by suitably competent, trained and experienced

personnel?

Are legible and accurate records (IT and/or hard

copy) of all quality tests and batch retention

samples retained in appropriate containers in clean,

dry conditions for at least the shelf life of the

material plus two years?

What laboratory analyses on finished products

supplied are carried out? What is the sampling

regime? Is the method statistically validated?

Are QC tests carried out on all relevant criteria as

described in the material specifications for all

materials supplied?

What is the minimum shelf life of the material as

supplied?

File Location Prepared By: Approved By:

Issue Date:

Supplier Audit Questionnaire 10.06.2013

Issue No: 1

Page 14 of 14

Which organisms are tested for and who by?

Specify the testing laboratory and its accreditation?

If tested on site is the pathogen lab separated from

production?

Does the supplier carry out contaminants testing

applicable to products supplied? Specify the testing

laboratory and its accreditation, and the frequency

and type of the testing undertaken?

What scheme or schemes is the supplier affiliated to

in respect of validating testing capabilities?

Customer Complaints/Supplier Non Y/N Comments/Answers

Conformances

Check the customer complaint handling/ supplier

non conformance procedure is in place

Who is responsible for the system?

Are non-conformances/complaints trend analysed

and their findings used as a continuous

improvement tool?

What is the percentage of foreign body complaints

of the total number of complaints registered in the

last six months, and is this an increase or decrease

compared to the previous 6 month period?

Are complaints communicated for investigation to

the relevant people and are the findings

communicated to all relevant persons for training

purposes?

Name

Position

Date

Signature

File Location Prepared By: Approved By:

You might also like

- Mock Drill FormatDocument3 pagesMock Drill FormatMagesha kumar67% (9)

- Fomaous Trails Metal Detector MD7012-3006manualDocument8 pagesFomaous Trails Metal Detector MD7012-3006manualdennyreno67% (3)

- Supplier Evaluation FormDocument11 pagesSupplier Evaluation FormMATTHEW MUNGAINo ratings yet

- FSSC Check List PRPDocument26 pagesFSSC Check List PRPAneel100% (3)

- FSSC 22000 Audit TemplateDocument15 pagesFSSC 22000 Audit Templatedakalo8375% (8)

- Comparative BRC FSSC22000Document14 pagesComparative BRC FSSC22000Tati BarbieroNo ratings yet

- FSMS Compliance ChecklistDocument18 pagesFSMS Compliance ChecklistJose III LlanetaNo ratings yet

- Metal Detection: Quality Systems ManualDocument8 pagesMetal Detection: Quality Systems ManualNaizil Kareem100% (2)

- Procedure For Preliminary Analysis of Production ProcessDocument14 pagesProcedure For Preliminary Analysis of Production ProcessNurulsakinah SailinNo ratings yet

- PRP Verification Check List: Appendix 2Document114 pagesPRP Verification Check List: Appendix 2jacky786No ratings yet

- Basic GMP Inspection Checklist - Written Sanitation Program 2015ADocument1 pageBasic GMP Inspection Checklist - Written Sanitation Program 2015AMarkNo ratings yet

- Ingredient Supplier Assessment QuestionnaireDocument24 pagesIngredient Supplier Assessment QuestionnaireVladimir JankovNo ratings yet

- Supplier Quality System Audit ChecklistDocument5 pagesSupplier Quality System Audit Checklistrickymmarief100% (1)

- H.8 Supplier Audit ChecklistDocument1 pageH.8 Supplier Audit ChecklistJoshua Laksamana100% (1)

- QMSSOP049 - 01 Supplier QualificationDocument13 pagesQMSSOP049 - 01 Supplier QualificationMohamed Kamal100% (1)

- Purpose & Scope: Procedure For Product Withdrawal & RecallDocument3 pagesPurpose & Scope: Procedure For Product Withdrawal & Recallsajid waqas100% (1)

- Form QP 07-2 Supplier Evaluation Questionnaire - REV 0Document3 pagesForm QP 07-2 Supplier Evaluation Questionnaire - REV 0Charles Bill Eldredge100% (1)

- Supplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDDocument6 pagesSupplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDPratik KarekarNo ratings yet

- Audit Checklist in Production AreaDocument5 pagesAudit Checklist in Production AreaPrince Moni100% (2)

- ISO 22000 2015 Internal Audit Checklist PDFDocument5 pagesISO 22000 2015 Internal Audit Checklist PDFMagesha kumarNo ratings yet

- Garrett CSI 250 ManualDocument23 pagesGarrett CSI 250 Manualclaudiu.simaNo ratings yet

- Anmart Metal Detector Manual Garrett 1165180Document2 pagesAnmart Metal Detector Manual Garrett 1165180douglas godoy100% (1)

- Stalcop Llc. Supplier Audit Form: Page 1 of 12Document12 pagesStalcop Llc. Supplier Audit Form: Page 1 of 12ArdiFebriansyahNo ratings yet

- Nestle NQRVDocument11 pagesNestle NQRVPurnendra Kumar GopalNo ratings yet

- Template - Supplier Quality Survey - Rev 0Document4 pagesTemplate - Supplier Quality Survey - Rev 0Karthi ThiyagarajanNo ratings yet

- Form Name: GMP Checklist Form Code: F-000 Issue Number Date: Update Number Date: Page: ( )Document30 pagesForm Name: GMP Checklist Form Code: F-000 Issue Number Date: Update Number Date: Page: ( )Qsolutions India100% (1)

- Supplier Audit ChecklistDocument16 pagesSupplier Audit Checklistvoigte0% (1)

- VERIFICATION PLAN HaccpDocument4 pagesVERIFICATION PLAN HaccpnasuhaNo ratings yet

- FSSC Version 6 Requirements (Foodkida)Document6 pagesFSSC Version 6 Requirements (Foodkida)jacky786No ratings yet

- GMP Checklist For PremisesDocument2 pagesGMP Checklist For PremisesEtta JeneeNo ratings yet

- Validation of Microbiology PDFDocument6 pagesValidation of Microbiology PDFMayur Jadhav0% (1)

- Guideline Supplier Qualification - Dec09FINALDocument34 pagesGuideline Supplier Qualification - Dec09FINALsksingh82100% (3)

- BRC Training Guide SampleDocument22 pagesBRC Training Guide SampleOsman AitaNo ratings yet

- ISO 13485 Audit Checklist: Management ControlsDocument26 pagesISO 13485 Audit Checklist: Management ControlsRicky MarkNo ratings yet

- FSSC 22000 V5.1 For Food Manufacturing ChecklistDocument40 pagesFSSC 22000 V5.1 For Food Manufacturing ChecklistAbdul Rhman100% (1)

- CCP3.5 Supplier Approval Procedure8Document5 pagesCCP3.5 Supplier Approval Procedure8Dutch Charming100% (1)

- US DMF-Document ChecklistDocument1 pageUS DMF-Document ChecklistSravaniNo ratings yet

- Jipl CL Pur 10 Testing Lab AuditDocument8 pagesJipl CL Pur 10 Testing Lab AuditMeghna SharmaNo ratings yet

- Change Control Alaxan FR Capsule 2020Document6 pagesChange Control Alaxan FR Capsule 2020Rio FebriansyahNo ratings yet

- SOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesDocument2 pagesSOP For Collection and Storage of Retained Samples of Raw Material Pharmaceutical GuidelinesMosub Al.Dirdiry100% (1)

- Supplier AuditDocument14 pagesSupplier AuditJayant Kumar JhaNo ratings yet

- Audit Checklist 1Document2 pagesAudit Checklist 1Jagi NikNo ratings yet

- Supplier Audit ChecklistDocument20 pagesSupplier Audit ChecklistSteven Singleton100% (1)

- QP03 Management ReviewDocument4 pagesQP03 Management ReviewhastinkakaNo ratings yet

- Analyst Validation Protocol PCR No.: Avalon Cosmetics PVT LTD ACPL/QA/AV/002 Page: 1 of 13Document13 pagesAnalyst Validation Protocol PCR No.: Avalon Cosmetics PVT LTD ACPL/QA/AV/002 Page: 1 of 13Sankar ChinnathambiNo ratings yet

- Food Equipment Hygienic DesignDocument6 pagesFood Equipment Hygienic Designsandi123inNo ratings yet

- Iso 22000 2018 Sample8 PDFDocument9 pagesIso 22000 2018 Sample8 PDFGabriel DoméNo ratings yet

- Supplier Audit ChecklistDocument11 pagesSupplier Audit ChecklistOlexei Smart100% (1)

- Change Control ProcedureDocument2 pagesChange Control ProcedurePavan Kumar0% (1)

- BRC Food Safety Management System Implementation WorkbookDocument36 pagesBRC Food Safety Management System Implementation WorkbookAbdellah Ftouhi100% (1)

- BRC Packaging Quick Start GuideDocument2 pagesBRC Packaging Quick Start GuideOsman Aita0% (1)

- Change Control Form: Page 1 of 5 F1/Qa-Xxx/NnDocument5 pagesChange Control Form: Page 1 of 5 F1/Qa-Xxx/NnLatesh Hole100% (1)

- Vendor, Supplier and Contractor AuditDocument1 pageVendor, Supplier and Contractor Auditqmdocs100% (3)

- MRM AgendaDocument2 pagesMRM AgendaBAlaNo ratings yet

- Supplier Process Audit Checklist TemplateDocument8 pagesSupplier Process Audit Checklist TemplateYang LishengNo ratings yet

- fssc22000 - (Iso22002-1) Requirements and Additional FSSC Requirements, 2014 PDFDocument8 pagesfssc22000 - (Iso22002-1) Requirements and Additional FSSC Requirements, 2014 PDFAlberto AyalaNo ratings yet

- Stage 2 Attendance FormDocument2 pagesStage 2 Attendance Formarjun PV Rao50% (2)

- Recall Log Appendix-ADocument1 pageRecall Log Appendix-APharmacistNo ratings yet

- Validation Procedure: 1. PurposeDocument7 pagesValidation Procedure: 1. PurposeAbhishek Kumar Singh100% (1)

- Supplier Audit Checklist - ZftvsDocument3 pagesSupplier Audit Checklist - Zftvsaboo2uNo ratings yet

- Haccp PlanDocument1 pageHaccp Planjlordmercader100% (1)

- Vendor Assessment Questionnaire: Pt. Bakrie Pipe IndustriesDocument7 pagesVendor Assessment Questionnaire: Pt. Bakrie Pipe IndustriesBang UcuppNo ratings yet

- Procedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical GuidelinesDocument2 pagesProcedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical Guidelineskavya nainitaNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- Modeling COVID-19 Epidemics in An Excel SpreadsheeDocument15 pagesModeling COVID-19 Epidemics in An Excel SpreadsheeMagesha kumarNo ratings yet

- Key Worker Authority Letter 24032020Document1 pageKey Worker Authority Letter 24032020Magesha kumarNo ratings yet

- Covid-19-Risk-Assessment TEMPLATEDocument7 pagesCovid-19-Risk-Assessment TEMPLATEMagesha kumar50% (2)

- Blank Process Flow FormDocument1 pageBlank Process Flow FormMagesha kumarNo ratings yet

- Invoice TrackerDocument6 pagesInvoice TrackerMagesha kumarNo ratings yet

- Regulatory Compliance India Covid 19 PDFDocument12 pagesRegulatory Compliance India Covid 19 PDFMagesha kumarNo ratings yet

- Regulatory Compliance India Covid 19 PDFDocument12 pagesRegulatory Compliance India Covid 19 PDFMagesha kumarNo ratings yet

- Conveyoyr Break Down ImagesDocument2 pagesConveyoyr Break Down ImagesMagesha kumarNo ratings yet

- Fse GMP Self Assessment Questionnaire PDFDocument40 pagesFse GMP Self Assessment Questionnaire PDFMagesha kumarNo ratings yet

- Process Flow Form Process NameDocument1 pageProcess Flow Form Process NameMagesha kumarNo ratings yet

- Food Defense Checklist - SafetyCultureDocument11 pagesFood Defense Checklist - SafetyCultureMagesha kumarNo ratings yet

- Personal Hygiene Training TamilDocument19 pagesPersonal Hygiene Training TamilMagesha kumarNo ratings yet

- Door Metal DetectorDocument5 pagesDoor Metal DetectorbarfitakillaNo ratings yet

- Xtreme Metal Detector PDFDocument93 pagesXtreme Metal Detector PDFroy_nhp0% (1)

- Thư viện Tài liệuDocument9 pagesThư viện Tài liệusafe150_239331910No ratings yet

- MY Mini ProjectDocument9 pagesMY Mini ProjectPravin SalunkheNo ratings yet

- CZ-20 Quicksilver: Deep Search, Land and Underwater, Target I.D. Metal DetectorDocument42 pagesCZ-20 Quicksilver: Deep Search, Land and Underwater, Target I.D. Metal DetectorJerNo ratings yet

- Search With Metal DetectorsDocument33 pagesSearch With Metal DetectorsDCLXVINo ratings yet

- Iq3 en B1Document82 pagesIq3 en B1CasHeerNo ratings yet

- Pistol Detector - TOTeMDocument10 pagesPistol Detector - TOTeMValdenor Costa100% (1)

- SPesifikasi Teknis RemovedDocument18 pagesSPesifikasi Teknis Removedcv.putraabungsentosaNo ratings yet

- Brochure CW & MDDocument2 pagesBrochure CW & MDOkky PoerwantoNo ratings yet

- OKM Catalog enDocument59 pagesOKM Catalog enemilio275655100% (1)

- Eddy Curent Metal Detectors - Pulse vs. CW: Pavel Ripka - Adam LewisDocument3 pagesEddy Curent Metal Detectors - Pulse vs. CW: Pavel Ripka - Adam LewisHarshil AmbagadeNo ratings yet

- Deus Manual Uk V5 2018Document52 pagesDeus Manual Uk V5 2018joancarlesbarreraNo ratings yet

- Rakes2 150Document4 pagesRakes2 150Luis Alvarez100% (2)

- Metal Detection and Classifi Cation Technologies: Carl V. NelsonDocument6 pagesMetal Detection and Classifi Cation Technologies: Carl V. NelsonGigiPetreaNo ratings yet

- 48 kHIPEPTZInstMan050GBv2 1-1Document86 pages48 kHIPEPTZInstMan050GBv2 1-1Vlad VasiliuNo ratings yet

- Production Control & QC InspectionDocument11 pagesProduction Control & QC Inspectionalexander.bigreddotNo ratings yet

- Hand-Worn Metal Detectors Used in Safety and Security: Performance Standard ForDocument13 pagesHand-Worn Metal Detectors Used in Safety and Security: Performance Standard ForAlevj DbNo ratings yet

- Geo Examiner Ground Radar PDFDocument7 pagesGeo Examiner Ground Radar PDFAdem Makinacı100% (1)

- Robo Iiims+ NewDocument1 pageRobo Iiims+ NewAmber WalkerNo ratings yet

- Ace 150 250 Manual EnglishDocument50 pagesAce 150 250 Manual EnglishhatzelGrEshopNo ratings yet

- Pulse Induction DetectorDocument3 pagesPulse Induction DetectorZeeshanIrshadNo ratings yet

- Auditcheck Performance of Metal DetectorDocument4 pagesAuditcheck Performance of Metal DetectorAnwar TanuwijayaNo ratings yet

- Product Safety Requirements in Garments Industry:: Metal Detection ProcessDocument2 pagesProduct Safety Requirements in Garments Industry:: Metal Detection ProcessMd SunnyNo ratings yet

- 3.20 Premium Metal Detector TestingDocument20 pages3.20 Premium Metal Detector Testingdaniel100% (2)

- The Guide To Pharmaceutical Metal Detection and Validation ProtocolDocument21 pagesThe Guide To Pharmaceutical Metal Detection and Validation Protocolmezghiche abdelkrimNo ratings yet