Professional Documents

Culture Documents

Schneider Electric NPAG C11 Arc Protection

Schneider Electric NPAG C11 Arc Protection

Uploaded by

Shailesh ChettyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schneider Electric NPAG C11 Arc Protection

Schneider Electric NPAG C11 Arc Protection

Uploaded by

Shailesh ChettyCopyright:

Available Formats

Photo: J.

Vogler

C11

Arc Protection

Network Protection & Automation Guide

Network Protection & Automation Guide

Chapter

C11

Arc Protection

1. Introduction 401

2. Arc flash phenomenon 402

3. Causes of arc faults in switchgear 403

4. Impacts and consequences of arc faults 404

5. Arc protection related standards 406

6. Arc protection and mitigation methods 407

7. The principle of arc protection based on simultaneous detection of light and overcurrent 408

8. How to avoid nuisance tripping caused by switching arcs 409

9. Arc protection systems 409

10. Elimination of the arc fault 411

11. Typical application examples 412

Arc Protection

C11 1. Introduction

High power arc faults in switchgear are rare events but their

consequences can be extremely severe. They can be

characterised as electrical explosions. Personnel may be

seriously affected by the radiation, heat, pressure wave, and

flying particles associated with the arc flash. These impacts

can also devastate the switchgear and cause substantial

economic losses either directly by destroying components

of the system or indirectly by causing process outages or

medical and legal expenses. Traditional overcurrent protection

is inefficient in the detection of arcing faults because it is too

slow. Faster protection methods are needed in order to

significantly reduce the released energy.

Energy Damage & hazard

Figure C11.2a:

Extensive Arcing time 47ms - Minor damage

damage

Limited

damage

Minimal Arcing time

damage

Figure C11.1:

Damage level dependent on the arcing time

This chapter describes the state-of-the-art arc protection

technology which is based on minimisation of arcing time by

very fast arc detection and elimination. By using simultaneous

detection of fault arc light and overcurrent it is possible to

reliably detect the arc within 2ms and phase-to-phase faults

within 1ms. The principle of this protection method and the

Figure C11.2b:

associated sensors, devices and systems are explained and Arcing time 500 ms - Copper busbars have evaporated

clarified by typical application examples. Figure C11.1

illustrates that limitation of the arcing time is an efficient way

to mitigate damages on arc faults. Figure C11.2a and C11.2b

show the results of a 50kA 3 phase internal arc test with short

and long arcing time.

401 Schneider Electric - Network Protection & Automation Guide

Arc Protection

2. Arc flash phenomenon C11

An electric arc is a luminous discharge short circuit through

dielectric gas or fluid.

Arcs can be categorised as useful arcs (welding), breaking

arcs (in switching devices), and fault arcs. Fault arcs can

further be divided into low power arcs and high power arcs.

Examples of low power arc faults are series faults in power

systems (e.g. loose connections) and arcs in photovoltaic low

voltage systems. These arcs release very limited amount of

energy compared with high power arc faults.

This chapter is focused on high power arcs in gases where

the fault arc is formed between two or more conductive parts

of a power system, most commonly between two or more

phases or between phase and earth. The emphasis is in high

power fault arcs in air insulated switchgear. An arc fault in

switchgear is a short circuit through ionised gas (normally

air) between live parts or between one live part and earth. It

is very different from a bolted fault with a solid connection.

Air-insulated switchgear is commonly used, since dry air in

normal temperature is a reasonably good insulator. However,

when the temperature of the air is very high, more than 2000

K, thermal ionisation makes air conductive. The ionised air

and the ionised material from the electrodes form a conductive

plasma channel between the electrodes. The plasma consists

mainly of nitrogen and oxygen molecules, atoms and ions of

N and O, electrode material and electrons. The plasma is very

hot, temperatures as high as 20000 K have been reported,

and it radiates light. The light comes from hot particles and

from electrons returning from high energy states to lower

states.

In a high power arc fault very high amounts of electrical

energy turns into radiation and thermal energy extremely

rapidly. Due to the light and the high temperature with the

associated pressure wave and possible flying particles, arc Figure C11.3: [Photo: J.Vogler]:

Electrical explosions as result of an arc fault

faults can be characterised as electrical explosions (see

Figure C11.3).

Schneider Electric - Network Protection & Automation Guide 402

Arc Protection

C11 3. Causes of arc faults in switchgear

Internal arc faults in switchgear are caused by something that corrosion and maloperation of switching devices are also

leads to a failure in the insulation. Many arc faults are caused possible causes of arcs. Many arc faults start as single phase

by direct human errors, such as forgotten tools, forgotten faults and then rapidly escalate into three-phase faults.

earthing connections or errors while working on equipment.

IEC Standard 62271-200 provides a good overview of possible

Loose connection, vibration, insufficient mechanical

locations and causes of internal arc faults as shown in Table

dimensioning and overvoltage can also lead to an arc fault.

C11.1.

Animals, contamination, dirt, moisture, ageing of insulation,

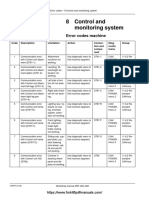

Locations where internal Possible causes of Examples of possible

arc faults are most likely to occur internal arc faults preventive measures

(1) (2) (3)

• Selection of adequate dimensions

Inadequate design

• Use of appropriate materials

• Avoidance of crossed cables connections

Connection compartments Faulty installation • Checking of workmanship on site

• Correct torque

Failure of solid or liquid insulation • Checking of workmanship and/or dielectric test on site

(defective or missing) • Regular checking of liquid levels, where applicable

• Interlocks

Disconnectors • Delayed reopening

Switches Maloperation • Independent manual operation

Earthing switches • Making capacity for switches and earthing switches

• Instructions to personnel

• Use of corrosion inhibiting coating and/or greases

• Use of plating

Corrosion

• Encapsulation, where possible

• Supplemental heating to prevent condensation

• Checking of workmanship by suitable means

Faulty assembly • Correct torque

Bolted connections and contacts

• Adequate locking means

During racking-in or racking-out of

withdrawable parts

E.g. due to dielectric change of state in • Checking of workmanship at site

combination with damage or distortion of

the plugging contacts and/or shutters

• Avoidance of these electrical influences by suitable

Ferro-resonance

design of the circuit

Instrument transformers

• Avoid short circuit by proper means for example,

Short circuit on low-voltage side for VTs

protection cover, low-voltage fuses

• Regular programmed maintenance

Circuit-breakers Insufficient maintenance

• Instructions to personnel

• Limitation of access by compartmentalisation

Error by personnel • Insulation of embedded live parts

• Instructions to personnel

Ageing under electric stresses • Partial discharge routine tests

All locations • Measures to ensure that the specified service

Pollution, moisture ingress of dust, vermin,

conditions are achieved

etc

• Use of gas filled compartments

• Surge protection

Overvoltages • Adequate insulation co-ordination

• Dielectric tests on site

Table C11.1:

Locations, causes and examples of measures to decrease the probability of internal arc faults [IEC Standard 62271-200]

403 Schneider Electric - Network Protection & Automation Guide

Arc Protection

4. Impacts and consequences of arc faults C11

Figure C11.4 illustrates the impacts and consequences of

arc faults.

Psychological

trauma

Vaporised copper

Intense light, burning (volume 67.000 times solid copper)

and blinding radiation → Pressure wave

→ Toxic gases

High temperature

Shrapnel and

up to 20.000 K

molten metal

Heated air → Hazardous

pressure and sound wave voltage

(Air expands 1.600 fold)

Fire

Figure C11.4:

Consequences of arc faults

In a high power arc fault incident huge amounts of electrical arc flash can cause eye damage and it also plays a part in

energy are converted into radiation and thermal energy. The the burning impact of the arc (see Figure C11.5a to C11.5c).

radiation includes visible light. The very intense light of the

Figure C11.5a, 5b, 5c: Light arcing flash

Schneider Electric - Network Protection & Automation Guide 404

Arc Protection

C11 4. Impacts and consequences of arc faults

Most of the burning effect comes from the thermal energy

which in fact has many impacts. The high temperature heats

up the air, and it vaporises the metal of the busbars. The hot

plasma and the convection of the hot gases can cause serious

arc burns to personnel.

Serious damage to equipment is also possible. If the arcing

time is high the busbars can be totally destroyed, and the

arc can burn holes to the switchgear housing.

Since arcs can ignite fire, additional damage to switchgear

or substations is possible. Personnel's clothes may catch fire

and increase the risk of burns. Additional safety hazard comes

from toxic gases, due to evaporation of metal parts. Humans

nearby are also vulnerable to hazardous voltage caused by

the fault, and an arc fault may cause subsequent psychological

trauma.

When the temperature of the air rises the volume of the air

increases. Furthermore, when metals evaporate, they expand Figure C11.6b:

dramatically (see Figure C11.6a and C11.6b). For example Damage after an arc fault

when copper evaporates its volume is 67000 times as large

as in the solid form. This instantaneous expansion creates

Arc blast gives arc fault incidents an explosive nature. Since

another major impact of the arc, the pressure wave. The

the peak value of the pressure, measured at the compartment

pressure wave, often called the arc blast, is dangerous to

walls, is normally reached 4-15ms after the ignition of the

humans. In addition to ear damage and lung collapse, it can

fault (peak pressure buildup time is relative to volume),

throw humans against walls or to the floor causing bone

mitigation of the pressure impact requires either efficient arc

fractures or more serious injuries. Additional injuries can be

containment, redirection of the arc blast or high speed

caused by flying particles and molten metal from the damaged

mitigation of the arc.

busbar and assembly.

The above mentioned consequences, serious safety hazard

and significant damage to equipment are not the only risks

caused by arc faults. Injury or even death of humans may

lead to substantial medical and legal expenses. When it comes

to equipment, indirect costs are possible as well. Prolonged

power and process outages due to the destroyed equipment

are possible and in process industries particularly the

interruption costs can be very high.

Figure C11.6a:

Damage after an arc fault

405 Schneider Electric - Network Protection & Automation Guide

Arc Protection

5. Arc protection related standards C11

In some countries arc protection based on simultaneous phase-to earth arc fault current.

detection of light and overcurrent is a ‘de facto’ standard

IEEE Std 1584™-2002, IEEE Guide for Performing Arc-

which means that practically all new industrial switchgear and

Flash Hazard Calculations, is a safety oriented guide. It

primary substations of the utilities are equipped with the

provides techniques to apply in determining the arc-flash

technology. However, currently in 2015, there are no

hazard distance and the incident energy to which employees

international standards directly standardising methodology

could be exposed during their work on or near electrical

or equipment for arc protection.

equipment. Its applications cover an empirically derived model

Currently available standards concerning arc fault issues are including enclosed equipment and open lines for voltages

the following: from 208 V to 15 kV, and a theoretically derived model

applicable for any voltage. The standard also provides a good

a. IEC 62271-200, High-voltage switchgear and controlgear

list of arc fault related definitions.

- Part 200: AC metal-enclosed switchgear and controlgear

for rated voltages above 1 kV and up to and including One of the most central definitions is the concept of incident

52 kV, known as the international switchgear standard energy: The amount of energy impressed on a surface, a

certain distance from the source, generated during an

b. IEC 60364 Low-voltage electrical installations

electrical arc event. Incident energy is measured in joules

c. IEEE Std 1584™-2002, IEEE Guide for Performing Arc- per centimetre squared (J/cm²). The incident energy concept

Flash Hazard Calculations is used for developing strategies to minimise burn injuries.

d. NFPA 70E®, Standard for Electrical Safety in the The guide is based upon testing and analysis of the hazards

Workplace, 2015 Edition, NFPA (National Fire Protection presented by incident energy. It provides a detailed step-by-

Association) step process for arc flash analysis. This analysis ends up with

determining the incident energy level and the flash-protection

IEC 62271-200 (Edition 2.0, 2011) is a MV switchgear

boundary (The distance from live parts that are uninsulated

standard and it "specifies requirements for prefabricated

or exposed within which a person could receive a second

metal-enclosed switchgear and controlgear for alternating

degree burn) based on incident energy of 5.0 J/cm². One

current of rated voltages above 1 kV and up to and including

should note that the analysis only covers the thermal impact

52 kV for indoor and outdoor installation and for service

of the arc fault, not the pressure related impact for example.

frequencies up to and including 60 Hz. Enclosures may include

fixed and removable components and may be filled with fluid The standard is well known but mostly utilised in North America.

(liquid or gas) to provide insulation." Arc faults are briefly Although incident energy levels are seldom calculated in

discussed in the standard. Europe, incident energy calculations are a useful tool when

comparing the effectiveness of different arc protection

The standard aims at preventing the occurrence of internal

methods. Because the incident energy level depends on four

arc faults. It gives a good list of locations where faults are

key parameters: the arcing current, the voltage, the working

most likely to occur, and explains causes of failure and

distance and the arcing time, it is relatively easy to see that

possible measures to decrease the probability of faults.

normally the most practical factors in the mitigation of the

Additionally IEC 62271-200 gives examples of supplementary

thermal impacts of arc faults are the arcing time and the

measures - in practice arc protection technologies - to provide

arcing current.

protection to persons:

IEEE Std 1584™-2002 includes reporting of the tests carried

a. rapid fault clearance times initiated by detectors sensitive

out with current-limiting fuses. The published figures confirm

to light, pressure or heat or by a differential busbar

the risk related to current-limiting fuses: high incident energy

protection

levels occur when the fault current is low, and the fuse is not

b. application of suitable fuses in combination with switching in its intended range of operation.

devices to limit the let-through current and fault duration

NFPA 70E, Standard for Electrical Safety in the

c. fast elimination of arc by diverting it to metallic short Workplace® by National Fire Protection Association addresses

circuit by means of fast-sensing and fast-closing devices electrical safety-related work practices, safety-related

d. remote operation instead of operation in front of the maintenance requirements and other administrative controls

switchgear and controlgear for the practical safeguarding of employees. It has some links

to arc protection and it provides some commonly used arc

e. pressure-relief device fault related definitions, such as:

f. transfer of a withdrawable part to or from the service a. Arc Flash Boundary: When an arc flash hazard exists,

position only when the front door is closed the distance from a prospective arc source at which a

IEC 62271-200 recognises two important ratings of the arc person could receive a second degree burn if an electrical

fault currents: a) three-phase arc fault current and b) single arc flash were to occur. (A second degree burn is possible

Schneider Electric - Network Protection & Automation Guide 406

Arc Protection

C11 5. Arc protection related standards

by an exposure of unprotected skin to an electric arc NFPA 70E includes an informative annex giving guidance on

flash above the incident energy level of 5 J/cm² selection of arc-rated clothing and other PPE (Personal

Protective Equipment) when it is not practical to eliminate

b. Arc-Resistant Switchgear: Equipment designed to

exposure to incident energy.

withstand the effects of an internal arcing fault and that

directs the internally released energy away from the

employee

6. Arc protection and mitigation methods

Naturally the primary goal is to prevent arc faults by, for Incident energy calculations, based on testing, show that the

example, careful design, education of personnel and adequate released energy is proportional to the arc time. When traditional

maintenance of equipment. In some cases early detection overcurrent protection is applied, the arc time is normally

of developing faults is possible by special monitoring some hundreds of milliseconds. This leads to extensive

equipment. However, it is very difficult to totally eliminate arc damage and a serious safety hazard. This is why several

faults in distribution systems. different arc fault mitigation approaches have been introduced,

that are much more efficient than overcurrent protection.

As shown previously, the incident energy depends on the

voltage, working distance, arc current and arc duration. From The following Table C11.2 presents evaluation of some well

an arc protection point of view it is normally not possible to known arc mitigation methods.

effect the applied voltage. The working distance is only related

to humans working on the equipment, and it is often difficult

to increase this distance. In practice there are two major

approaches for decreasing the released energy: limitation of

the arc current or reduction of the arc time.

Method Benefits Drawbacks

• Good protection for personnel at least

Arc-resistant switchgear

when the doors are closed

Equipment designed to withstand the • If used as the only arc mitigation approach,

• Provides protection against the pressure

effects of an internal arc fault and that provides no protection to the equipment in the

impact

directs the internally released energy enclosure

• Gives very good protection if used in

away from the employee

combination with fast protection

Maintenance switch

A switch that when turned on (during

maintenance at a substation) makes • Rather good protection of personnel • Effective only during maintenance

circuit breakers operate without any

intentional delay

Zone-selective interlocking • Rather simple, relatively low costs • Not very fast

• Very fast operation and good protection if

• When fault current is low (as it can be for various

the fault current is in the operation range

Current-limiting fuses reasons) the arc time and the incident energy are

of the fuse

high

• Limits both current and arc time

• Increase cost and losses

Current-limiting reactors • Limit fault current

• Limited effect

• Complicated settings

Busbar differential protection • Fast protection • Requires careful CT selection

• Does not operate in cable terminal faults

Table C11.2:

Comparison of mitigation methods

407 Schneider Electric - Network Protection & Automation Guide

Arc Protection

7. The principle of arc protection based on

simultaneous detection of light and overcurrent C11

The leading method in arc protection is based on simultaneous

very fast detection of light and overcurrent as shown in Figure

C11.7. This approach can be divided into two parts: Arc

detection and Arc mitigation. The arc can be detected within

<1 milliseconds which is outstanding performance compared

with conventional protection technology. The arc time varies

according to the elimination technology. When applying

conventional circuit breakers the arc time is some tens of

milliseconds. If a short-circuit device is applied, the arcing

time is less than half cycle.

Figure C11.8: Figure C11.9:

Point type of optical sensor Fibre type of optical sensor

&

Light

Trip signal 7.2 Fast detection of overcurrent

Overcurrent In order to minimise the possible nuisance tripping caused by

external light, an overcurrent condition, i.e. detection of

overcurrent (secondary sensor) is often required in parallel

with the detection of light (primary sensor). The current can

be measured with normal (existing) current transformers. In

Figure C11.7: arc protection applications it is however necessary to minimise

Modern arc protection logic

the operation time and special methods are used to enable

the rapid detection of the overcurrent. Very fast (less than

1ms) detection of overcurrent is possible by applying an

Normally the overcurrent condition increases costs only a little

analogue comparator. The method is illustrated in Figure C11.10.

since existing current transformers can be used. However,

there are applications where "light only" based arc detection Because many arc faults start as single-phase faults, it is

can be applied. For example, if the probability of intense justified to detect phase-to-earth faults as well. If the arc is

external light can be practically closed out, measurement of detected and eliminated before it escalates into high-power

current would be very difficult, or where low cost is essential three-phase fault, the damage will be lower. The detection of

the "light only" condition can be justified. phase-to-earth arc fault is normally based on simultaneous

detection of light and zero-sequence overcurrent, but zero

7.1 Fast optical detection of light

sequence voltage can be utilised as well.

There is a strong correlation between the power of the arc and

the intensity of the observed light. Fault arcs can be detected

practically immediately by using light sensitive sensors, such 3xl

f

as photodiode (point type of sensor) or optical fibre (loop or

3xI + Io + U A/D

point type of sensor).

3xl

Io

There is not an exact universal sensitivity threshold value which 3xl

Comp

Pickup value Io

could always differentiate between light emanating from arc Io>> I>>

faults and the light coming from other sources. Practical

experience has shown that sensitivity of approximately 10000 CONF.

lux (visible light) gives excellent results. Sensors with the MEMORY

sensitivity of 10000 lux are very likely to detect the light in all

relevant arc fault situations with metal-enclosed switchgear FPGA

while at the same time the risk of false activation is low. This is

true especially in the cases where the detection of the arc is

confirmed by the simultaneous detection of overcurrent.

Point type of sensors (Figure C11.8) enable more selective CPU

protection than fibre loop sensors, identifying the location of

the arc more accurately. Loop sensors (Figure C11.9) are a

cost effective solution for applications where protection

selectivity is not a critical. Figure C11.10:

A method for very fast detection of overcurrent, utilising an

analogue comparator

Schneider Electric - Network Protection & Automation Guide 408

Arc Protection

C11 8. How to avoid nuisance tripping caused by switching arcs

In almost all cases, both in medium voltage (MV) and low

voltage (LV) systems, the trip condition of simultaneous

detection of light and overcurrent has proven to be successful.

However, some low voltage circuit breakers (air-magnetic

type) emit light and other type of pollution while operating.

This problem can be mitigated by using special types of light

sensors, less sensitive or designed for limited wavelength

ranges or by applying pressure sensors.

9. Arc protection systems

9.1 Stand-alone arc protection systems An example of applications is a primary substation (HV/MV)

where arc faults can be selectively tripped . e.g. in cable

The simplest arc protection solutions can be based on stand-

terminations of outgoing feeders - a typical location of arc

alone devices (Figure C11.11). When "light only" detection

faults.

criteria is applied, all that is required is the optical sensors,

and a device that collects the information from the sensors

and sends the trip command to the appropriate circuit breaker.

Some wind power applications, secondary substations and

limited low voltage switchboards are examples of possible

application areas for stand-alone devices. Vamp 321

ON

OK

F1 F2

I O

vamp

Cable Vamp 321

ON

L> (CB, BB)

OK

F1 F2

I O

vamp

CB

BB

CB CB

Cable ON

Vamp 321

Cable ON

Vamp 321

Figure C11.11: F1

OK

F2 F1

OK

F2

Stand alone arc protection system

I O I O

vamp vamp

9.2 Arc protection integrated in numerical protection L> (CB, BB)

relays

Another cost effective and very widely applied solution is to

integrate arc protection into normal protection devices (Figure

Figure C11.12:

C11.12). Because most relays already include current

Integrated arc protection function in a protection device

measurement, it is relatively easy to add the input for light

sensors to achieve the light and overcurrent based trip

condition. However, the overcurrent detection must be very

fast.

When the relays are equipped with communication and several

light sensor inputs, selective arc protection can be provided.

409 Schneider Electric - Network Protection & Automation Guide

Arc Protection

9. Arc protection systems C11

9.3 Dedicated arc protection systems circuit breakers, if both light and overcurrent are detected.

Very high speed communication between the components is

Arc protection is most often implemented by a separate system

an essential feature of the system, transmitting information

using arc flash detectors connected to dedicated arc

on detected light, detected overcurrent, addresses (location)

protection relays (Figure C11.13). Overcurrent and earth-fault

of detection, and trip commands.

protection is carried out by other relays. A comprehensive,

selective arc protection system comprises of optical sensors, A separate system enables large installations with selective

current transformers (normally no additional CTs are needed), protection and multiple protection zones. It provides very high

I/O units collecting data from the sensors and CTs, speed protection and can also provide some protection

communication cabling, and a master unit or several master redundancy.

units for final collection of all the sensor data. The master

unit(s) are measuring the current and tripping the appropriate

CBFP* CBFP

= Point sensor T2 T4

VAMP 321

VAM 4CD

V

T, T1, T2, T3, T4 = Trip

T3 T

S1, S2, S3 ... = Sensors

* Either CBFP or Direct Zone 1 trip

T1

T1 Zone 4

Zone 1

VAM 12L

V

Zone 2 Zone 3

T3 Zone 2.1 T1

Zone 2.2 Zone 2.3 Zone

e 2.4

4 Zone

Zone 2.5

5 Zone 2.6

T2 T3

T3

S1 S2 S3

S

S2 S3 S1

T T

T2 T1

VAM 12LD VAM 12LD VAM 3L

V

Figure C11.13:

Dedicated arc protection system

Schneider Electric - Network Protection & Automation Guide 410

Arc Protection

C11 10. Elimination of the arc fault

10.1 The importance of the arc elimination time Fast communication between the arc protection relay and the

short-circuit device is vital. The combination of optical arc

The incident energy is proportional to the arcing time. From

detection and a short-circuit device provides extremely fast

a protection point of view the arcing time consists of two

and efficient protection. The arcing time is only a few

components: arc detection time and arc elimination time. By

milliseconds. The thermal impact of the fault is minimal, and

applying arc detection methods described above, minimal

the pressure impact is significantly mitigated.

arc detection time can be achieved. The arcing time then

depends almost entirely on arc elimination time. 10.4 Current-limiting fuses

10.2 Circuit breakers The use of current-limiting fuses in arc protection requires

good product and system knowledge otherwise the protection

In most applications arc protection relays send the trip signal

level may be much lower than expected. CL fuses can be

to appropriate circuit breakers which then open the circuit

very efficient in both limiting the current and reducing the arc

and extinguish the fault arc. In MV applications using arc

time. When the fault current is in the current-limiting range,

protection relays and CBs the total arcing time is in the order

the fuse is able to break the current very rapidly, and also

of 60ms, consisting of 1ms detection time and <60ms CB

reduce the peak current. The reduction of the peak current

operation time. The operating times of LV CBs are usually

is a benefit, because high current causes mechanical forces

shorter than MV CBs' operation times. When total arcing time

that are detrimental to transformers feeding the current. Figure

is in only a few tens of milliseconds, the thermal impacts of

C11.15 below illustrates the current-limiting impact of a CL

faults arcs are efficiently mitigated (see Figure C11.14).

fuse.

Prospective wave

I

(I rms = A)

B

Limited wave

Cut-off current

(peak value)

Figure C11.15:

Current-limitation of a CL fuse

Current-limiting fuses are not a perfect solution. They are very

Figure C11.14:

Low impact on an arc fault with fast arc protection trip effective in limiting the released energy only if they are in

their current-limiting range. Particularly in low voltage

applications it is difficult to determine the arc fault current

level. The current can be as low as 20-40 % of the bolted

10.3 Short-circuit devices (arc eliminators)

fault current. Low fault current can lead to prolonged arc

Arc eliminating by means of a short-circuit device (crowbar times and thus higher released energy and greater damage.

unit, arc quencher or high speed earthing device) is recognised

by IEC Standard 62271-200 as an option to provide the highest

possible level of protection to personnel in case of an internal

arc in MV switchgear. When using a short-circuit device the

arc protection systems sends trip commands to both the arc

eliminator and the appropriate circuit breakers. The short-

circuit device will create an intentional high speed short circuit

in the system so that the voltage collapses and the arc is

extinguished. The short-circuit current is then eliminated by

the circuit breaker within a few cycles.

411 Schneider Electric - Network Protection & Automation Guide

Arc Protection

11. Typical application examples C11

11.1 Single main application

The following Figure C11.16 gives an overview of a single

main application.

VAM VAM VAM

10LD 10LD 10LD

0AN 1AN 2AN 3AN 4AN 5AN

VAMP

321

5BN

1BN 2BN 3BN

3CN 4BN

1CN 2CN

5CN

3DN 4CN

1DN 2DN 5DN

4DN

1EN 3EN 5EN

up-stream

breaker 2EN

Section 1 Section 2 Section 3 Section 4 Section 5 Section 6

Figure C11.16:

Single main application

Every compartment is equipped with an arc sensor. The trip

output relay of AFS units control the incomer breakers. Any

of the point sensors will cause a trip of the main breaker to

mitigate the arc fault. Additionally overcurrent measurement

is taken account if the application requires a minimisation of

the possible nuisance tripping caused by external light.

Schneider Electric - Network Protection & Automation Guide 412

Arc Protection

C11 11. Typical application examples

11.2 Main tie main application + CBF (circuit breaker

failure)

The following Figure C11.17 gives an overview of a main tie

main application with circuit breaker failure.

A B

Vamp 321 1

ON

F1

OK

F2 2

vamp

4 3

Zone 1 X1 X2 Zone 2 X3 X4 X4 X5

Figure C11.17:

Main tie main application

The protected target is a medium voltage enclosure with two enclosure backup detection. When defining the CBFP delay

separate incomers. The enclosure has a longitudinal busbar time, the standard break-time of the feeder circuit breaker of

between the incomers. To minimise the fault zone, the enclosure the enclosure must be taken into account.

is divided into two separate protection zones.

The main unit and extension units serve as trip units. The main

The different zones are divided by a bus-coupler circuit unit (1) trips its own feeder circuit breaker in zone 1 faults and

breaker and monitored by light sensors connected to the light serves as CBFP in zone 1 and 2 faults. The arc sensor units

detecting units (3 & 4). The system receives current criteria (3 and 4) trip the bus-coupler circuit breaker between zones

from the main unit(1) and current measurement unit (2), which 1 and 2 in faults in their own zone. The zone 2 light detecting

have been installed on incomers. unit (3) trips its own bus-coupler circuit breaker.

The CBFP (circuit breaker failure protection) contacts have

been wired to the HV side of the supply transformer for

413 Schneider Electric - Network Protection & Automation Guide

Arc Protection

11. Typical application examples C11

11.3 Feeder selective multiple busbar application

The following Figure C11.18 gives an overview of a feeder

selective multiple busbar application.

Vamp 321 Vamp 321

ON ON

OK OK

F2 F2

I>

F1 F1

vamp

I> vamp

Q1 Q4

MF MF

E1.1 E1.2 E1.1 E1.2

Zone 3 Zone 3

Zone 1 Zone 2

Q5.1 Q5.2 Q5.3

MF MF MF

Zone 1

Feeder Feeder Zone 2

Zone 3

Feeder

Figure C11.18:

Multiple busbar application

The protected target is a medium voltage enclosure with breaker between different zone faults in their own zone. The

multiple separate incomers. The enclosure has a longitudinal outgoing feeder zone light detecting units trips their own

busbar between the incomers. To minimise the fault zone, the feeder circuit breakers.

enclosure is divided into four separate protection zones (zone1,

Selective tripping schemes on main units automatically adjust

2, 3 and Feeder). The different zones are divided by bus-

according to incomer disconnector positions (E1.x and E2.x)

coupler circuit breakers and monitored by light sensors

and changes the tripping logic accordingly. This will allow arc

connected to the light detecting units in zones 1, 2,3 and

flash protection to fullfill full selective protection.

feeder. The detection system receives current criteria from

the main units, which are installed on incomers. The outgoing feeder section is protected by using dedicated

light detecting units. These individially trip the corresponding

The main units and extension units serve as trip units. The

feeder circuit breaker to limit the impact without shutting down

main units trip their own feeder circuit breaker for internal arc

the entire busbar in the system e.g. cable fault.

faults when a fault is fed from their own incomer. The arc

sensor units in zones 1, 2 and 3 trip the bus-coupler circuit

Schneider Electric - Network Protection & Automation Guide 414

You might also like

- Solar Turbine Turbotronic 4 SPTT-PG PDFDocument29 pagesSolar Turbine Turbotronic 4 SPTT-PG PDFINGRgomez100% (5)

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Substation Automation Systems: Design and ImplementationFrom EverandSubstation Automation Systems: Design and ImplementationRating: 4.5 out of 5 stars4.5/5 (3)

- Prs Tu Cmc-Standard-Course EnuDocument215 pagesPrs Tu Cmc-Standard-Course EnuhaydarNo ratings yet

- D3 IEC 61850 and ApplicationsDocument40 pagesD3 IEC 61850 and ApplicationsShailesh ChettyNo ratings yet

- Crane Control Catalogue Brosure Cutler HammerDocument25 pagesCrane Control Catalogue Brosure Cutler HammerSholhan AzizNo ratings yet

- 200 Top Electrical Engineering Interview Questions and AnswersDocument94 pages200 Top Electrical Engineering Interview Questions and Answersraj33% (3)

- PCM 600Document90 pagesPCM 600Felix CristianNo ratings yet

- Numerical Transformer Protection Relay Terminal-CSC326Document23 pagesNumerical Transformer Protection Relay Terminal-CSC326billymcrealNo ratings yet

- Cable Thermal Analysis Short Circuits EADocument19 pagesCable Thermal Analysis Short Circuits EAErsiAgoNo ratings yet

- BA300Document7 pagesBA300carthic1979No ratings yet

- ANGEN - En006 B Restricted Earth Fault ProtectionDocument5 pagesANGEN - En006 B Restricted Earth Fault ProtectionAlejandro Mira EstradaNo ratings yet

- Snubbers:: Protecting Medium-Voltage Transformers From Electrical TransientsDocument4 pagesSnubbers:: Protecting Medium-Voltage Transformers From Electrical TransientsANTONIO SOLISNo ratings yet

- APN-052 Directional Ground-Fault ProtectionDocument17 pagesAPN-052 Directional Ground-Fault ProtectionWalter Andres Estevez VasquezNo ratings yet

- Guia de Formación SELDocument72 pagesGuia de Formación SELJefferson Gutama Valladares100% (1)

- Directional Protection - Course Sample - 589890-591528Document47 pagesDirectional Protection - Course Sample - 589890-591528medanite ashebir100% (1)

- Iec 61850 Training Program: A True Hands-On Experience..Document5 pagesIec 61850 Training Program: A True Hands-On Experience..saravananNo ratings yet

- Abb Rel670 v1.1 A32 Iec Xrio Converter Manual Enu Tu2.30 v2.000Document10 pagesAbb Rel670 v1.1 A32 Iec Xrio Converter Manual Enu Tu2.30 v2.000eswaran005100% (1)

- 07 TT 03 Using-DfrDocument5 pages07 TT 03 Using-Dfrcarlos vidalNo ratings yet

- Redundancy in Digital SubstationsDocument14 pagesRedundancy in Digital SubstationsJorge AzabacheNo ratings yet

- Current Transformers For HV ProtectionDocument20 pagesCurrent Transformers For HV ProtectiondaodoquangNo ratings yet

- Industrial & Commercial Power System Protection: Energy AutomationDocument36 pagesIndustrial & Commercial Power System Protection: Energy Automationmubarakkirko100% (1)

- Synchronization of OMICRON CMC Test Sets Via IRIG-BDocument21 pagesSynchronization of OMICRON CMC Test Sets Via IRIG-BMosa DalahmaNo ratings yet

- Littelfuse Protection Relay Protection Relays White Paper PDFDocument6 pagesLittelfuse Protection Relay Protection Relays White Paper PDFRamphani NunnaNo ratings yet

- Busbar Protection TheoryDocument13 pagesBusbar Protection TheoryDEADMANNo ratings yet

- An Improved Transformer Inrush Restraint AlgorithmDocument29 pagesAn Improved Transformer Inrush Restraint AlgorithmNguyen Xuan TungNo ratings yet

- CB Oper and ControlDocument7 pagesCB Oper and Controlpriyanka236No ratings yet

- Accusine® Power Correction System (PCS) Selection Program: Project IdentificationDocument22 pagesAccusine® Power Correction System (PCS) Selection Program: Project IdentificationBJNE01No ratings yet

- Xmer TestingDocument91 pagesXmer TestingSush SonkNo ratings yet

- Siemens Three Windings Transforemr ImpedancesDocument19 pagesSiemens Three Windings Transforemr ImpedancesMoon3pellNo ratings yet

- iCP-440 Capacitor Bank Protection RelayDocument12 pagesiCP-440 Capacitor Bank Protection Relayqwkerbk090909No ratings yet

- Easergy P3F30 Manual PDFDocument350 pagesEasergy P3F30 Manual PDFFelipe OliveiraNo ratings yet

- ANSI Relay SymbolsDocument2 pagesANSI Relay Symbolsrupash_82100% (1)

- 1 Motor Protection - Double SessionDocument36 pages1 Motor Protection - Double Sessionmubarakkirko100% (1)

- Inadvertent Energization Generator Protection IEEEDocument1 pageInadvertent Energization Generator Protection IEEEFirmanJohannesMaruliTuaSimanullangNo ratings yet

- MN 225008 enDocument48 pagesMN 225008 enCae FueNo ratings yet

- 3 - Circuit Breaker Operation PrincipleDocument29 pages3 - Circuit Breaker Operation PrincipleCô Nàng Song TửNo ratings yet

- Transformer Inrush Currents and Protection 2603 003 A00Document4 pagesTransformer Inrush Currents and Protection 2603 003 A00Joshi Dhvanit100% (1)

- Line ProtectionDocument79 pagesLine Protectionjoiaros7No ratings yet

- Entendiendo La Protección de Distancia MhoDocument17 pagesEntendiendo La Protección de Distancia MhoAndres MartinezNo ratings yet

- XRIO Converter Manual AREVA P443 P445 ENU TU2.22 V1.000Document13 pagesXRIO Converter Manual AREVA P443 P445 ENU TU2.22 V1.000Sakthi MuruganNo ratings yet

- Areva B-Ct-En-Ap-B11 PDFDocument50 pagesAreva B-Ct-En-Ap-B11 PDFmarkgaloNo ratings yet

- SIL-A Overcurrent and Earth-Fault Relay User ManualDocument236 pagesSIL-A Overcurrent and Earth-Fault Relay User ManualarolnNo ratings yet

- Arc Flash Risk Assessment Draft Report - VB Engineering India PVT LTD PDFDocument201 pagesArc Flash Risk Assessment Draft Report - VB Engineering India PVT LTD PDFSudhir Saini100% (1)

- Back Up Impedance ProtectionDocument3 pagesBack Up Impedance ProtectionNeelakandan MasilamaniNo ratings yet

- Sifang Csc-211eb V1.06Document346 pagesSifang Csc-211eb V1.06MarkusKunNo ratings yet

- Arrester Protection DistanceDocument8 pagesArrester Protection DistanceyaoNo ratings yet

- Advantages and Applications of Zigzag Transformer - Engineering Tutorial PDFDocument4 pagesAdvantages and Applications of Zigzag Transformer - Engineering Tutorial PDFmentongNo ratings yet

- Weak Infeed Conditions PDFDocument22 pagesWeak Infeed Conditions PDFMuhammad Fahad SheikhNo ratings yet

- 1KHL020319 Aen Apn Note BBP Io enDocument40 pages1KHL020319 Aen Apn Note BBP Io enhaichau199No ratings yet

- GE-Guide To Instantaneous SelectivityDocument19 pagesGE-Guide To Instantaneous SelectivityJOSE LUIS FALCON CHAVEZNo ratings yet

- 263 Controlled Closing of HVAC Circuit BreakerDocument56 pages263 Controlled Closing of HVAC Circuit BreakerepriNo ratings yet

- Easergy P5 External Presentation - V14Document58 pagesEasergy P5 External Presentation - V14Jefri Yan SipahutarNo ratings yet

- An Overview of Dynamic Contact Resistance Measurement of HV Circuit BreakersDocument8 pagesAn Overview of Dynamic Contact Resistance Measurement of HV Circuit BreakersRana SarkarNo ratings yet

- P63x RestrictedEarthFault ApplicationGuide EN eDocument32 pagesP63x RestrictedEarthFault ApplicationGuide EN eAllama HasanNo ratings yet

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Power System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)From EverandPower System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)No ratings yet

- Paper (Kumpulainen) Selective Arc-Flash ProtectionDocument4 pagesPaper (Kumpulainen) Selective Arc-Flash ProtectionDanielNo ratings yet

- Air Liquide HandBook Nov 2020Document106 pagesAir Liquide HandBook Nov 2020Shailesh ChettyNo ratings yet

- C11 Arc ProtectionDocument16 pagesC11 Arc ProtectionShailesh ChettyNo ratings yet

- D4 Frequency and Load SheddingDocument10 pagesD4 Frequency and Load SheddingShailesh ChettyNo ratings yet

- Fundamentals of Protection Practice: Network Protection & Automation GuideDocument589 pagesFundamentals of Protection Practice: Network Protection & Automation GuideShailesh Chetty100% (1)

- C7 Transformer and Transformer Feeder ProtectionDocument28 pagesC7 Transformer and Transformer Feeder ProtectionShailesh ChettyNo ratings yet

- Adjustable Frequency Drives and Power Factor Correction CapacitorsDocument4 pagesAdjustable Frequency Drives and Power Factor Correction CapacitorsShailesh ChettyNo ratings yet

- Schneider Electric NPAG C6 Busbar ProtectionDocument24 pagesSchneider Electric NPAG C6 Busbar ProtectionShailesh ChettyNo ratings yet

- Effects of Capacitor Bank Installation in A Medium Voltage (MV) SubstationDocument6 pagesEffects of Capacitor Bank Installation in A Medium Voltage (MV) SubstationShailesh ChettyNo ratings yet

- Sodium Analyzer Manual V1.2 (2015.10, Vietnam)Document22 pagesSodium Analyzer Manual V1.2 (2015.10, Vietnam)vũ trầnNo ratings yet

- Telefire Accessories Brochure PDFDocument2 pagesTelefire Accessories Brochure PDFJoseph BoshehNo ratings yet

- TSA 1000XEn112 PDFDocument83 pagesTSA 1000XEn112 PDFJoseph BoshehNo ratings yet

- V7.01.08-01 StandardDocument39 pagesV7.01.08-01 StandardBagwisNo ratings yet

- PNOZ X10 11P Operating Manual 20820-EN-15Document25 pagesPNOZ X10 11P Operating Manual 20820-EN-15Míla ZajíčekNo ratings yet

- Mo - Unit Basic Blue Manual en 2.6Document45 pagesMo - Unit Basic Blue Manual en 2.6Dimitri DeryckeNo ratings yet

- TR50 D Wiring Diagram enDocument61 pagesTR50 D Wiring Diagram enIrul UmamNo ratings yet

- Bulletin 937 Intrinsic Safety Modules: Specialized Solutions For Hazardous Location ApplicationsDocument4 pagesBulletin 937 Intrinsic Safety Modules: Specialized Solutions For Hazardous Location ApplicationsNixiusNo ratings yet

- User Manual Functional Description: Marflex Variable Speed Drive SystemDocument67 pagesUser Manual Functional Description: Marflex Variable Speed Drive SystemSagar Anchan100% (1)

- DKG 309Document48 pagesDKG 309Dikr ElhakimNo ratings yet

- 1492 br016 - en P PDFDocument8 pages1492 br016 - en P PDFdocrafiNo ratings yet

- Operating Instructions GSM ModuleDocument44 pagesOperating Instructions GSM ModuleDavid CurkanNo ratings yet

- Price LG ControleriDocument7 pagesPrice LG ControleriVasile RachierNo ratings yet

- List Alarm EnshuDocument438 pagesList Alarm EnshuWidya LalaNo ratings yet

- Electrical Maitenance Details-1.doc - 1507369103641-1Document37 pagesElectrical Maitenance Details-1.doc - 1507369103641-1anas060100% (7)

- DETECTOR - Service ManualDocument40 pagesDETECTOR - Service ManualOrlando Velado100% (1)

- Electrical System 120H and 135H Motor Grader: Machine Harness Connector and Component LocationsDocument2 pagesElectrical System 120H and 135H Motor Grader: Machine Harness Connector and Component LocationsCicero MeloNo ratings yet

- Kalmar DRF 400 450 Forklift Trucks Error Codes & Wiring Diagrams PDFDocument223 pagesKalmar DRF 400 450 Forklift Trucks Error Codes & Wiring Diagrams PDFGabrielNo ratings yet

- Switches and Relays For The Power IndustryDocument82 pagesSwitches and Relays For The Power IndustryMuhamad PriyatnaNo ratings yet

- MS-N - Technical Catalogue PDFDocument44 pagesMS-N - Technical Catalogue PDFRandy Yoan EksaktaNo ratings yet

- Programmable Logic Controller (PLC) : Abhishek SoniDocument36 pagesProgrammable Logic Controller (PLC) : Abhishek SoniAbhishek SoniNo ratings yet

- XGK-CPU Manual V2.1 202012 ENDocument264 pagesXGK-CPU Manual V2.1 202012 ENBurhan EpendiNo ratings yet

- © Siemens AG 2007Document24 pages© Siemens AG 2007angeljavier9No ratings yet

- Bentley NevadaDocument4 pagesBentley NevadarenvouzNo ratings yet

- Instructions: IR Flame Detector X9800Document32 pagesInstructions: IR Flame Detector X9800leunamsayanNo ratings yet

- SINAMICS-V90 Connecting-STO-function FAQ enDocument11 pagesSINAMICS-V90 Connecting-STO-function FAQ enJosé AngeloNo ratings yet

- Textron Weber Electrical Parts & ComponentsDocument1 pageTextron Weber Electrical Parts & Componentsd5b75bn422No ratings yet